Playing ball with flat joint and manufacture method thereof

A sports ball and flat technology, applied in the field of ball products, can solve the problems of being unable to meet more and more perfect requirements, and achieve the effect of easy implementation and simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

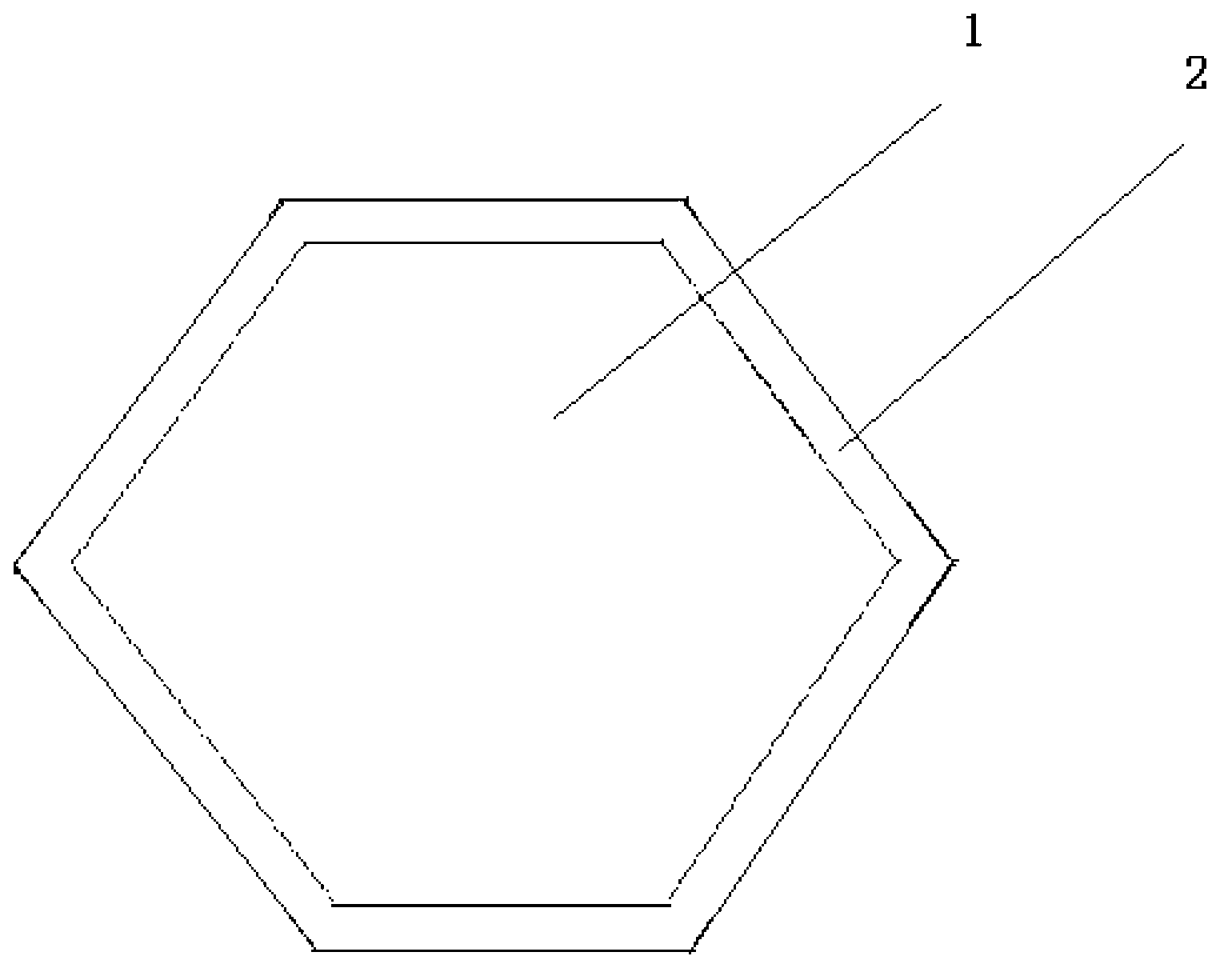

Image

Examples

Embodiment 1

[0037] Embodiment 1, a sports ball with a flat seam, and a preparation method for a sports ball with a flat seam:

[0038] ⑴. Use the outer layer material (single-layer leather on the surface of the ball skin, or a combination of single-layer leather on the surface of the ball skin and a layer of base cloth) to form the raw material of the ball skin. According to the sewing requirements of the ball skin, the "outer layer material "The raw material of the ball leather is divided into leather blocks of the required shape;

[0039] ⑵. According to the sewing requirements of the ball skin, divide the step 1 to get the leather block with the outside facing inward, and sew it into a spherical shell with the inside facing outward and a flip opening (generally called "no seal");

[0040] ⑶. Composite at least one layer of inner layer material to the surface of the spherical shell with the inner surface facing outward obtained in step 2 (the outer surface during the composite operation...

Embodiment 2

[0045] Embodiment 2 is substantially the same as Embodiment 1, but its manufacturing steps are as follows:

[0046] ⑴. Using at least two layers of multi-layer composite materials as the raw material of the ball skin, according to the sewing requirements of the ball skin, make several leather blocks of the same shape or different shapes;

[0047] ⑵. According to the predetermined width, draw the stitching area around the edges of each leather block;

[0048] ⑶. Removing the inner material of the sutured area around the edge of each leather block, and only retaining the outer material;

[0049] ⑷. The outer surface of the leather block obtained in step ⑶ faces inward, and is sewn into a spherical shell with the inner surface facing outward and with a turning opening;

[0050] ⑸. Turn over the composite spherical shell obtained in step 4;

[0051] ⑹. Suture the overturned opening, and leave the bladder opening;

[0052] ⑺. The bladder is made of rubber or composite materials; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com