Automatic welding method of flow production line for hydraulic support grid box type structure members

A technology of automatic welding and hydraulic support, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of inability to guarantee the quality of welding forming, narrow application range of automatic welding of unitary robots, and low production efficiency, so as to improve efficiency , high production efficiency and guaranteed welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings.

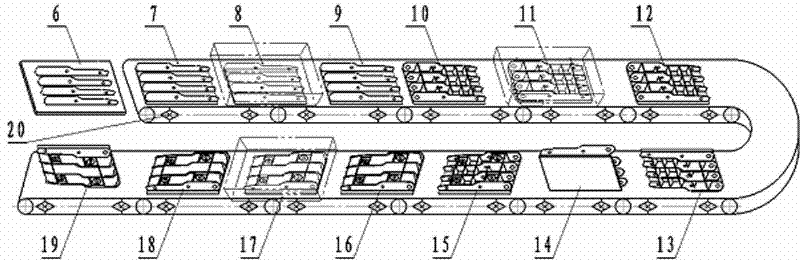

[0038] As shown in Figure 1-9, the automatic welding process of the assembly line for the grid-type box structure of the hydraulic support, the process steps are as follows:

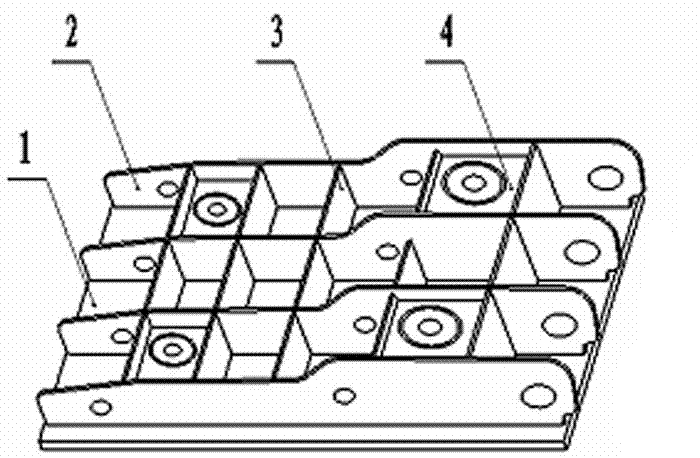

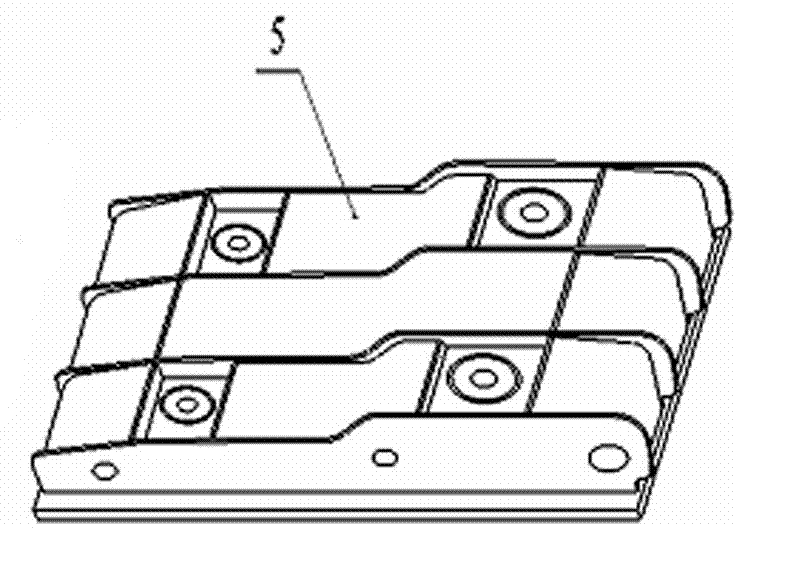

[0039] ⑴. According to the production design drawings of the grid-type box-type structural parts of the hydraulic support, the plates are cut and shaped, and the formed plates are classified into five categories: bottom plate 1, main rib 2, partition plate 3, functional parts 4, and cover plate 5 ,

[0040] The various stations refer to the sequential stations formed by point assembly, preheating and welding of the bottom plate 1 and the main rib plate 2, and the sequential stations formed by point assembly, preheating and welding of the partition plate 3 and the main rib plate 2 of the bottom plate 1. The sub-stations, and the sequential stations formed by spot-fitting, preheating, and weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com