Heat-sealing positioning control method of battery

A technology of positioning control and storage battery, which is applied in secondary battery manufacturing, conveyor control device, final product manufacturing, etc., can solve the problems of inaccurate positioning, easy deflection, and difficulty in shifting the storage battery 14 to the center position, etc. Easy to pinpoint, improve performance and quality of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

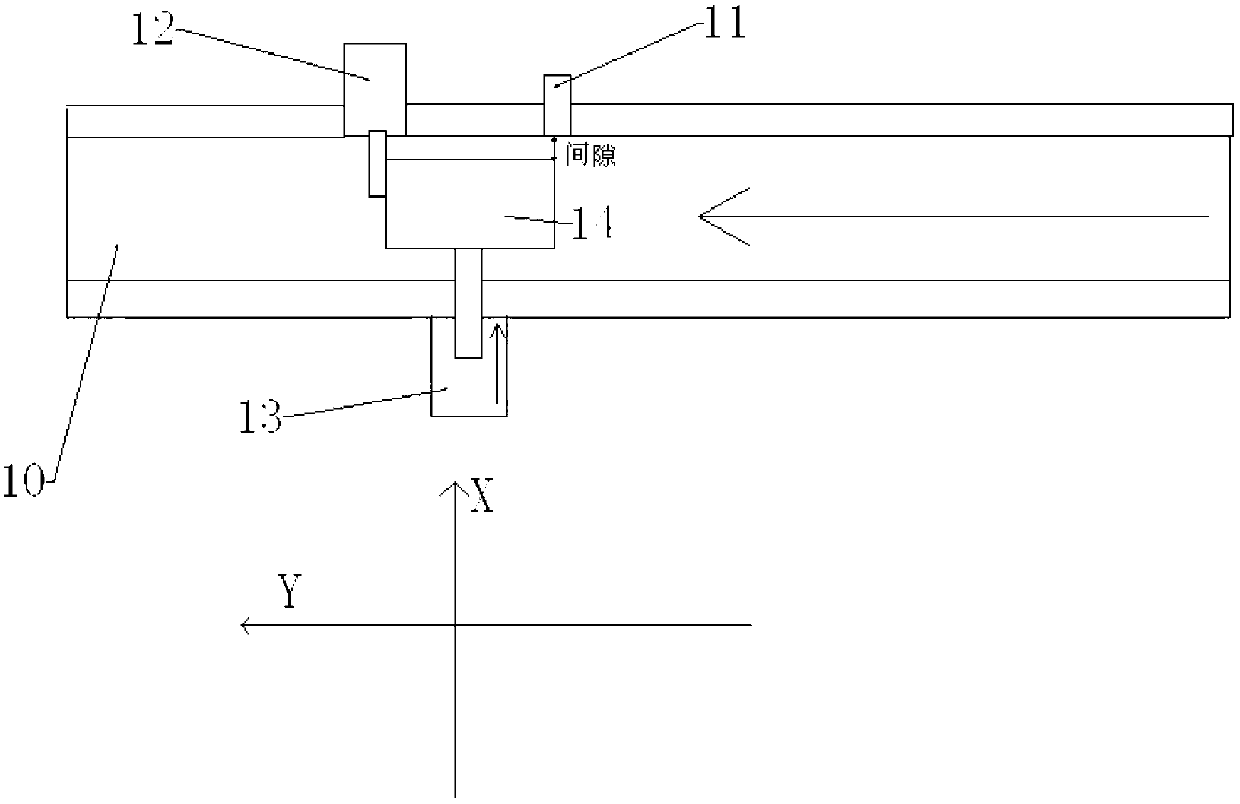

[0026] Hereinafter, the present invention will be further described in detail through specific embodiments in conjunction with the drawings.

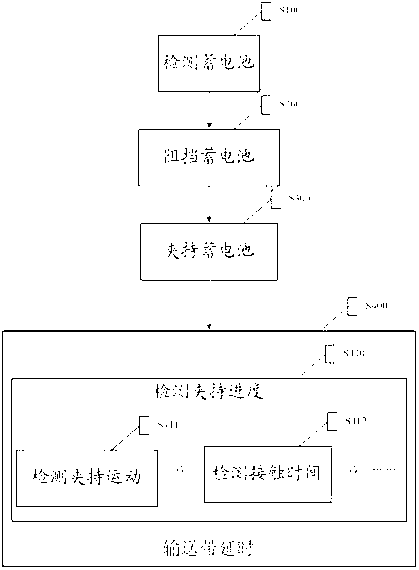

[0027] Please refer to figure 2 , This embodiment provides a method for controlling positioning of battery heat sealing, which includes:

[0028] The motor is connected to the conveyor belt, the sensor, the stop cylinder and the clamping cylinder are respectively connected to the controller, and the battery is transported by the conveyor belt; and the following steps are performed:

[0029] S100: Detect the battery, that is, the sensor detects the battery on the conveyor belt to obtain the induction signal and transmit it to the controller.

[0030] After the controller receives the sensing signal, it performs the following steps:

[0031] S200: Block the battery, that is, control the blocking level cylinder to block the battery.

[0032] S300: Clamp the battery, that is, control the clamping cylinder to start clamping the battery.

[0033] S400: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com