Electric reactor iron core pull rod clamping method and structure

A reactor and tie rod technology, applied in transformer/inductor cores, inductors, fixed inductors, etc., can solve the problems of low insulation resistance of iron core clips, equipment accidents, loose structural parts, etc., to eliminate insulation resistance. too low, reducing vibration, reducing the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

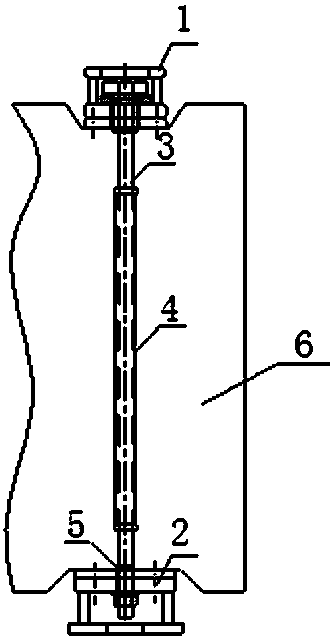

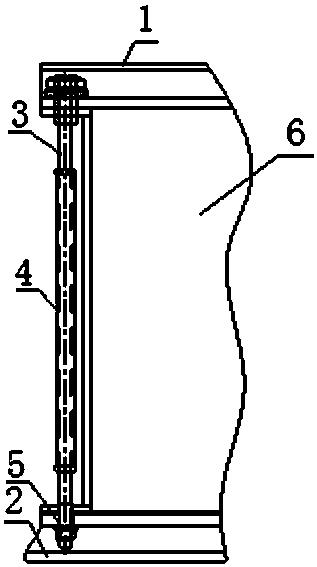

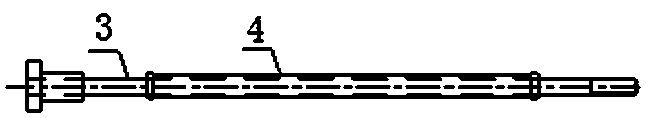

[0016] Refer to attached figure 1 , 2 , 3, a reactor iron core pull rod clamping structure, including support plate 1, pad 2, pull rod 3, copper tube 4, insulating tube 5 and reactor core 6, support plate 1 is located at the reactor core 6 In the upper part, the feet 2 are set at the lower part of the reactor core 6, and the support plate 1, the reactor core 6 and the feet 2 are fixedly clamped and connected by the tie rod 3, and the tie rod 3 is set in the copper tube 4, and the tie rod 3 and the support plate An anti-loosening disc spring is arranged between 1, and an insulating tube 5 is arranged between the pull rod 3 and the feet 2.

[0017] A method for clamping a tie rod of a reactor iron core, adopting the above-mentioned tensioning structure, the steps are as follows: the upper part of the reactor iron core has a support plate 1, and the lower part h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com