Patents

Literature

35results about How to "Enhanced clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forklift

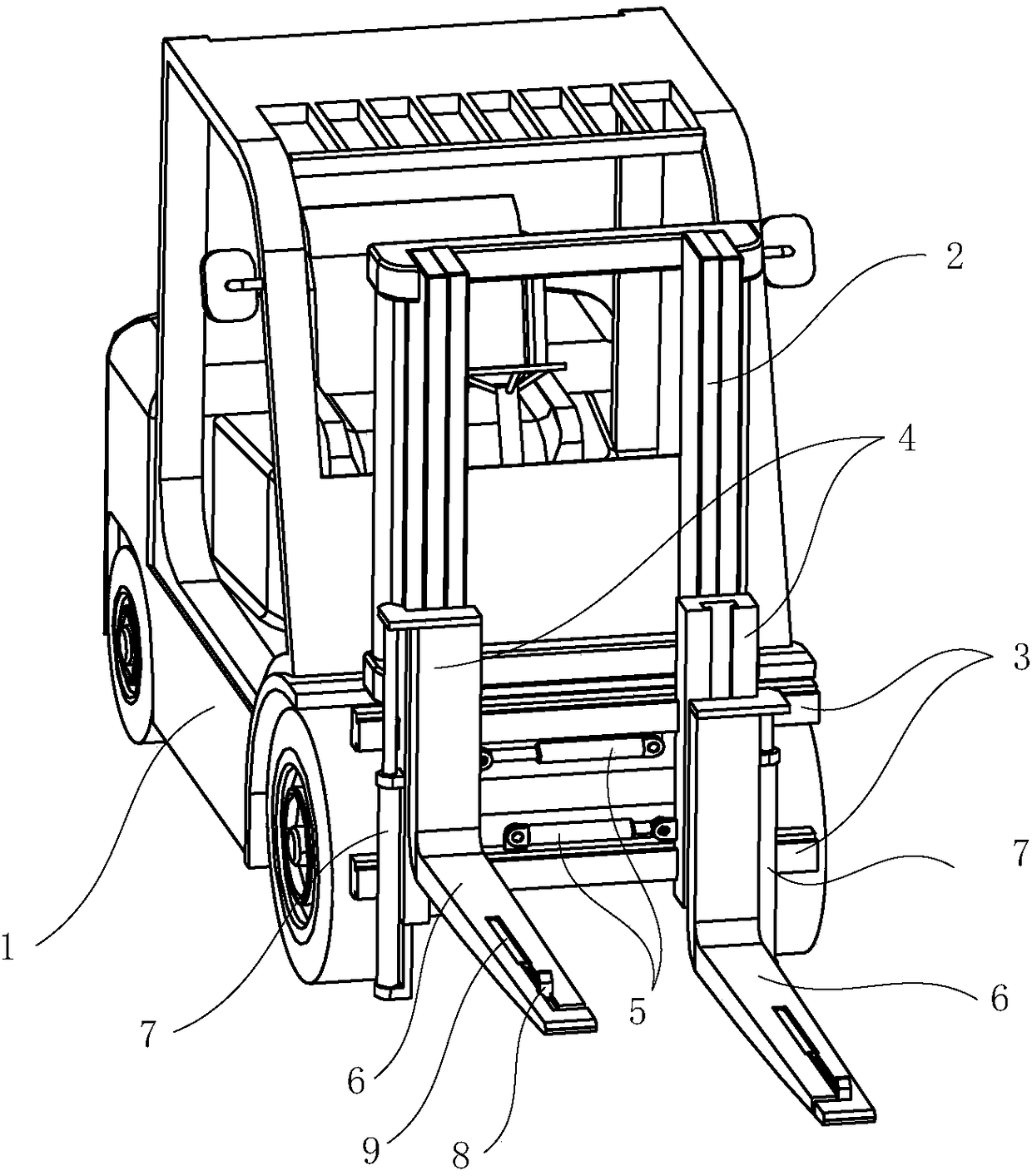

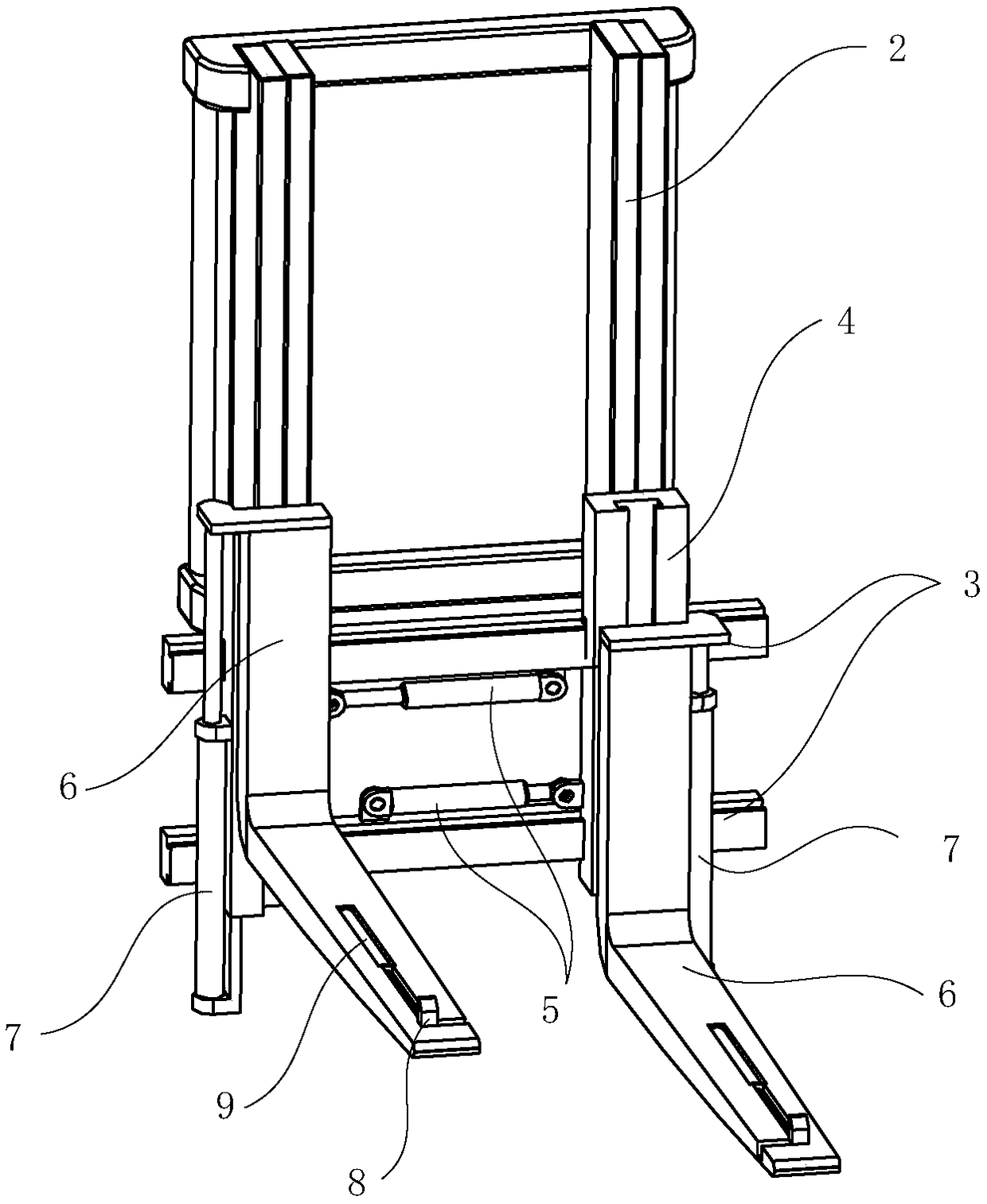

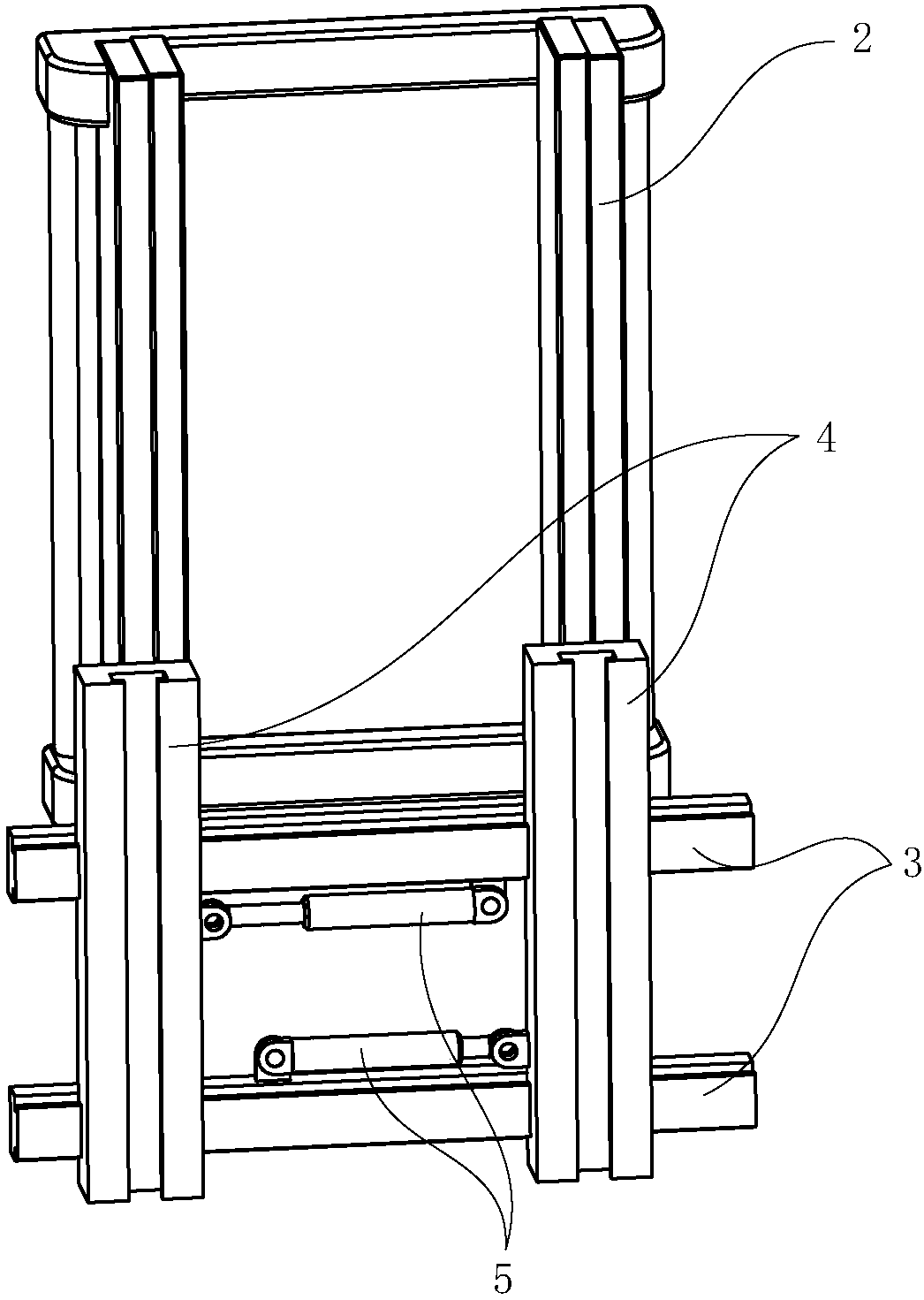

InactiveCN108483352AImprove securityCapable of overturning momentLifting devicesEngineeringCounterforce

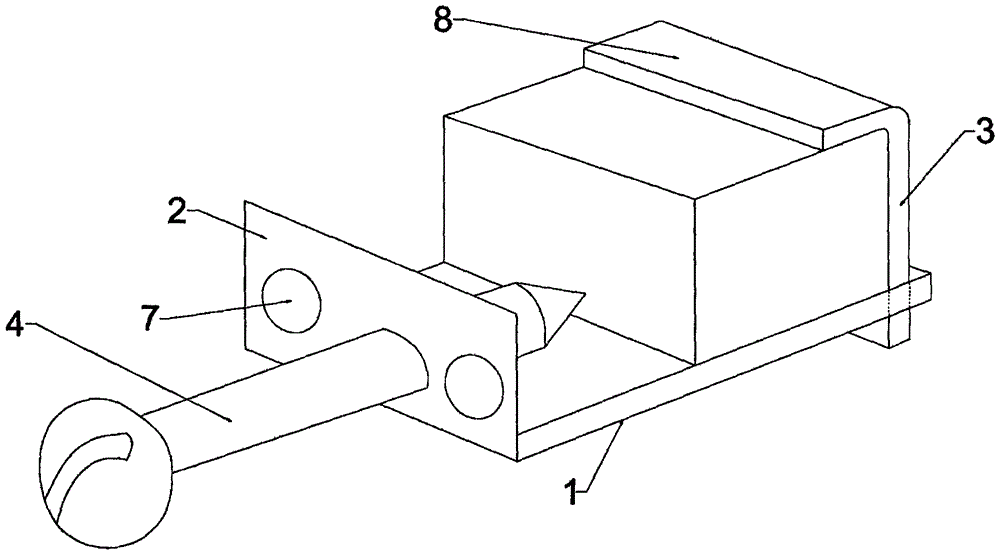

The invention relates to a forklift which is mainly formed by a forklift body, a lifting frame, horizontal guide rails, longitudinal guide rails, horizontal drive cylinders, forks, longitudinal drivecylinders, clamping blocks, clamping drive cylinders and clamping block rotating drive devices. According to the forklift, the two forks can be driven to move horizontally through the horizontal drivecylinders, so that a forking position can be adjusted, an opening range of the forks can be adjusted, and the working efficiency is improved. In addition, due to the longitudinal guide rails, the twoforks can move up and down within a certain range, so that the carrying requirement of special cargoes is met, and the application range of the forklift is increased. Meanwhile, the clamping blocks are additionally arranged at the front ends of the forks so as to clamp a cargo, so that the safety of the cargo to be transferred is improved. The clamping blocks are stretched and retracted through lateral rotating, so that the capability of the clamping devices on bearing an overturning moment produced by a counterforce of a cargo clamping force is better.

Owner:王灿灿

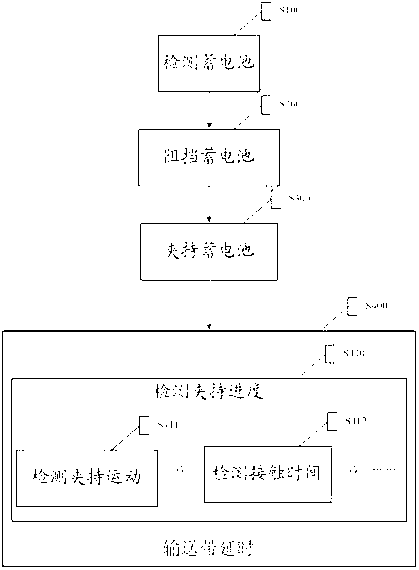

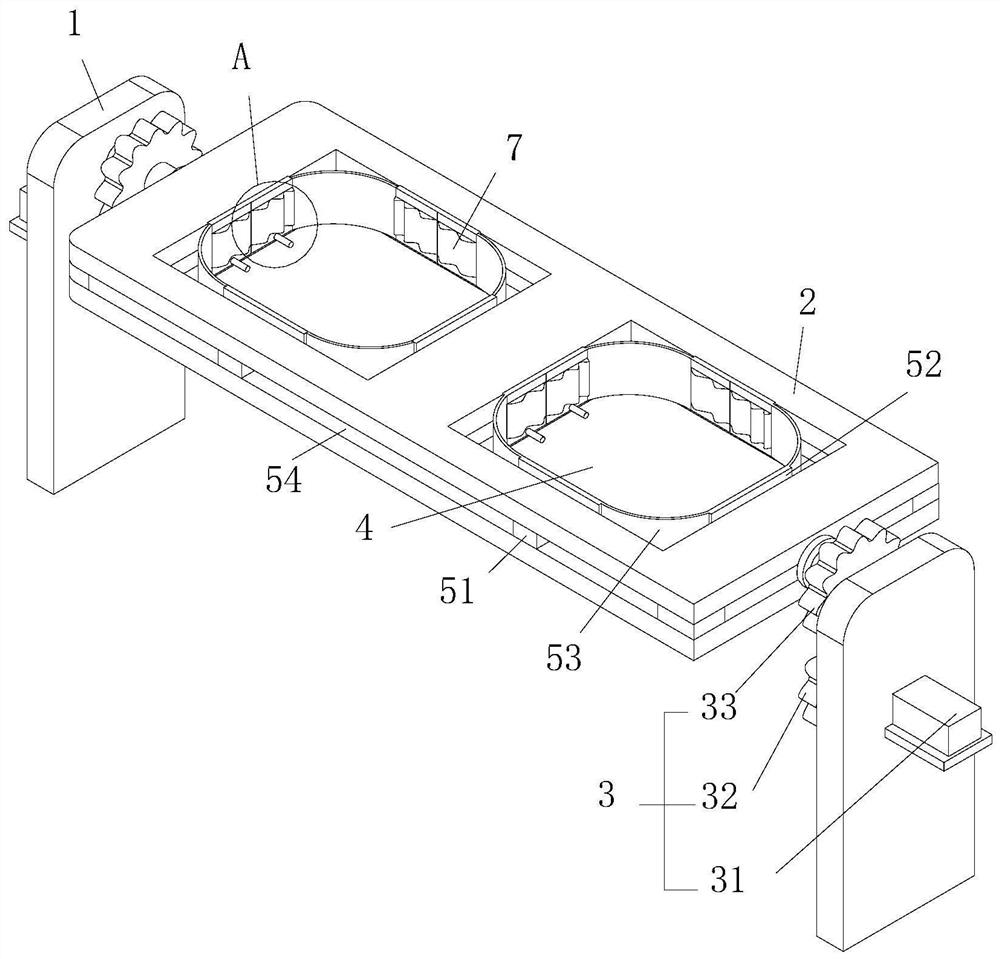

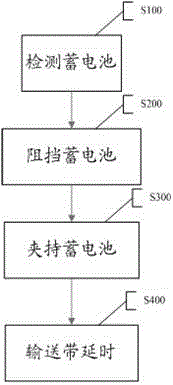

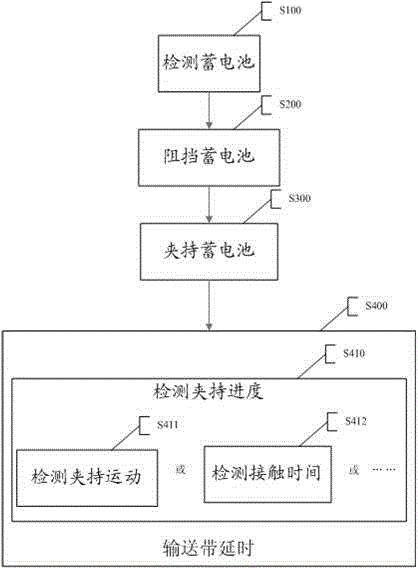

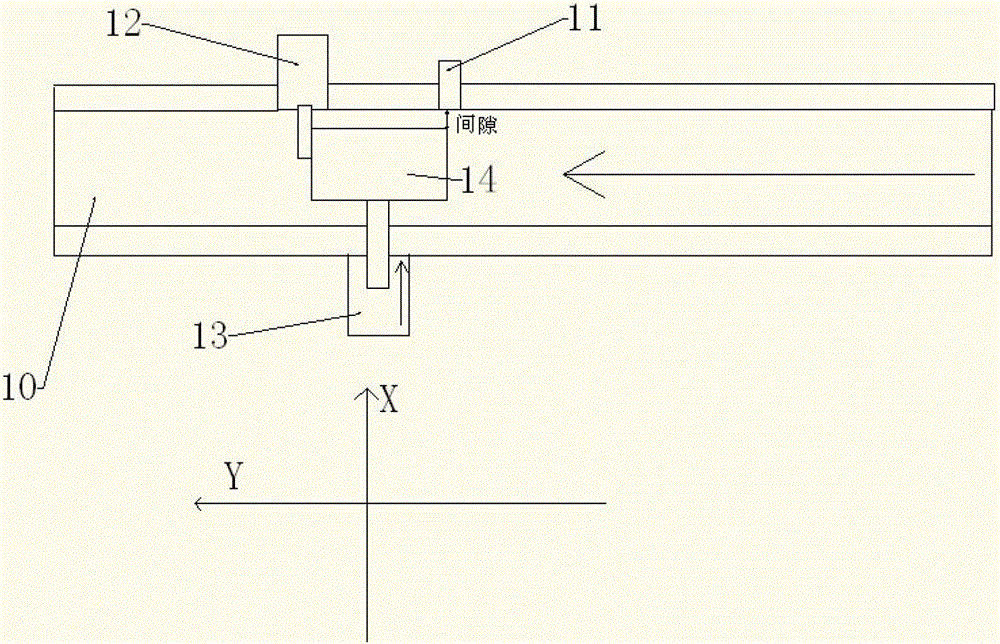

Heat-sealing positioning control method of battery

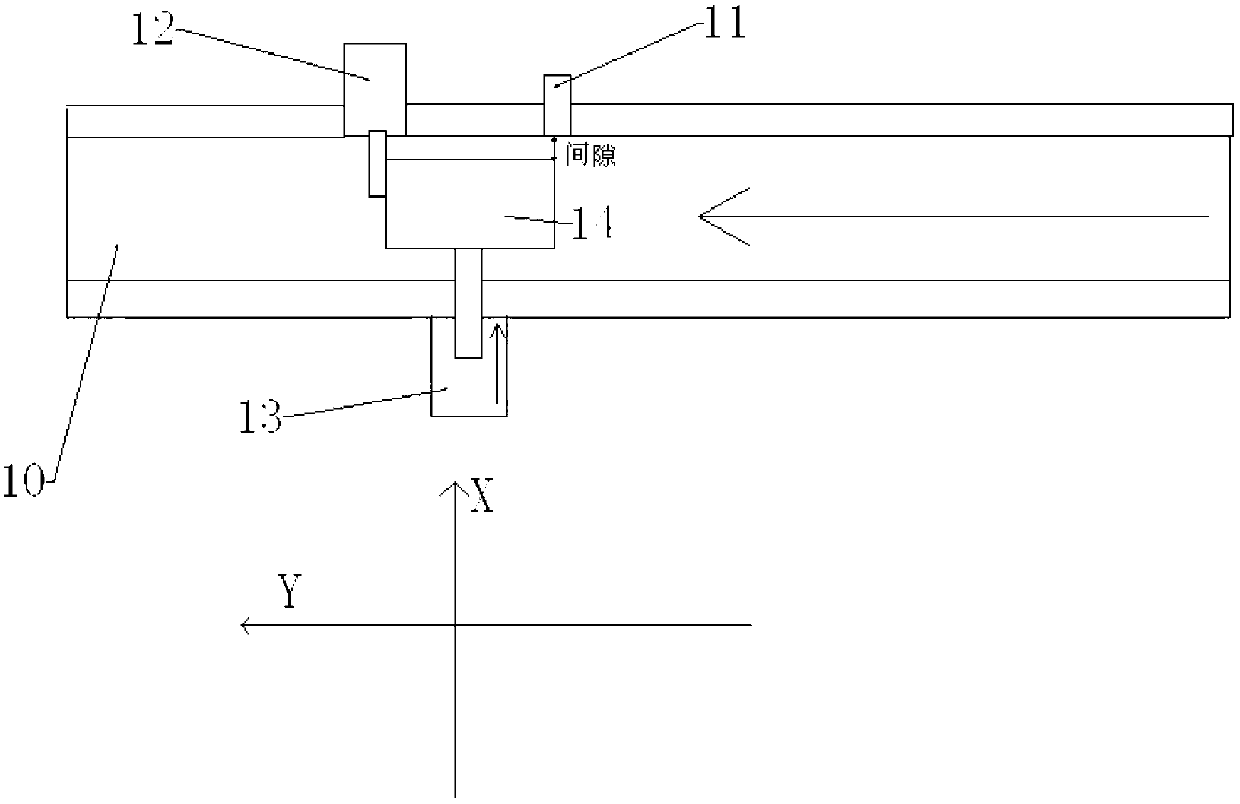

ActiveCN102765593ALess prone to skewPrecise positioningFinal product manufactureControl devices for conveyorsPosition controlElectrical and Electronics engineering

The invention discloses a heat-sealing positioning control method of a battery, which comprises the steps that a motor is in transmission connection with a conveying belt, a sensor, a material level stopping cylinder and a clamping cylinder are respectively connected with a controller, and the battery is conveyed by the conveying belt; the battery on the conveying belt is detected by the sensor to obtain sensing signals and transmit the sensing signals to the controller; and after receiving the sensing signals, the controller controls the material level stopping cylinder to stop the battery, controls the clamping cylinder to start to clamp the battery, and controls the motor to delay and stop operation so as to make the conveying belt delay and stop operation. The heat-sealing positioning control method of the battery disclosed by the invention effectively solves the problem that positioning deviation is prone to occur during heat sealing of the battery in the prior art, and enhances the heat-sealing efficiency and the product qualification rate.

Owner:ANHUI LEOCH POWER SUPPLY

Cable used for computer equipment

The invention discloses a cable used for computer equipment and relates to the technical field of cables. The cable comprises a cable rotary storing box and a cable extending fixing box. The bottom ofthe cable extending fixing box is movably connected with the top of the cable rotary storing box. A fixing groove is formed in the top of the cable rotary storing box. The bottom of the inner surfaceof the fixing groove is fixedly connected with oblique baffles. According to the cable used for the computer equipment, a cable at the top of the cable extending fixing box is matched with an internal extrusion fixing block and a torsional spring through a lantern ring, when the cable extending fixing box is pulled, the extrusion fixing block can be clamped tightly to the oblique baffles fast, each time the cable is stored, the cable can be straightened when passing through the lantern ring, cable disorder during storing is avoided, in addition, the device is simple and reliable and convenient to operate, the cable limited storing scope can be further expanded conveniently, a lateral push power rod on one side of the extrusion fixing block is in sliding connection with the extrusion fixing block, and operation by workers is facilitated.

Owner:北京神州数码云科信息技术有限公司

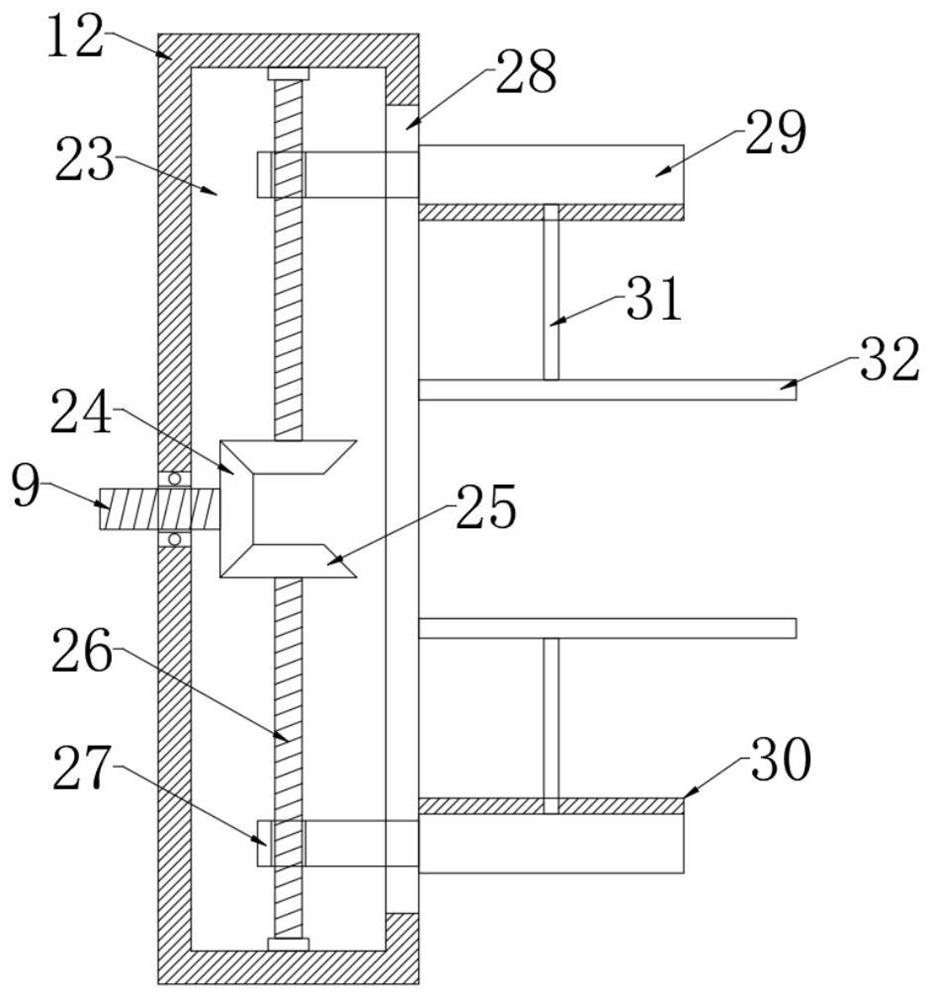

Test tube cleaning device for biological experiments

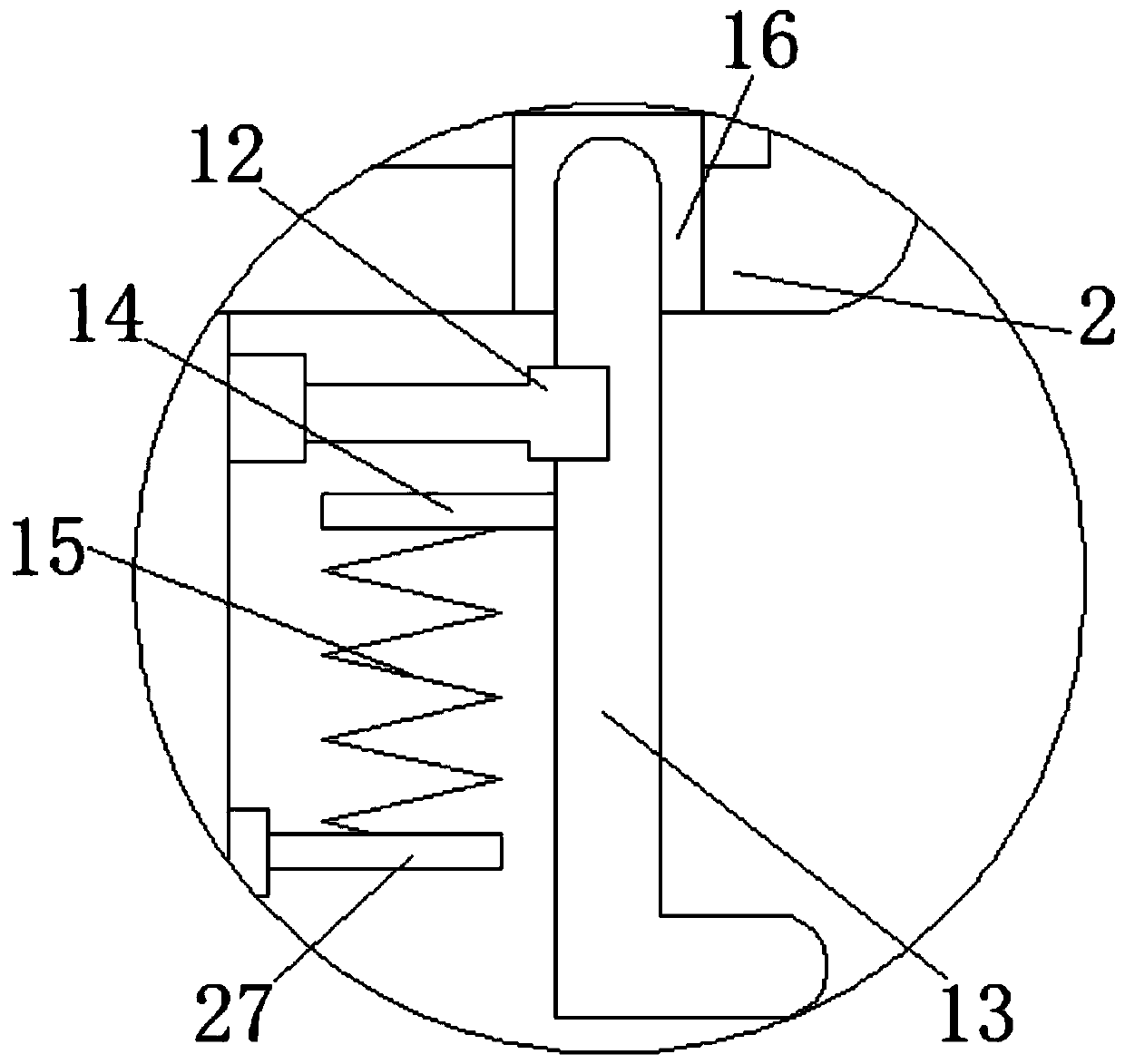

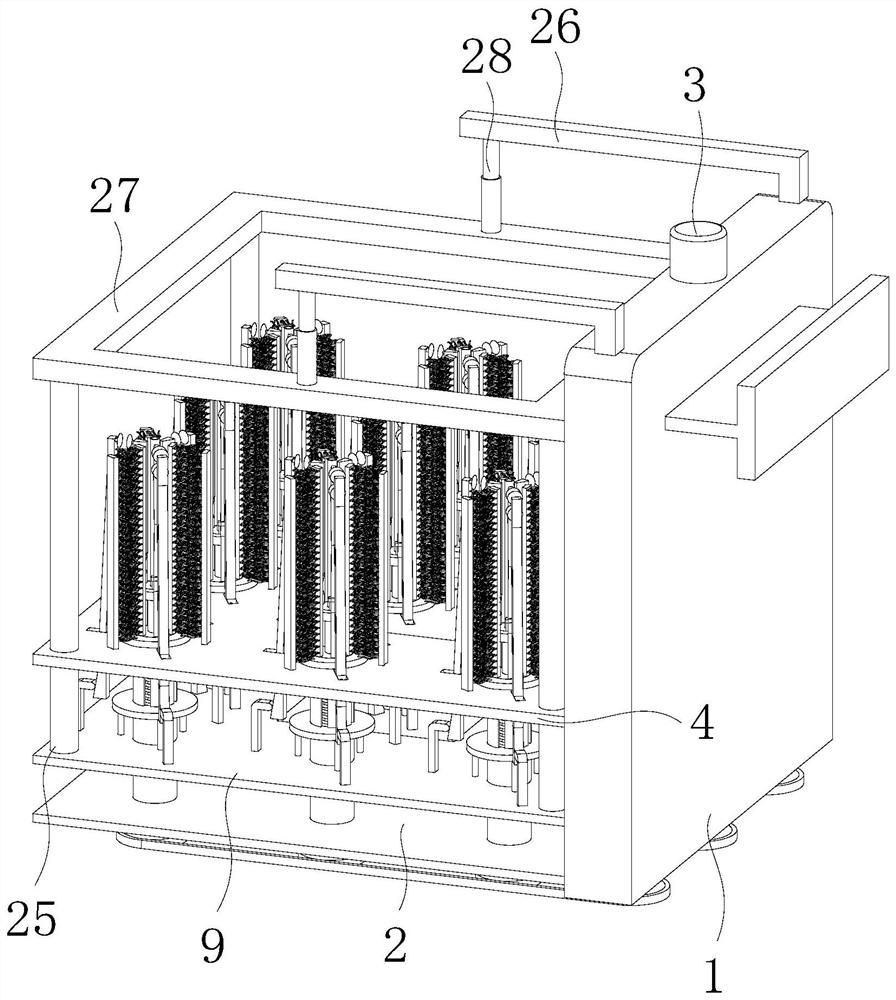

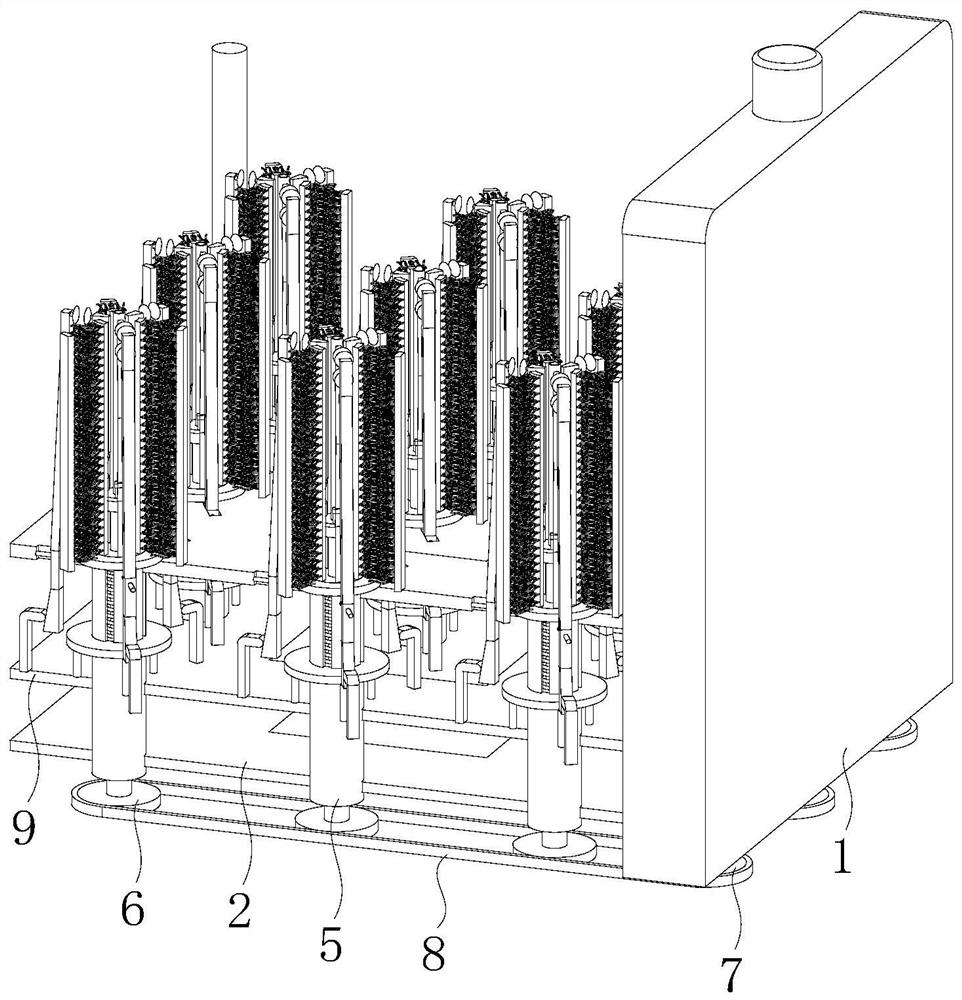

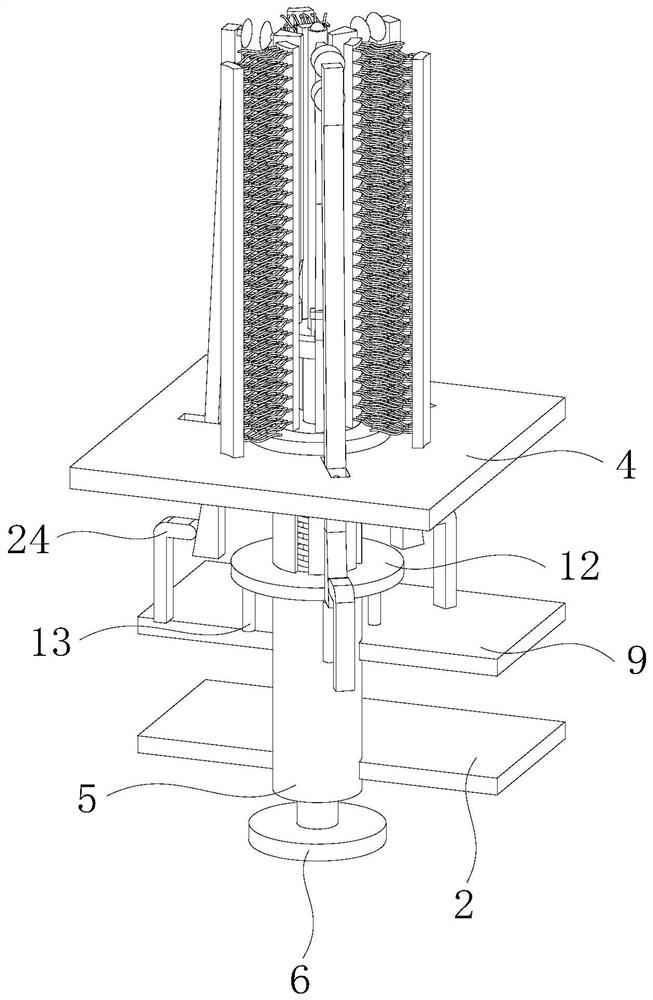

PendingCN112871932ASolve the problem of low cleaning effectTo achieve the effect of separate cleaningHollow article cleaningPhysicsTest tube

The invention provides a test tube cleaning device for biological experiments, and relates to the field of biological experiment test tube cleaning. The test tube cleaning device for the biological experiments comprises a transmission box, a supporting plate and a motor, the motor is located above the transmission box and fixedly connected with the transmission box, the output end of the motor is fixedly connected with the output end of the transmission box, the right side face of the supporting plate is fixedly connected with the left side face of the transmission box, a fixing plate is arranged above the supporting plate, the right side face of the fixing plate is fixedly connected with the left side face of the transmission box, and a rotating shaft rotationally penetrates through the upper surface of the supporting plate. According to the test tube cleaning device for the biological experiments, by arranging an inner elastic plate, a push block, an inner brush plate, an outer elastic plate and an outer brush plate, the effect of cleaning the inner wall and the outer wall of a test tube is achieved, and the problems that the inner wall and the outer wall of the test tube are inconvenient to adjust and clamp during cleaning of the test tube at present, mostly, only the inner wall or the outer wall of the test tube is brushed and cleaned once, and the cleaning effect on the test tube is relatively low are solved.

Owner:贾健华

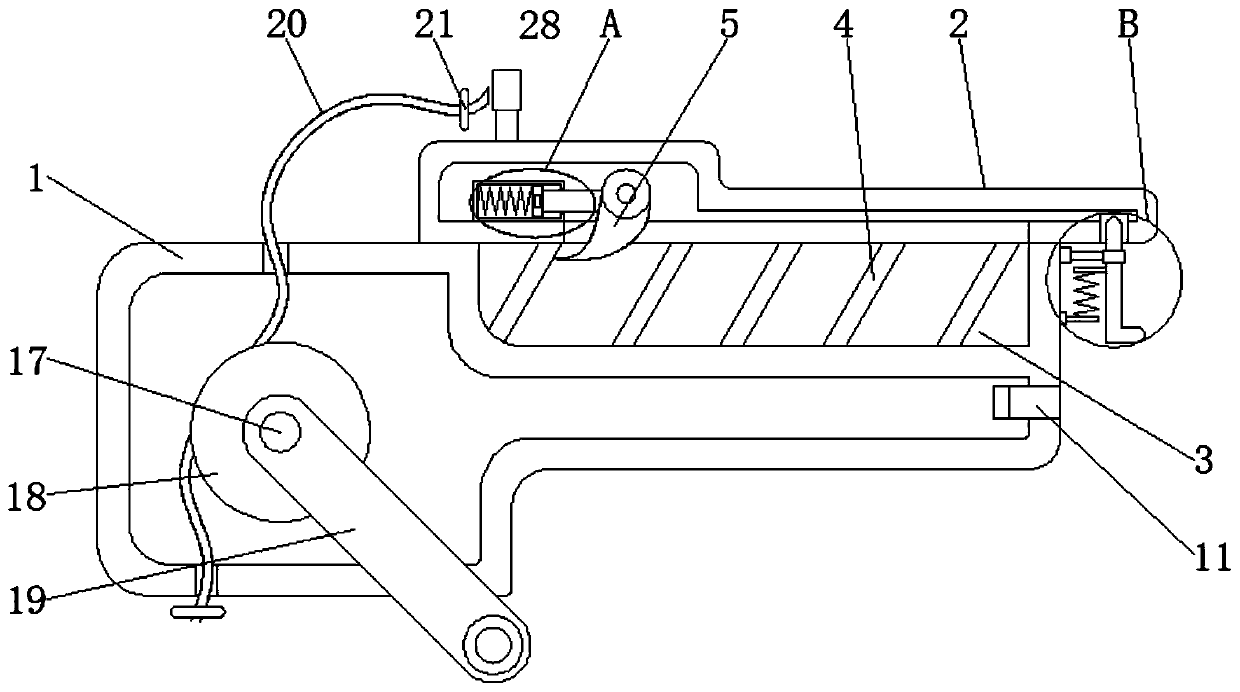

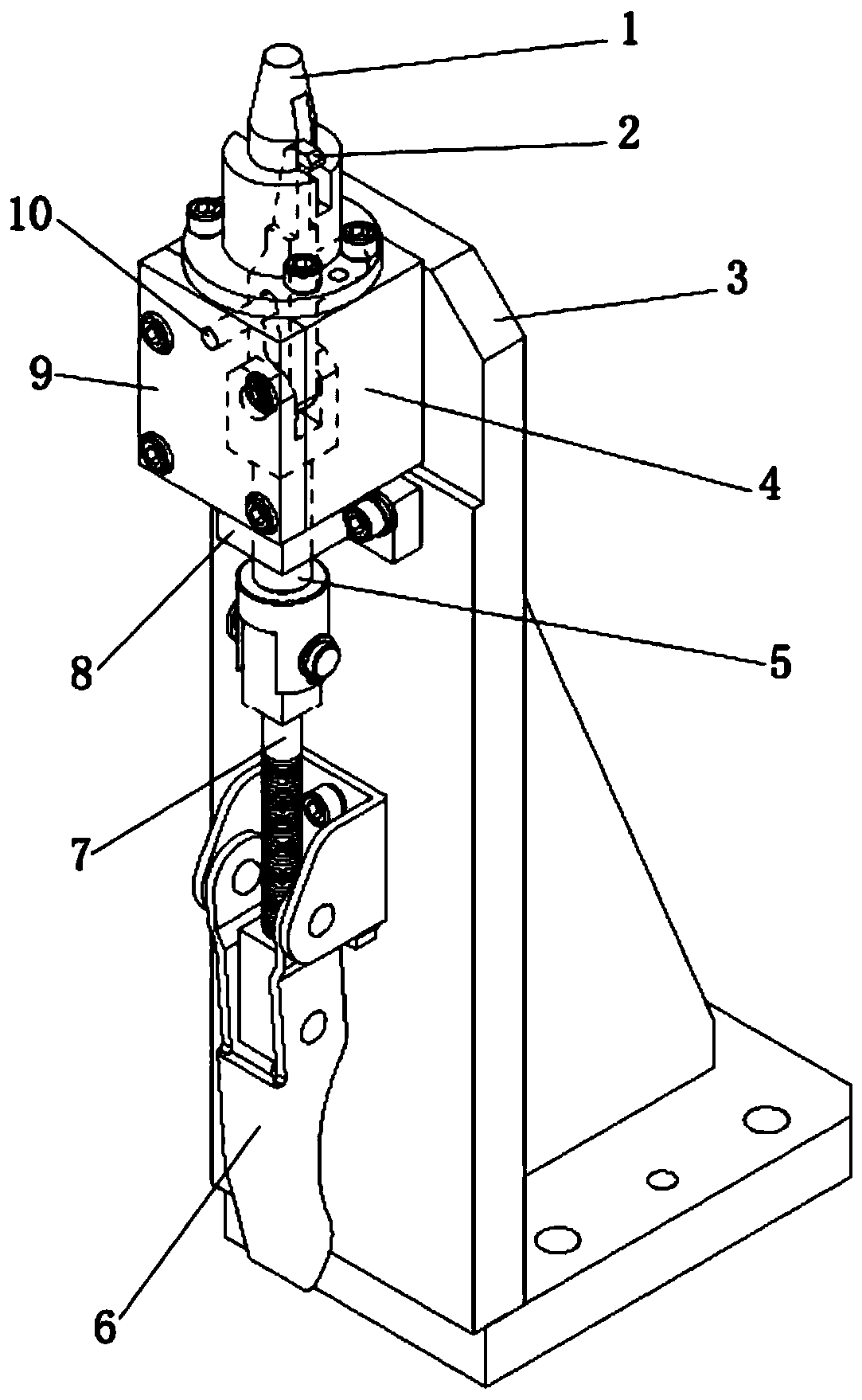

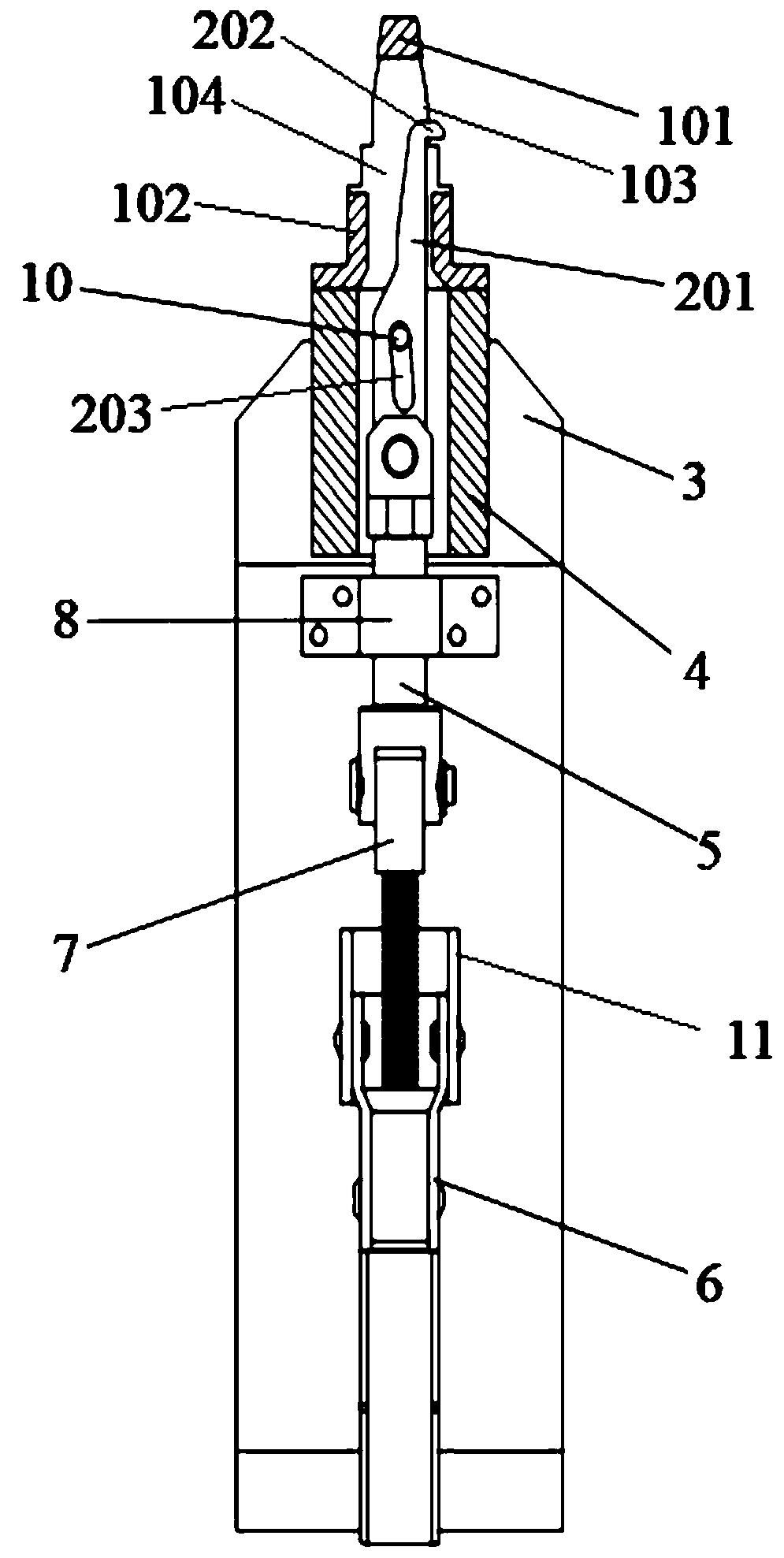

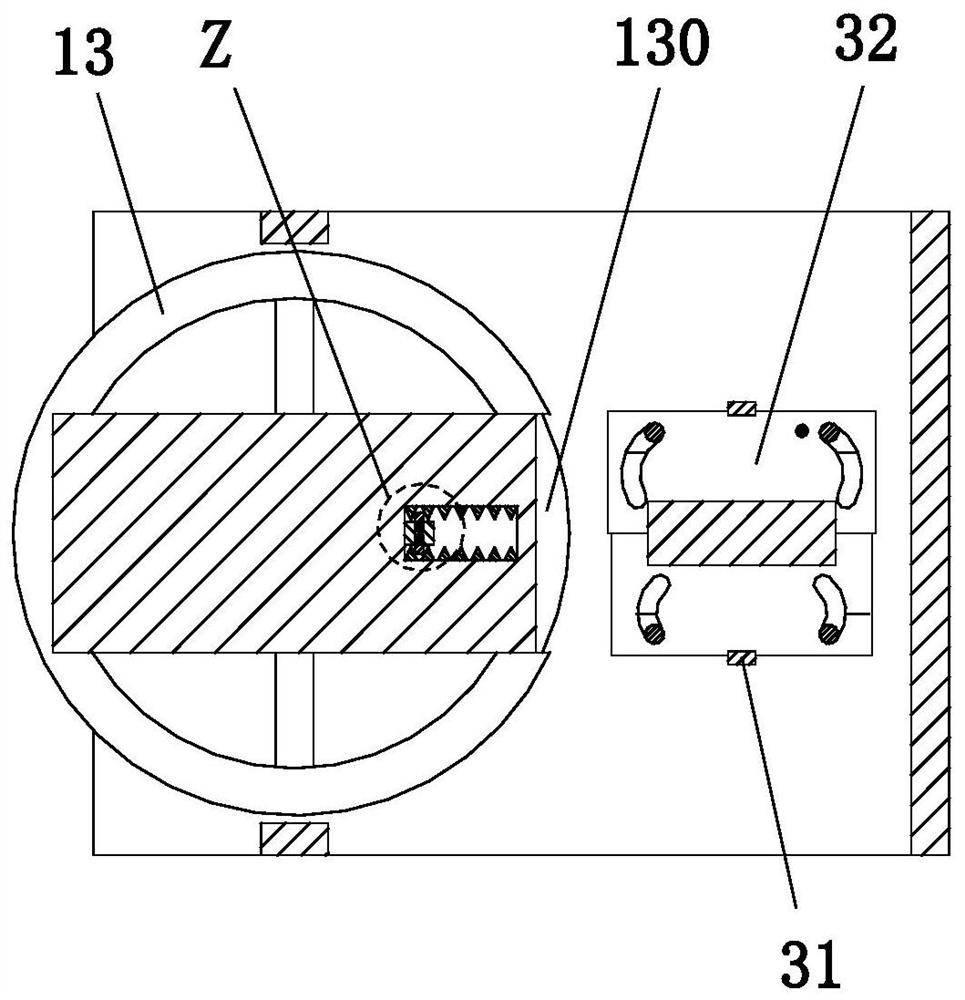

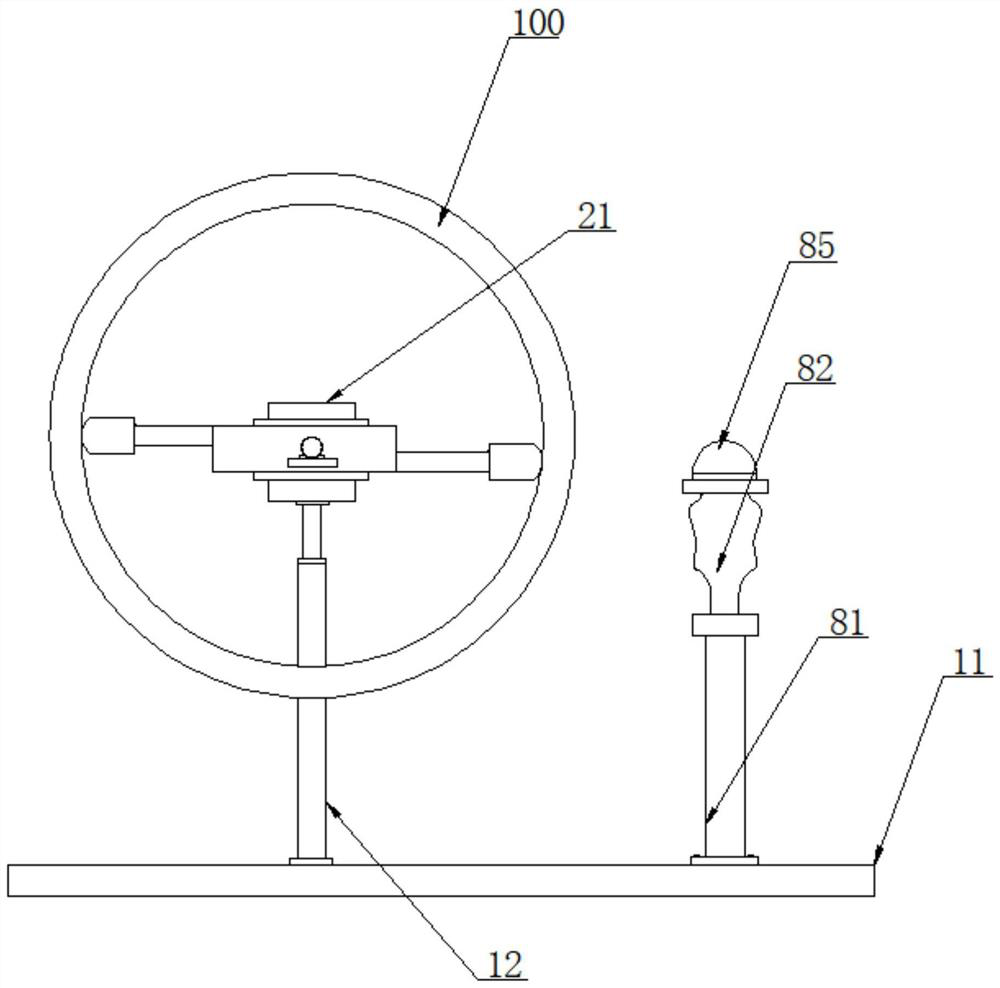

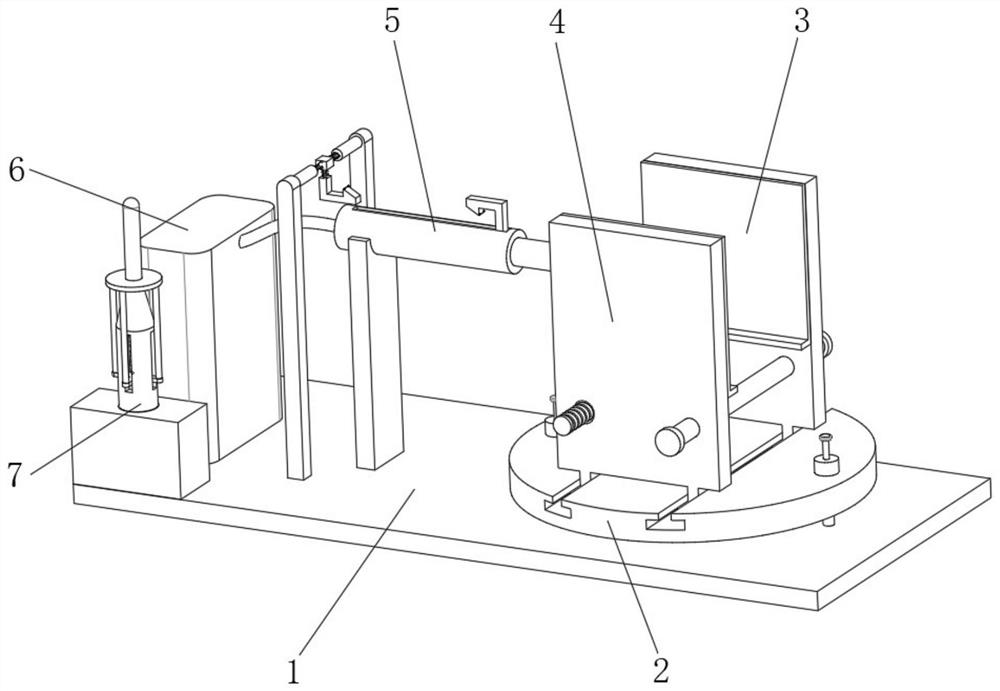

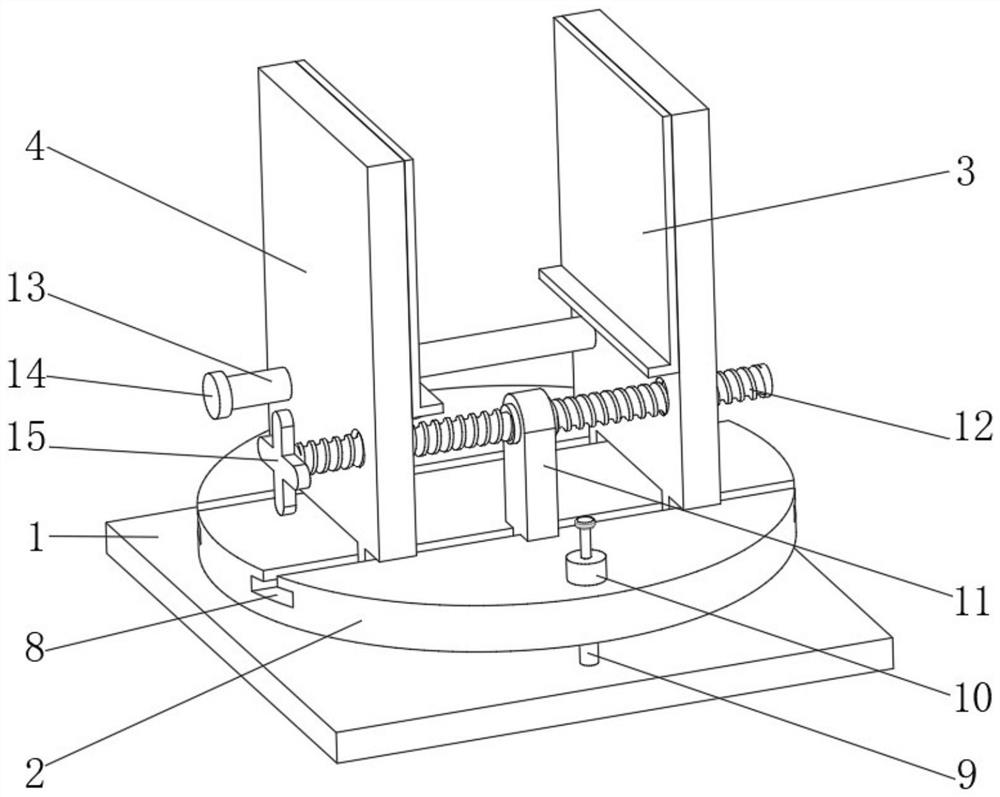

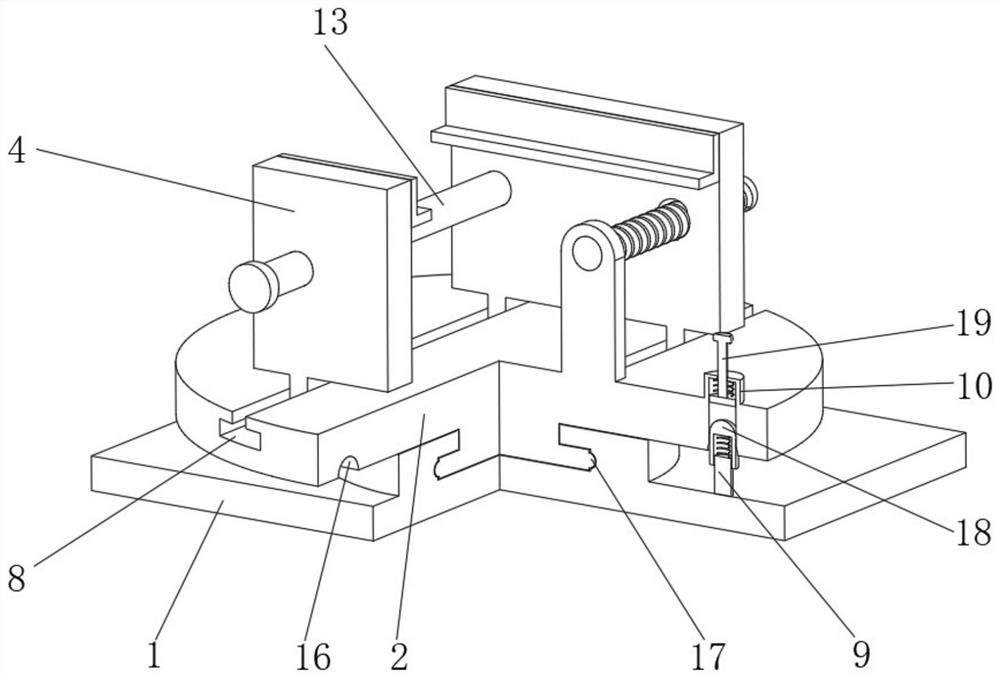

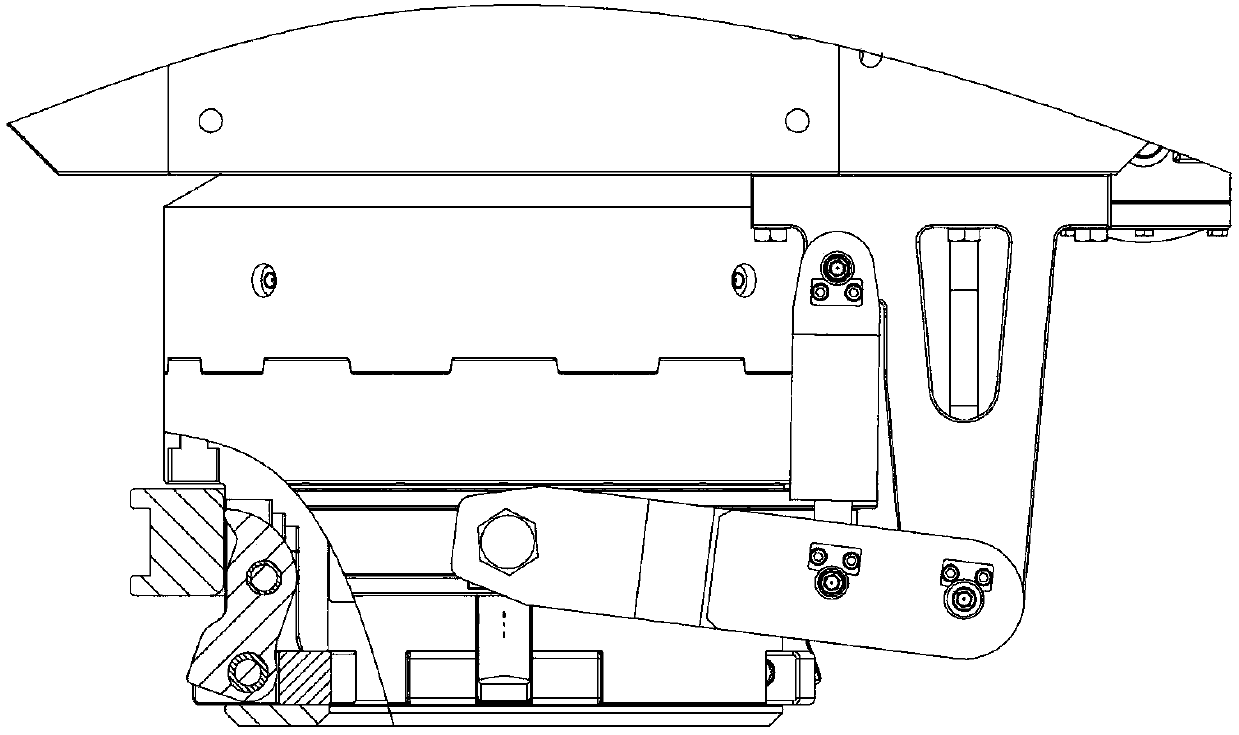

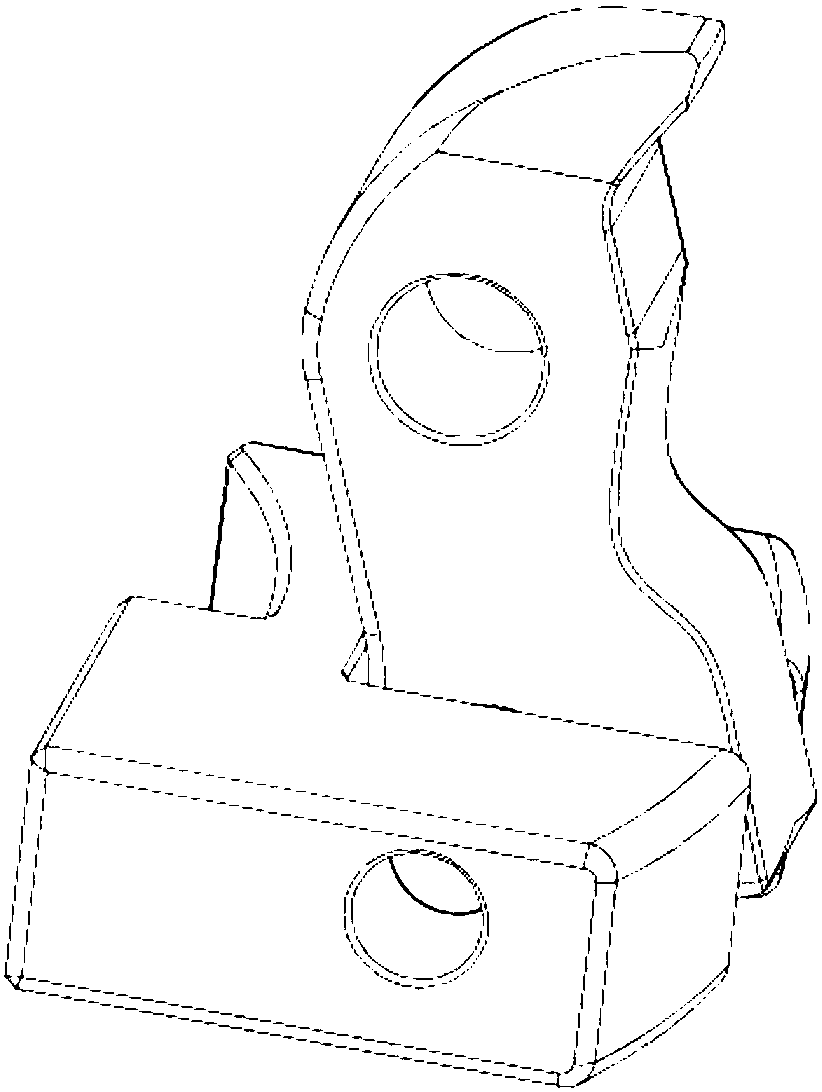

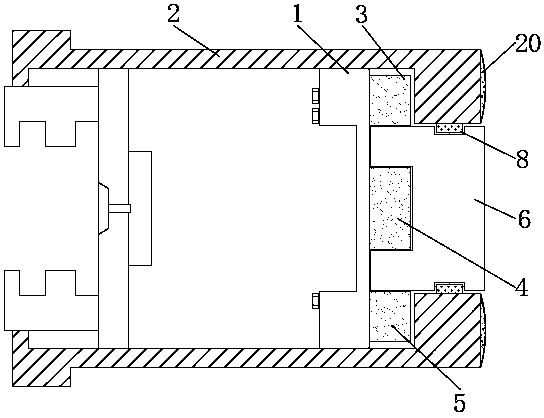

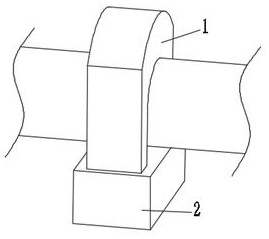

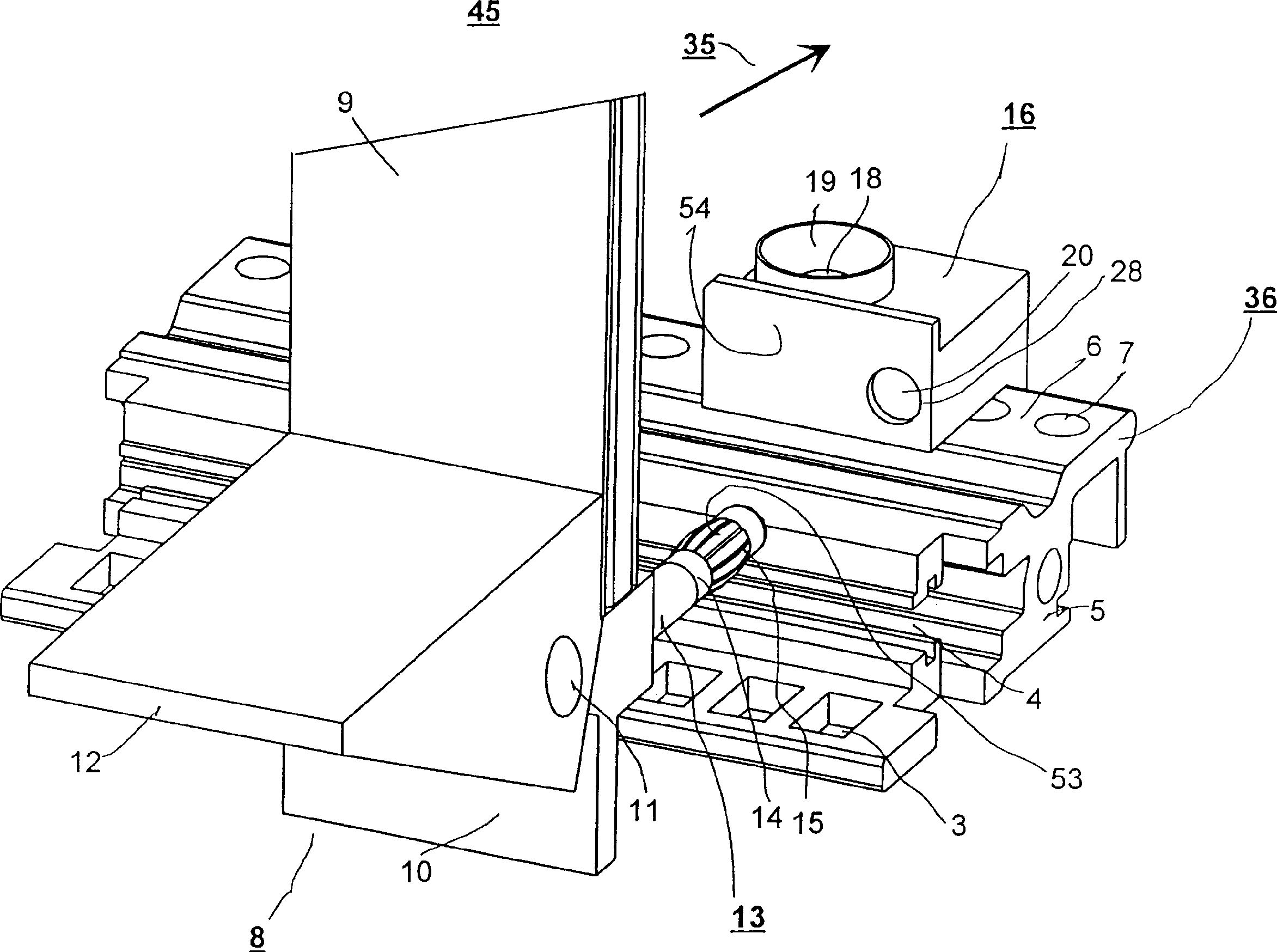

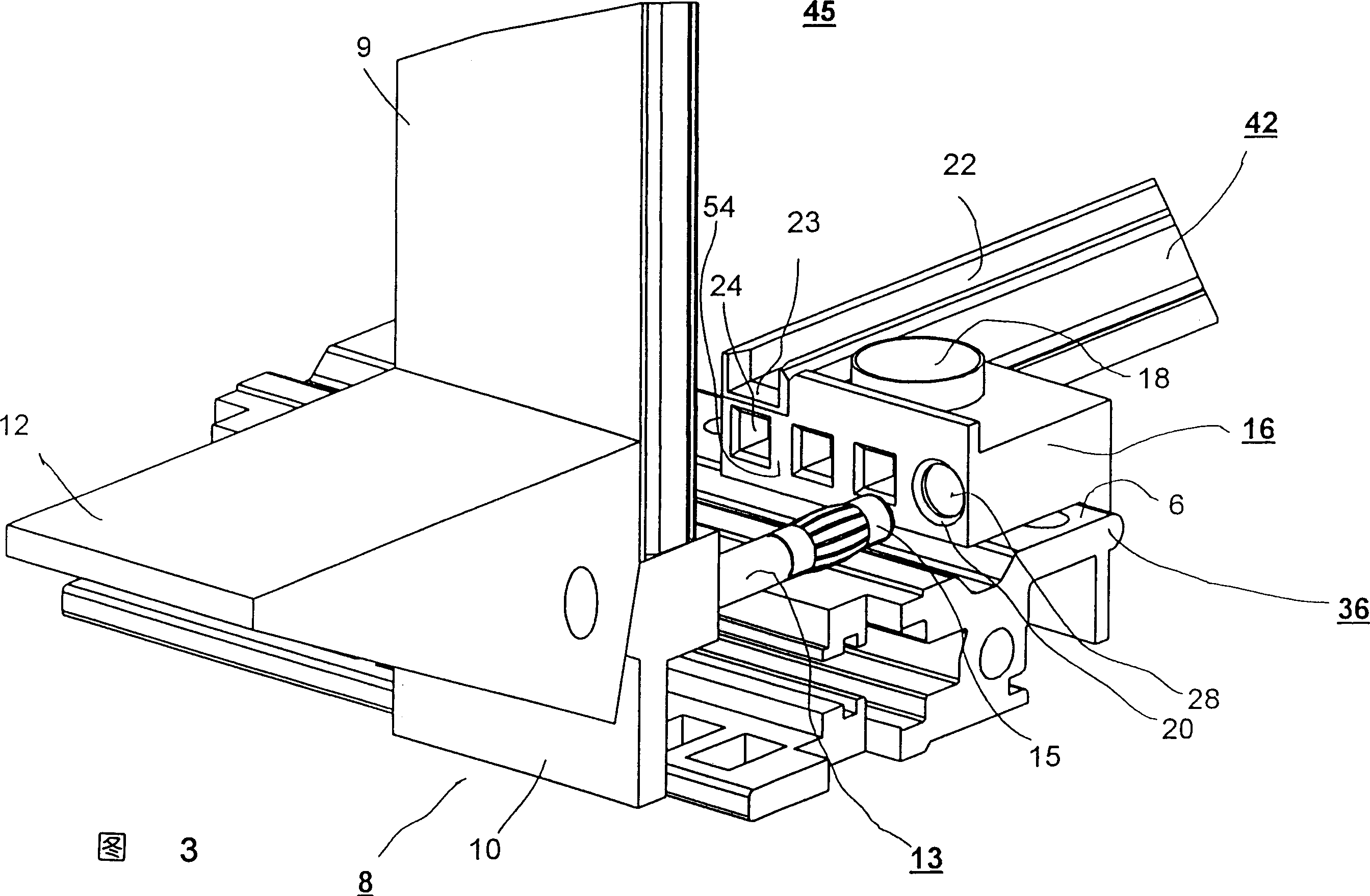

Car body clamping positioning device suitable for car welding production line

InactiveCN110102950AClamp firmlyEnhanced clampingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringManufacturing line

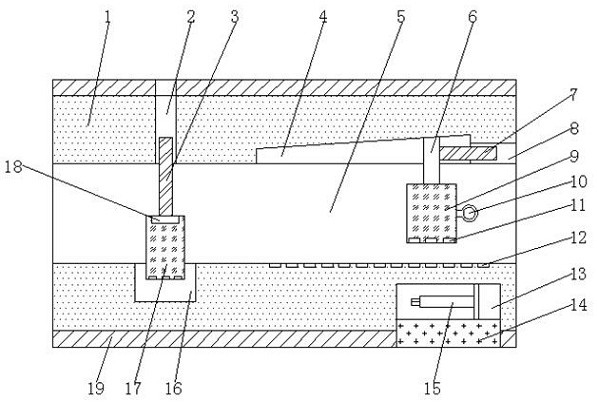

The invention discloses a car body clamping positioning device suitable for a car welding production line. The car body clamping positioning device comprises a supporting base, a guide base arranged on the supporting base, a dowel pin which is arranged on the guide base for positioning a car body, a pressure plate which is arranged inside the guide base and the dowel pin, and is matched with the dowel pin for clamping the car body, and an operating mechanism which is used for controlling the pressure plate to switch between a clamping state and a loosening state; and the dowel pin is providedwith an avoiding slot for allowing the pressure plate to pass while switched to a clamping state. The car body clamping positioning device suitable for the car welding production line disclosed by theinvention is compact in structure, is convenient in layout, can stably position and clamp the car body, and improves the car body clamping and positioning effect.

Owner:湖北大冶汉龙汽车有限公司

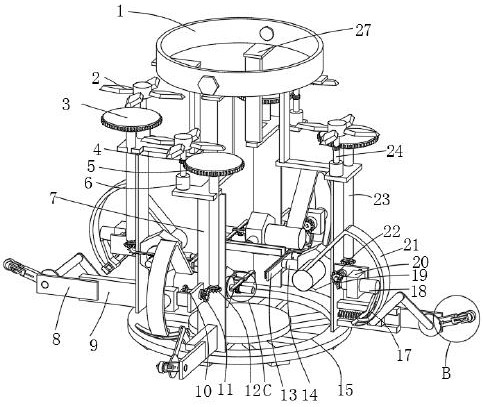

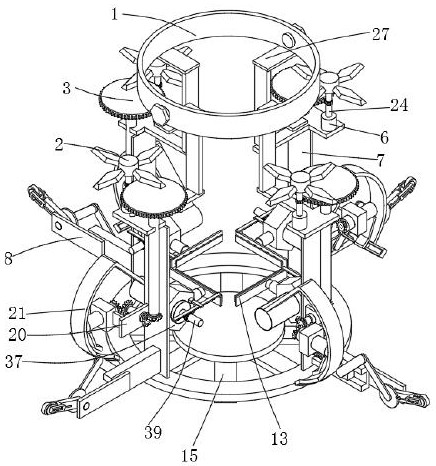

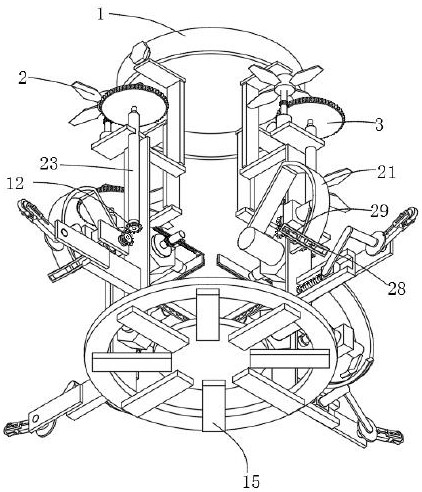

Garden big tree transplanting and binding equipment

InactiveCN112438174AImprove the stabilityImprove the efficiency of migration workAgricultural machinesForestryTree rootAgricultural engineering

The invention relates to garden big tree transplanting and binding equipment. The garden big tree transplanting and binding equipment comprises a dragging vehicle, a fixing unit and a binding mechanism, the dragging vehicle is of an L-shaped structure, the fixing unit is installed at the upper end of the left end face of the dragging vehicle, and the binding mechanism is connected between the leftend of the fixing unit and the upper right end of the dragging vehicle. According to the garden big tree transplanting and binding equipment, the design concept of combining multiple controllable clamping and fixing structures is adopted for garden big tree transplanting and binding, so that the purpose of improving the overall stability degree of trees in the root binding process is achieved; and compared with a manual binding manner, the binding manner adopted by the binding mechanism has the advantages that the binding treatment of automatic annular wrapping of tree roots with soil can berealized, so that the efficiency of tree transplanting work can be greatly improved, and the artificial inconvenience and the labor intensity of workers can also be reduced.

Owner:HANGZHOU JINGYU LANDSCAPE ENG CO LTD

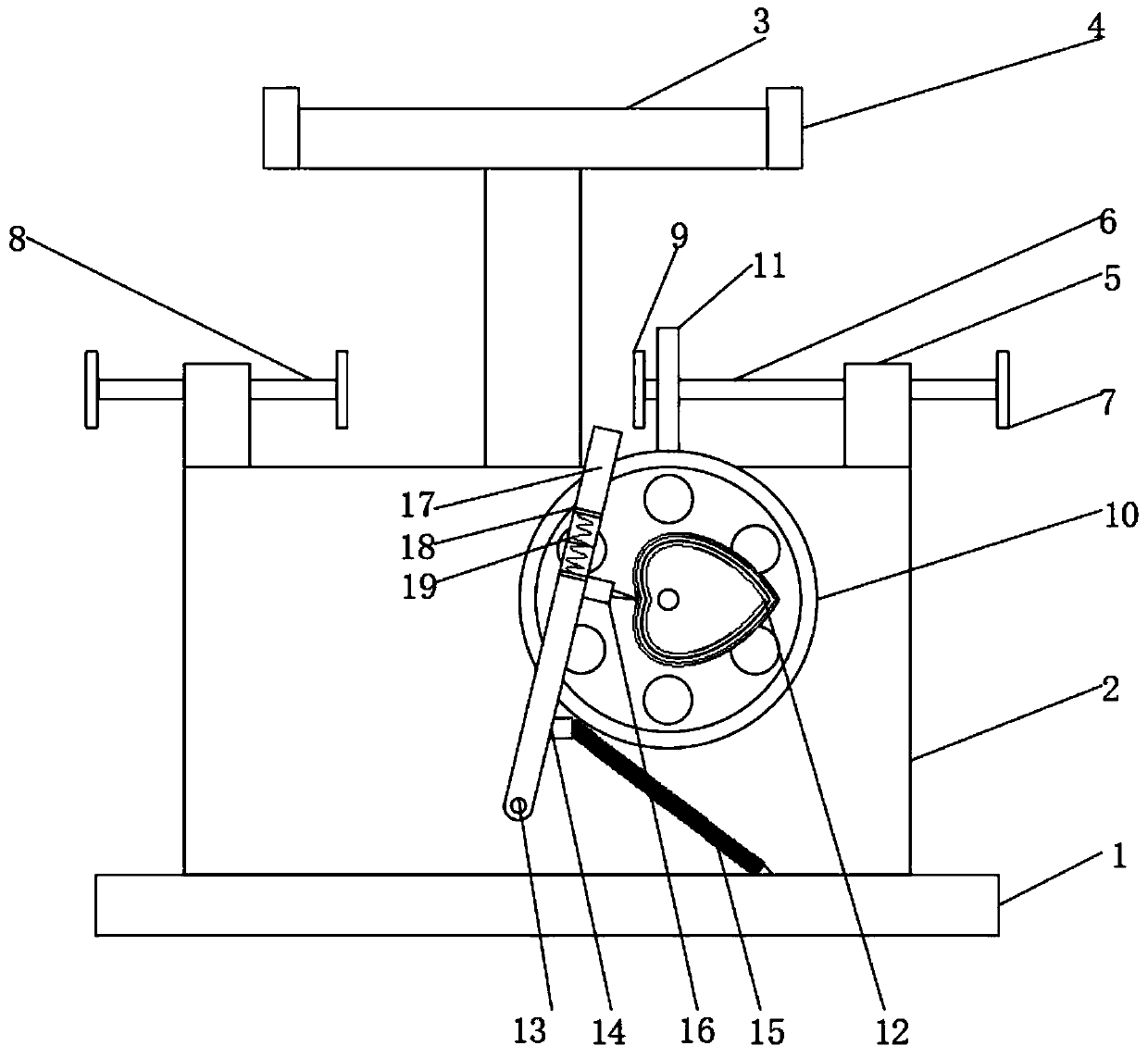

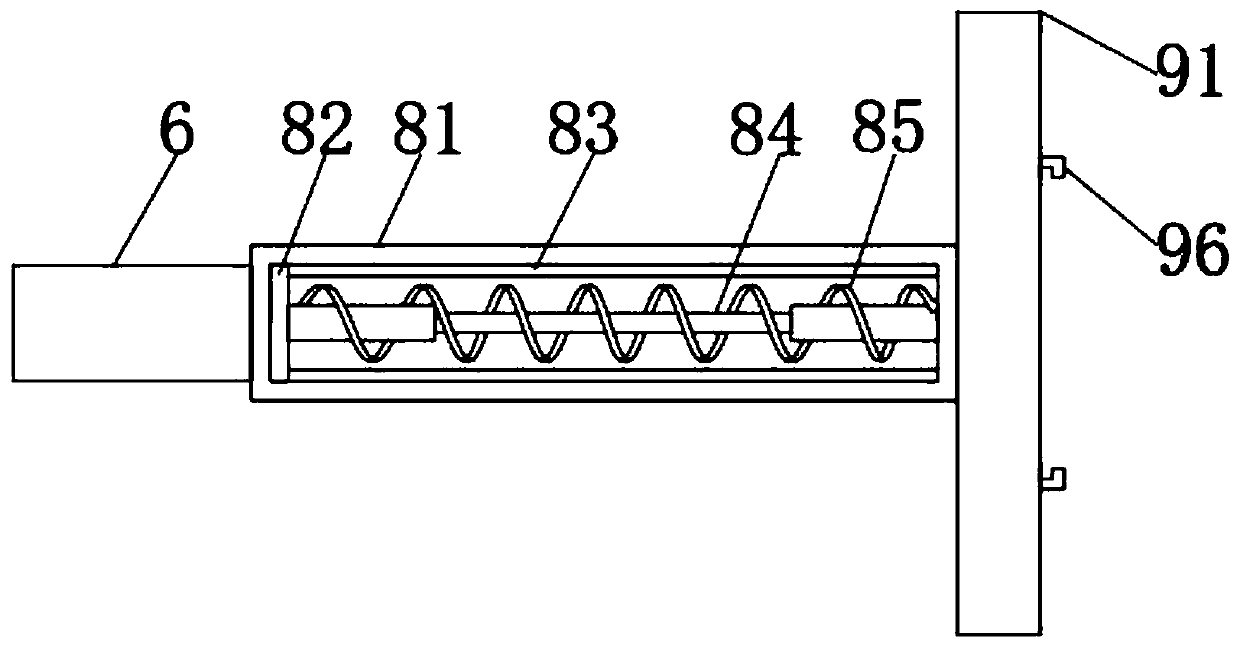

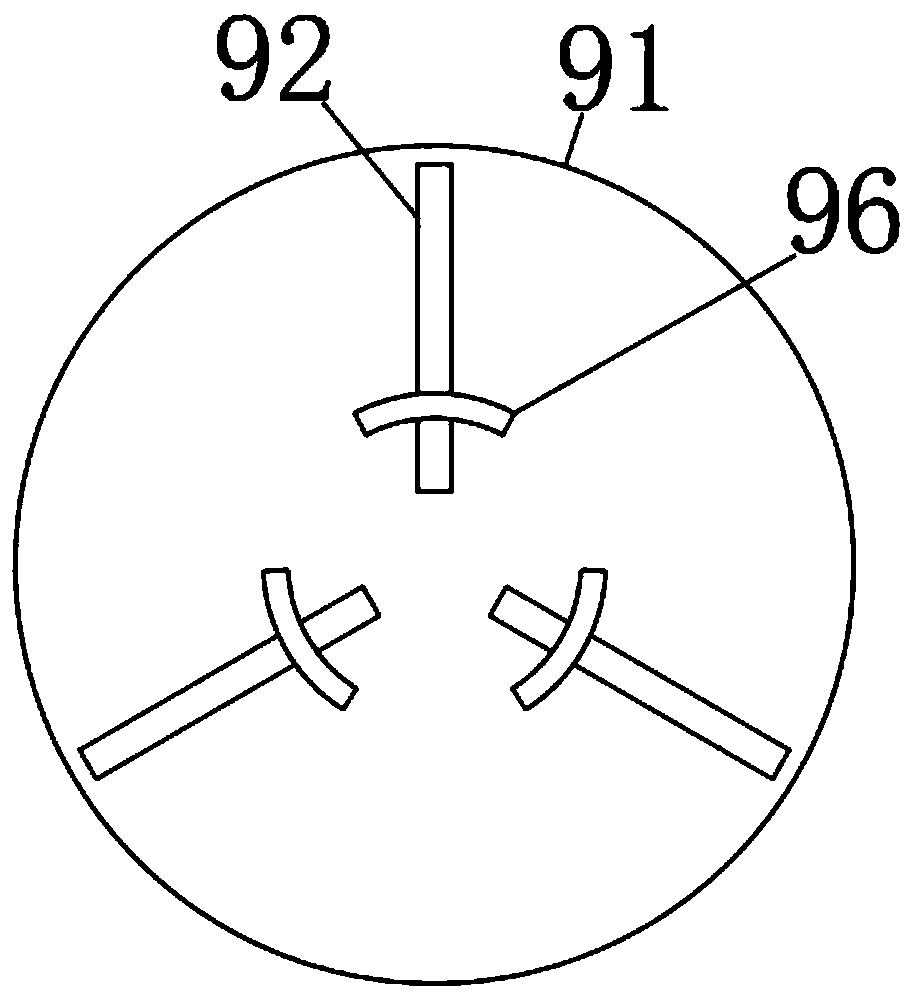

Reciprocating type coil winding device

The invention relates to the technical field of reciprocating coil winding devices, and discloses a reciprocating type coil winding device, which comprises a base, wherein a device shell is fixedly connected to the top of the base, a placing frame is fixedly connected to the middle of the front side of the top of the device shell, two placing seats are fixedly connected to the left side and the right side of the front face of the placing frame, and adjusting seats are fixedly connected to the left side and the right side of the top of the device shell. In the specific use process, when a heart-shaped disc drives a swing rod to move towards the left side, actually the heart-shaped disc rotates half a circle, and when the heart-shaped disc continuously rotates, a tension spring can enable the labor swing rod to quickly return to the state of moving rightwards, so that the stable winding is ensured; and a driving turbine is engaged with a driven turbine, and a driving device can drive a workpiece and the swing rod to rotate at the same time, so that the mechanical loss is reduced, the cost of a power supply is reduced, the device can be quickly operated by inexperienced people, and the employee can conveniently start the device.

Owner:安徽聚益德电子科技有限公司

Anti-interference pneumatic finger and preparation method thereof

The invention discloses an anti-interference pneumatic finger and a preparation method thereof, wherein the wave-shaped buffer jacket of the anti-interference pneumatic finger is sleeved on the outside of the pneumatic center bone, and an inner surface of the wave-shaped buffer jacket and the outer surface of the pneumatic center bone are provided. There is a gap; the end of the wave-shaped buffer jacket is detachably sealed and fixedly connected with the end of the pneumatic center bone through the end coupling device; the bushing is detachably sealed and fixed between the proximal end of the pneumatic center bone and the proximal end of the wave-shaped buffer jacket , the bushing is provided with an outer inflation port that can inflate into the gap between the inner surface of the wave-shaped cushioning jacket and the outer surface of the aerodynamic bone; the finger root connector is detachably sealed and fixed on the proximal end of the pneumatic bone , There are two inner inflation ports that can respectively inflate air into the two inner cavities of the pneumatic centerbone on the finger joint. The invention has the advantages of anti-interference, high action precision, strong flexibility and low production cost, and has broad prospects.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

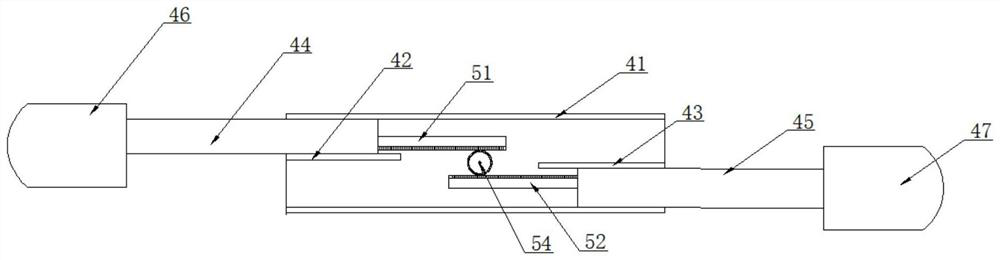

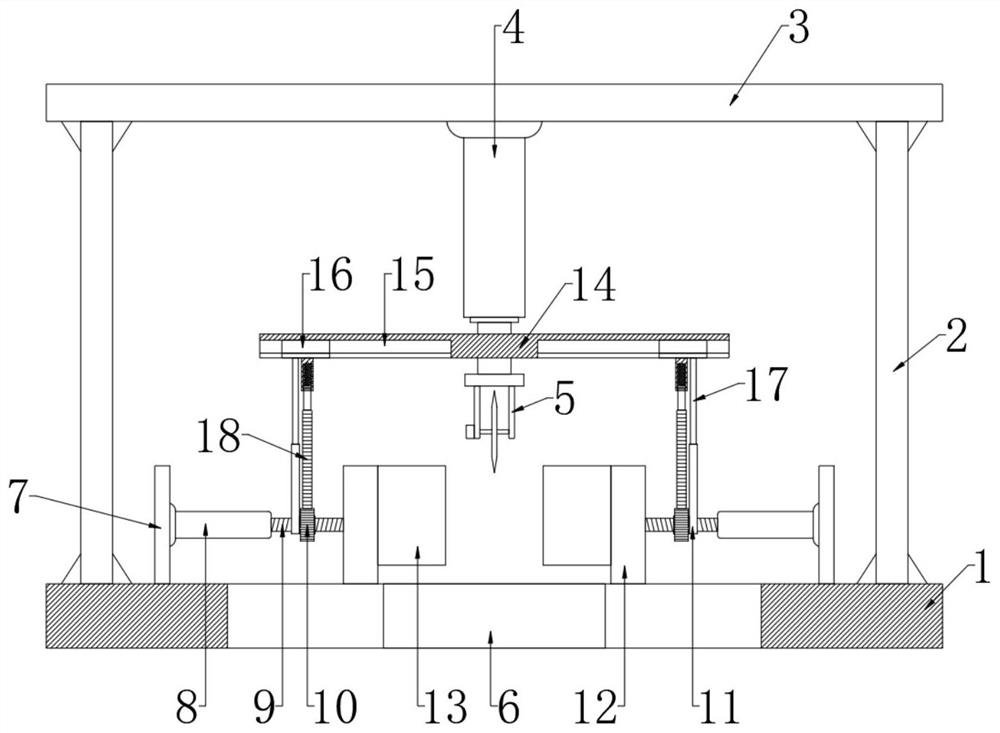

Machining mechanism for automobile cylinder covers

InactiveCN113263207AImprove processing efficiencyReduce the problem of increased processing timeLarge fixed membersMilling equipment detailsStructural engineeringMachine tool

The invention relates to a machining mechanism for automobile cylinder covers. The machining mechanism comprises machine frames, a machining tool and machining grooves, the machine frames are symmetrically distributed on the two sides of the machining tool, the multiple machining grooves are formed in the machining tool and are used for containing the cylinder covers to be machined, driving mechanisms are arranged between the machining tool and the machine frames, clamping mechanisms are arranged on the machining tool, and a lifting mechanism is further arranged on the lower surface of the machining tool. According to the machining mechanism, one or two machining grooves are formed in the machining tool, the multiple clamping mechanisms are arranged above the machining grooves, the cylinder covers needing to be machined are placed in the machining grooves, then the clamping mechanisms are started to clamp the cylinder covers, milling is carried out on the upper end surfaces of the cylinder covers by utilizing an arranged milling device, after milling of the upper end surfaces is completed, the clamping mechanisms do not need to be loosened, the driving mechanisms are directly used for driving the machining tool to turn over by 180 degrees, the lower end surfaces are made to face upwards, milling is carried out again, and therefore the problem that the machining efficiency is low due to repeated clamping can be effectively solved.

Owner:常州美通备品车辆配件有限公司

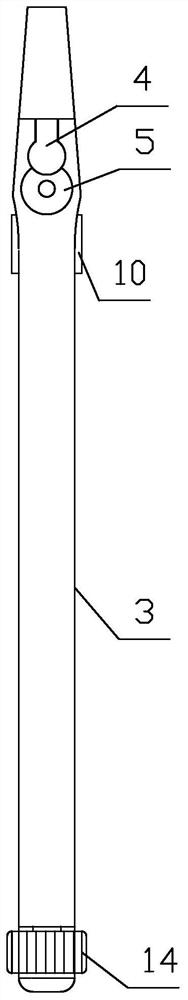

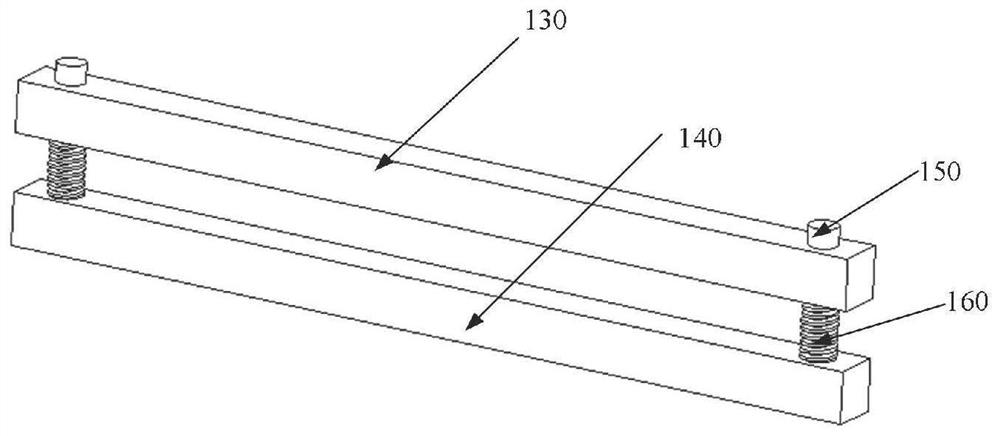

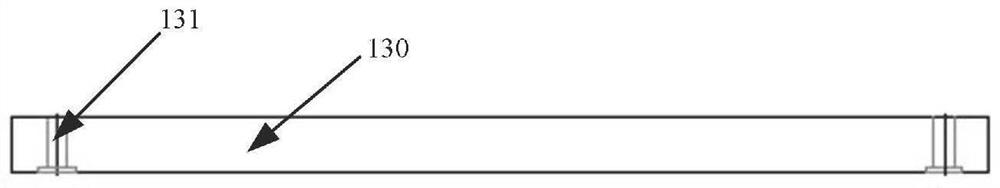

Press-plate-type top support for bass drum

InactiveCN102339600AEnhanced clampingClamp firmlyPercussion musical instrumentsMusical supportsDrumheadKnurling

The invention provides a press-plate-type top support for a bass drum. In the invention, a connecting insertion tube with a top tooth surface is inserted into the top of a steel tube of the support; two sides of the steel tube are respectively equipped with a mechanism for fixing a drumhead ball bar; the mechanism for fixing the drumhead ball bar at one side comprises a fixing seat fixed on the connecting insertion tube, a lower press plate is arranged at the lower part of the fixing seat and is connected with the steel tube through a knurling pin, and the fixing seat and the lower press plate tightly clamp the drumhead ball bar through a bolt and a locking knob; and for the mechanism for fixing the drumhead ball bar at the other side, a tooth surface is arranged on the bottom surface at one side of an upper movable press plate seat and corresponds to the top tooth surface of the connecting insertion tube, the upper movable press plate seat is fixed on the connecting insertion tube through a locking bolt, the middle part of the upper movable press plate seat is equipped with an insertion hole and is connected with the one side of the lower press plate through a knurling pin inserted into the insertion hole, and the other side of the upper movable press plate seat and the other side of the lower press plate tightly clamp the drumhead ball bar through bolts and locking knobs. The press-plate-type top support has the beneficial effects that the clamping mechanisms of the top support for the bass drum can adjust the clamping direction of drumheads and generate large and steady clamping forces, thus reducing the adjustment time during a performance process; and the appearance is unique and beautiful.

Owner:TIANJIN JINBAO MUSICAL INSTR

Automobile tire detection and maintenance device for automobile maintenance

InactiveCN112046212AAchieve clampingAchieve relaxationLighting support devicesWork benchesRotational axisGear wheel

Owner:XINGTAI POLYTECHNIC COLLEGE

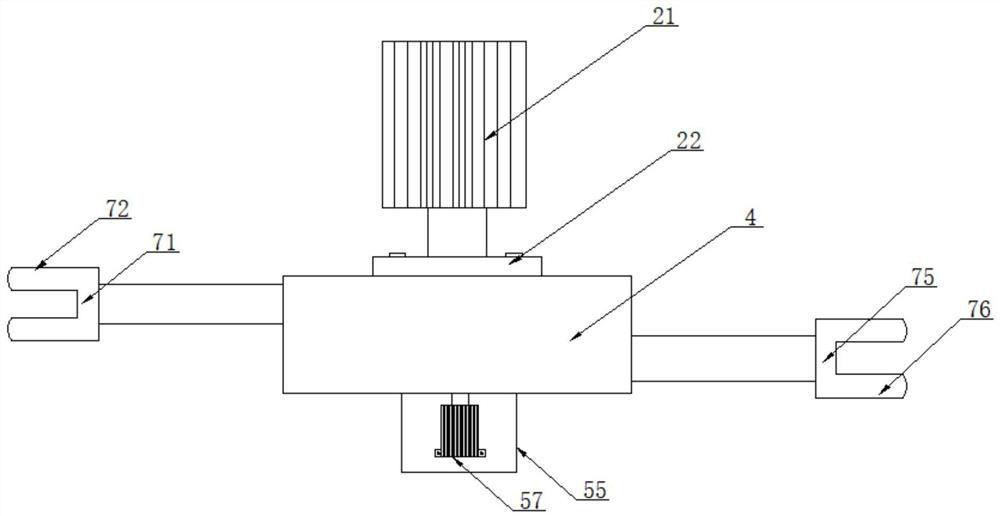

Solenoid valve group assembly auxiliary device

ActiveCN112276551BEasy to fixGuaranteed reliabilityAssembly machinesWork holdersSolenoid valveScrew thread

Owner:嘉兴达鼎自动化科技有限公司

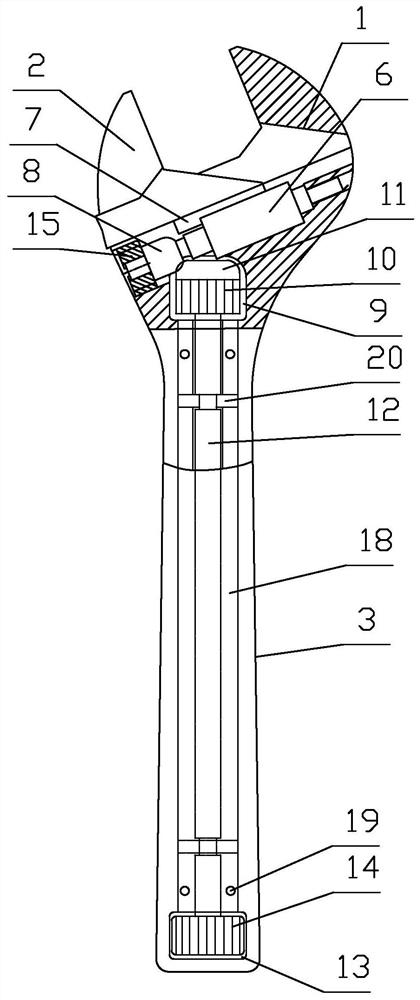

Double-knob adjustable wrench adjusting method for rapidly adjusting opening amount

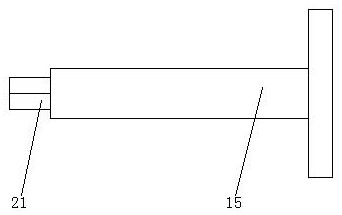

Provided is a double-knob adjustable wrench adjusting method for rapidly adjusting the opening amount. A fixed wrench lip, a movable wrench lip and a handle are included. A circular shaft hole is formed in the upper portion of the fixed wrench lip, and the movable wrench lip is movably installed in the circular shaft hole. A front knob is installed at the front end of the handle, and a rear knob is installed at the tail end of the handle. The front knob and the rear knob are linked through a rotatable transmission shaft arranged in the handle, the front knob is connected with the movable wrench lip through a transmission part arranged in the fixed wrench lip, and the movable wrench lip can be driven to move in the circular shaft hole by screwing the front knob or the rear knob so as to adjust the size of the wrench opening. Rapid clamping can be achieved in two modes, and the clamping speed and the loosening speed are greatly increased when the size of the wrench opening is adjusted. The method can be used for occasions where the opening is inconvenient to adjust in a narrow space, the operation is convenient, time and labor are saved, the requirement for the use space is lowered, time is saved, and the working efficiency is improved.

Owner:WEIHAISHIWEILI TOP GRADE TOOL CO

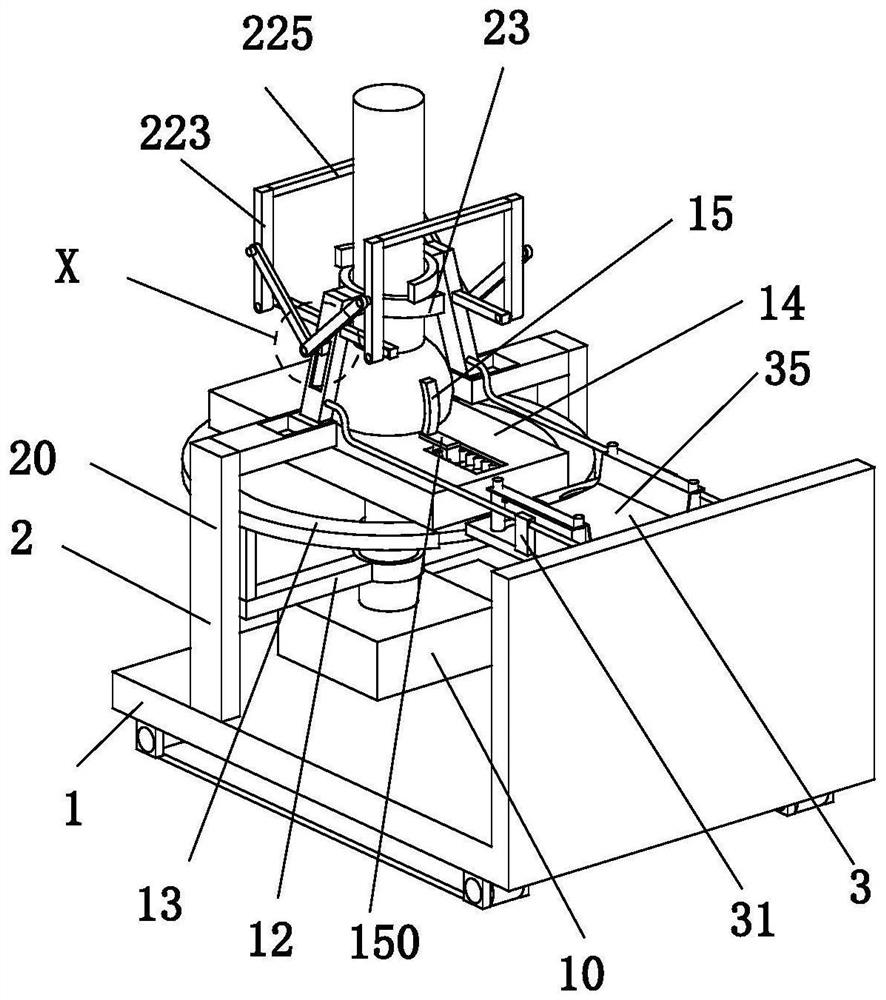

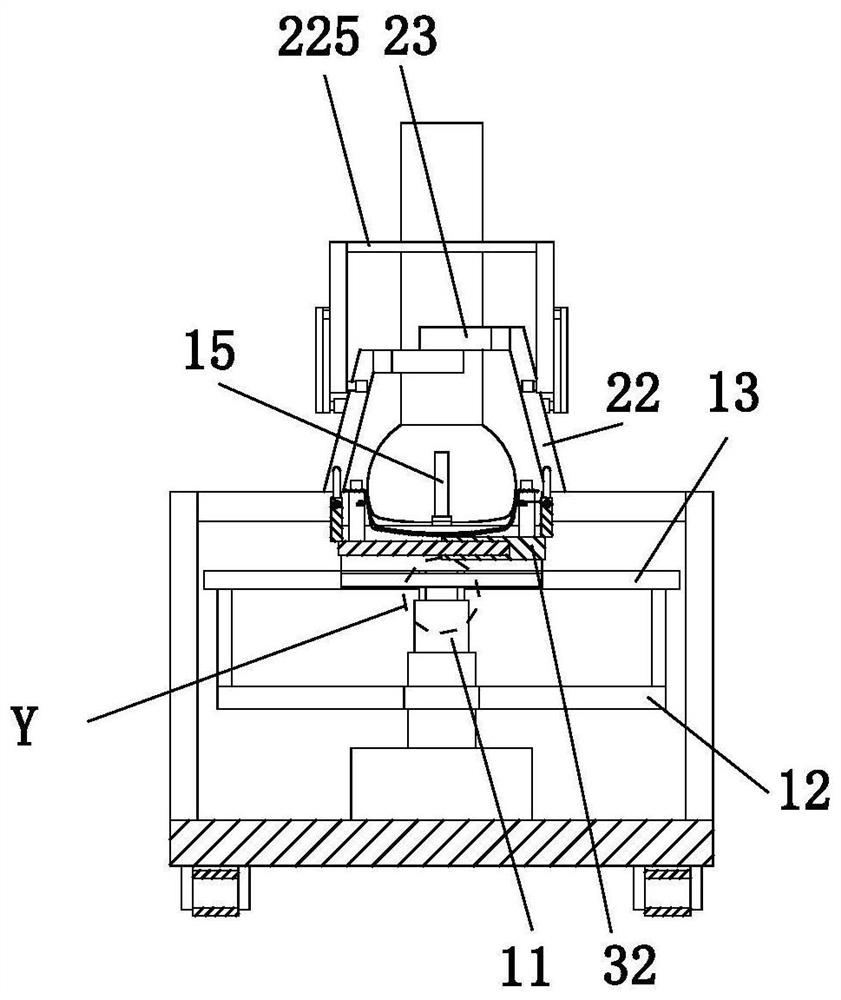

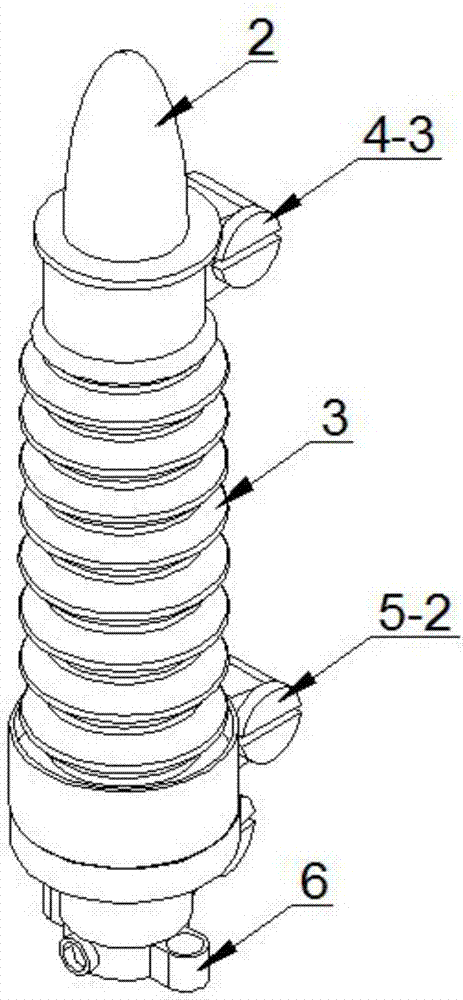

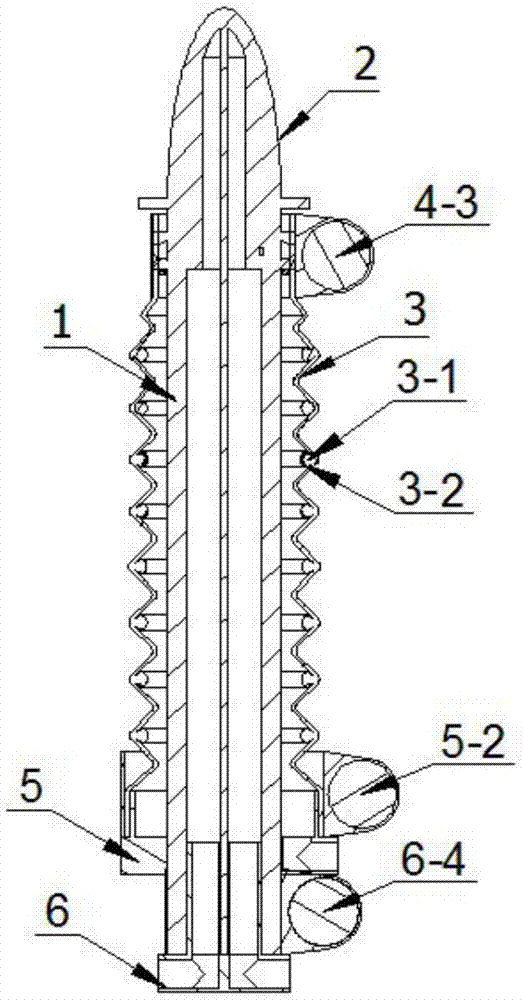

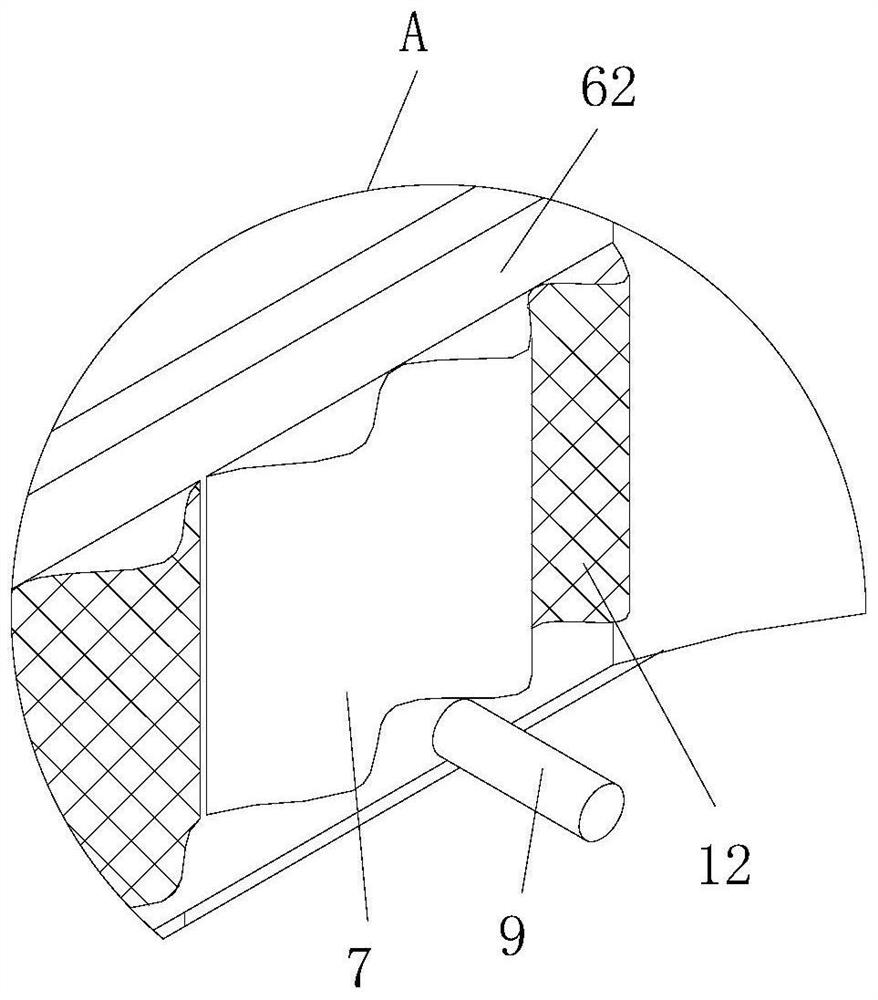

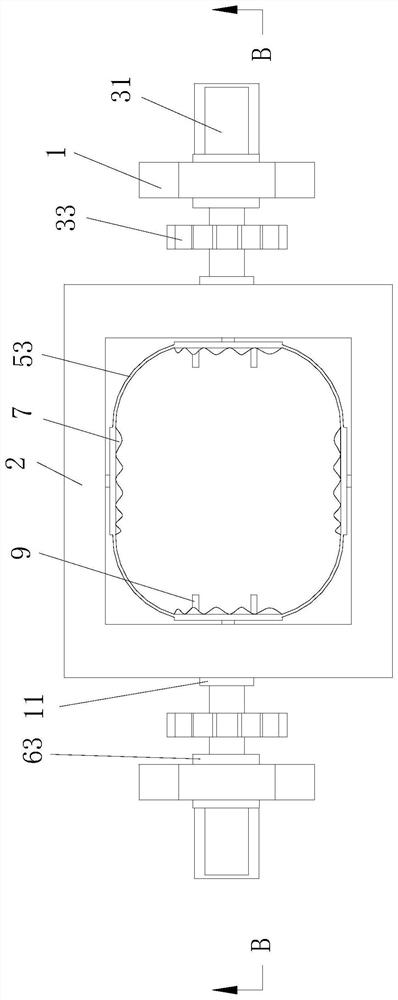

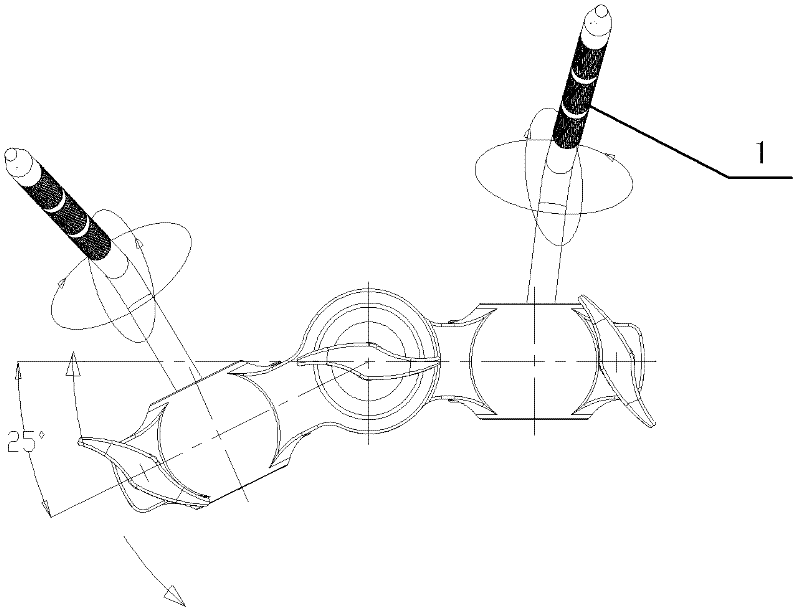

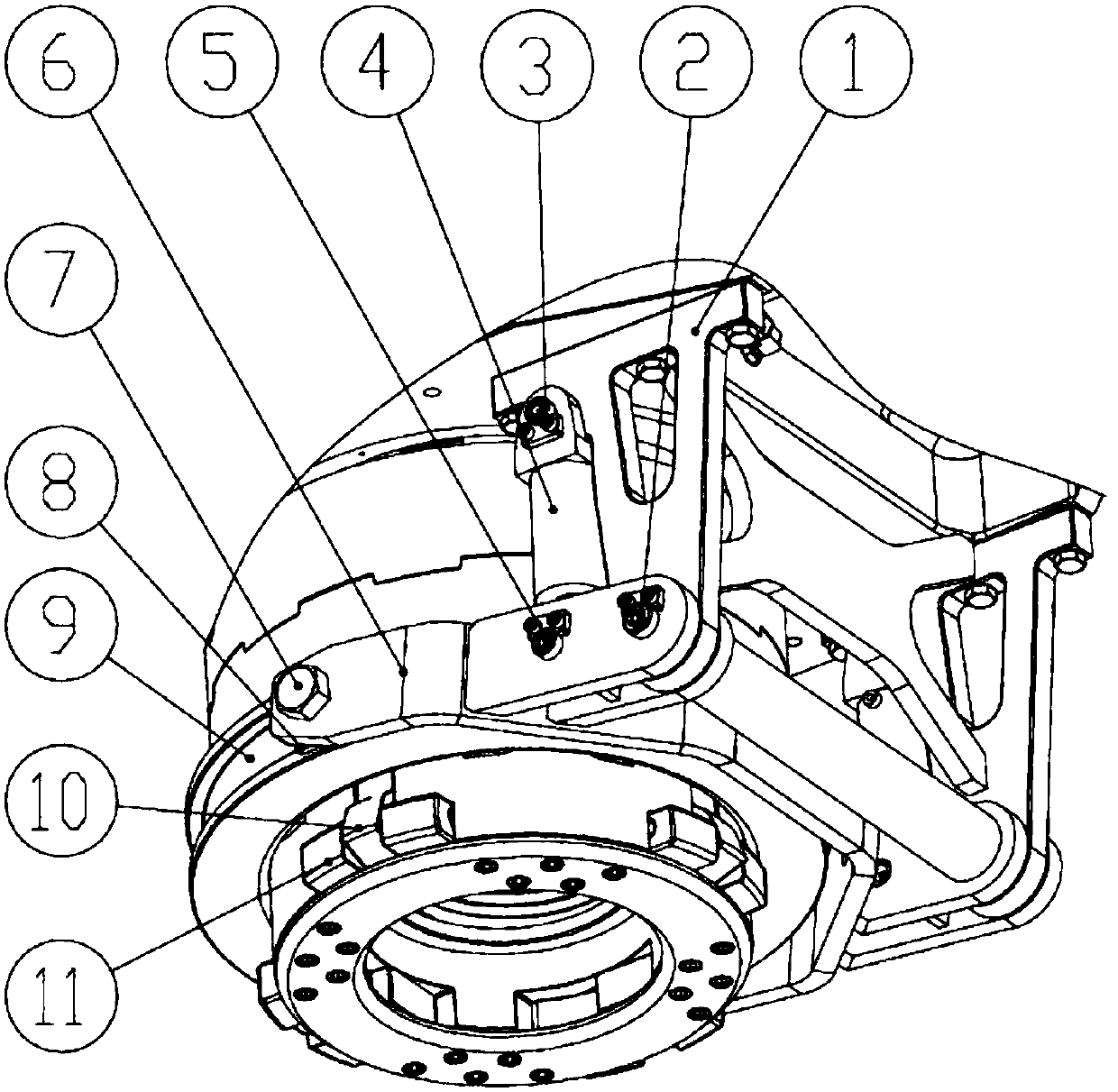

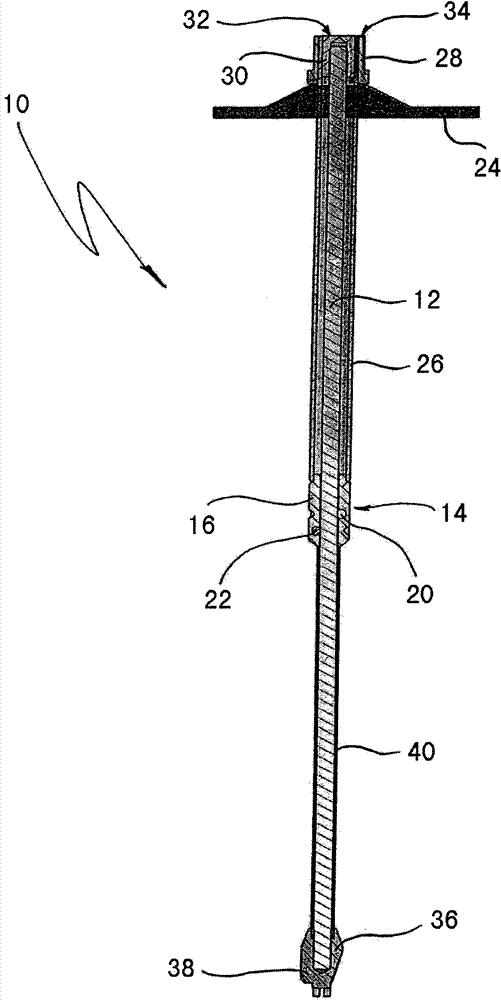

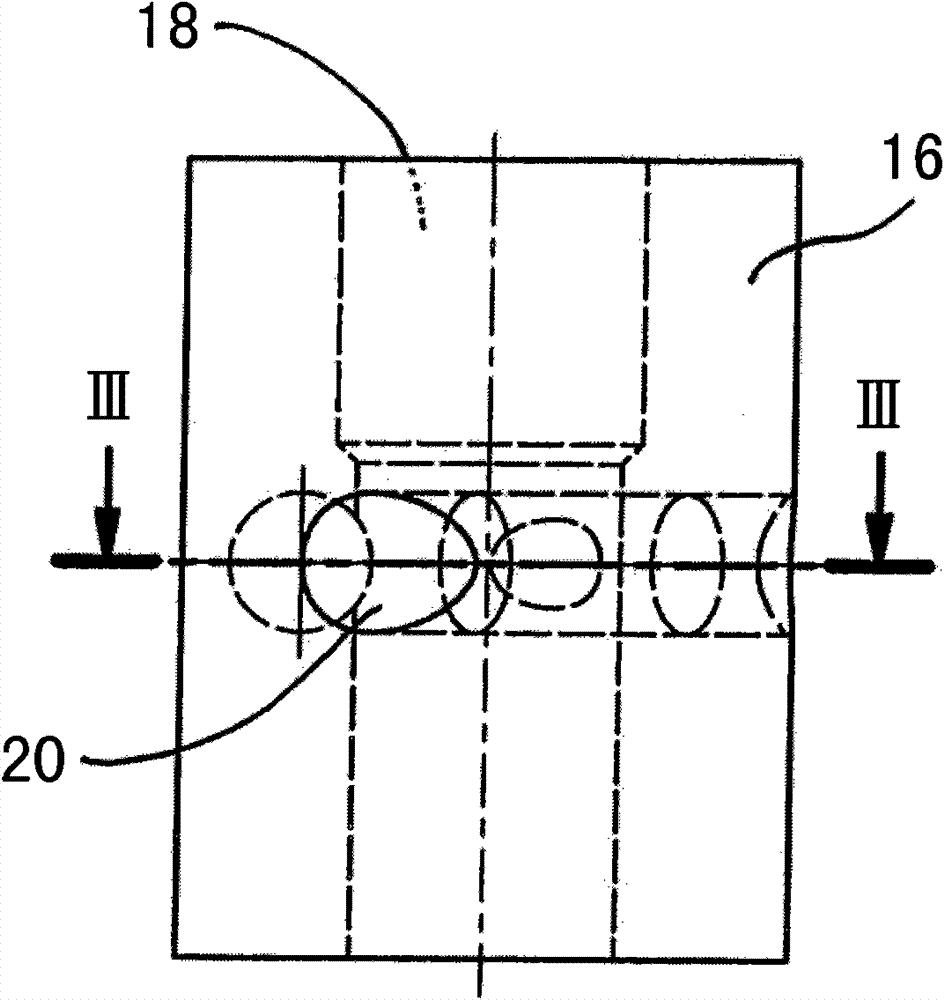

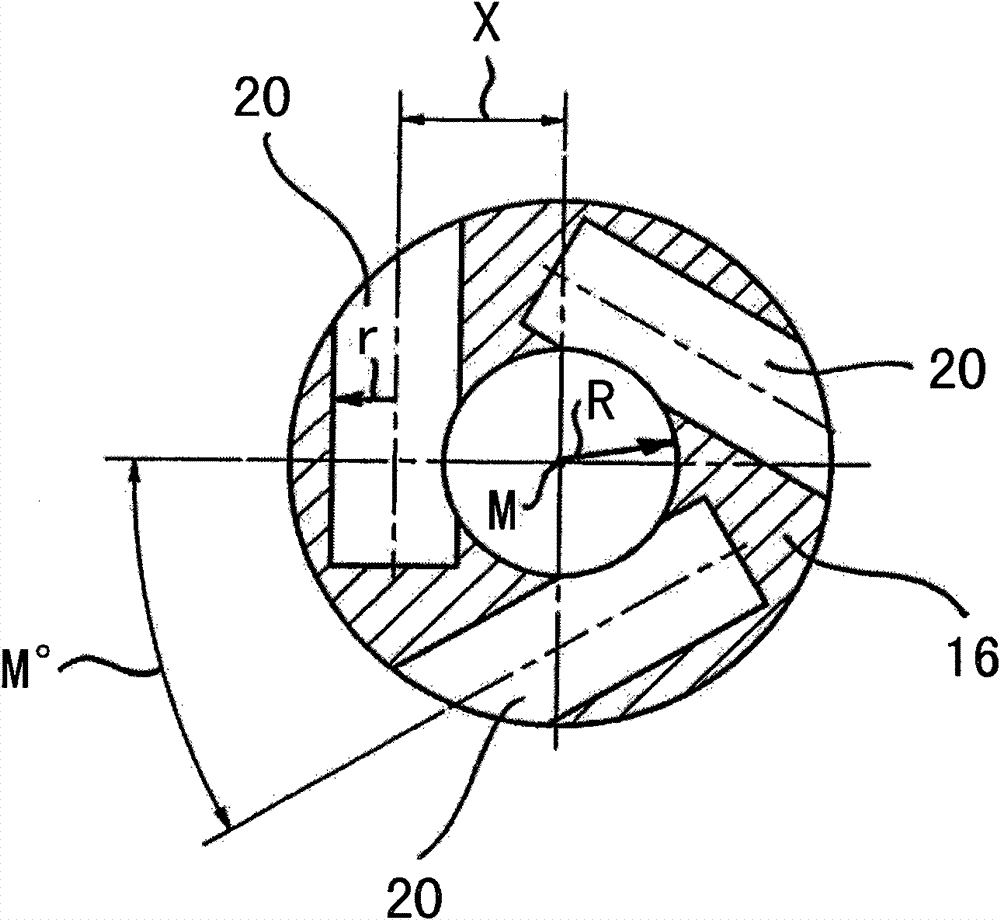

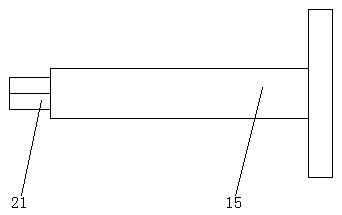

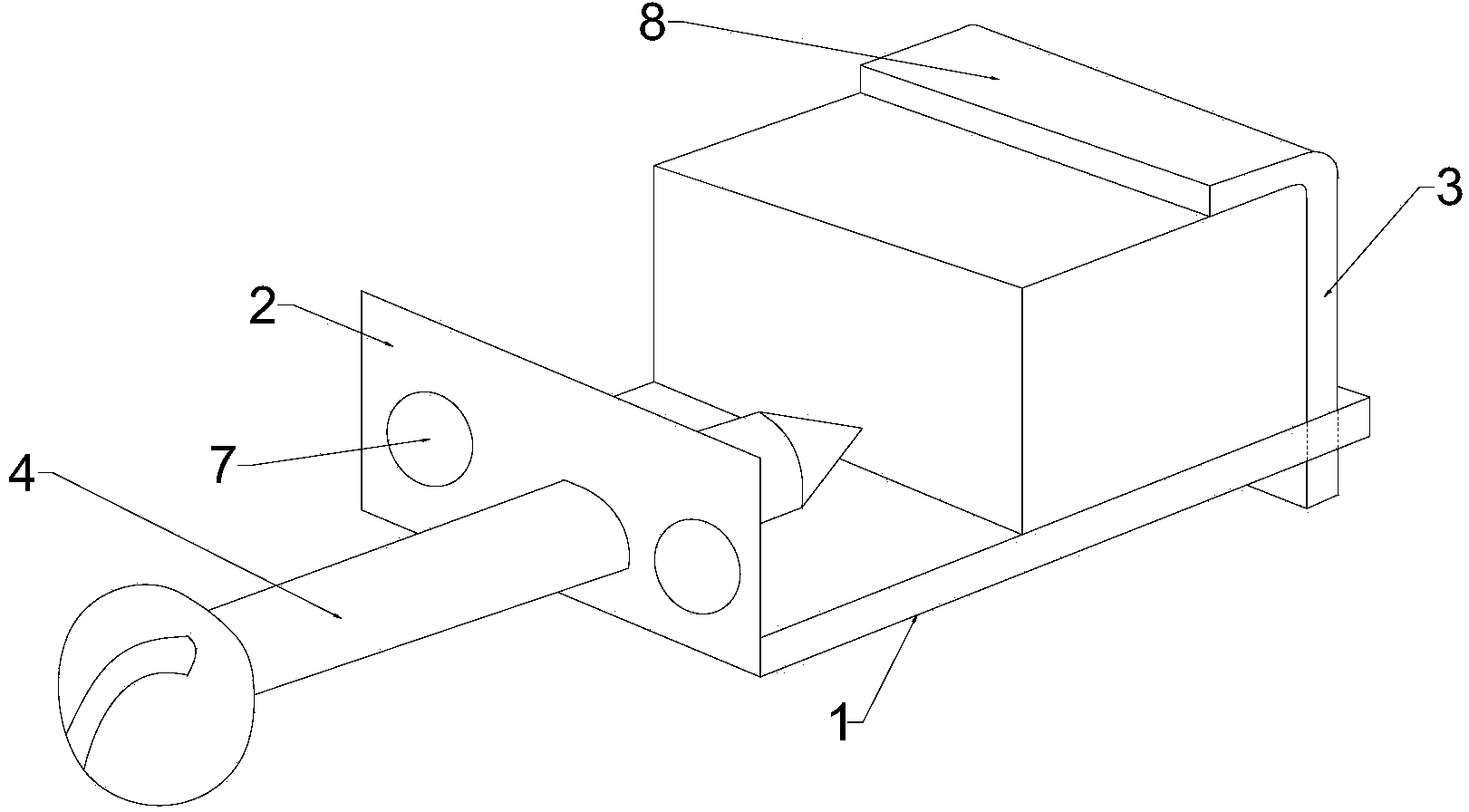

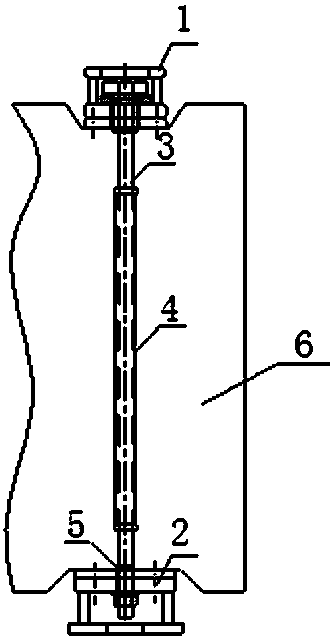

A Dynamic Loading and Unloading Rod Structure for Raise Drilling Rig

ActiveCN105735917BQuick clampingEnhanced clampingDrilling rodsDrilling casingsDrive shaftEngineering

The invention discloses a dynamic upper rod disassembling structure for a raise boring machine. The dynamic upper rod disassembling structure comprises a mounting base, a lifting arm, a cylinder, a driving sleeve, a sliding block, a shifting block and a clamping block, wherein the mounting base is connected with a rotary box body; the cylinder drum of the cylinder is connected with the mounting base through a cylinder drum hinge pin; the mounting base is connected with the lifting arm through the lifting arm hinge pin; the piston rod of the cylinder is connected with the lifting arm through the piston rod hinge pin; the sliding block is connected with the lifting arm through a sliding block pin; the sliding block is clamped into a sliding groove of the driving shaft; the shifting block is connected with a rotary power head machine head body through an upper hinge pin; the shifting block is connected with the clamping block through a lower pin shaft. By adopting the dynamic upper rod disassembling structure, a drilling rod of the raise boring machine can be rapidly clamped, so that a drilling rod can be rapidly disassembled, and the operation can be convenient.

Owner:HUNAN CHUANGYUAN HIGH TECH MACHINERY CO LTD

Improved sliding anchor

Owner:ATLAS COPCO MAI

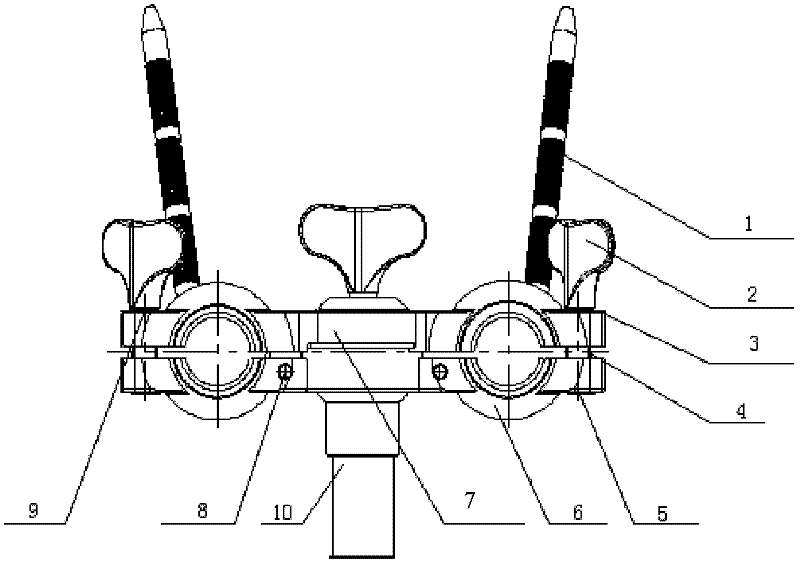

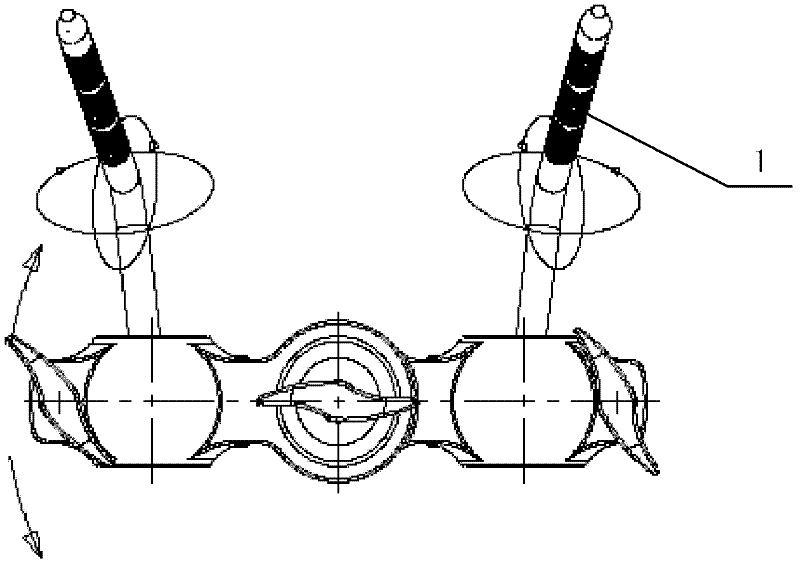

A special anti-collision locking device for UAV transportation

ActiveCN114044153BReduce the risk of fallingImprove securityAircraft controlFreight handlingUncrewed vehicleElectric machinery

The invention discloses a special anti-collision locking device for the transportation of unmanned aerial vehicles, which includes a base plate, an annular array of mounting racks on the upper surface of the base plate, and the inner wall of each mounting rack is connected with a locking device for fixing transported goods. Clamping mechanism, the top of each mounting frame is connected with a fan adjustment mechanism for keeping the UAV in balance, the fan adjustment mechanism includes a motor fixedly installed on the top of the mounting frame, and the top of the connecting shaft is fixed with an adjusting fan blade , the inside of the anti-collision mechanism is provided with a pressure-sensitive sensor for driving the corresponding side fan adjustment mechanism to operate. The invention can generate downward airflow by adjusting the rotation of the fan blades, so that the working position of the adjusted fan blades can generate an upward reverse thrust, so as to compensate for the inclination of the UAV after the collision, thereby effectively reducing the impact of the UAV. In the event of a fall, its safety performance is improved.

Owner:云奕智创航空科技(南通)有限公司

Heat-sealing positioning control method of battery

ActiveCN102765593BLess prone to skewPrecise positioningFinal product manufactureControl devices for conveyorsPosition controlElectrical and Electronics engineering

The invention discloses a heat-sealing positioning control method of a battery, which comprises the steps that a motor is in transmission connection with a conveying belt, a sensor, a material level stopping cylinder and a clamping cylinder are respectively connected with a controller, and the battery is conveyed by the conveying belt; the battery on the conveying belt is detected by the sensor to obtain sensing signals and transmit the sensing signals to the controller; and after receiving the sensing signals, the controller controls the material level stopping cylinder to stop the battery, controls the clamping cylinder to start to clamp the battery, and controls the motor to delay and stop operation so as to make the conveying belt delay and stop operation. The heat-sealing positioning control method of the battery disclosed by the invention effectively solves the problem that positioning deviation is prone to occur during heat sealing of the battery in the prior art, and enhances the heat-sealing efficiency and the product qualification rate.

Owner:ANHUI LEOCH POWER SUPPLY

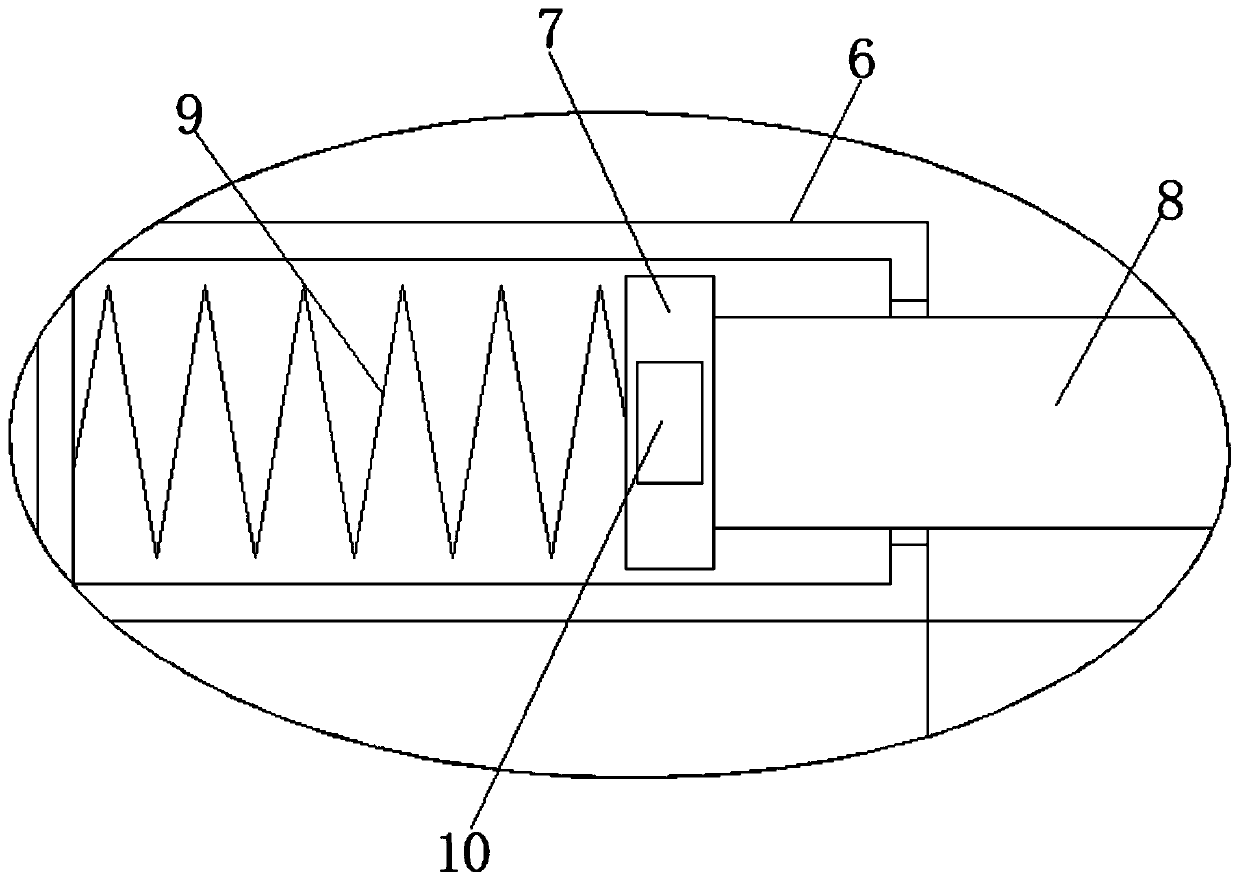

Quick connecting device for steel wire rope

ActiveCN111577829AInhibit sheddingEnhanced clampingRopes and cables for vehicles/pulleyTextile cablesScrew threadThreaded rod

The invention discloses a quick connecting device for a steel wire rope. The quick connecting device comprises a connecting body; the middle of the right side surface of the connecting body is provided with a through slot; a first groove is arranged on the left side of the inner bottom wall of the through slot; a fixture block is arranged inside the first groove; a bearing is fixedly embedded at the middle of the upper surface of the fixture block; the left side of the upper surface of the connecting body is configured with a first threaded hole; a first threaded rod adapted to the first threaded hole is in threaded connection with the interior of the first threaded hole; and the bottom end of the first threaded rod penetrates through the first threaded hole and extends to the interior ofthe through slot, and the lower part of the outer surface of the first threaded rod is fixedly connected with an inner ring of the bearing. According to the quick connecting device for the steel wirerope provided by the invention, by setting a second fixture block, under the action of a sliding chute, a slider, a second threaded rod and a second threaded hole, two sections of steel wire ropes canbe clamped for the first time; and by setting a first fixture block, and under the action of the first groove, the first threaded rod and the first threaded hole, the steel wire ropes can be clampedfor the second time to sufficiently prevent the steel wire ropes from falling off.

Owner:网都河北科技服务有限公司

Non-pressurized tool changing device with accurate positioning function

The invention discloses a non-pressurized tool changing device with an accurate positioning function, and relates to the technical field of shield tunneling machines. The non-pressurized tool changingdevice with the accurate positioning function comprises a tool apron and a protection cylinder, the two ends of the tool apron are fixedly connected with the inner surface of the protection cylinderseparately, one side of the tool apron is fixedly connected with one sides of a first fixing block, second fixing block and third fixing block separately, the second fixing block is located in the middle of one side of the tool apron, the first fixing block and the third fixing block are symmetrically distributed at the two sides of the second fixing block, and the other side of the second fixingblock is in fitting connection with the middle of one side of a tool bit. The non-pressurized tool changing device with the accurate positioning function has the advantages that on the one hand, position setting of the first fixing block, second fixing block and third fixing block at one side of the tool apron facilitates positioning of the tool bit, on the other hand, a wedge block of a chuckingdevice is inserted into a clamping groove in the tool bit to rapidly and tightly clamp the tool bit, thereby saving a lot of installation and debugging time.

Owner:ANHUI TONGDU FLOW TECH

Rapid locking clamp

InactiveCN107433463AAchieve clampingEnhanced clampingPositioning apparatusMetal-working holdersEngineeringScrew thread

Owner:陈锦

A wire rope quick connection device

ActiveCN111577829BInhibit sheddingEnhanced clampingRopes and cables for vehicles/pulleyTextile cablesEngineeringScrew thread

The invention discloses a quick connecting device for steel wire ropes, which comprises a connecting body, a through groove is opened in the middle part of the right side of the connecting body, a first groove is opened on the left side of the inner bottom wall of the through groove, and the inside of the first groove is The first clamping block is placed, the middle part of the upper surface of the first clamping block is fixedly embedded with a bearing, and the left side of the upper surface of the connecting body is provided with a first threaded hole, and the internal thread of the first threaded hole is connected with a thread that matches the first threaded hole. The first threaded rod, the bottom end of the first threaded rod passes through the first threaded hole and extends to the inside of the through groove, and the lower part of the outer surface of the first threaded rod is fixedly connected with the inner ring of the bearing. The wire rope quick connection device can clamp the two steel wire ropes for the first time under the action of the chute, the slider, the second threaded rod and the second threaded hole by setting the second clamping block. The block, under the action of the first groove, the first threaded rod and the first threaded hole, can clamp the steel wire rope for the second time to fully prevent it from falling off.

Owner:网都河北科技服务有限公司

A fixed device for laying hidden floor heating pipes

ActiveCN113669505BAvoid shaking situationsEasy to limitPipe supportsLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a fixed device for laying hidden floor heating pipelines, and relates to the technical field of floor heating. The present invention connects the arc-shaped block to the top of the second fixed block through the arc-shaped block. The first arc-shaped block will be squeezed by the floor heating pipeline to move upward, and the fixed plate will be pressed by the pressure of the first arc-shaped block. Moving, the push plate will be moved upward by the force driven by the cylindrical rod by the fixed plate, and the squeezed air will enter the arc-shaped air groove through the air groove. As the air in the arc-shaped air groove suddenly increases, the sliding Plate 1 is squeezed by the air and moves downward along with the arc-shaped air groove. At this time, arc-shaped plate 1 will move to the left with the push of arc-shaped block 2 to limit and fix the floor heating pipe. Driven by the shape plate 1, it contacts the floor heating pipe, thereby improving the effect of limiting and fixing, avoiding the shaking of the floor heating inside the circular card slot, so as to achieve the effect that the floor heating pipe can be clamped for a long time.

Owner:南通蓝铭冷暖设备有限公司

Clamp and operation table

Owner:XIAOGAN HUAGONG GAOLI ELECTRONICS

Cutting device for mold production

InactiveCN112935373AStable clampingReduce workloadShearing machinesFeeding apparatusEngineeringMechanical engineering

The invention discloses a cutting device for mold production. The cutting device comprises a base, four supporting rods are fixedly connected to the base, the upper ends of the four supporting rods are jointly and fixedly connected with a top plate, the bottom of the top plate is fixedly connected with an electric push rod, and the output end of the electric push rod is fixedly connected with a cutting machine. A cross rod is fixedly connected to the outer wall of the output end of the electric push rod, two T-shaped grooves are formed at the bottom of the cross rod, T-shaped blocks are slidably connected to the interiors of the two T-shaped grooves, two supporting blocks are fixedly connected to the base, and threaded cylinders are fixedly connected to the opposite faces of the two supporting blocks. The cutting machine can move through one electric push rod so as to cut a mold raw material part, meanwhile, the mold raw material part can be clamped in multiple directions, the stability of the mold raw material part during cutting is guaranteed, meanwhile, chippings on the mold raw material part can be cleaned, and the labor amount of workers is reduced.

Owner:唐中友

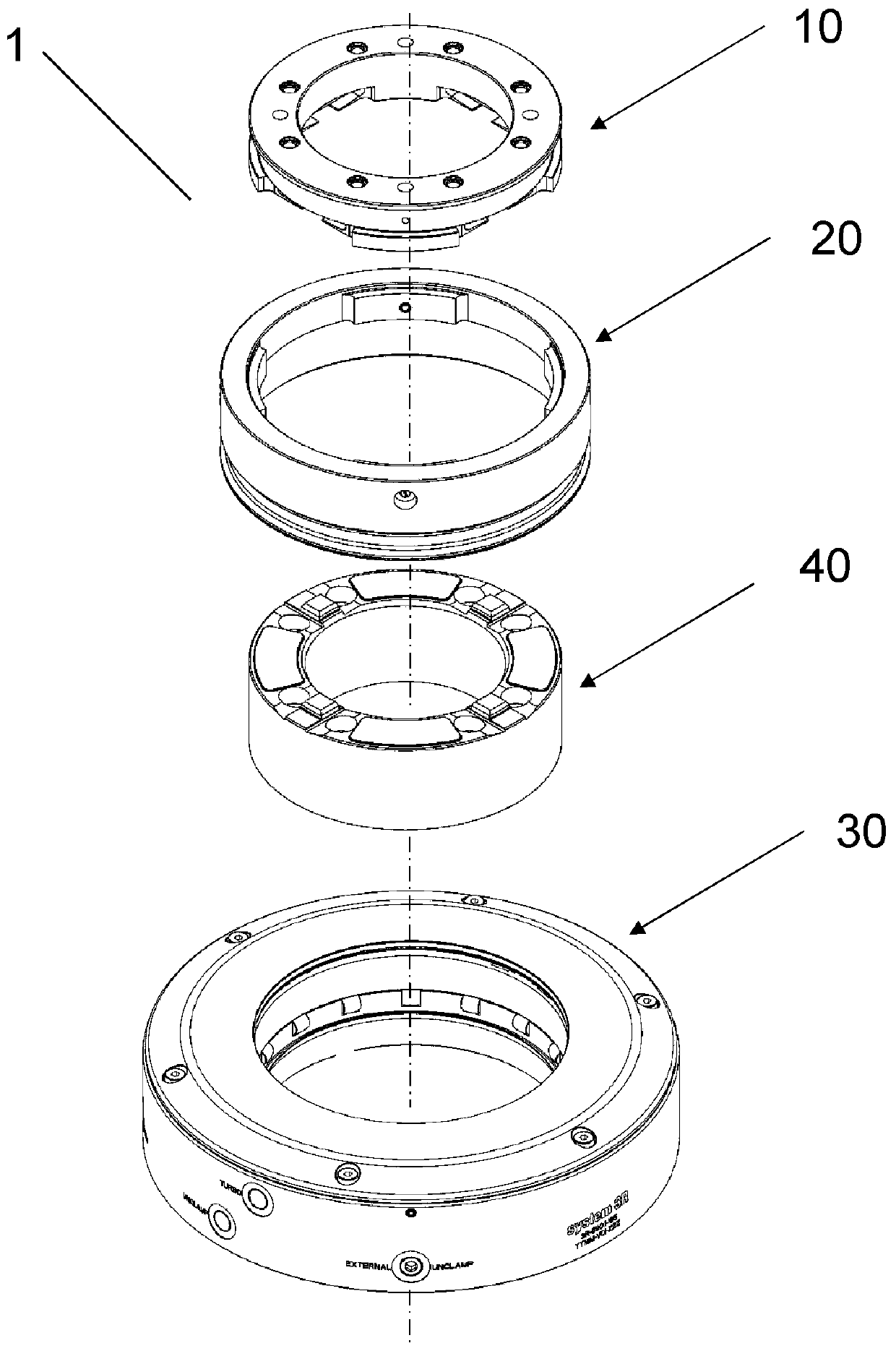

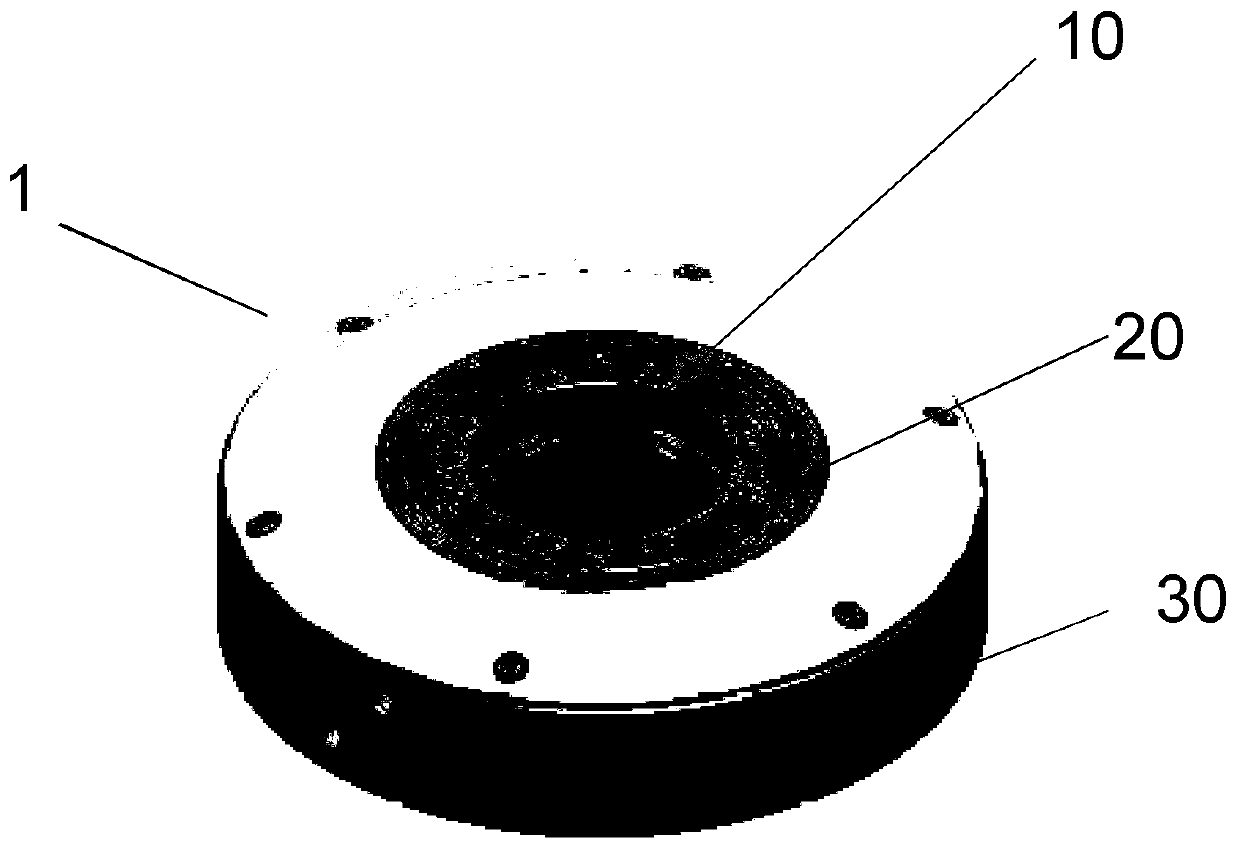

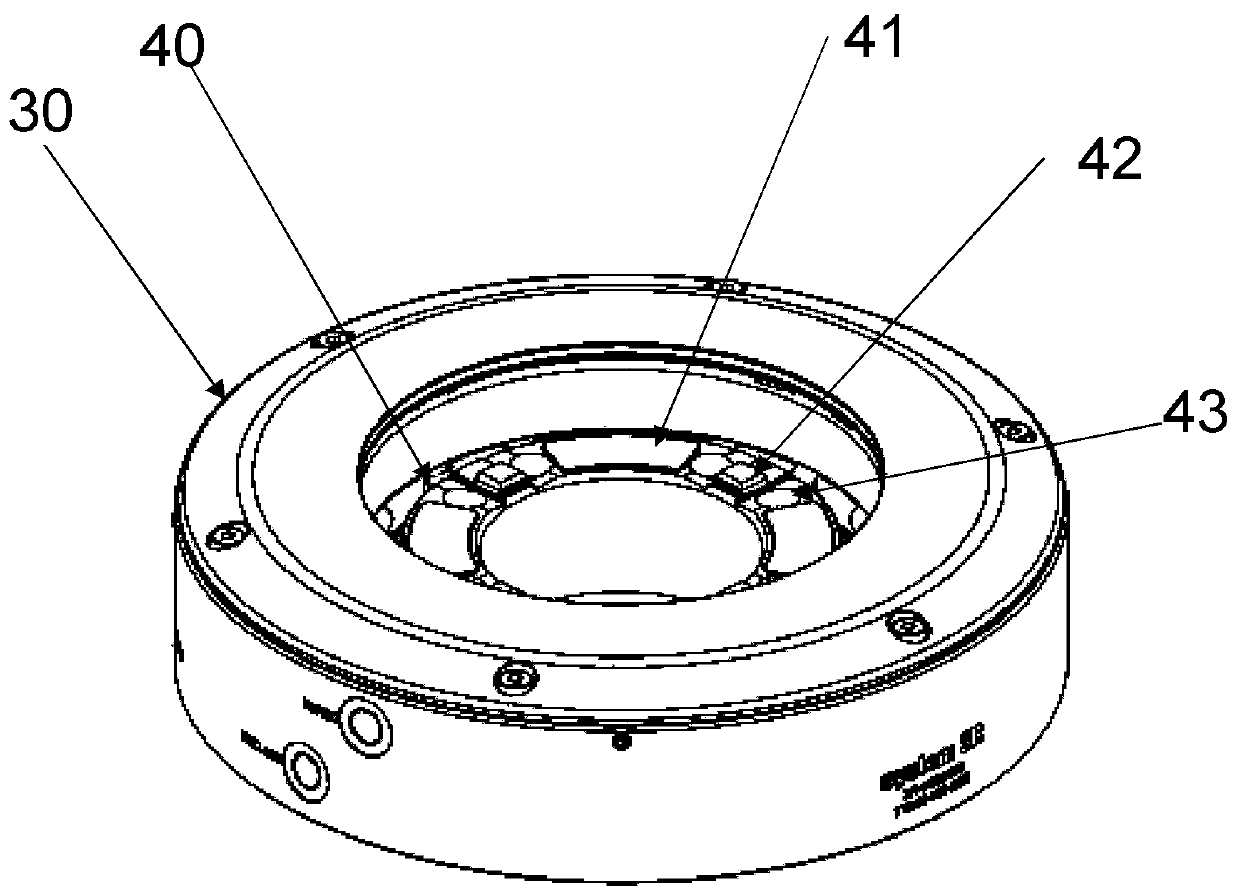

Modular clamping system

ActiveCN110653372AReduce the overall heightAvoid side forceSleeve/socket jointsPrecision positioning equipmentEngineeringPallet

The invention relates to a modular clamping system. The present invention is directed to a modular clamping device for a tool or a workpiece including a pallet having a plurality of x-y references andz references for alignment with a chuck and a clamping unit, which is arranged in the clamped state concentrically at the outside of the chuck. In the clamped state, a tubular part is arranged concentrically between the pallet and clamping unit, and the tubular part is designed such that it is connected to the pallet by a first connecting mechanism and connected to the clamping unit by a second connecting mechanism.

Owner:SYST 3R INT

Clamp with quick locking function

InactiveCN104369003AAchieve clampingEnhanced clampingPositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:常州恒源钢结构工程有限公司

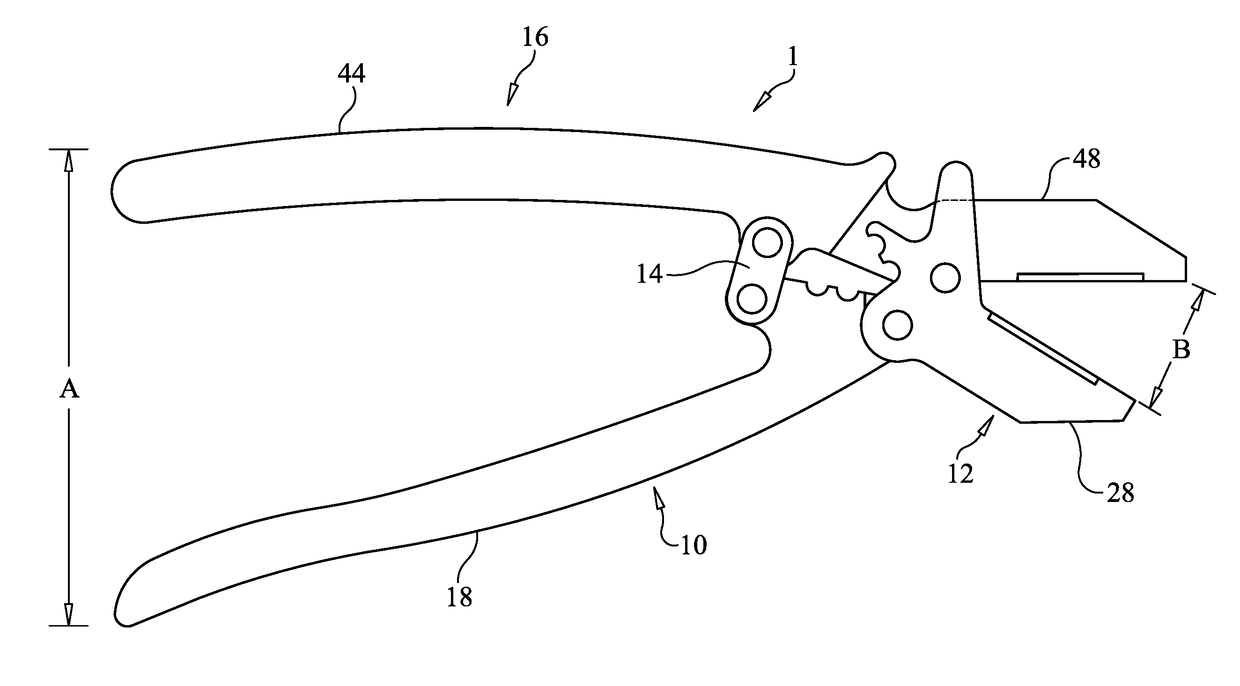

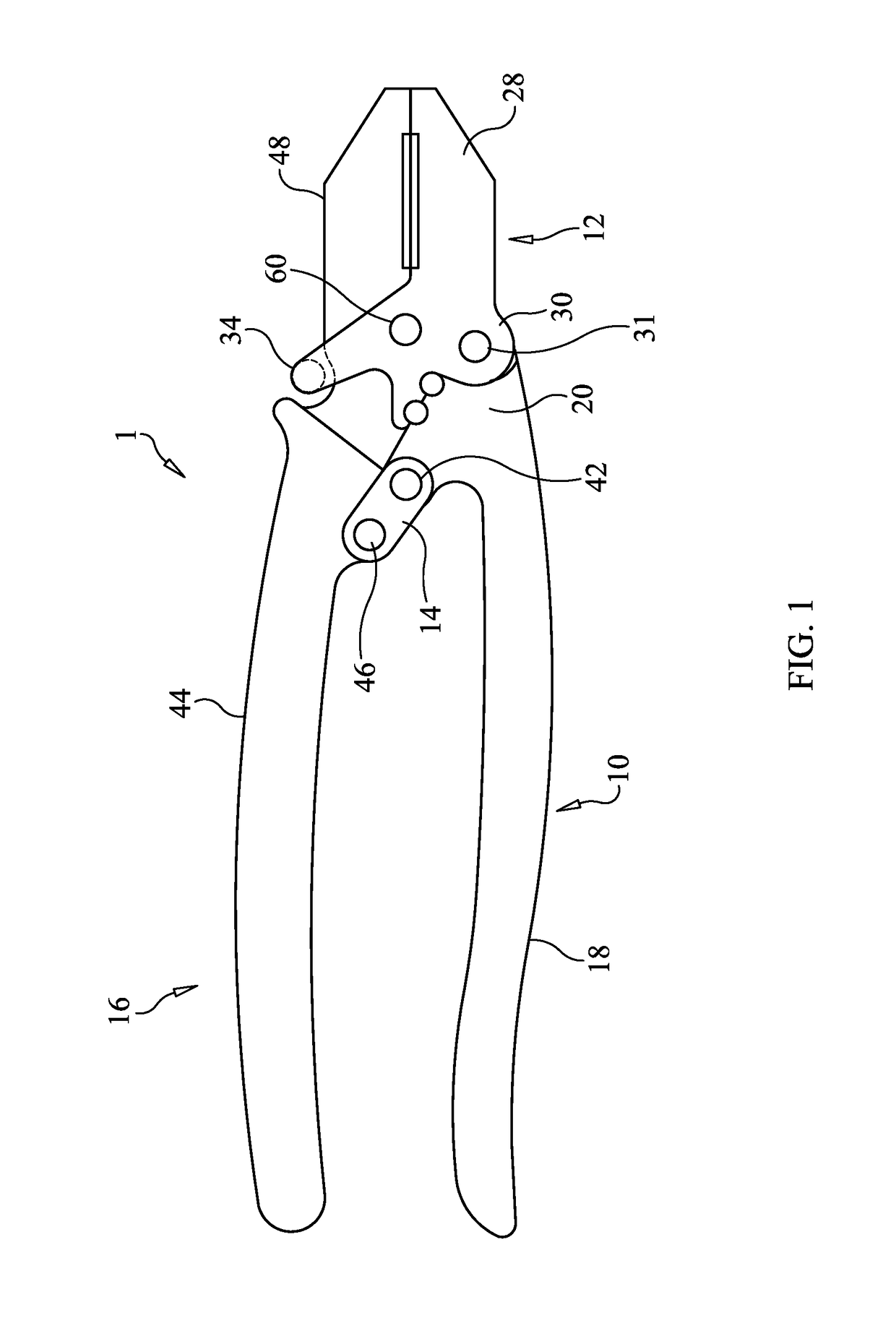

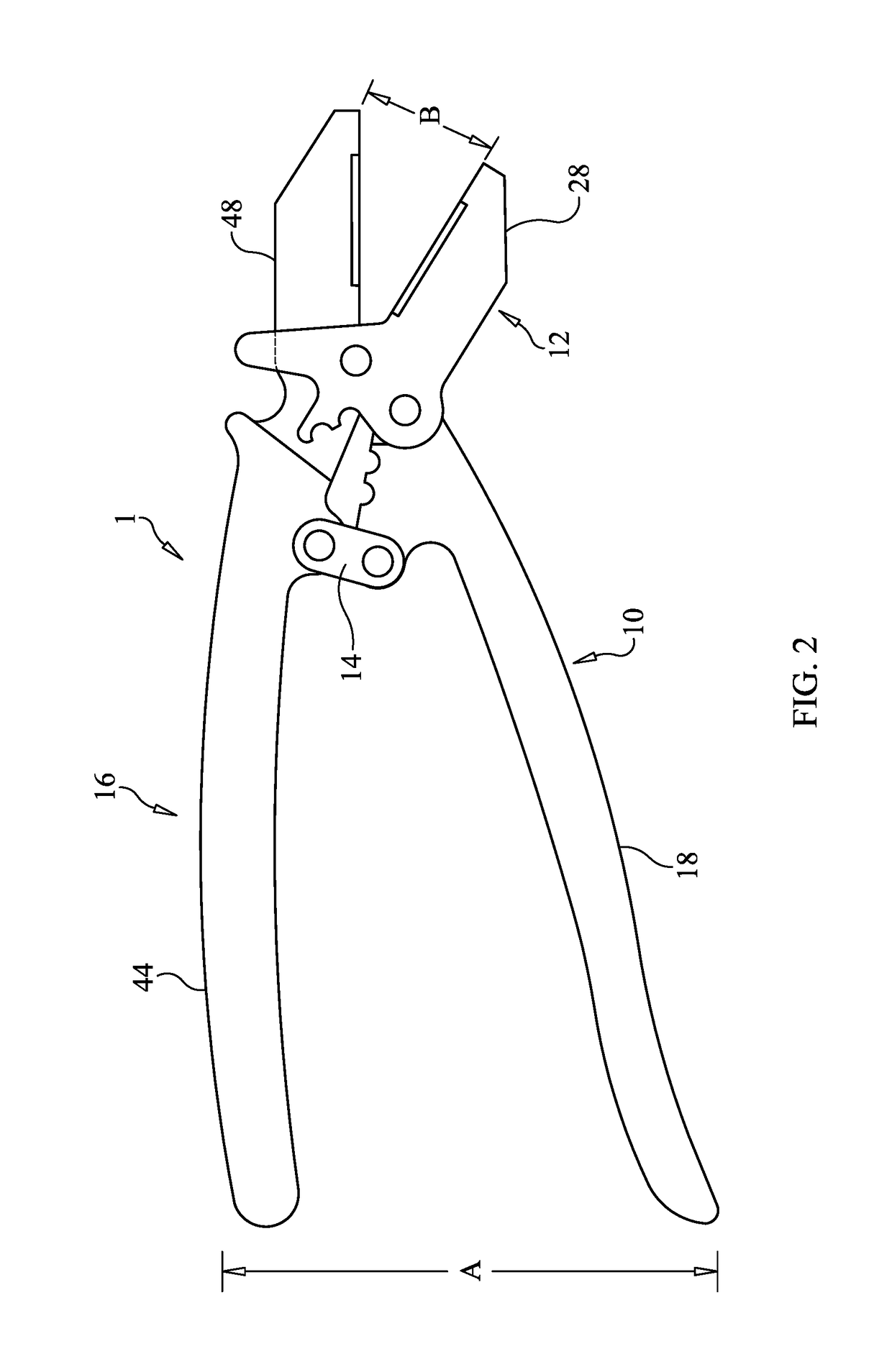

Linesman pliers

InactiveUS10014672B1Enhanced clampingIncrease cutting forcePliersConnection formation by deformationEngineering

An improved linesman pliers preferably includes a lower handle, a lower jaw, a pair of link plates and a combination upper handle and jaw. The lower handle includes a lower handle portion and a lower pivot portion. The lower jaw preferably includes a lower jaw portion, a pivot boss, a stripper projection and a crimp projection. At least one upper stripper cavity is formed in the stripper projection, which is aligned with the at least one lower stripper cavity formed in the lower pivot portion. The pivot boss is pivotally engaged with the lower pivot portion. A pair of link plates pivotal engage the combination upper handle and jaw with the lower handle. The combination upper handle and jaw includes the upper handle portion and an upper jaw. The upper handle portion is pivotally engaged with the lower jaw portion.

Owner:ALDREDGE ROBERT L

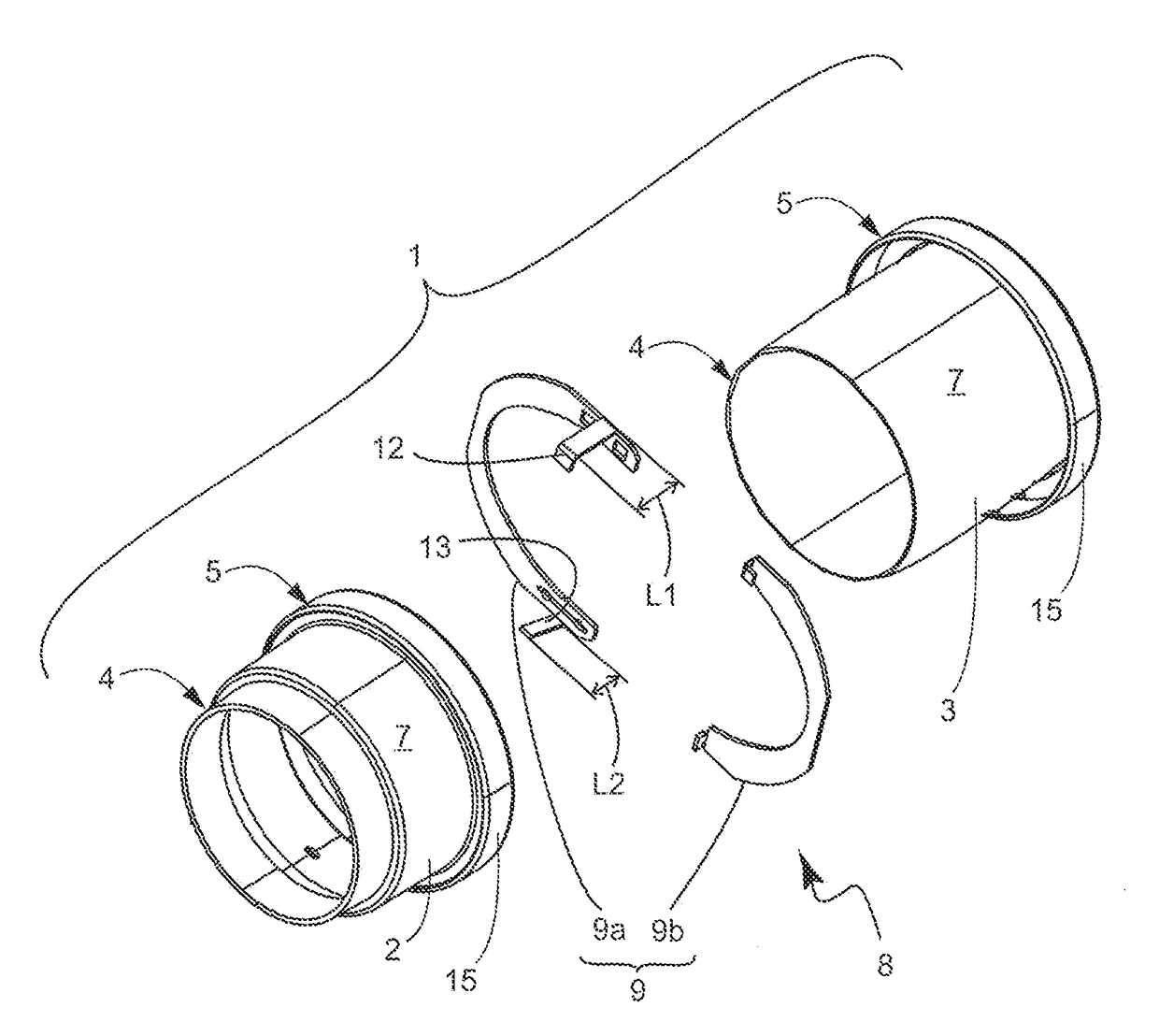

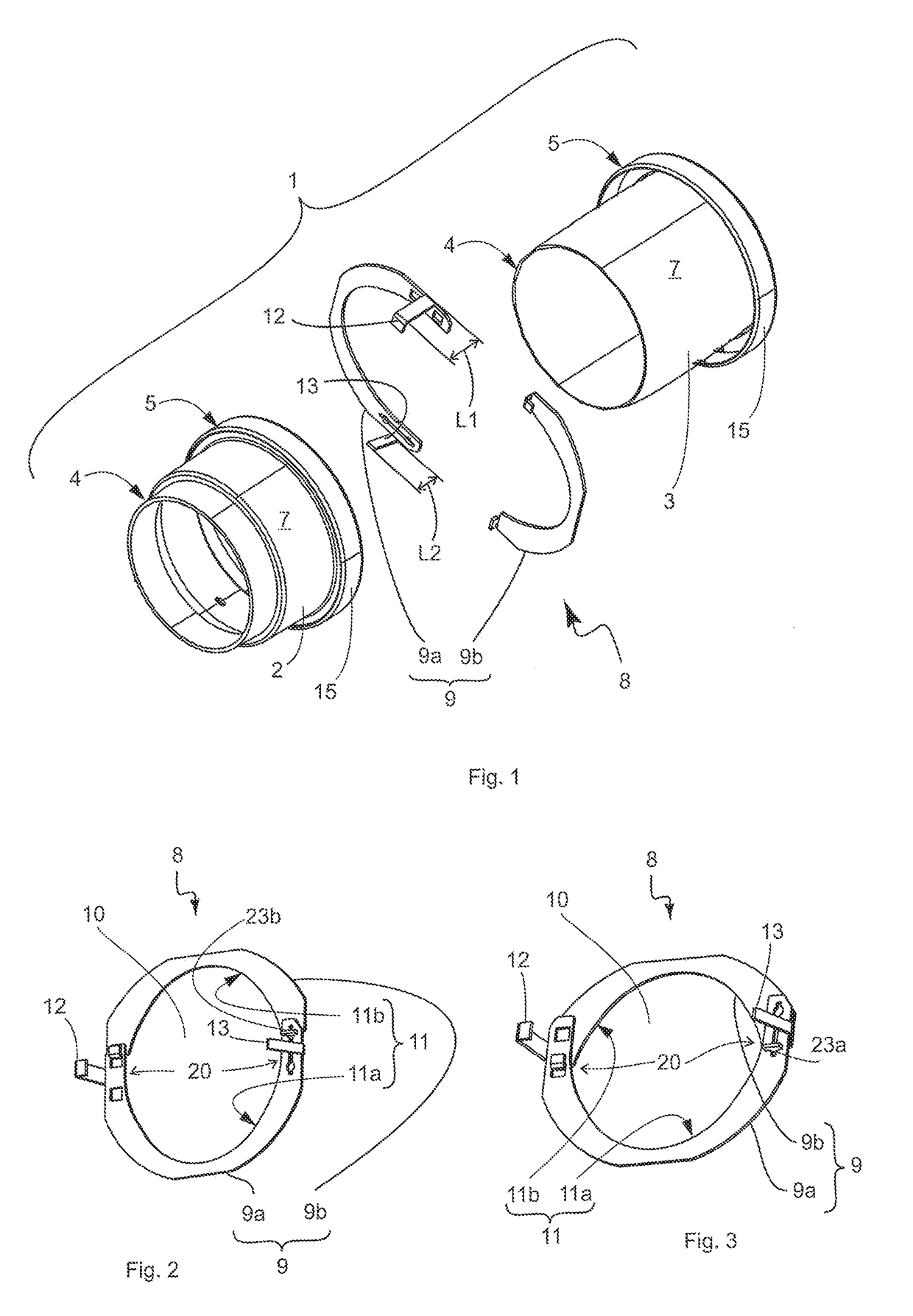

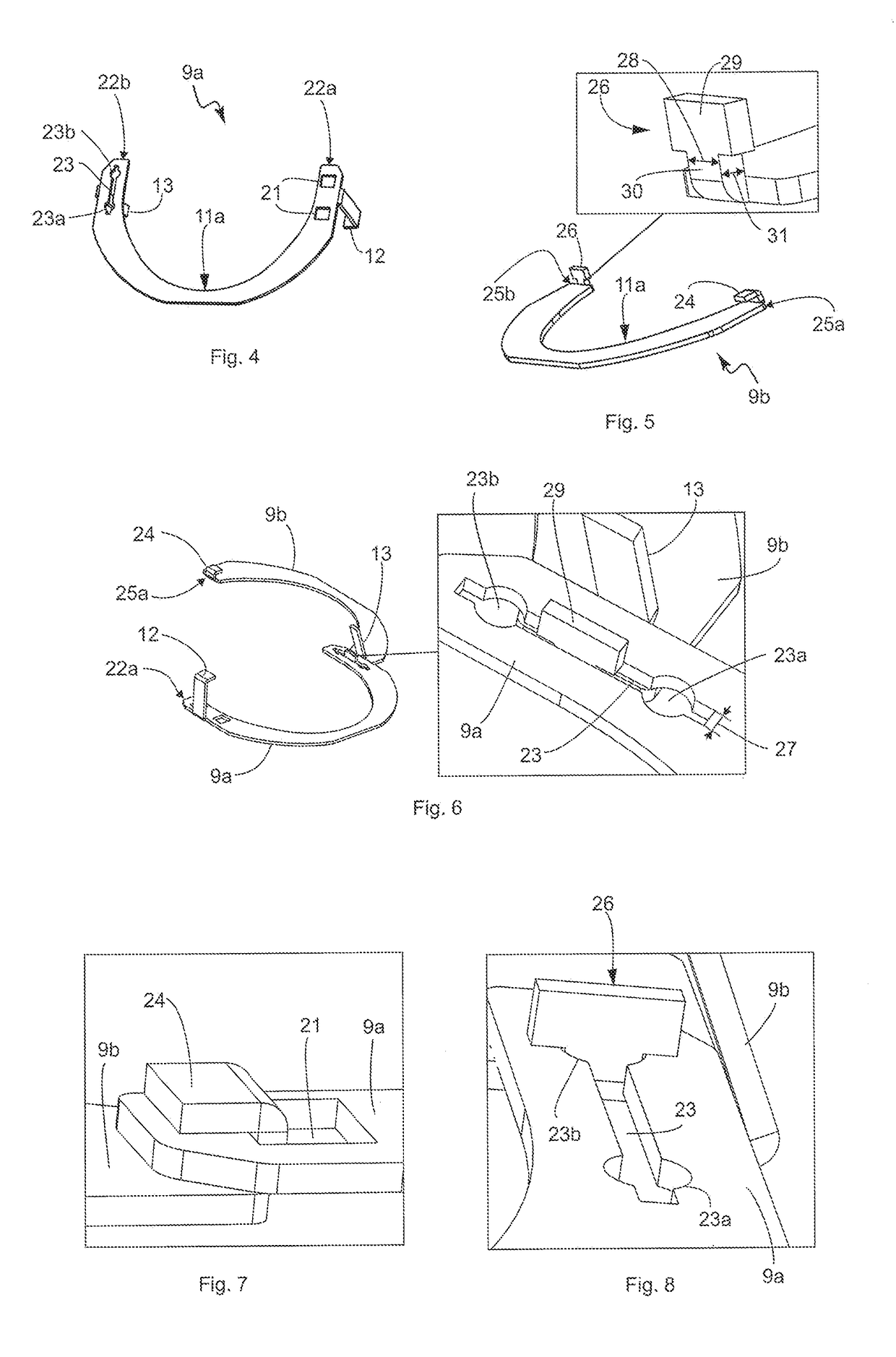

Fluid line connection safeguard

InactiveUS20170211733A1Easy clamping actionEnhanced clampingSleeve/socket jointsCouplingsLine tubingEngineering

A fluid line connection safeguard for axial connection of a socket-shaped end portion of a first fluid line part with an end portion of a second fluid line part formed as a spigot end includes an annular clamping body which has a through opening with an overall internal contour and at least two clamping body elements forming a clamping body, wherein a respective clamping body element has a circular segment-shaped internal contour and the circular segment-shaped internal contours of the at least two clamping body elements form the overall internal contour, and wherein the at least two clamping body elements are connected to one another by means of an adjusting connection in such a way that the overall internal contour is adjustable to at least two different diameters.

Owner:CENTTHERM SYSTTECHN

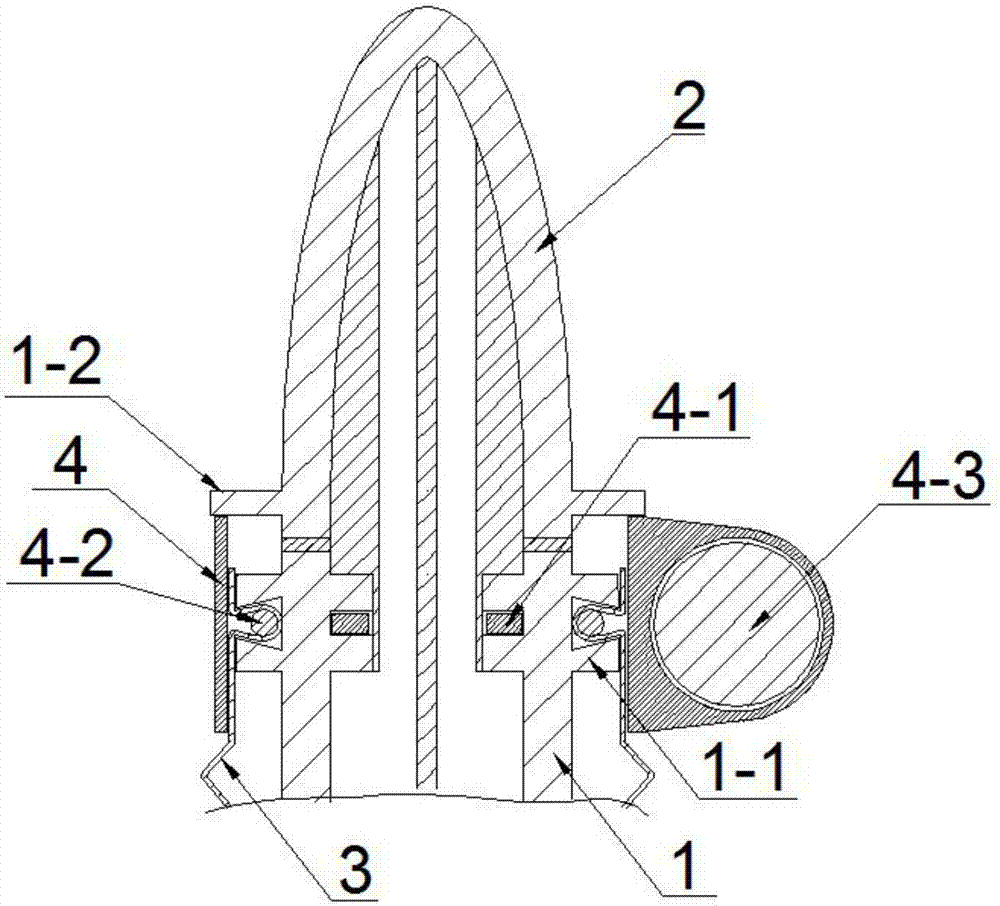

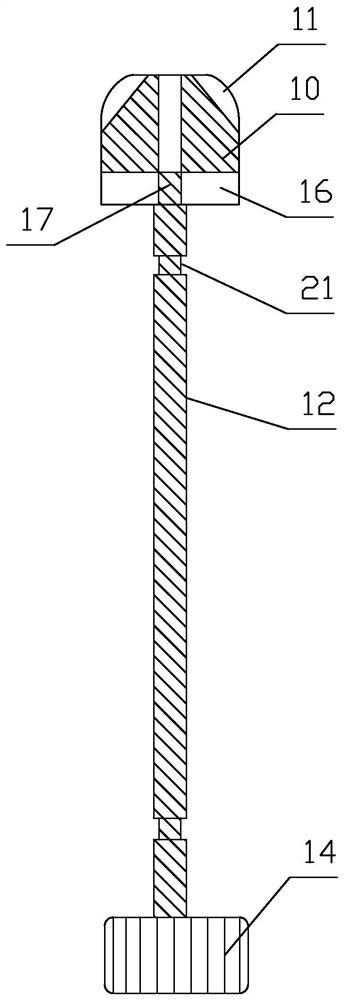

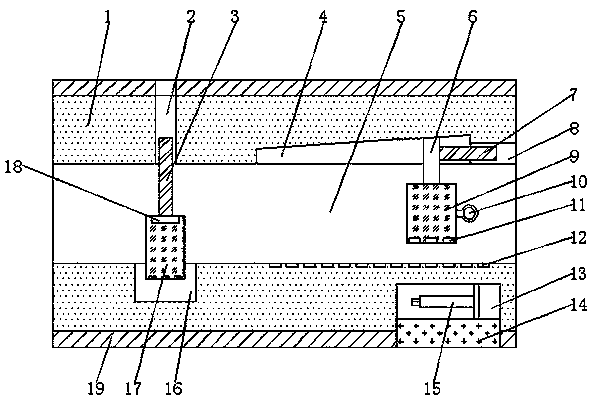

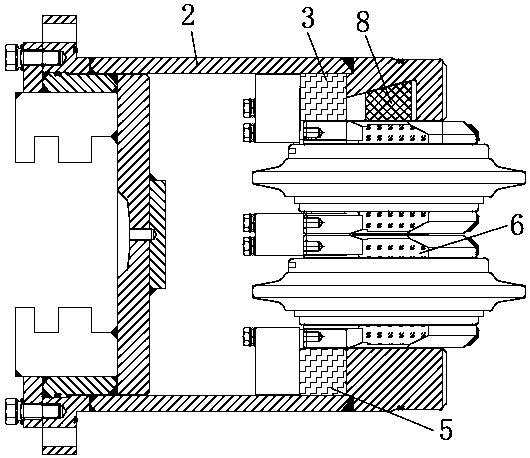

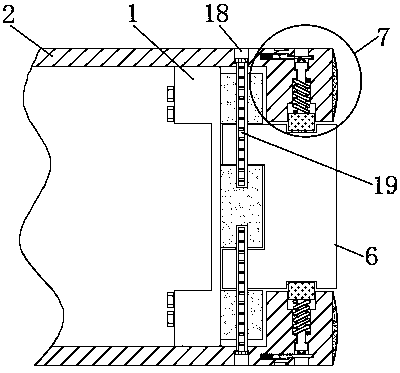

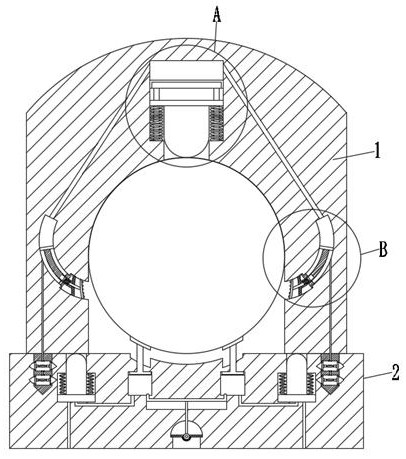

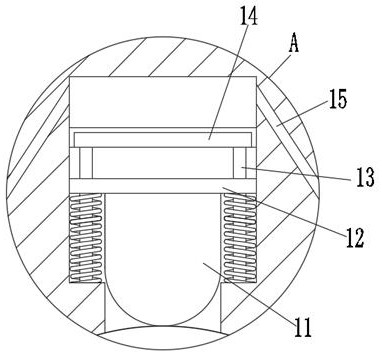

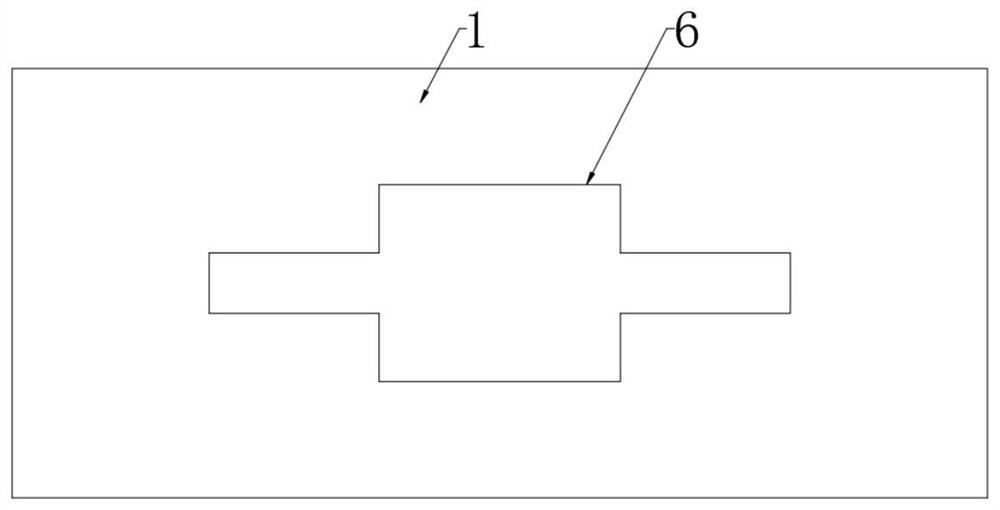

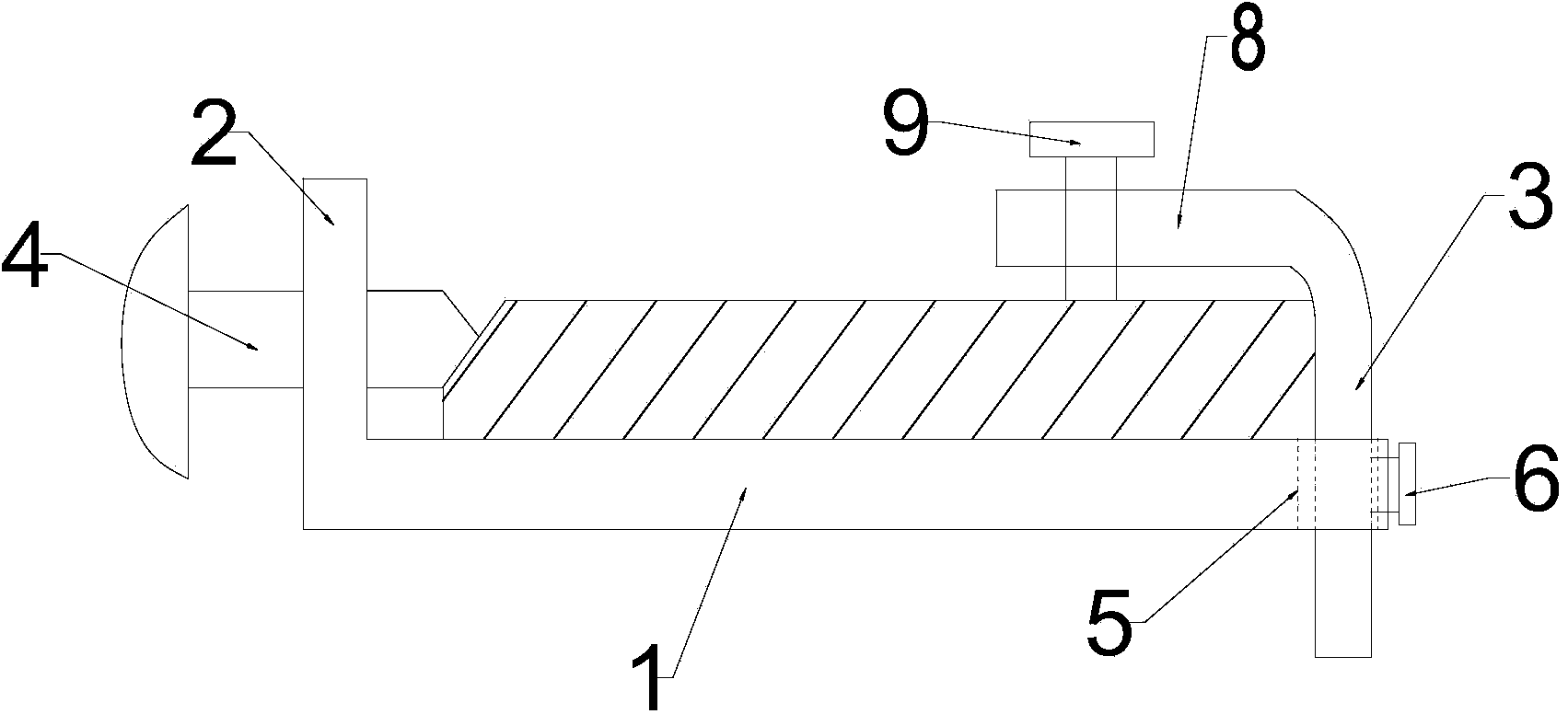

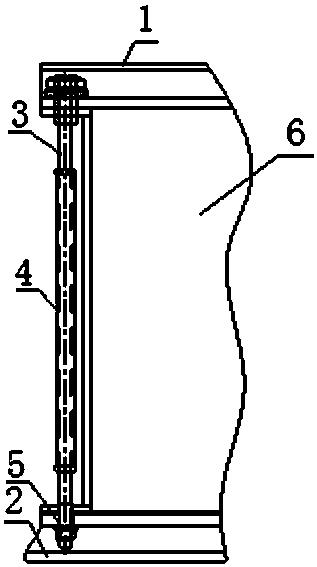

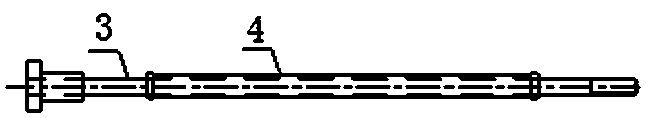

Electric reactor iron core pull rod clamping method and structure

PendingCN108597798AEnhanced clampingTo achieve the purpose of clampingTransformers/inductances noise dampingTransformers/inductances magnetic coresElectrical resistance and conductanceNuclear engineering

The invention relates to an electric reactor iron core pull rod clamping method and structure, and belongs to the technical field of the electric reactor equipment. The technical scheme comprises a bracing plate (1), a foot pad (2), a pull rod (3), a copper pipe (4), an insulating pipe (5) and an electric reactor iron core (6); the bracing plate (1) is arranged at the upper part of the electric reactor iron core (6), the foot pad (2) is located at the lower part of the electric reactor iron core (6), the bracing plate (1), the electric reactor iron core (6) and the foot pad (2) are fixed, clamped and connected through the pull rod (3); the pull rod (3) is arranged in the copper pipe (4), an anti-loose disc spring is arranged between the pull rod (3) and the bracing plate (1), and the insulating pipe (5) is arranged between the pull rod (3) and the foot pad (2). The clamping method disclosed by the invention has the advantages that the iron core is clamped by using the iron core external pull rod, the noise of the iron core is reduced, and the vibration of the electric reactor is reduced; and the problem that the equipment accident is caused since the insulation resistance of the iron core clamp is too low due to the loosening of the structural member is eliminated.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

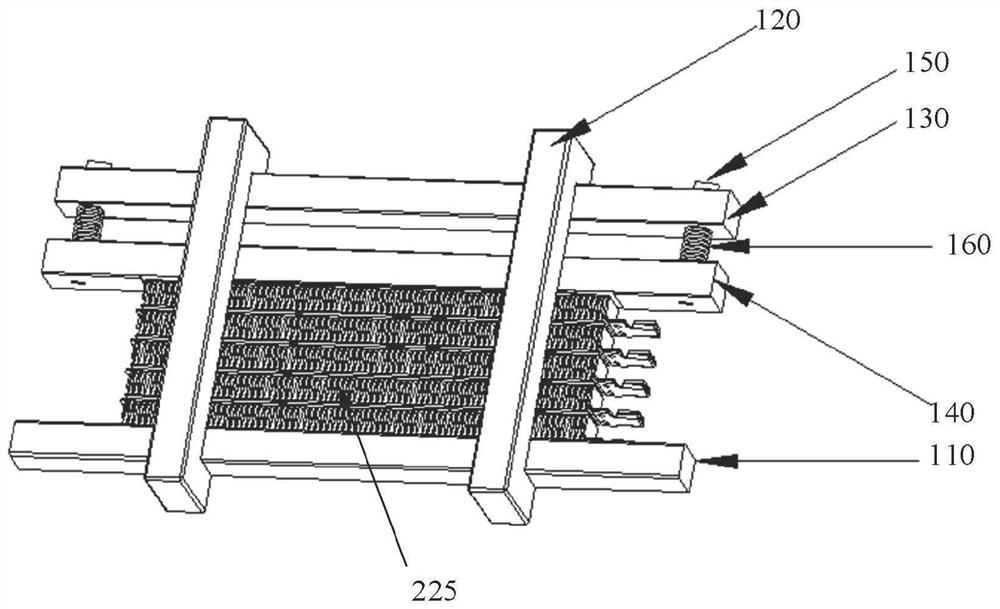

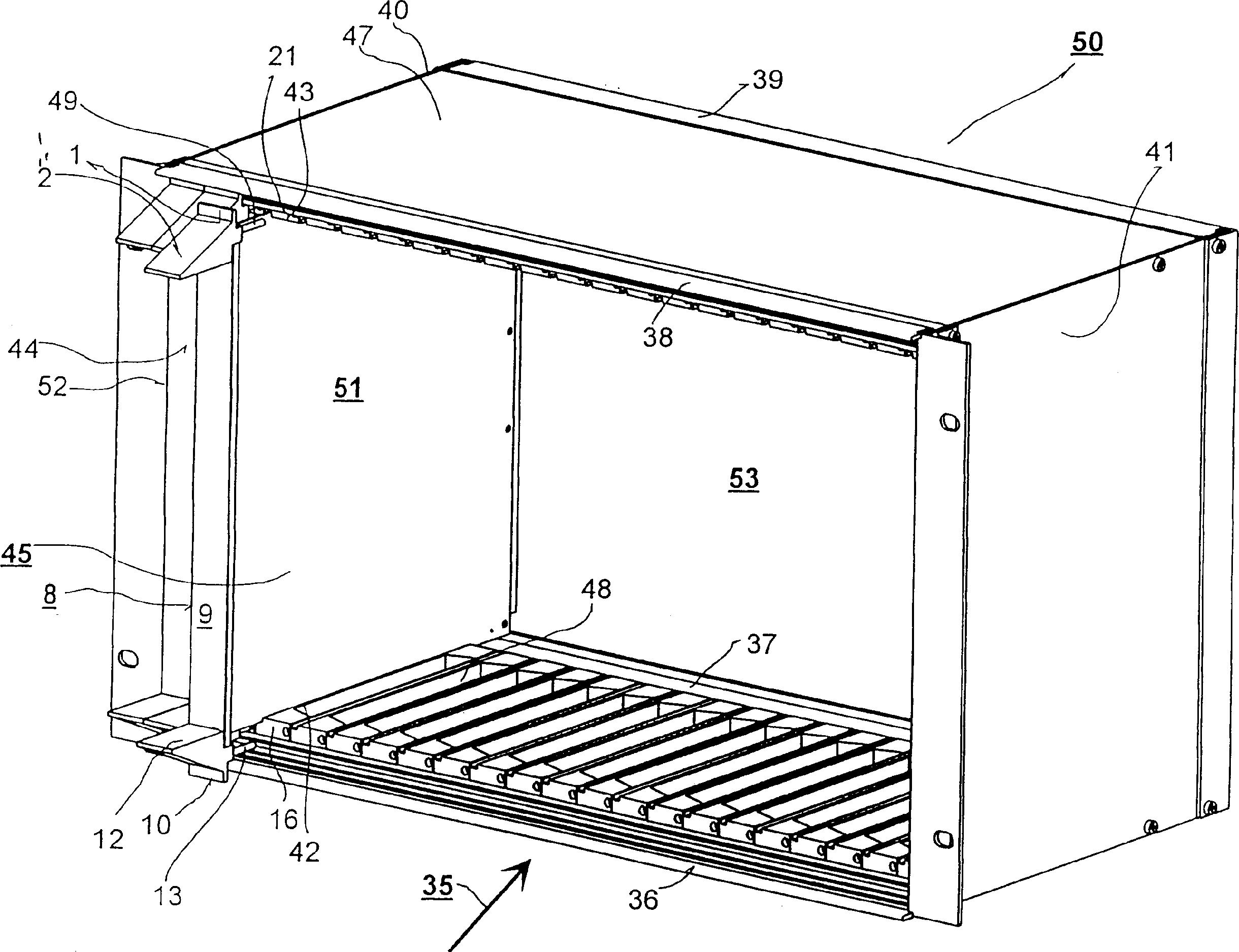

Rack system for inserting electrical printed circuit boards

InactiveCN1130112CImprove current carrying capacityEnhanced clampingClamping/extracting meansRack/frame constructionElectrical resistance and conductanceCarrying capacity

In a rack system for inserting electrical printed circuit board assemblies, front elements (52,8) for slots are provided with projecting plug-in and withdrawable centering and contact elements (13,49). These elements have associated receiving elements (16,21) composed of electrically conductive material and are mounted with low impedance to a transverse connecting rail. During an insertion process, the receiving elements and the centering and contact elements come into contact in a centered manner. When inserted, the receiving elements and the centering and contact elements provide a vibration-proof mechanical connection with a high adhesion force and a low-impedance contact with a high current carrying capacity.

Owner:RITTAL RES ELECTRONICS SYST GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com