Sewage pump motor shaft friction welding method

A friction welding and motor shaft technology, applied in the field of friction welding, can solve the problems of reduced production efficiency, intergranular corrosion, coarse grains, etc., and achieve the effect of improving product qualification rate, refining grains of welds, and dense structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

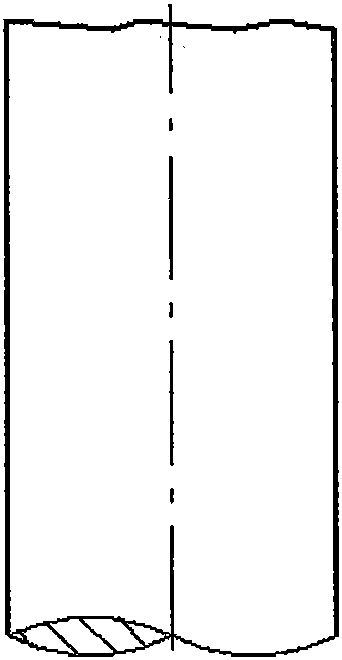

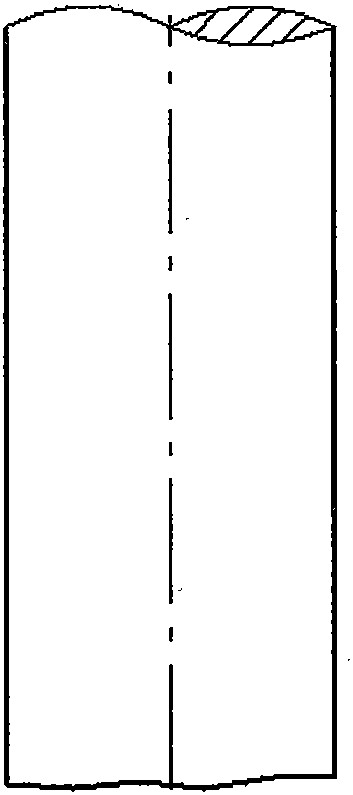

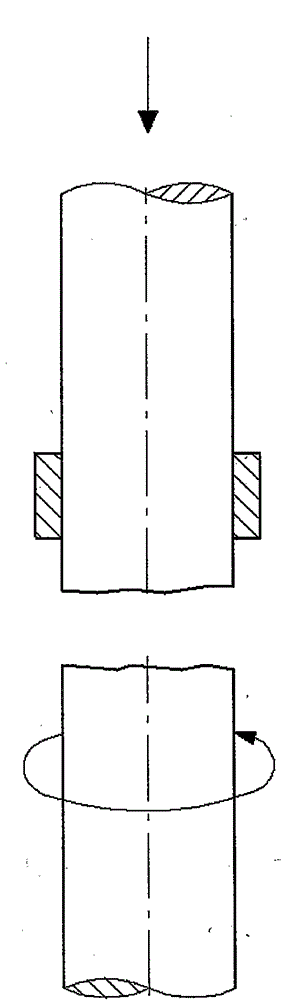

[0017] Example 1: Friction welding of the motor shaft of a PW-type 7.5KW sewage pump. Cut the round steel with a diameter of ¢40 and materials of stainless steel 0Cr18Ni9Ti and alloy structural steel 42CrMo into sections by a sawing machine, and clamp the round steel 1 of stainless steel 0Cr18Ni9Ti in the rotating fixture of the C-50 friction welding machine , the material is that the round steel 2 of alloy structural steel 42CrMo is clamped in the mobile fixture of C-50 type friction welding machine; On the outer circle of alloy structural steel 42CrMo round steel, a restraint cover 3 is adorned near the welding end face; 1100rpm, initial friction pressure 80-90MPa, friction welding 1.2-2.0 seconds, workpiece speed 1.5mm / s, to achieve initial friction and increase the temperature of the welding surface; then at 1450rpm, workpiece speed 3.5mm / s, secondary friction pressure 160~180MPa, friction welding for 5~7 seconds; with a speed of 1300rpm, a workpiece speed of 3.5mm / s, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com