Method and structure for leakage seepage prevention construction for two-walls-in-one structure of deep-underground engineering

A construction method and deep ground technology, applied in underwater structures, water conservancy projects, infrastructure engineering, etc., can solve problems such as the adverse effects of anti-seepage measures, disturbance of the envelope structure, and adverse effects of the environment, so as to improve the development of cracks and The effect of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

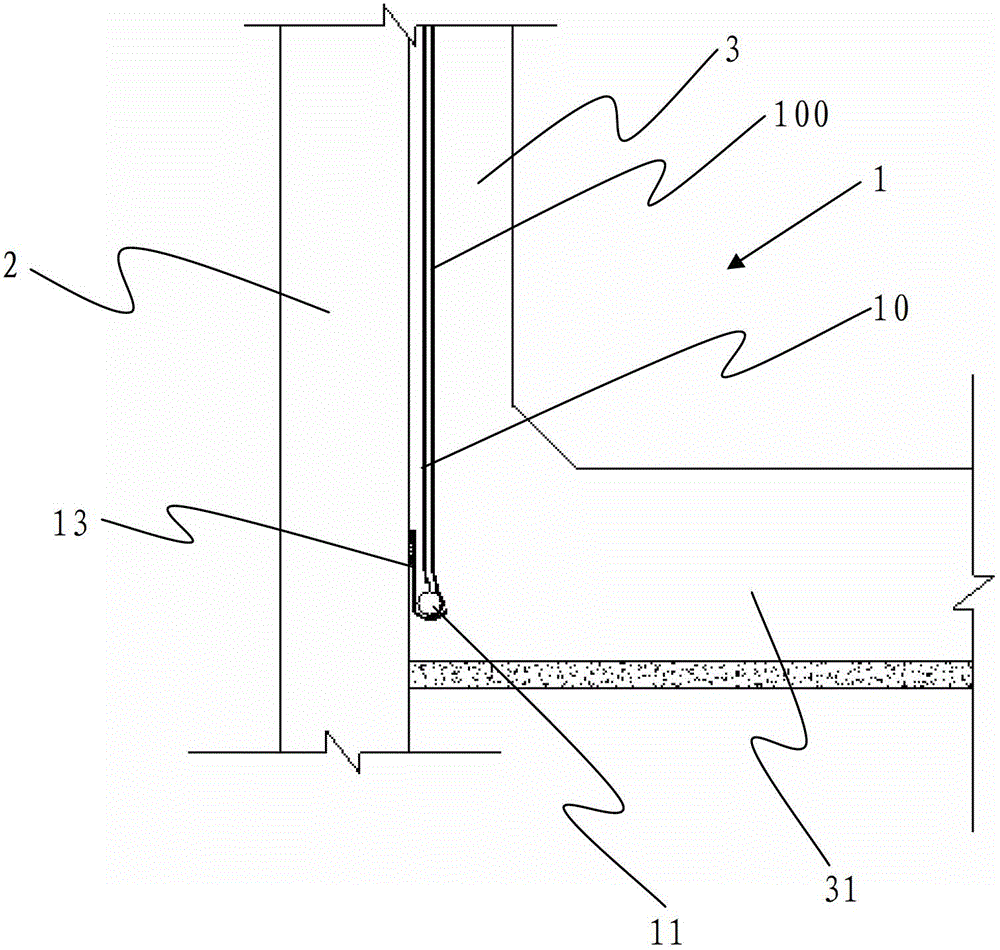

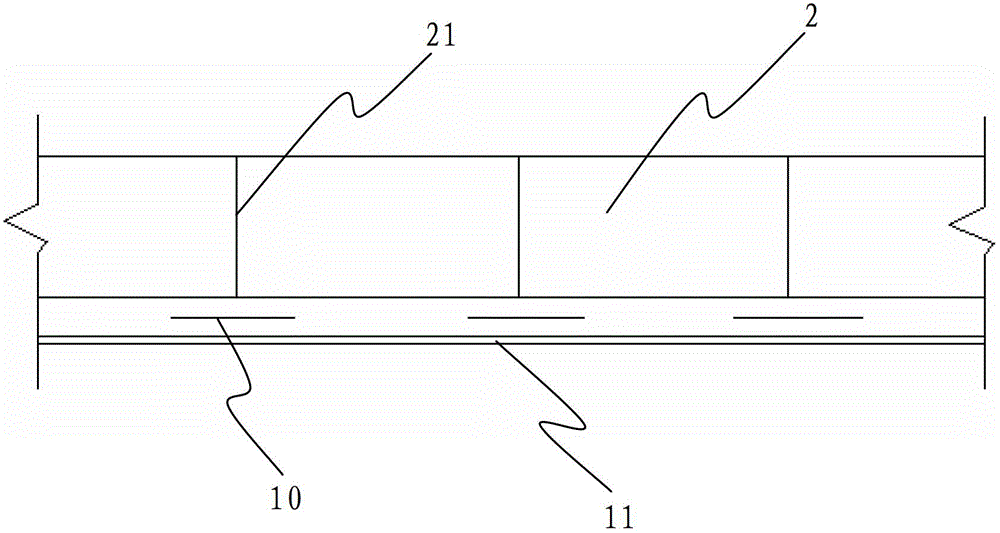

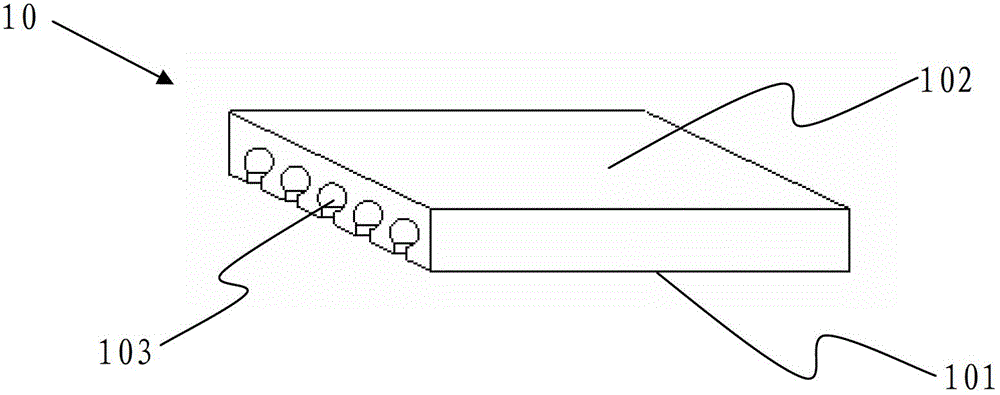

[0031] see first figure 1 and figure 2 As shown, the anti-seepage structure 1 for the two-wall-in-one structure of deep underground engineering of the present invention is mainly composed of a capillary drainage belt 10 and a water collection pipe 11, and the capillary drainage belt 10 is vertically laid and fixed along the joint 21 of the underground diaphragm wall 2 On the underground diaphragm wall 2 , the water collecting pipe 11 is laid horizontally along the underground diaphragm wall 2 in the base plate 31 at the bottom of the lining wall 3 . Cooperate image 3 and Figure 4 As shown, the capillary drainage strip 10 is made of thin-sheet soft plastic with a width of 200 mm, and includes a slotted surface 101 and a smooth surface 102. The slotted surface 101 is vertically densely covered with grooves 103, and the grooves 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com