Novel pulse ultrasonic arc hybrid welding device and welding method thereof

An ultrasonic arc and hybrid welding technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable pulsed ultrasonic field output, poor heat dissipation of the transducer, and inability to work for a long time, and reduce welding pores. Defects, improving cladding efficiency, and improving the quality of welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

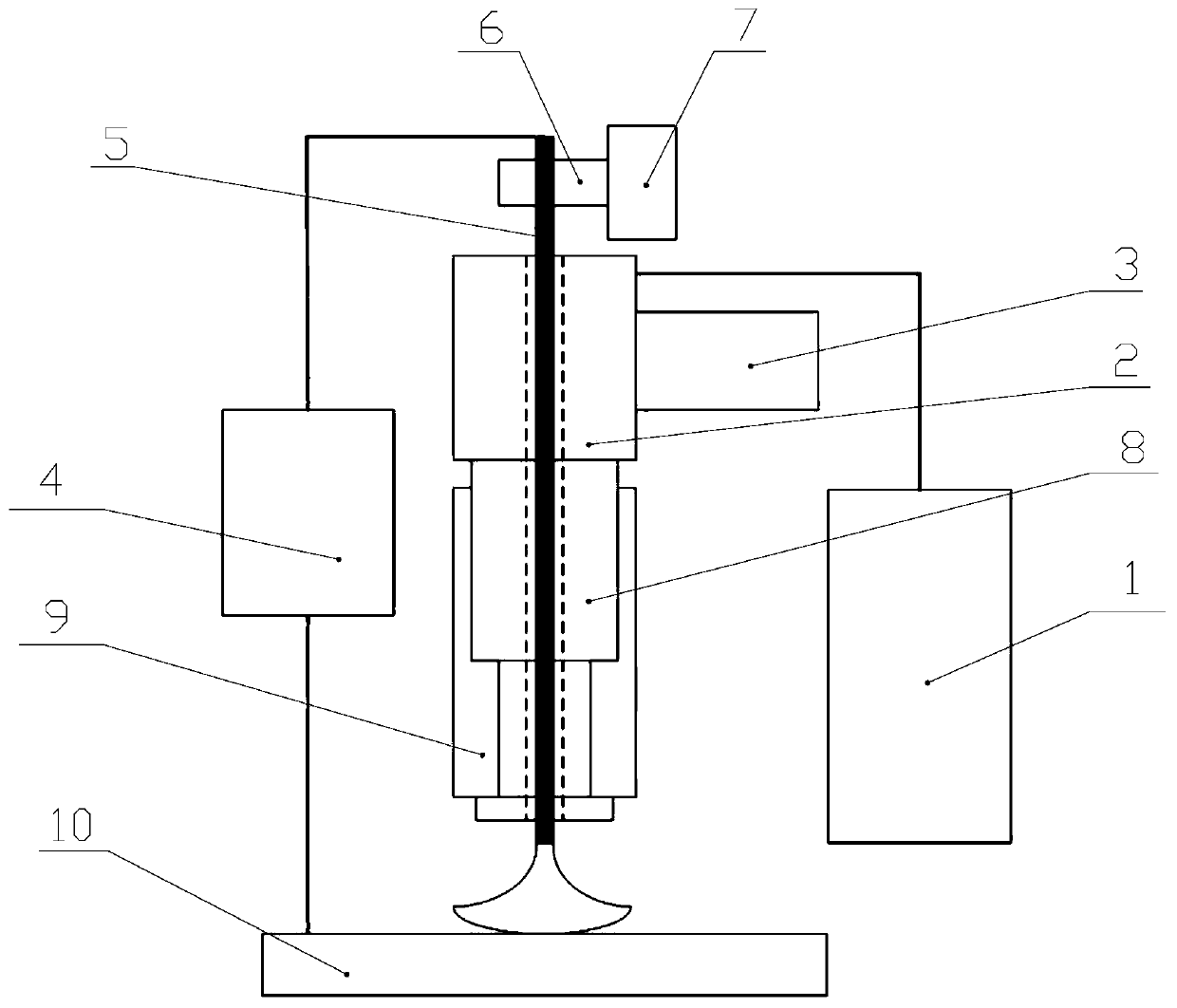

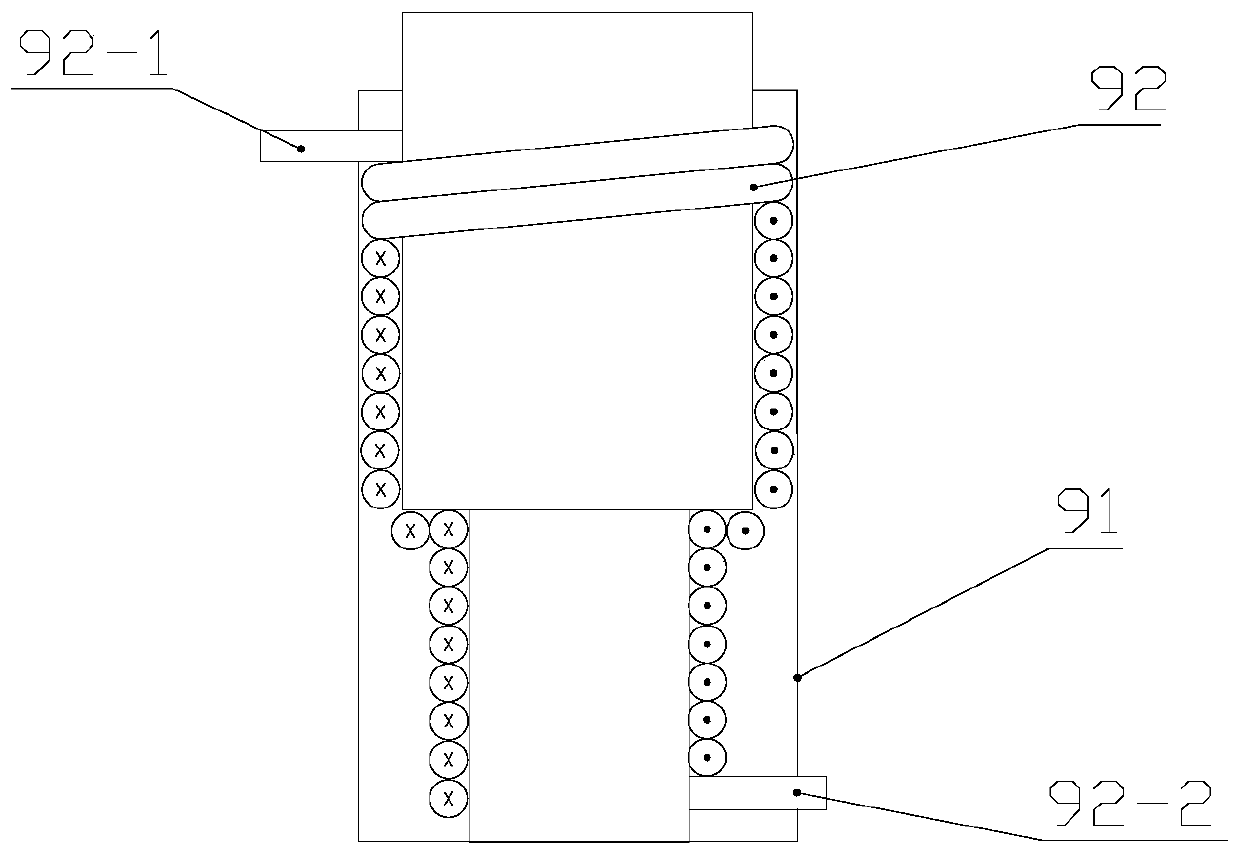

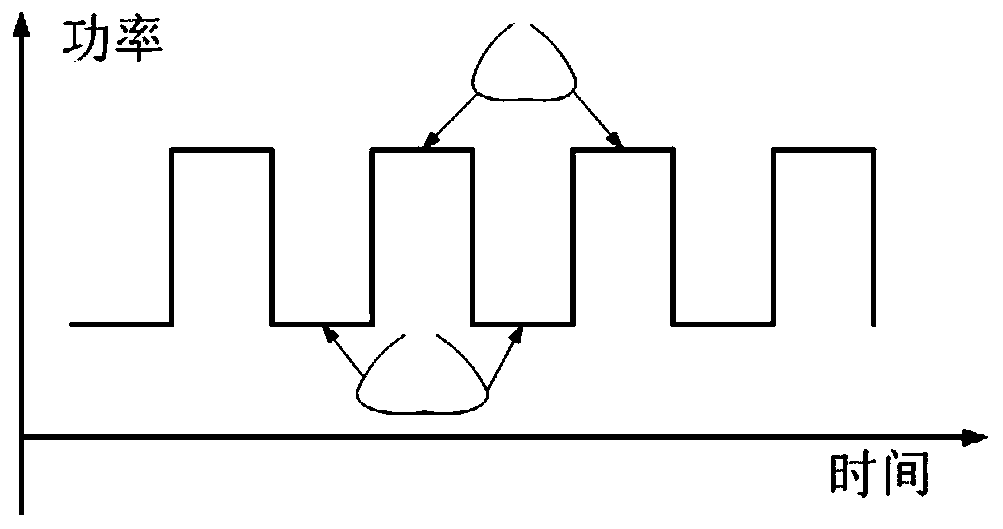

[0031] Specific implementation mode one: combine Figure 1~4 Description of this embodiment, a new type of pulsed ultrasonic arc hybrid welding device, which includes an ultrasonic power supply 1, a transducer 2, a transducer walking platform 3, a welding power supply 4, electrodes 5, electrode clamps 6, electrode walking platforms 7, variable The horn 8 and the water cooling system 9, wherein the transducer 2 is connected to the horn 8, the horn 8 is set in the water cooling system 9, and the transducer 2 realizes its horizontal and vertical movement through the transducer walking platform 3. direction displacement, the electrode 5 is installed in the central hole of the transducer 2, the upper part of the electrode 5 is fixed on the electrode walking platform 7 through the electrode clamp 6, and the electrode walking platform 7 realizes its movement along the horizontal direction and the vertical direction. Displacement, the welding power source 4 and the electrode 5 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com