Sewing machine

A sewing machine and lockstitch technology, which is applied in the direction of sewing machine components, sewing equipment, sewing machine control devices, etc., can solve the problems such as skipping stitches and intermittent locksewing, and achieve the effect of preventing looseness or distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments of the present invention will be described with reference to the accompanying drawings.

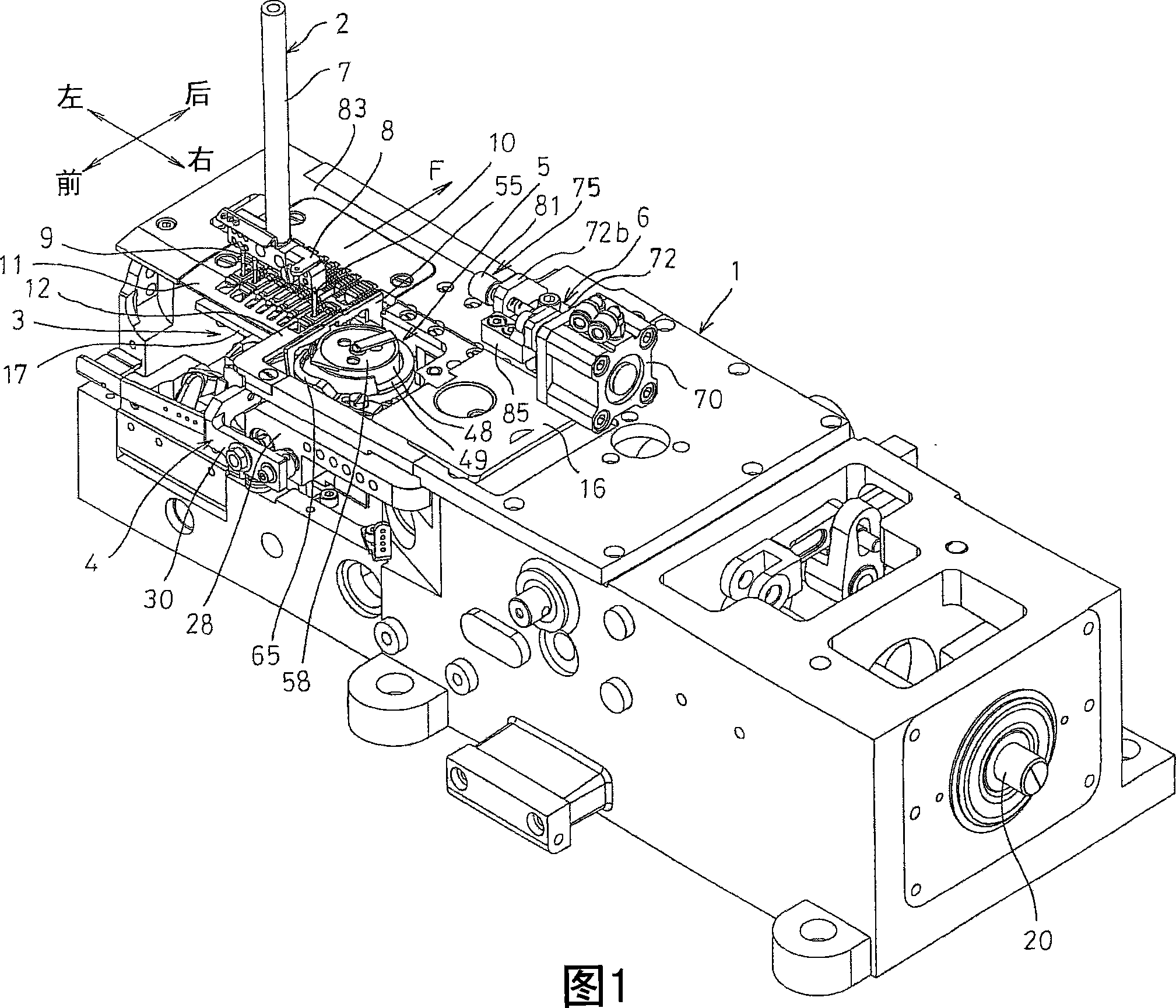

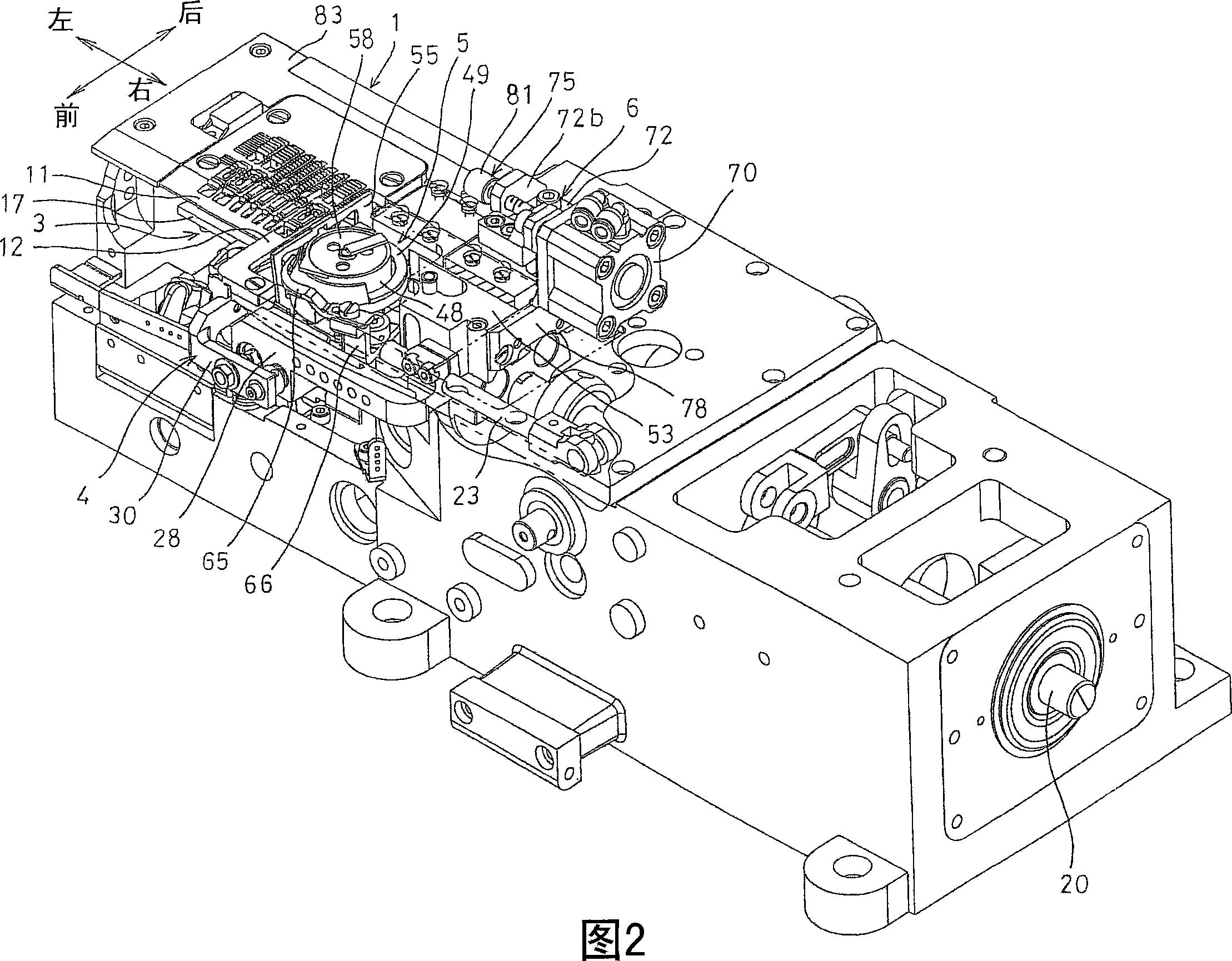

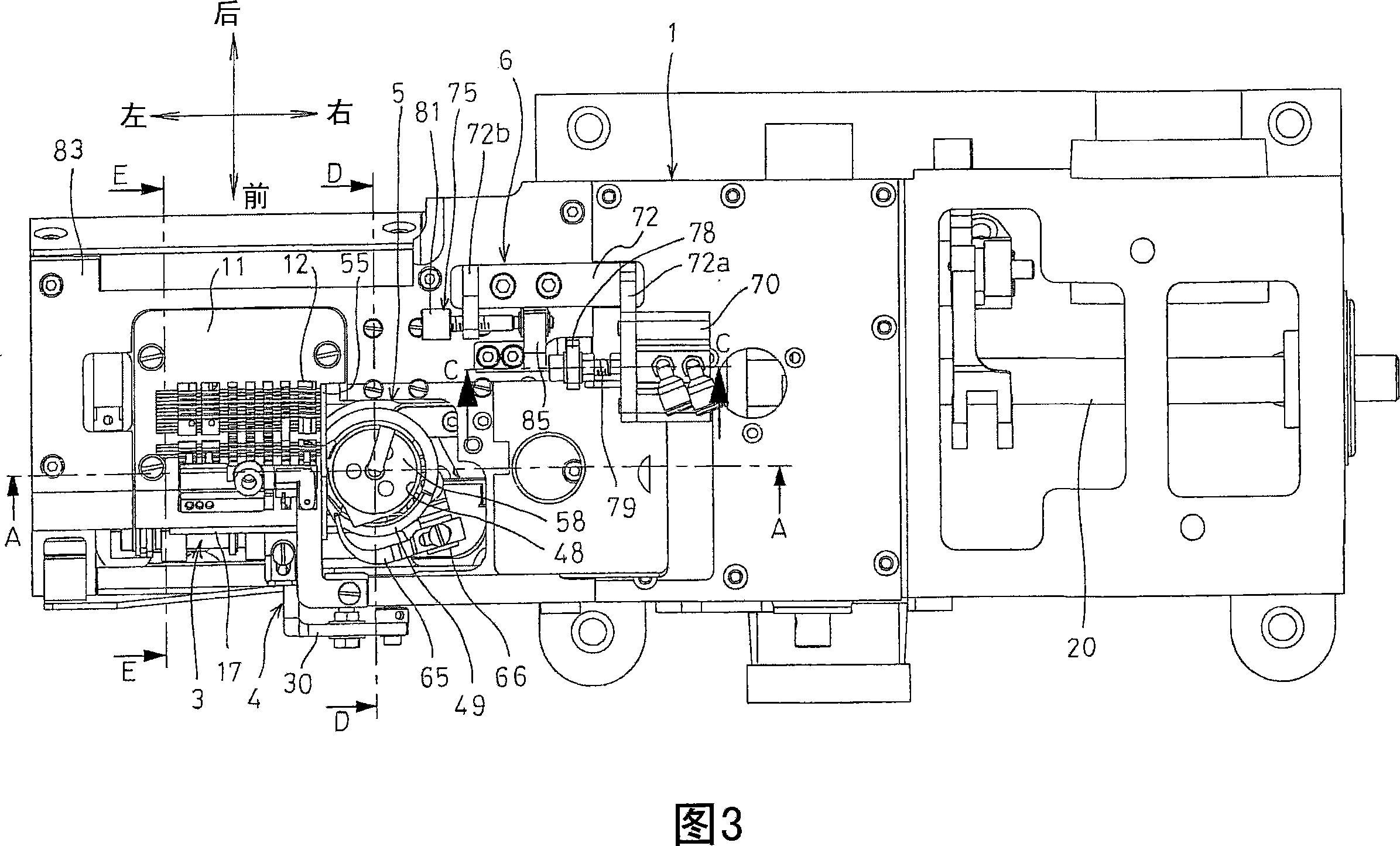

[0045]Fig. 1 is a perspective view showing the sewing machine head of a sewing machine according to an embodiment of the present invention in a state where the sewing machine arm is removed; Fig. 2 is a perspective view of the sewing machine head in a state where the difference plate 16 is removed from Fig. 1; The top view of the sewing machine head of Fig. 1, Fig. 4 is the front view of the sewing machine head of Fig. 1, Fig. 5 is a sectional view along the A-A line in Fig. 3, Fig. 6 is a sectional view along the C-C line in Fig. 3, Fig. 7 It is a sectional view along line 3D-D in the figure, and FIG. 8 is a sectional view along line E-E in FIG. 3 . In each figure, the sewing machine shown in the figures is a sewing machine capable of concurrently performing intermittent lock stitching and flat stitching in which skipped stitches are intentionally generated. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com