Patents

Literature

46results about How to "Less prone to skew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

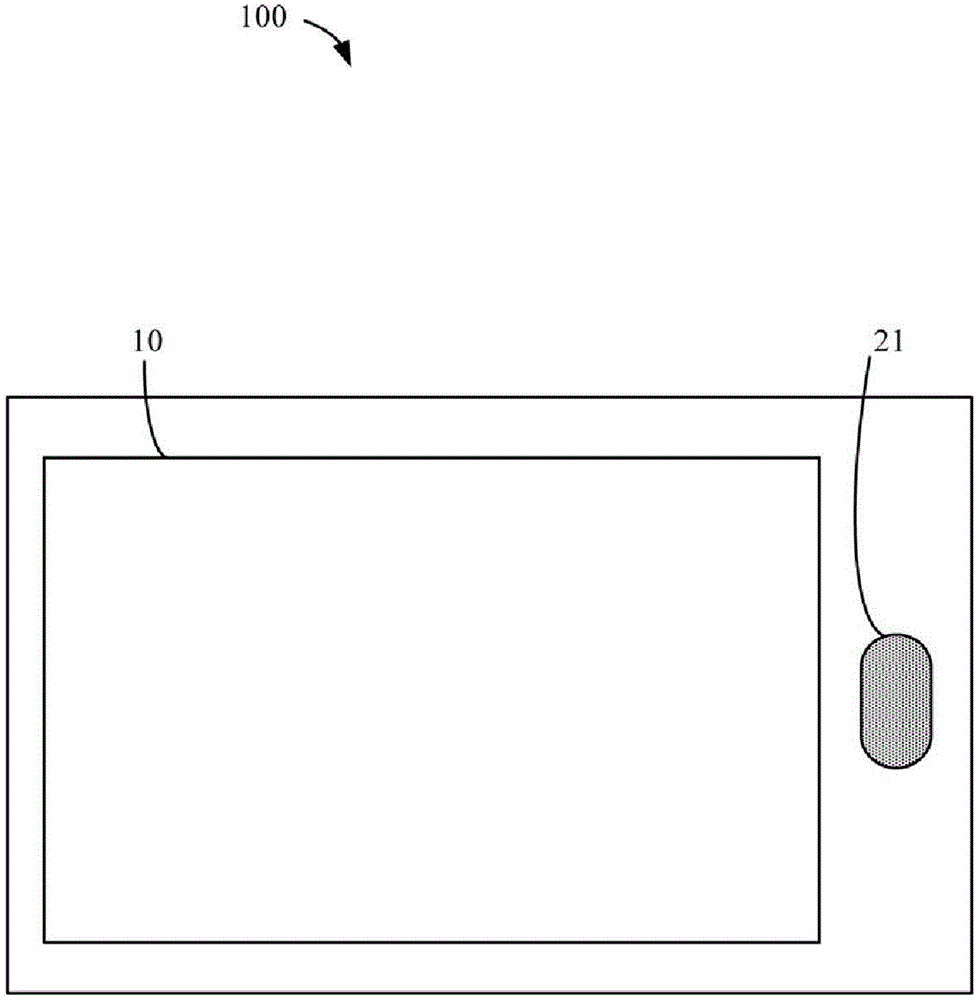

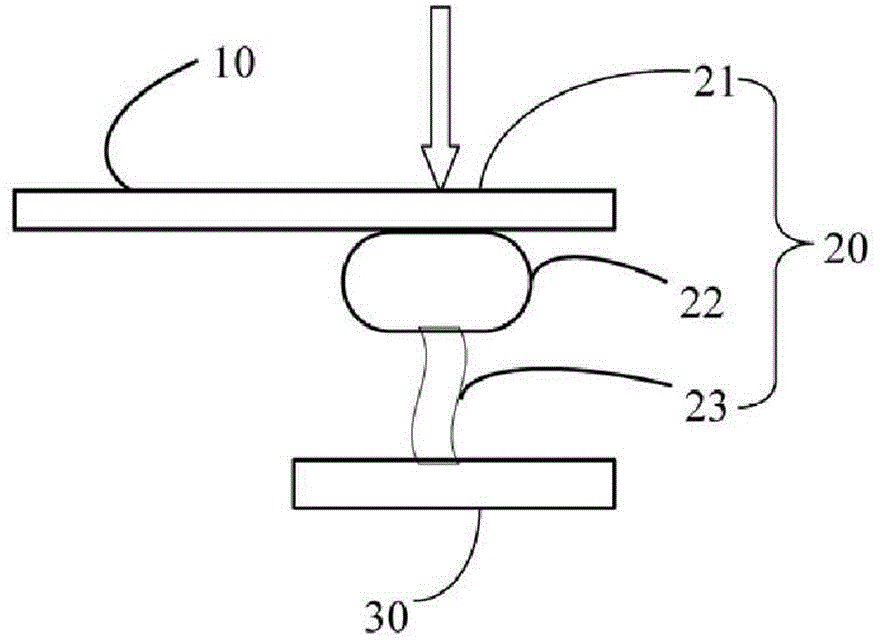

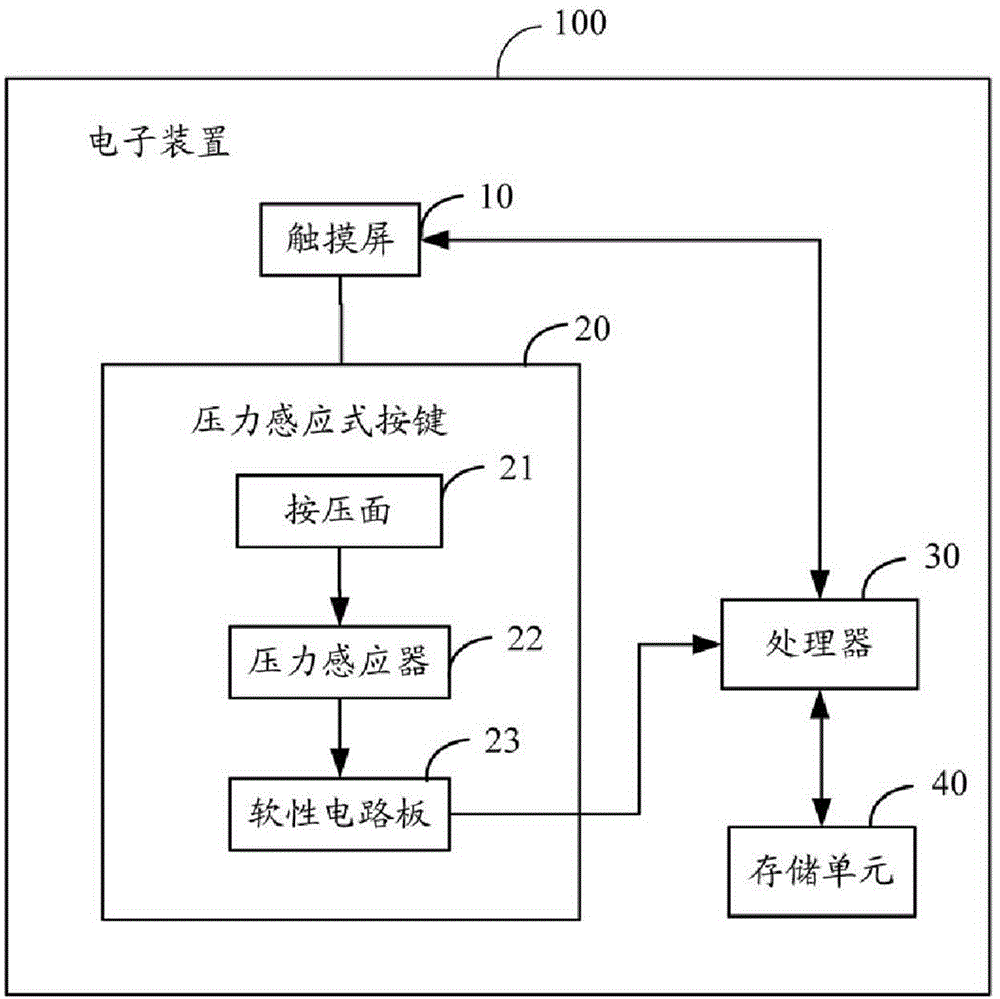

Pressure-sensitive button and electronic device with same

InactiveCN104579285AImprove reliabilityNot easy to sagElectronic switchingInput/output processes for data processingFlexible circuitsStorage cell

An electronic device comprises a storage unit, a touch screen, a processor and a pressure-sensitive button, wherein the storage unit is stored with a preset pressure value; the pressure-sensitive button comprises a pressing surface arranged on the touch screen, a pressure sensor and a flexible circuit board; the pressure sensor is mounted on the back surface of the pressing surface and is used for sensing a pressure transmitted by the pressing surface and converting the pressure into pressure information; the two ends of the flexible circuit board are connected to the pressure sensor and the processor respectively, and the flexible circuit board is used for transmitting the pressure information sensed by the pressure sensor to the processor; the processor is used for judging whether the pressure reaches the preset pressure value according to the pressure information, and if so, controlling the touch screen to display a main interface. The invention further provides the pressure-sensitive button. The pressure-sensitive button provided by the invention is unlikely to sink, deflect and / or fail, so that the reliability of the electronic device is improved.

Owner:FU TAI HUA IND SHENZHEN +1

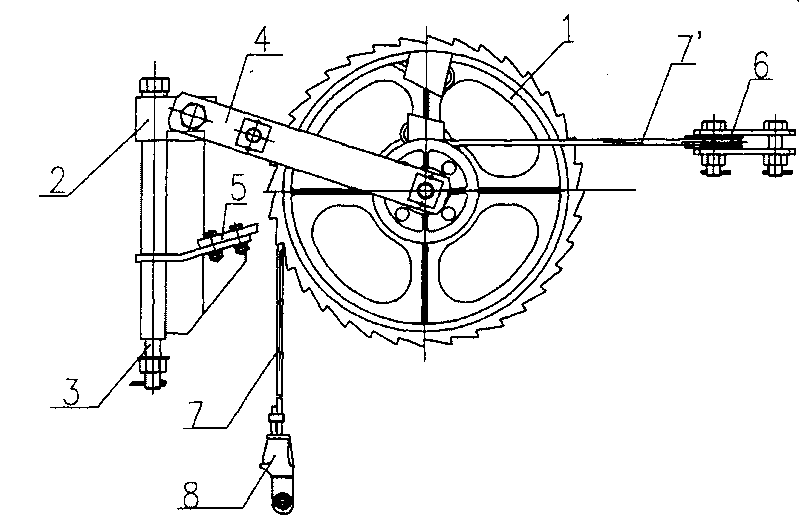

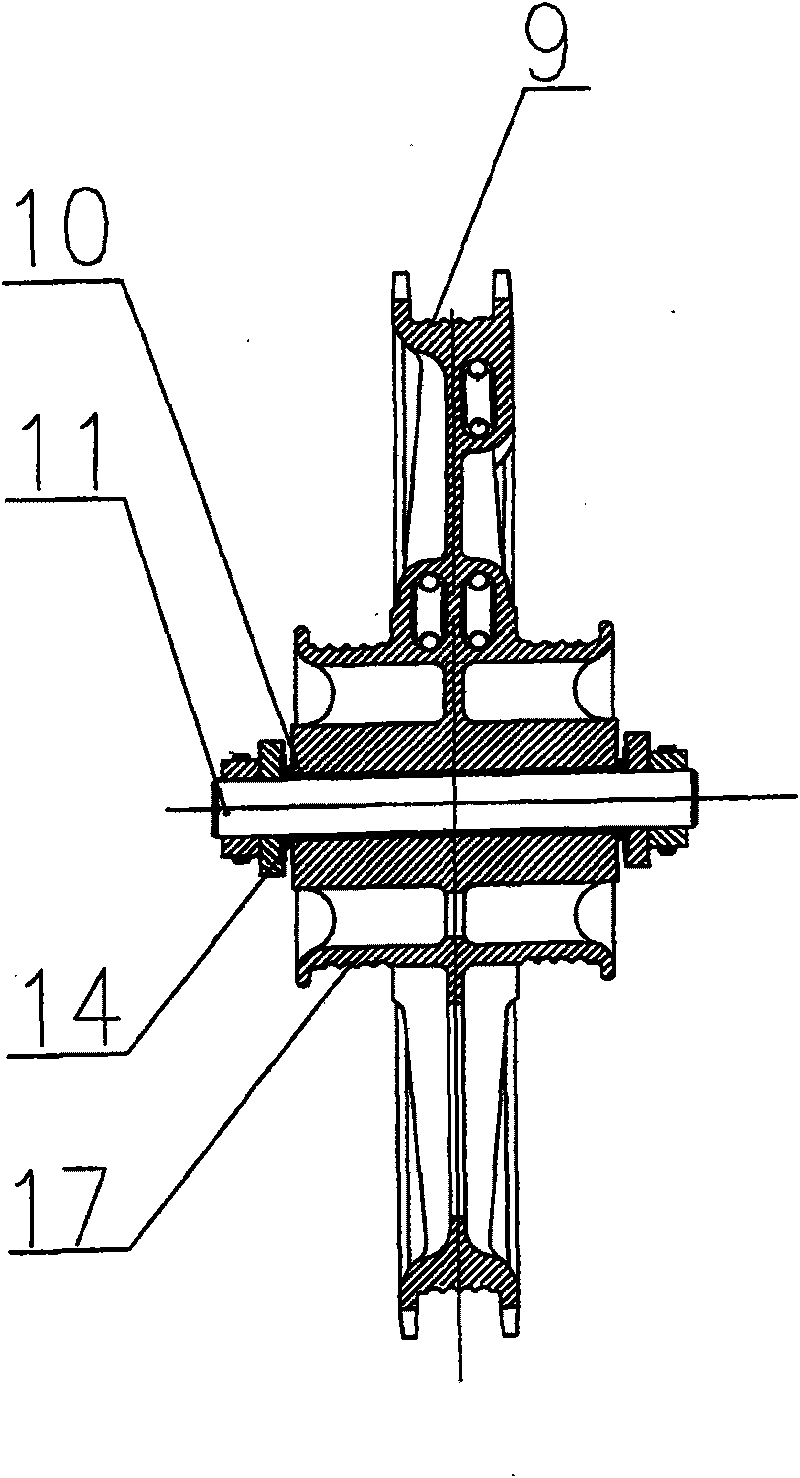

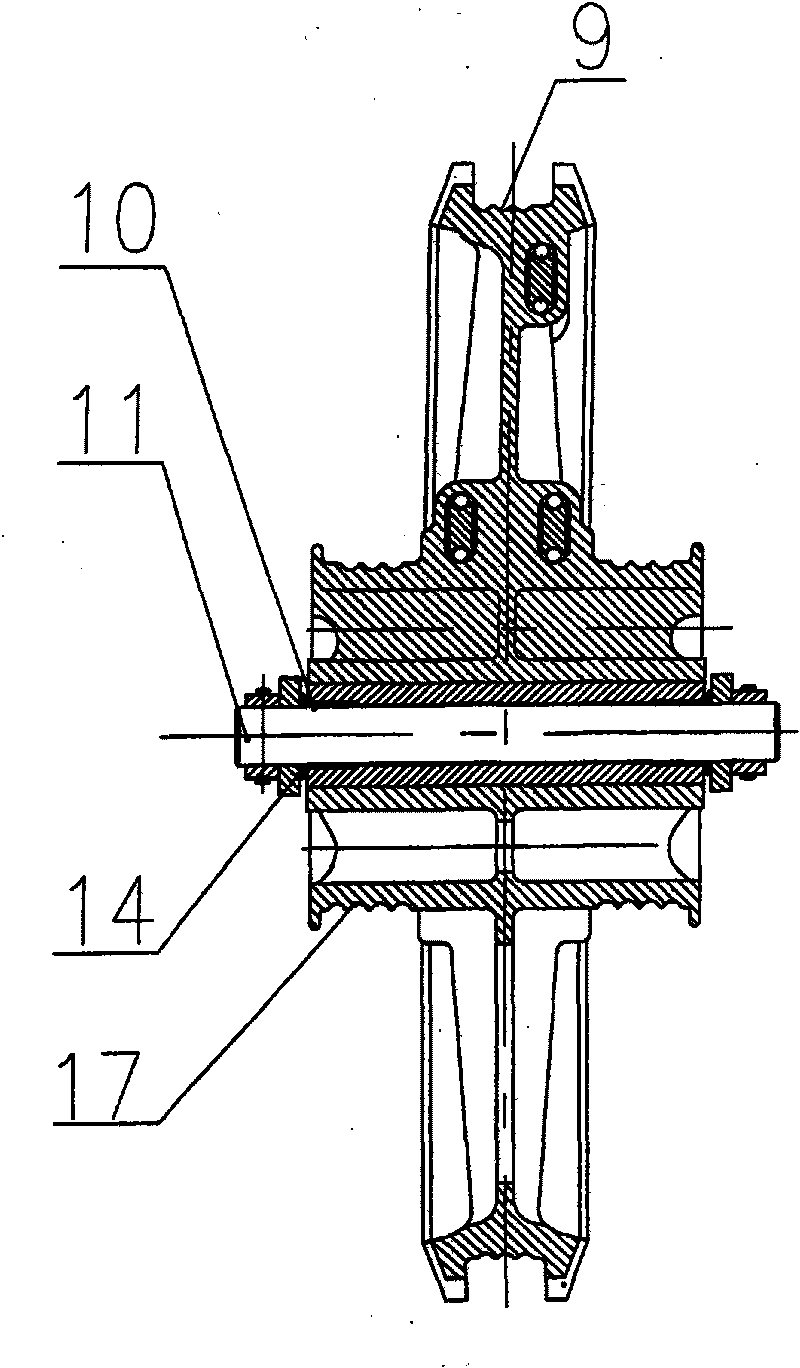

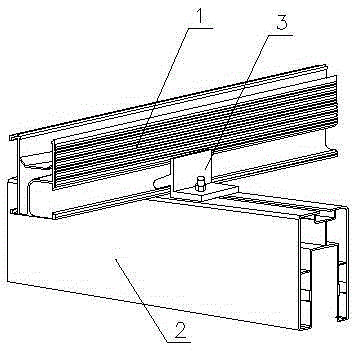

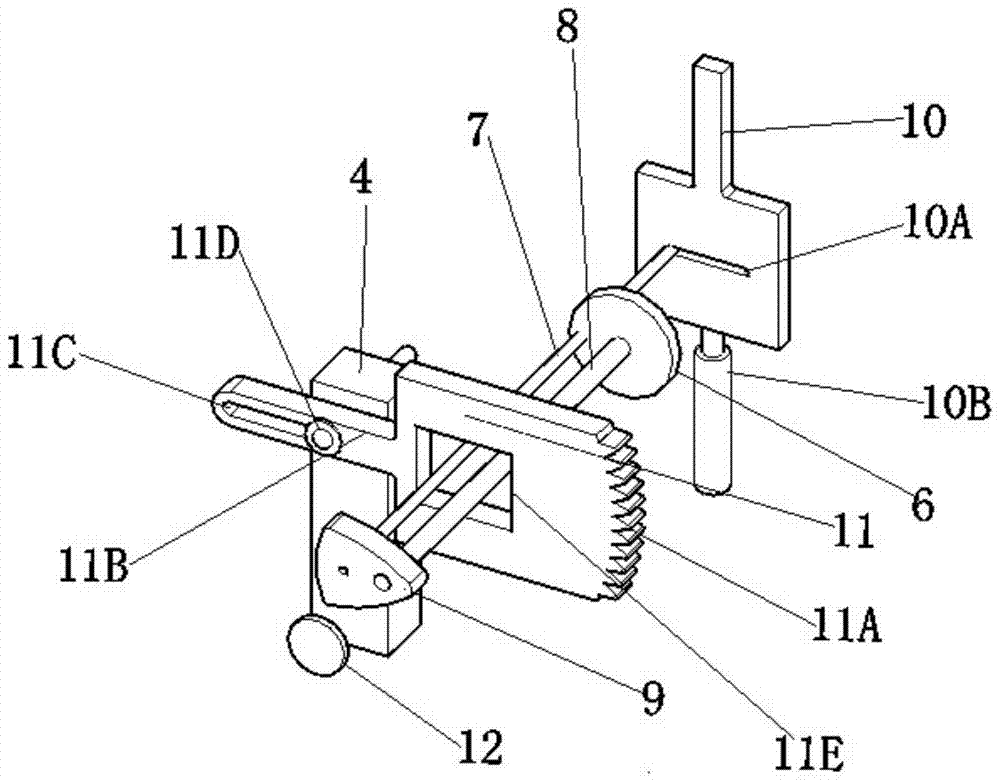

Novel ratchet compensating device

ActiveCN101722867AAvoid stuck and inflexible rotationImprove transmission efficiencyTrolley linesEngineeringRailway electrification system

The invention provides a novel ratchet compensating device. The novel ratchet compensating device comprises a ratchet body (1), a ratchet brake bracket (2), a long bolt pin (3), a ratchet frame connecting plate (4), a brake pallet (5), a balancing wheel (6), a wire cable I (7), a wire cable II (7') and a wire clamp (8), wherein the ratchet body (1) is arranged on a ratchet shaft (11) through a pair of self-lubricating sliding bearings (10); the two ends of the ratchet shaft (11) are fixed to the front end of the ratchet frame connecting plate (4), and are provided with end face self-lubricating bearings (14); and the end face self-lubricating bearings (14) are arranged between the ratchet frame connecting plate (4) and the self-lubricating sliding bearings (10). By optimizing the structural design, the manufacturing technique is simplified, the safe use performance is improved, the use working tension reaches 32kN, and a compensation distance reaches 950m. The novel ratchet compensating device not only can meet the requirements of high tension and compensation distance in a contact net of a high-speed electric railway, but also brings convenience to installation and maintenance.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

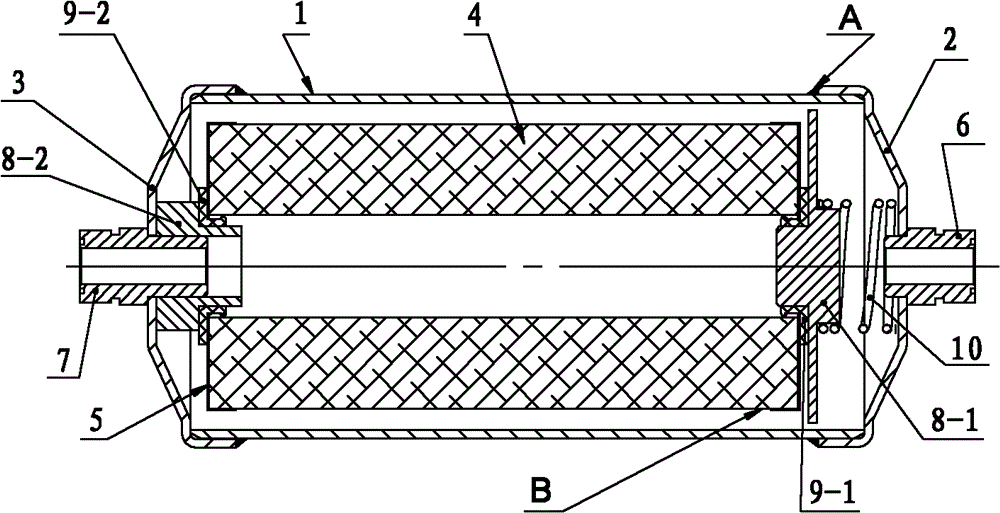

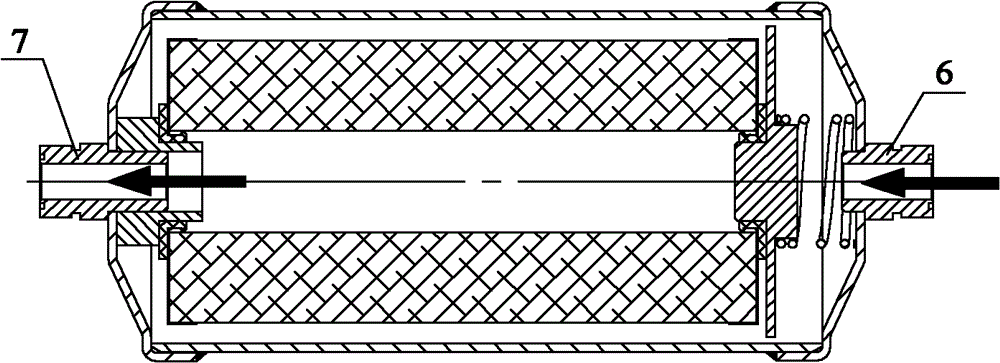

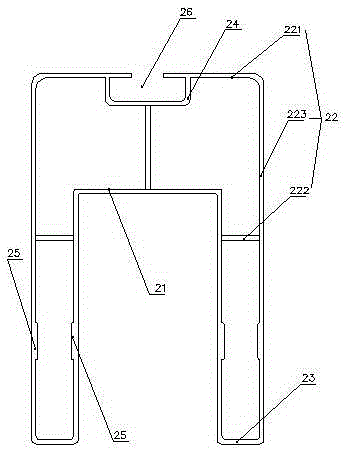

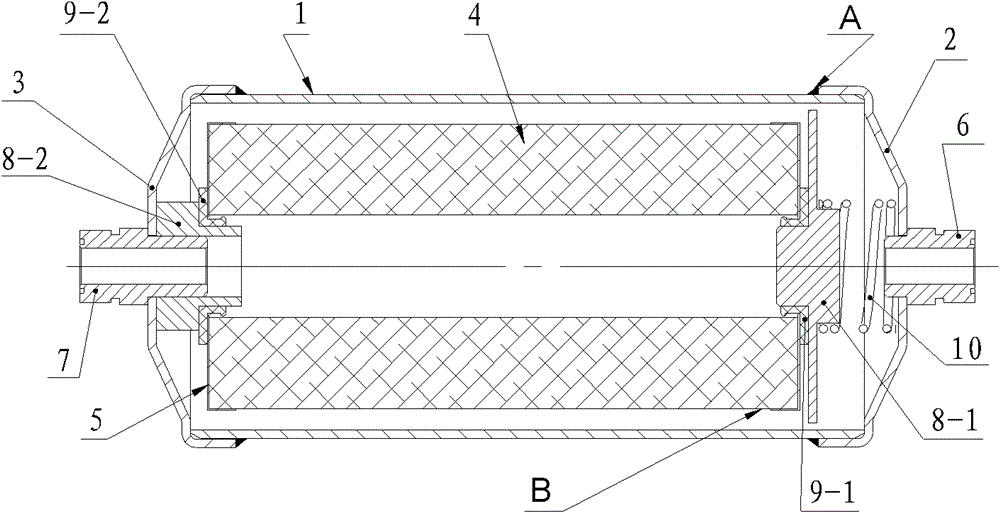

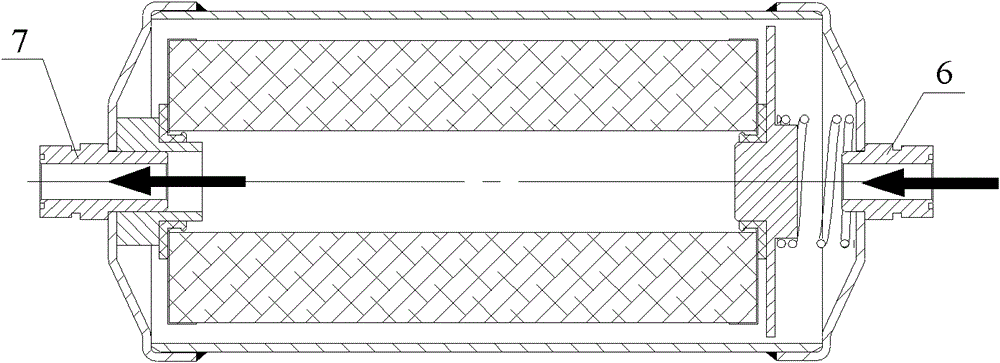

Oil filter and refrigerating system

ActiveCN102743915ASimple structureReduce manufacturing costRefrigeration componentsStationary filtering element filtersOil filterHigh heat

The present invention relates to the technical field of filter, and especially discloses an oil filter with a stably and reliably positioned filter component. The oil filter comprises a shell, a front end cover, a rear end cover and a filter component. The front end cover is provided with an inlet joint; the rear end cover is provided with an outlet joint; and end face of an outlet end of the filter component abuts against an inner side surface of the rear end cover; and the outlet joint and the outlet of the filter component form a socket cooperation. The oil filter can realize stability and reliability of positioning of the filter component; deflection is not likely to happen; and during a welding process of the front end cover and the shell, failure of the filter component caused by local high temperature and heating will not happen. A second supporting seat between the outlet joint and the filter component, and a welding process on the second supporting seat and the outlet joint are canceled, so as to realize simple process, simple structure of the oil filter and low manufacturing cost. The invention also discloses a refrigerating system with the oil filter.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

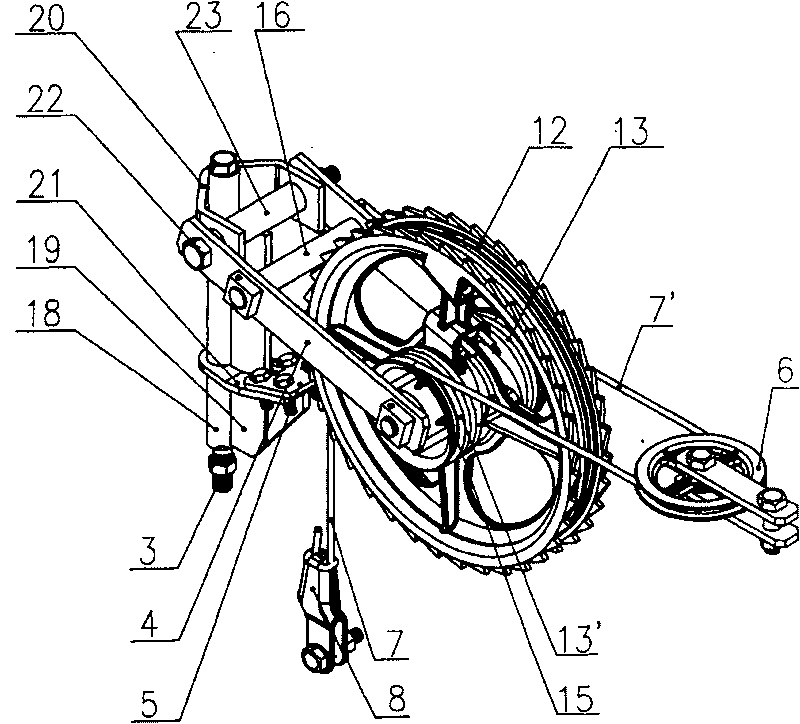

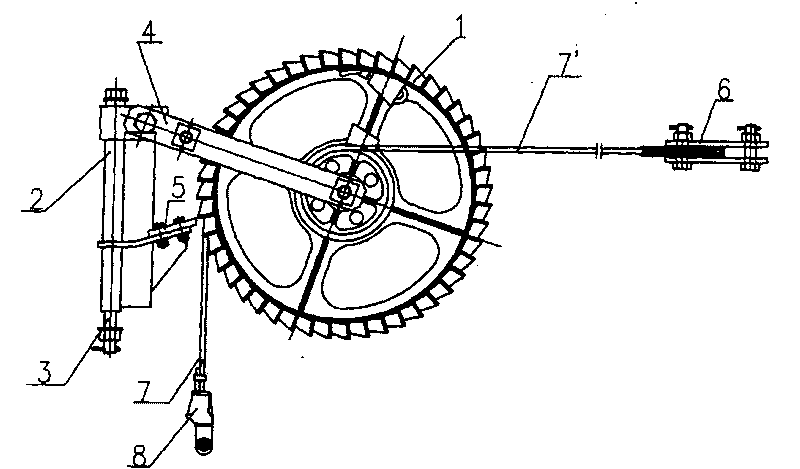

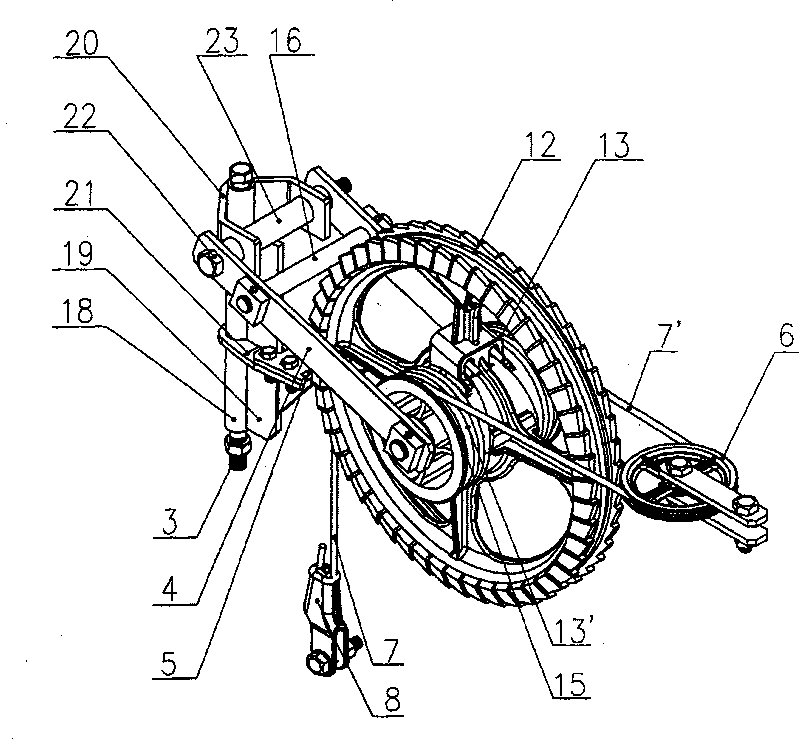

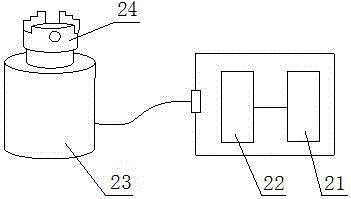

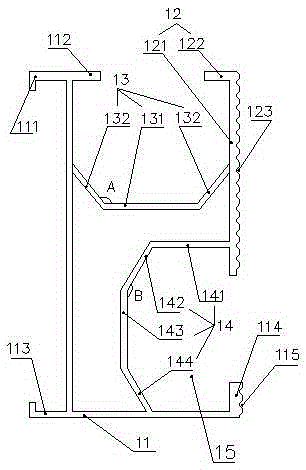

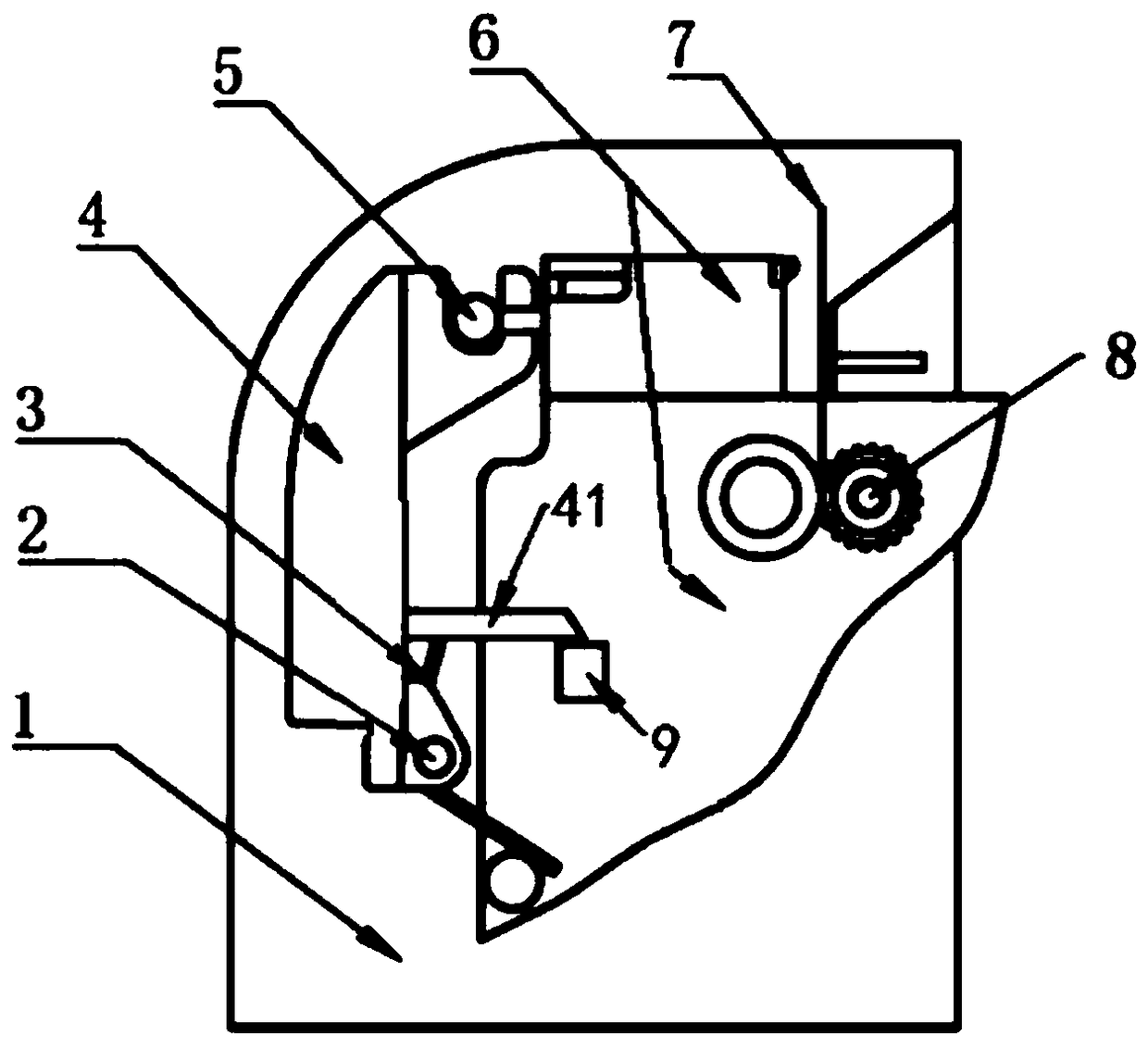

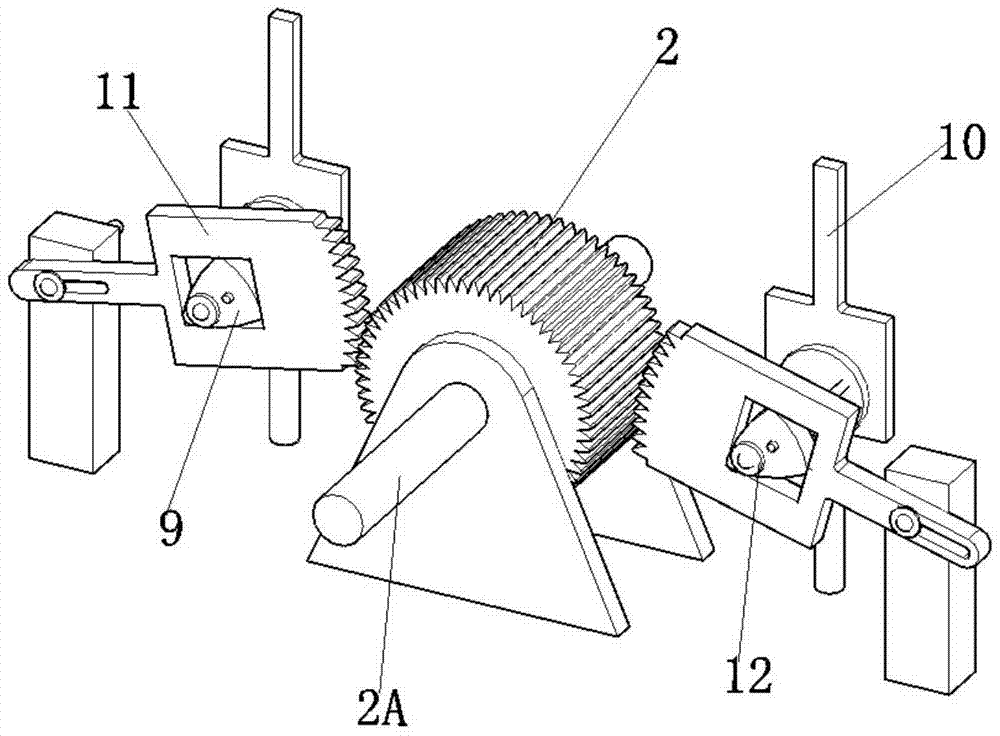

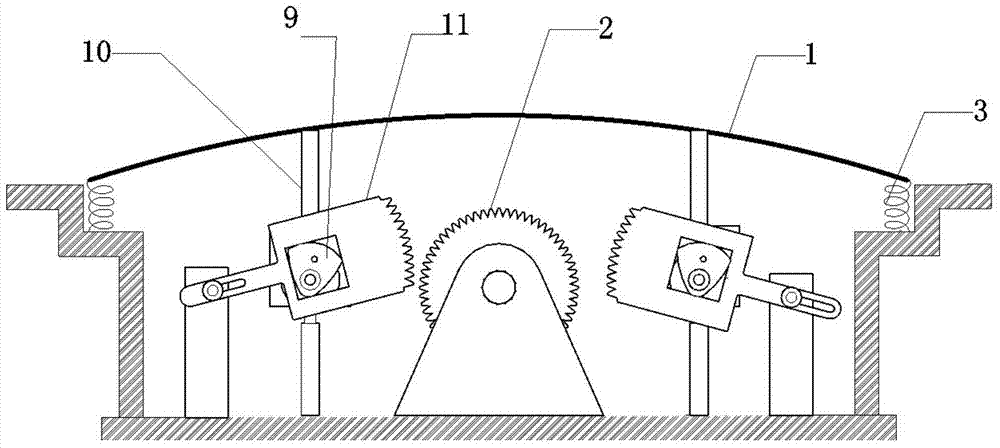

Bevel ratchet wheel compensating device

ActiveCN101716893AStrong impactComprehensive braking performance reliable insuranceTrolley linesManufacturing technologyEngineering

The invention provides a bevel ratchet wheel compensating device, comprising a ratchet wheel body (1), a ratchet wheel brake frame (2), a long bolt pin (3), a ratchet wheel framework connecting plate (4), a brake pallet (5), a balance wheel (6), a steel wire rope I (7), a steel wire rope II (7') and a cable clamp (8), wherein two rows of symmetrical bevel gears are arranged on the excircle of a bull wheel (12) of the ratchet wheel body (1), the bevel gear is composed of straight teeth (24) and side teeth (25), the straight teeth (24) are arranged at two sides of the circumference surface of the bull wheel (12), and side teeth (25) are arranged at the side wall of the bull wheel (12); and the front end of the brake pallet (5) is provided with a U-shaped brake port (26) of which the width is consistent with the spacing of the bottom parts of the two side teeth (25). In the invention, the ratchet adopts a bevel structure formed by the straight teeth and the side teeth; by optimizing the structure design, the manufacture technology is simplified, the safe use performance is improved so as to lead the working tension to reach 38.85kN and compensation distance to reach 800m, thus not only satisfying the requirements on high tension and large compensation distance for a high-speed electrified railway contact line, but also having convenient installation and maintenance.

Owner:CHINA RAILWAY HIGH SPEED ELECTRIFICATION EQUIP CORP LTD

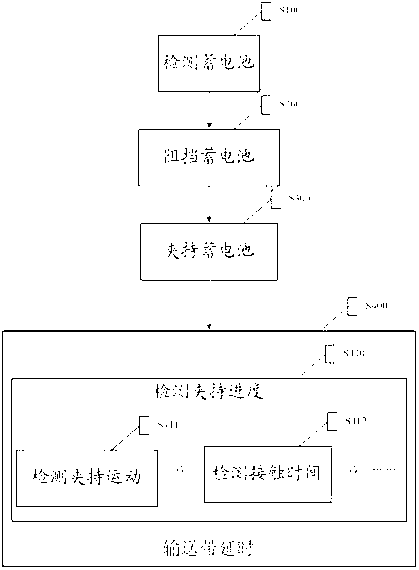

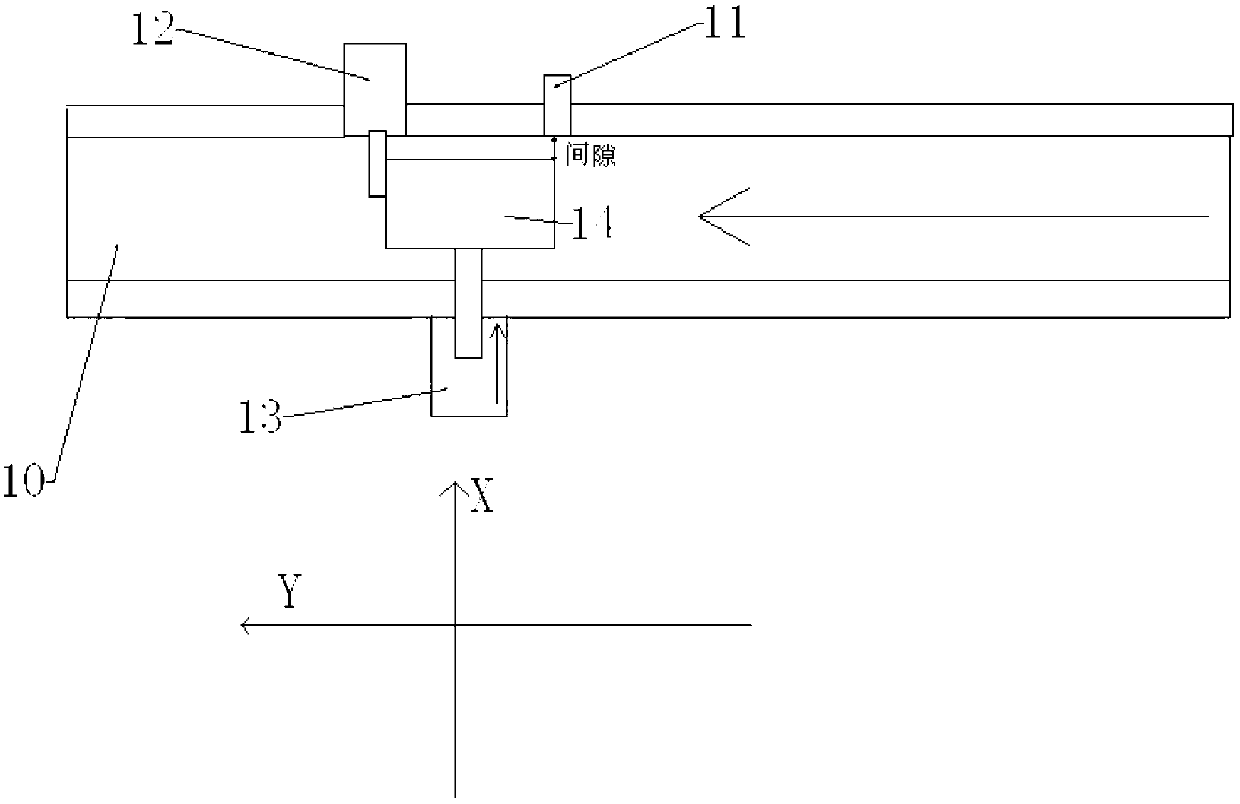

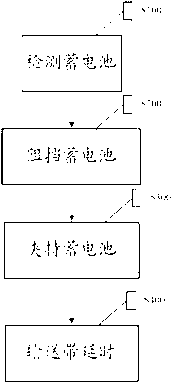

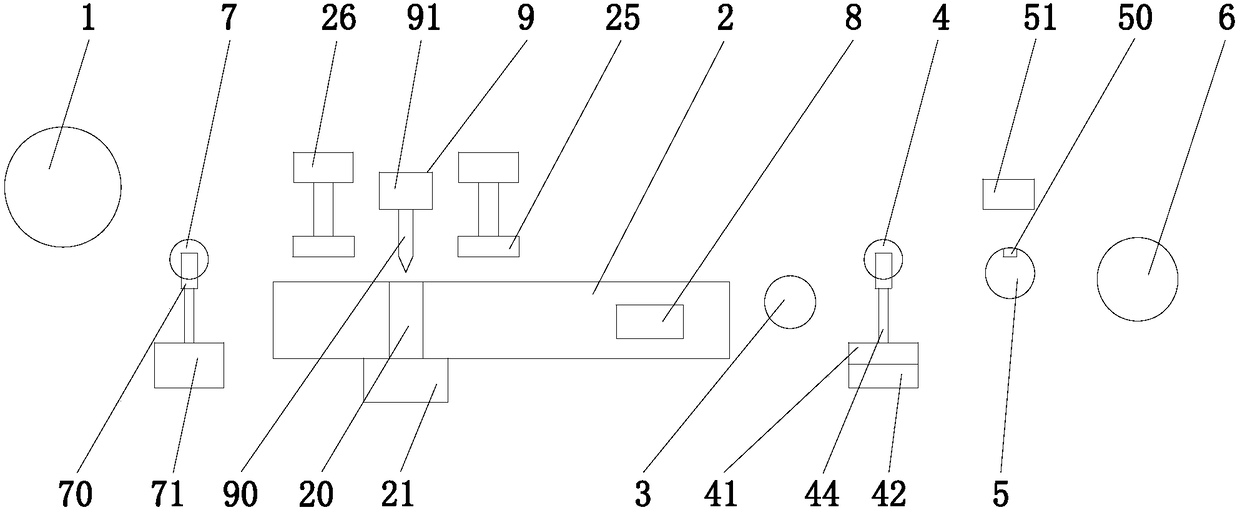

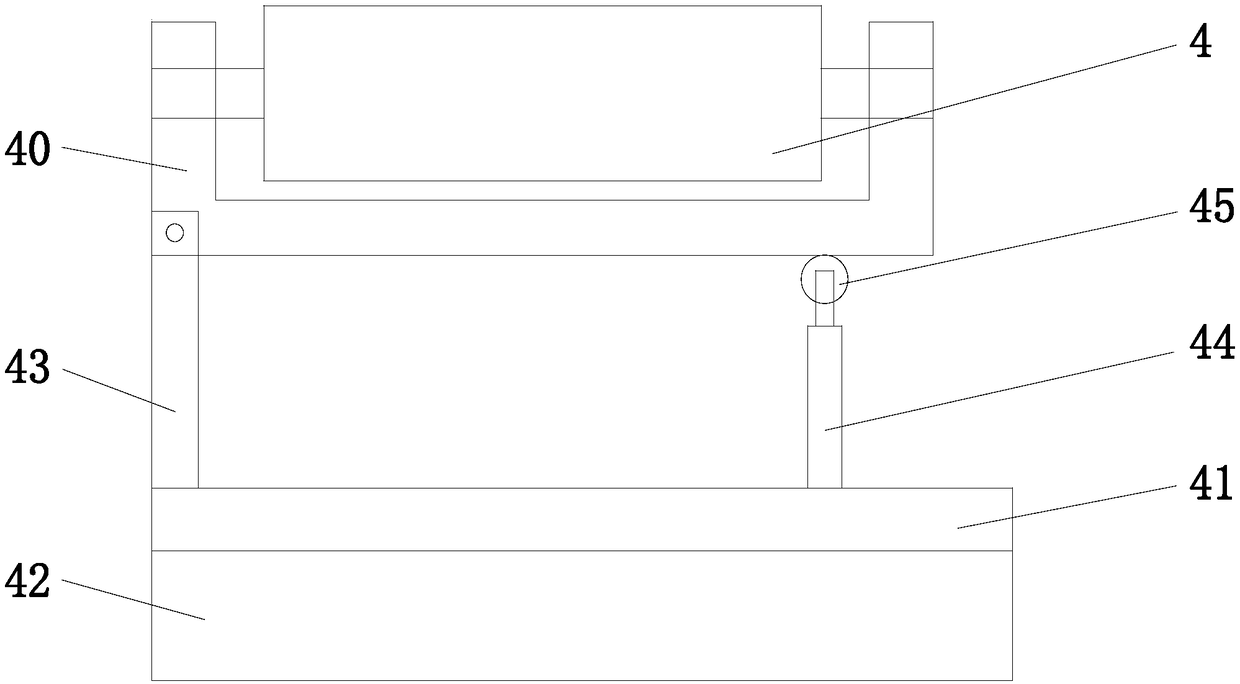

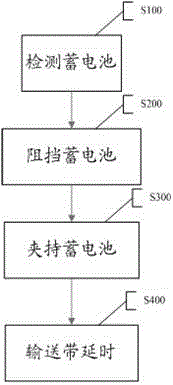

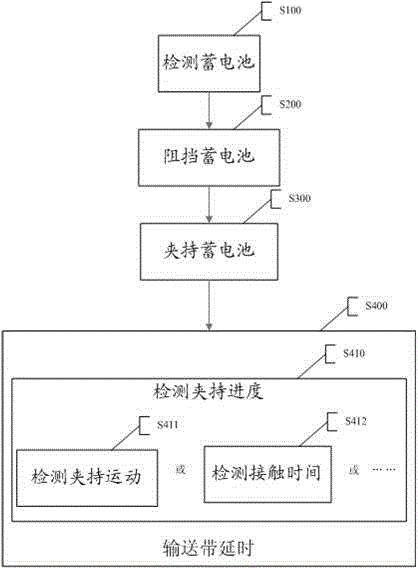

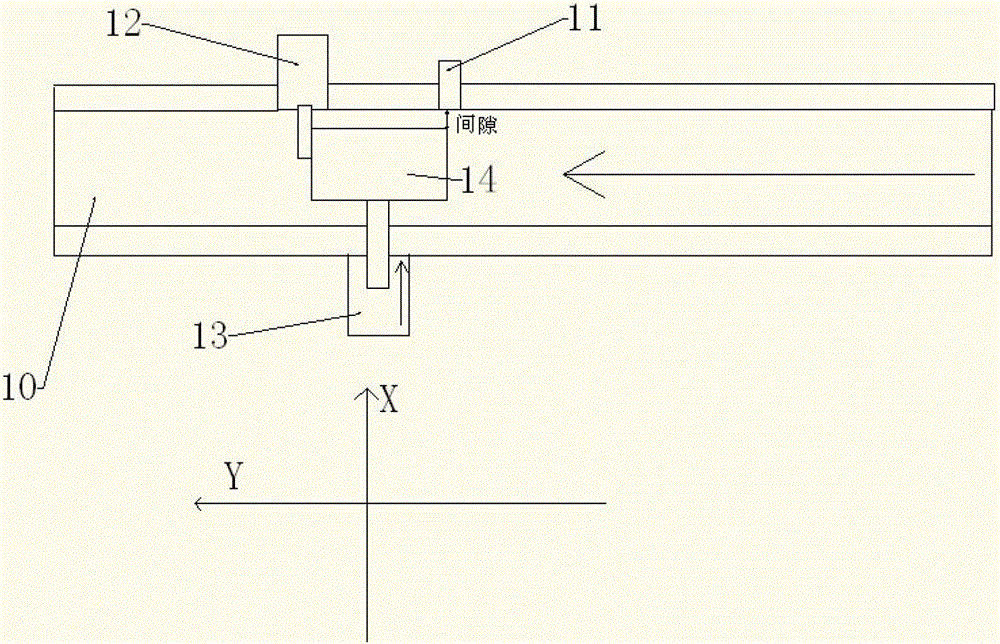

Heat-sealing positioning control method of battery

ActiveCN102765593ALess prone to skewPrecise positioningFinal product manufactureControl devices for conveyorsPosition controlElectrical and Electronics engineering

The invention discloses a heat-sealing positioning control method of a battery, which comprises the steps that a motor is in transmission connection with a conveying belt, a sensor, a material level stopping cylinder and a clamping cylinder are respectively connected with a controller, and the battery is conveyed by the conveying belt; the battery on the conveying belt is detected by the sensor to obtain sensing signals and transmit the sensing signals to the controller; and after receiving the sensing signals, the controller controls the material level stopping cylinder to stop the battery, controls the clamping cylinder to start to clamp the battery, and controls the motor to delay and stop operation so as to make the conveying belt delay and stop operation. The heat-sealing positioning control method of the battery disclosed by the invention effectively solves the problem that positioning deviation is prone to occur during heat sealing of the battery in the prior art, and enhances the heat-sealing efficiency and the product qualification rate.

Owner:ANHUI LEOCH POWER SUPPLY

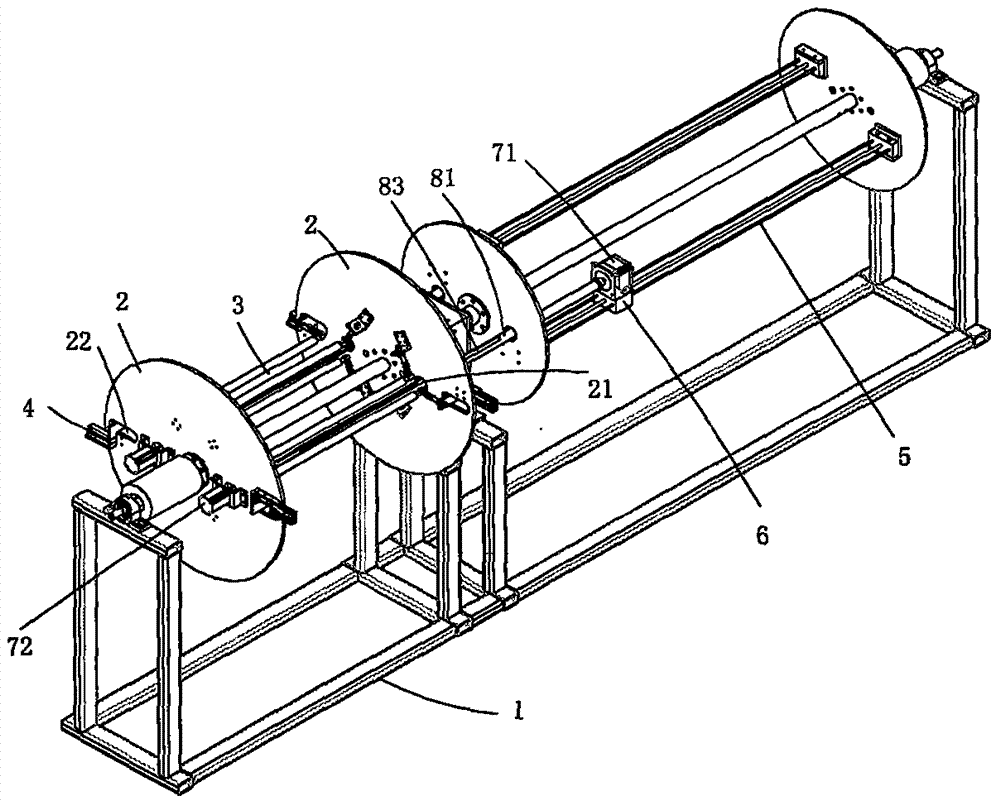

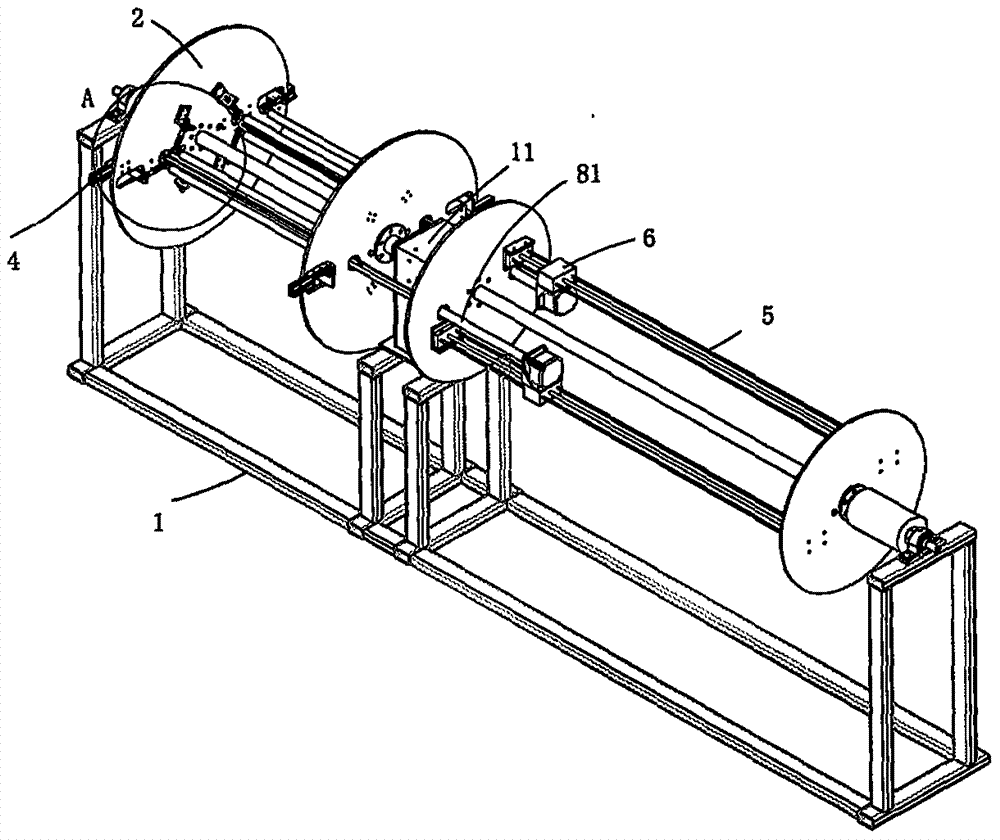

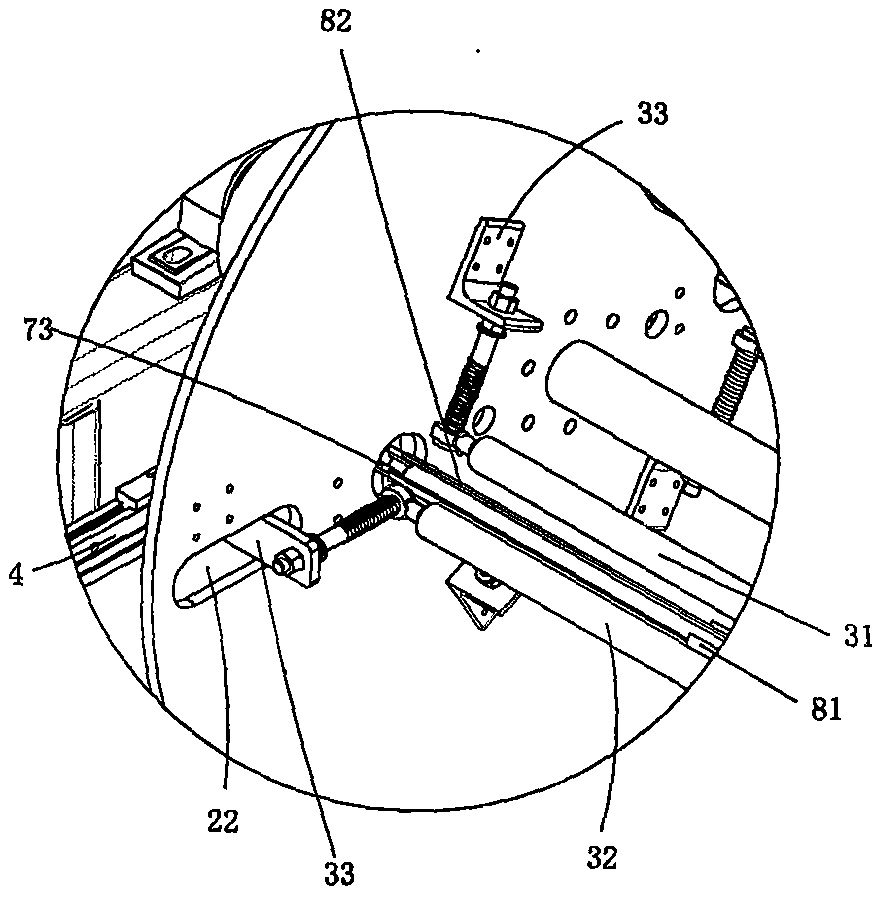

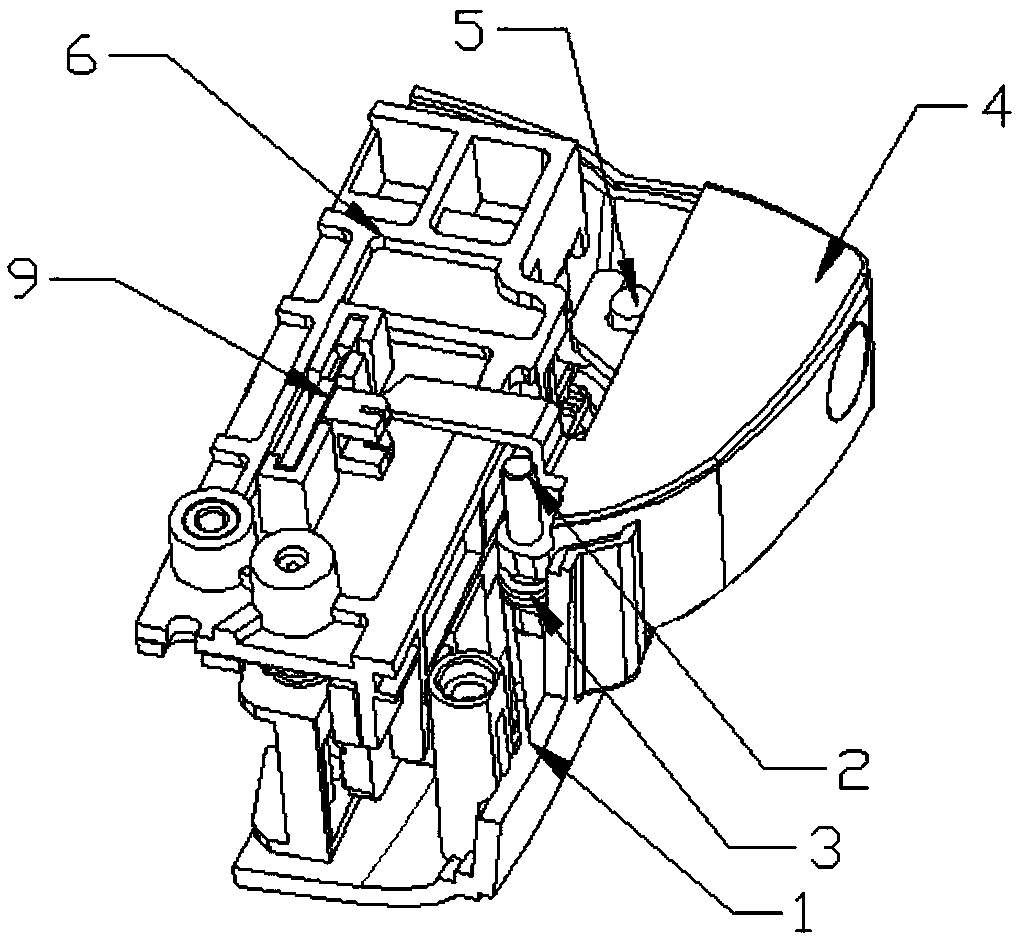

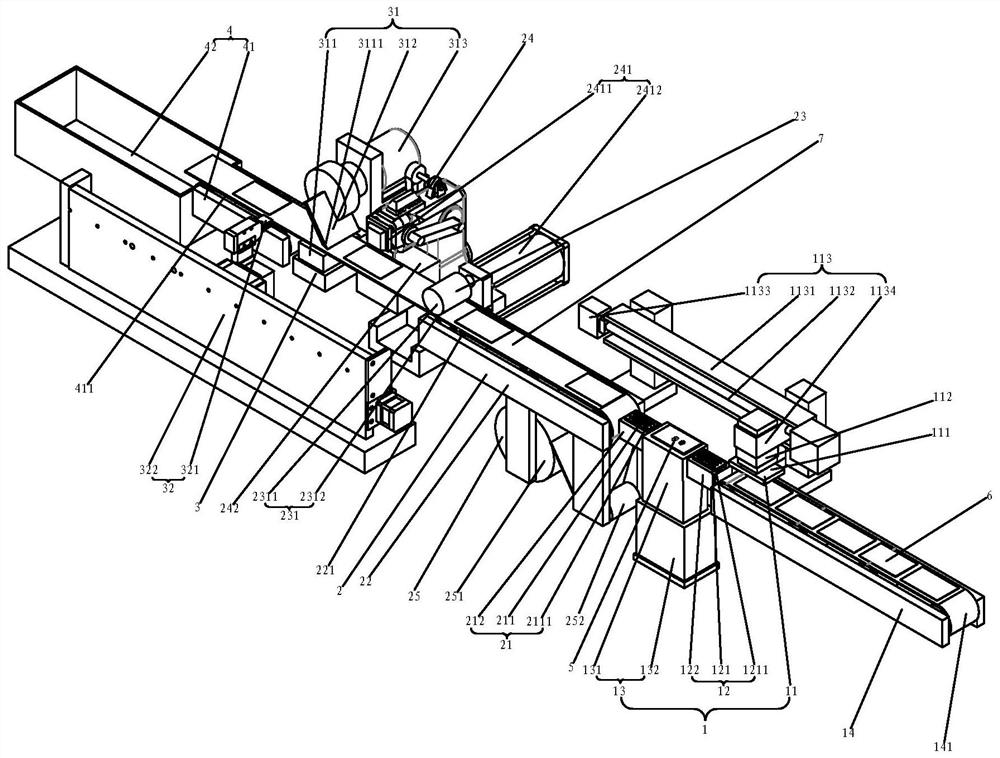

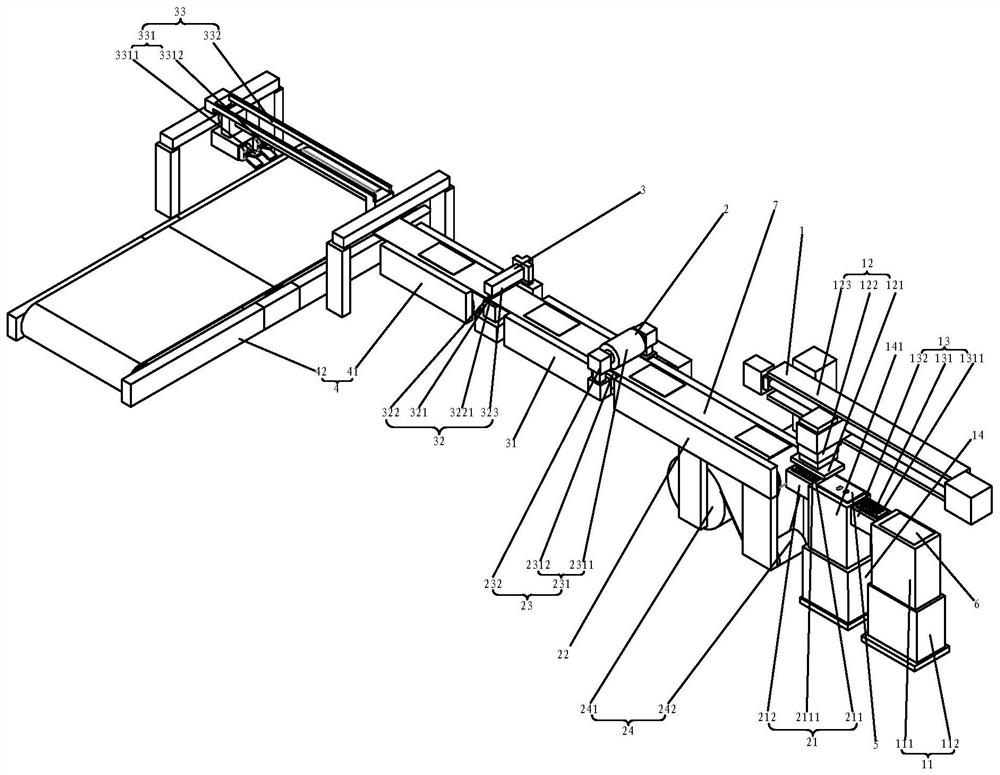

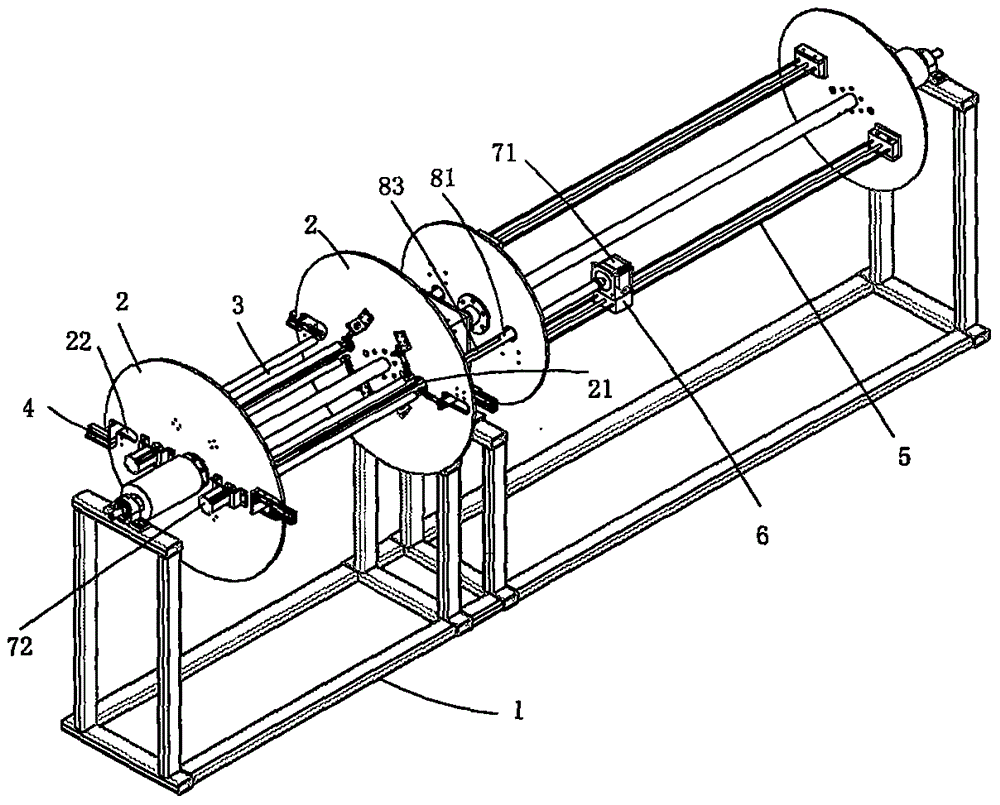

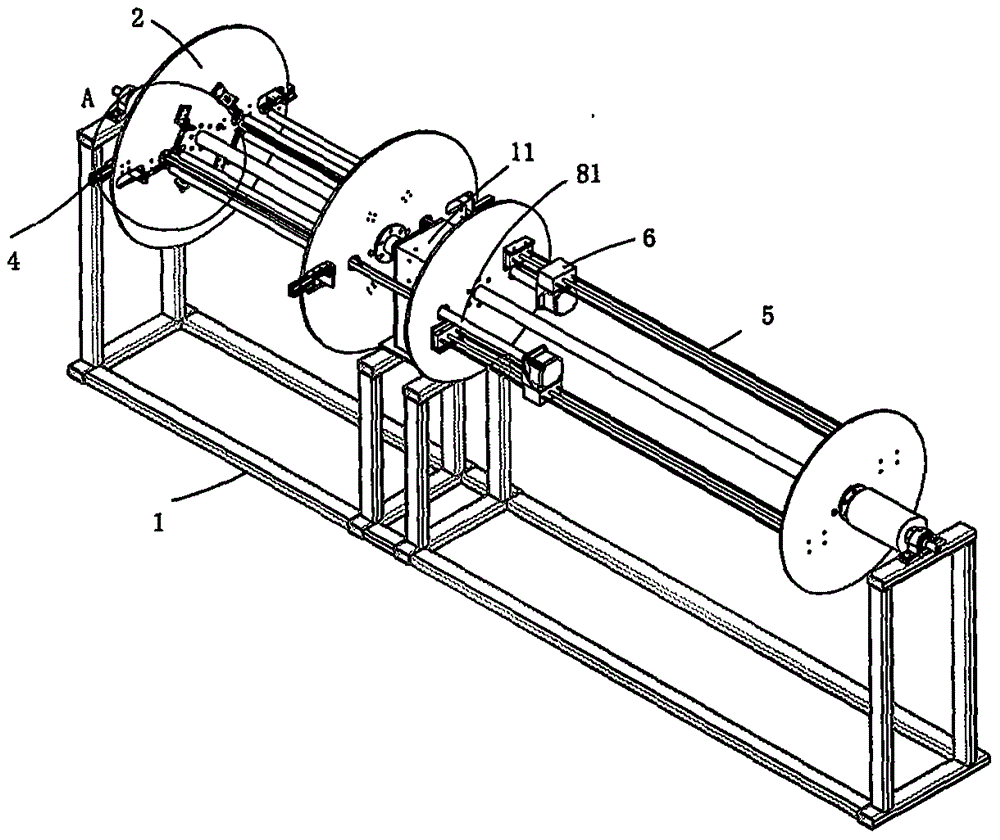

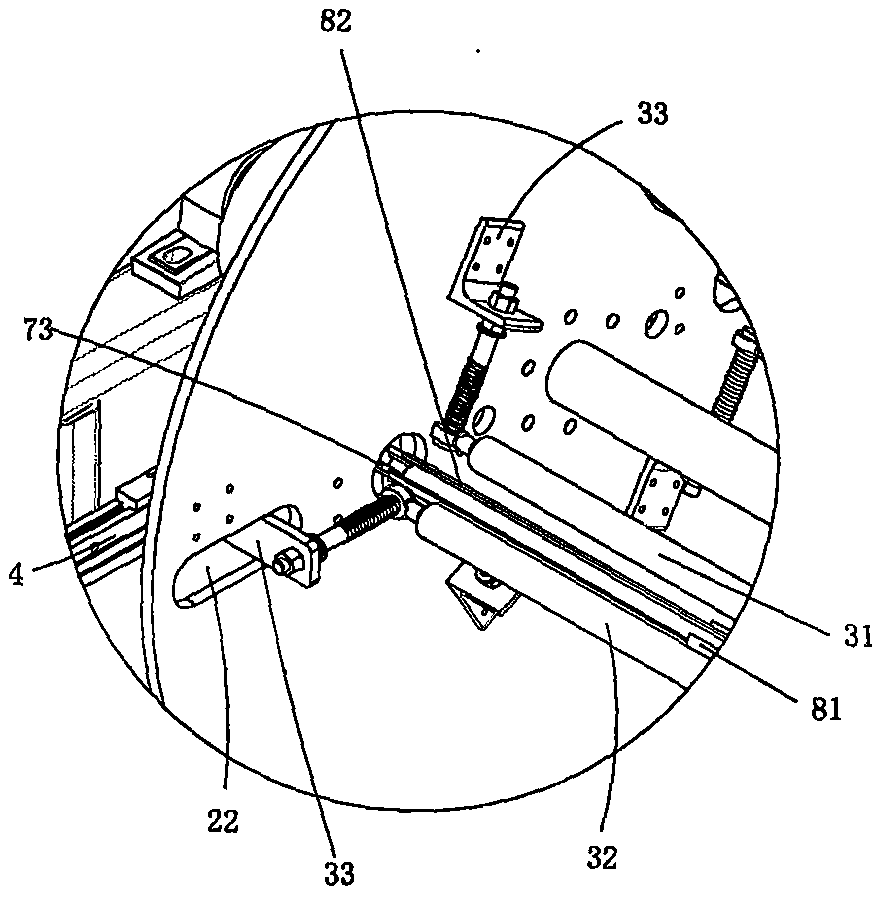

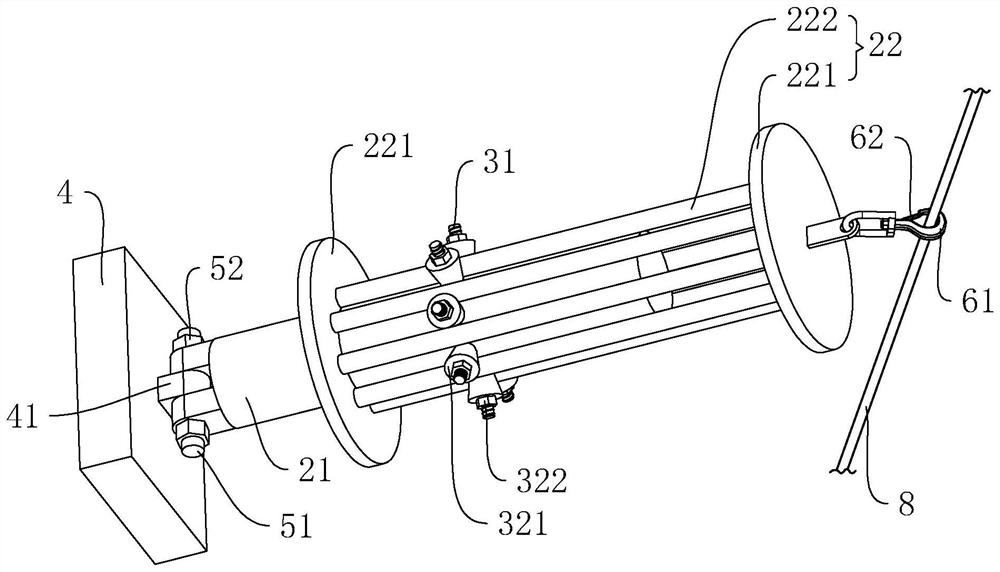

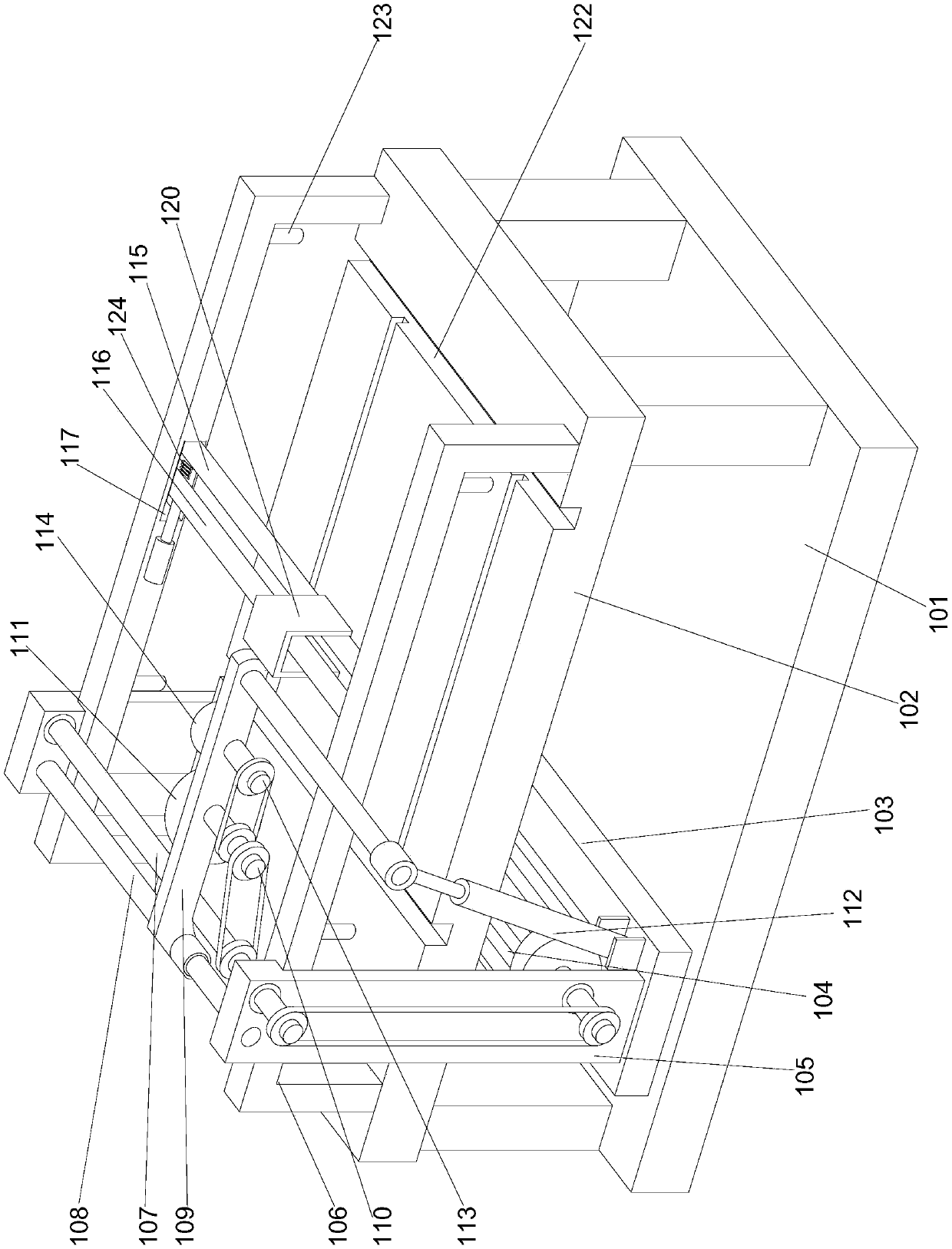

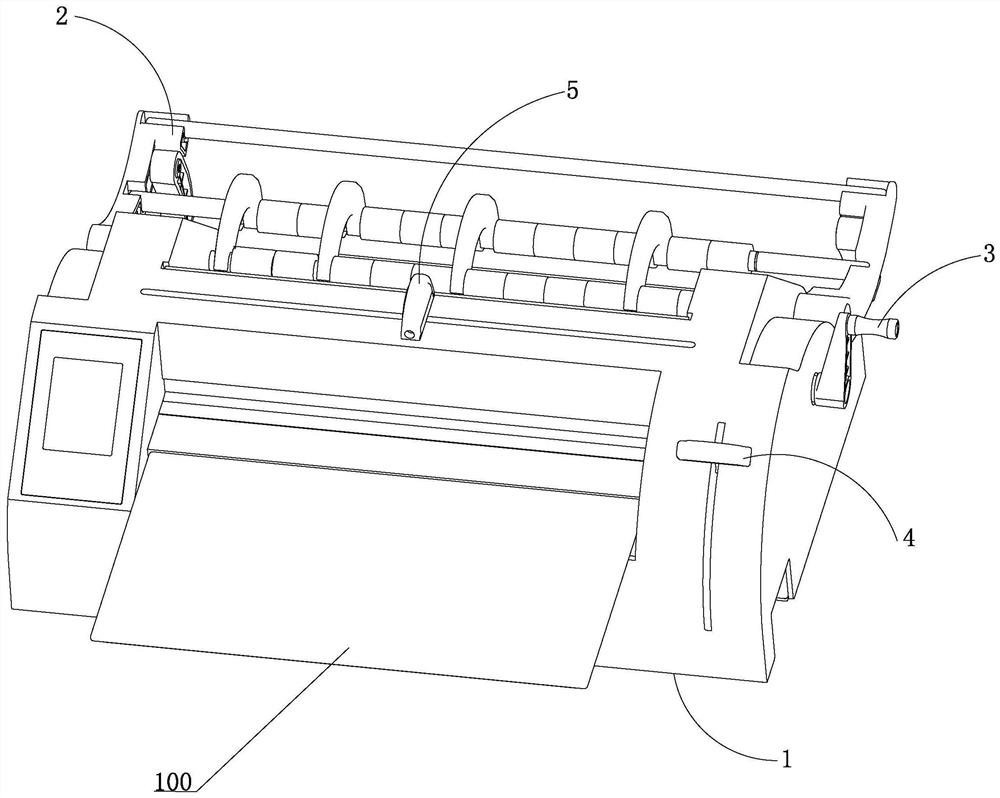

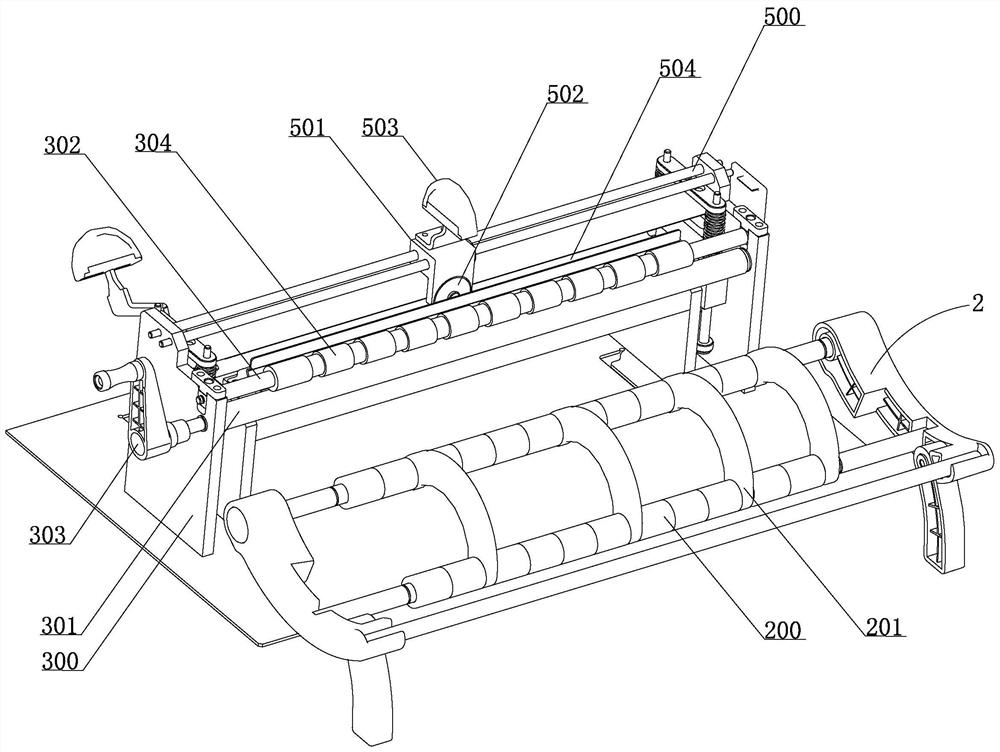

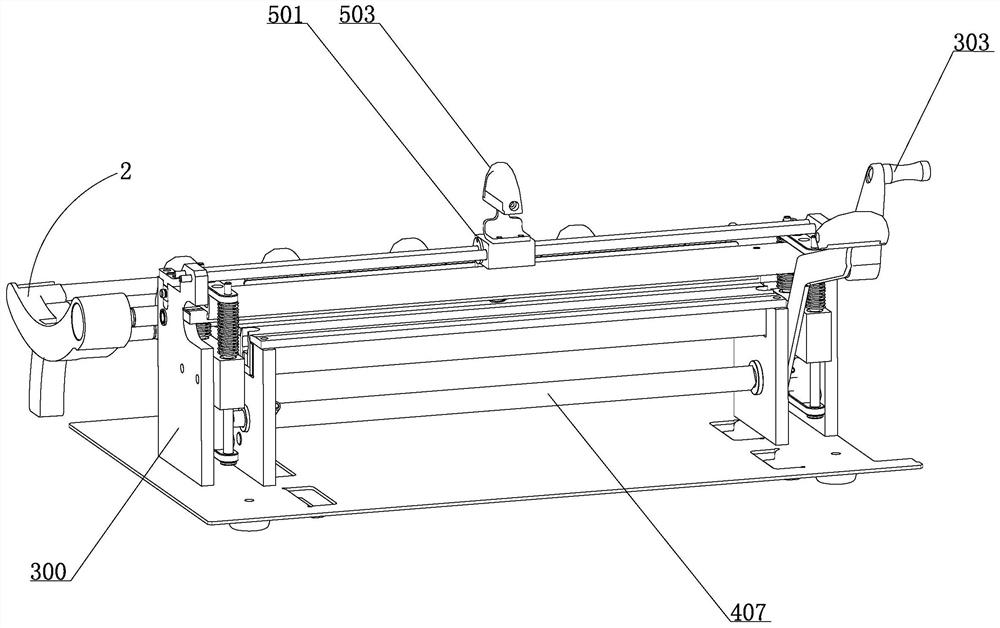

Yoga mat rewinding device

ActiveCN105752724BLess prone to skewReduce rework rateWebs handlingEngineeringMechanical engineering

The invention relates to a yoga mat winding device. Bend-winding work positions and a clamping part conveying mechanism are arranged on a support (1) of the device. The bend-winding work positions are located between two supporting sheets (2) and each provided with a bend-winding restraining mechanism (3). The clamping part conveying mechanism comprises a sliding rod (5) and a driving mechanism (6) moving along the sliding rod (5). A bend-winding stepping motor (71) is arranged on the driving mechanism (6) and connected with a clamping sleeve pipe. The clamping sleeve pipe comprises an outer bend-winding pipe (81) and an inner bend-winding pipe (82) which are circularly sleeved together. Strip-shaped gaps (83) allowing a yoga mat to be clamped therein are formed in the outer bend-winding pipe (81) and the inner bend-winding pipe (82). A follow-up stepping motor (72) capable of being connected with the molded surface of the end of the inner bend-winding pipe (82) is arranged on the supporting sheet (2) on the outer side. According to the technical scheme, winding is fast, the winding rework rate is low, and the layers of the wound yoga mat are dense.

Owner:HUZHOU TEACHERS COLLEGE

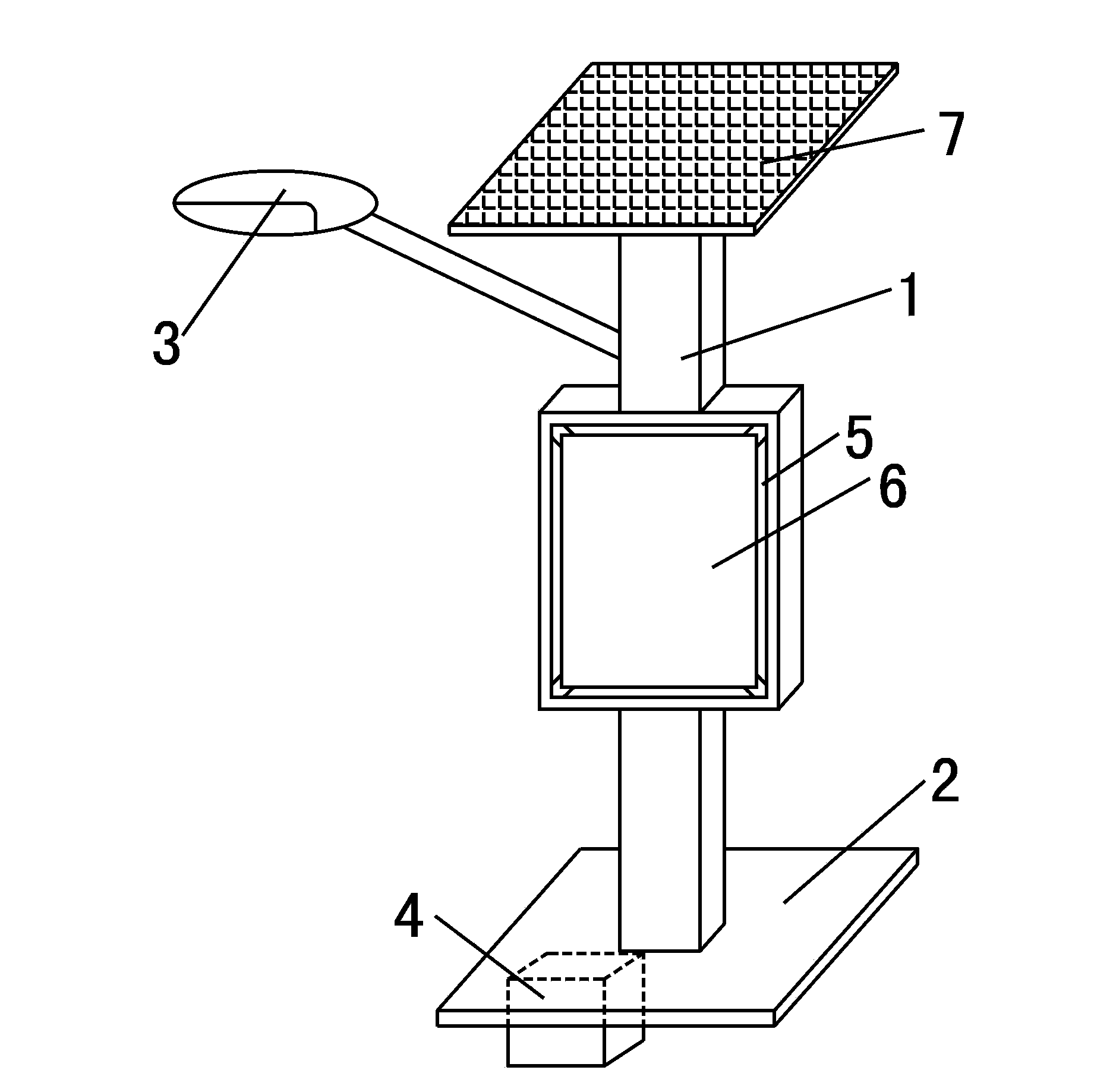

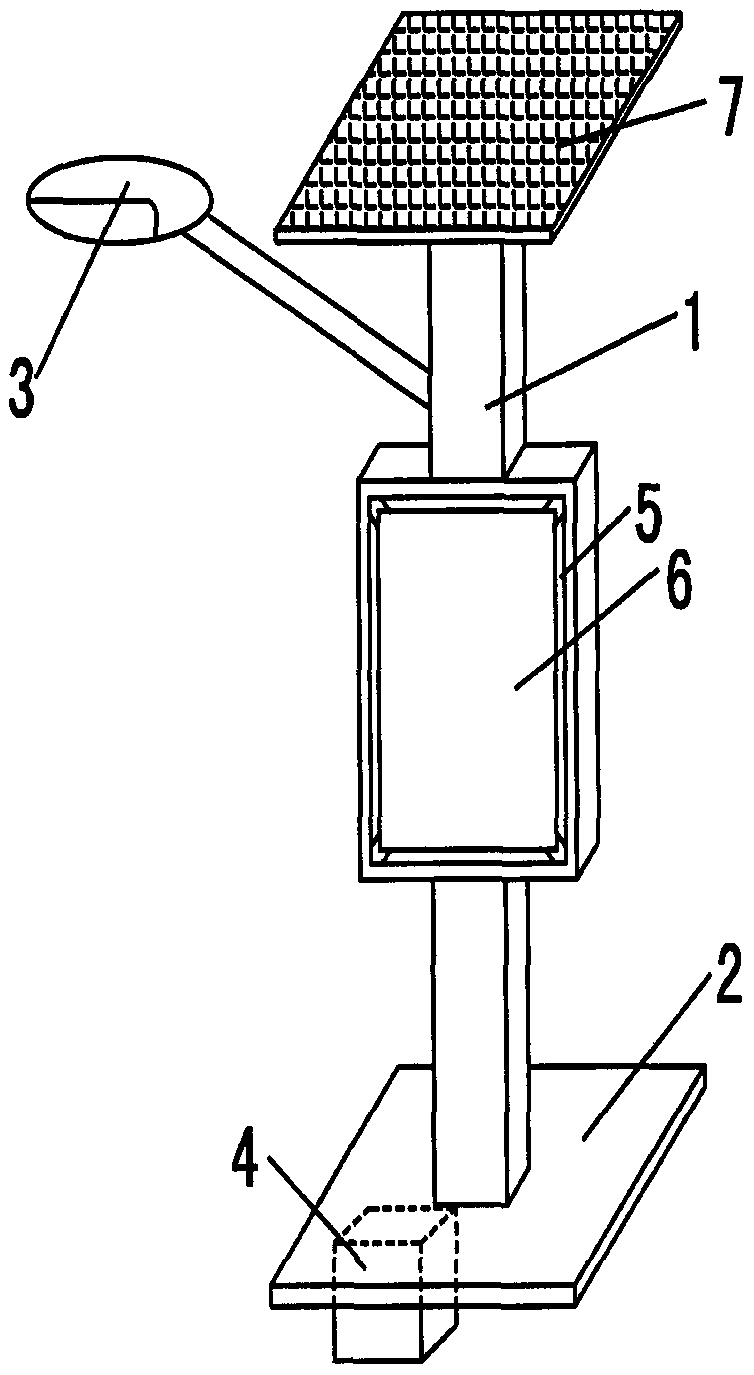

Integrated advertising street lamp

InactiveCN103672683ASolve the problem of simple structure and not stable enoughStable structurePoint-like light sourceLighting support devicesEngineeringSolar cell

The invention discloses an integrated advertising street lamp. The integrated advertising street lamp comprises a lamp pole, a base, a lamp holder and a storage battery. The lamp pole is fixed on the ground through the base, and the lamp holder is arranged on the lamp pole close to the top end through a supporting rod. A rectangular embedding groove is formed in the lamp pole below the lamp holder, and a multimedia display screen is embedded in the rectangular embedding groove. A solar cell panel is connected with the top end of the lamp post and is connected with the storage battery arranged in the base through a wire, and the storage batter is connected in series with the display screen. The rectangular embedding groove is formed in the lamp pole below the lamp holder, and the multimedia display screen is embedded in the rectangular embedding groove, so that the multimedia display screen is stable even in windy days. According to the integrated advertising street lamp, the design is ingenious, and by the aid of the integrated structure design, the structure is stable, and the street lamp is not prone to inclination and falling.

Owner:XIAN TIANYUNTANG ADVERTISEMENT CULTURAL COMM

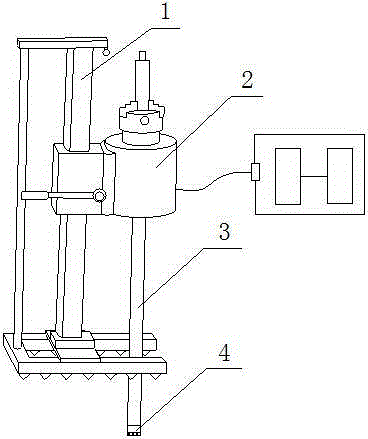

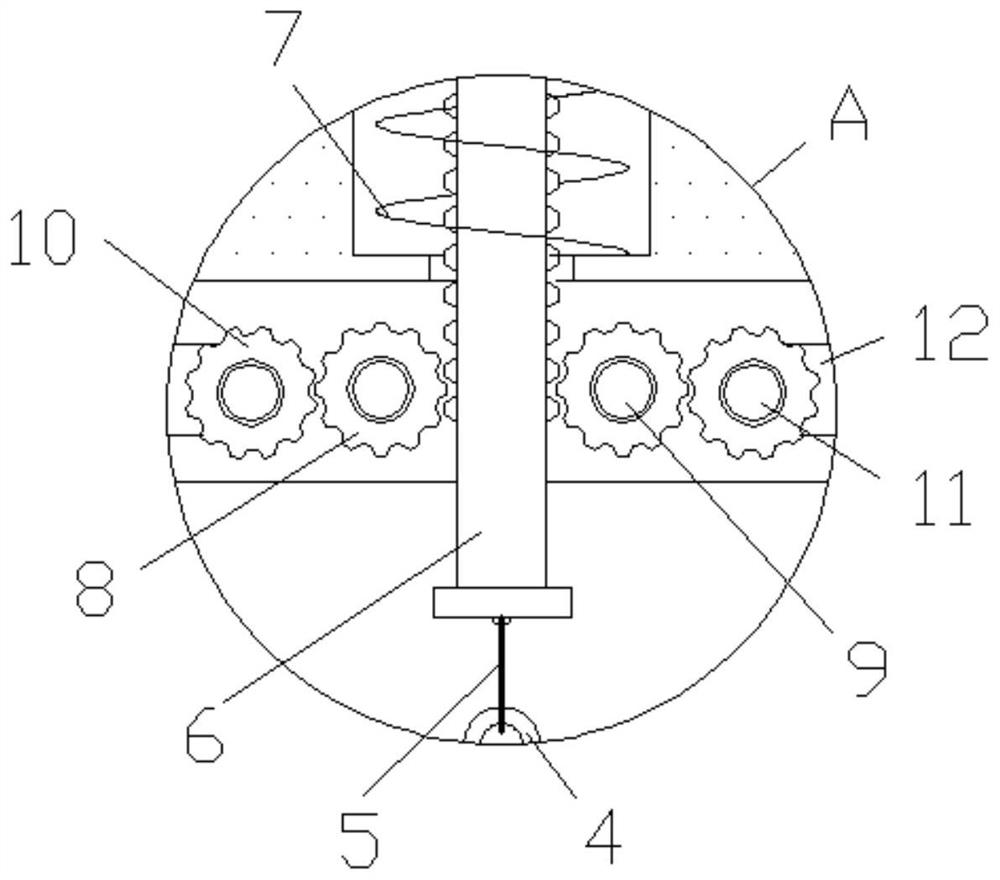

Electric geological core drilling rig

InactiveCN105178844AReduce noiseGood for healthConstructionsRotary drillingEngineeringMotor controller

The invention discloses an electric geological core drilling rig. The electric geological core drilling rig comprises a bracket, a power mechanism and a drilling mechanism, wherein the bracket comprises a supporting framework, a motor bracket and a lifting handle; the motor bracket is arranged on the supporting framework in a sleeving mode; the lifting handle is arranged on the motor bracket; an illuminating lamp is arranged on the supporting framework; anti-sliding teeth are arranged on the bottom of the supporting framework; the power mechanism comprises a current converter, a motor controller, a motor and a drill rod chuck; the motor is fixed on the motor bracket; the drilling mechanism comprises a drill rod and a drill bit; the drill bit comprises a drill bit steel body, a tool bit and a connecting layer; the tool bit is connected with the drill bit steel body by virtue of the connecting layer; and the lower end surface of the tool bit is a lip surface of the tool bit; and the lip surface is in the shape of a step which is internally low and externally high. The electric geological core drilling rig adopts the motor as a power source, is small in noise, does not generate tail gas and is beneficial for body health of an operator.

Owner:NORTHEASTERN UNIV

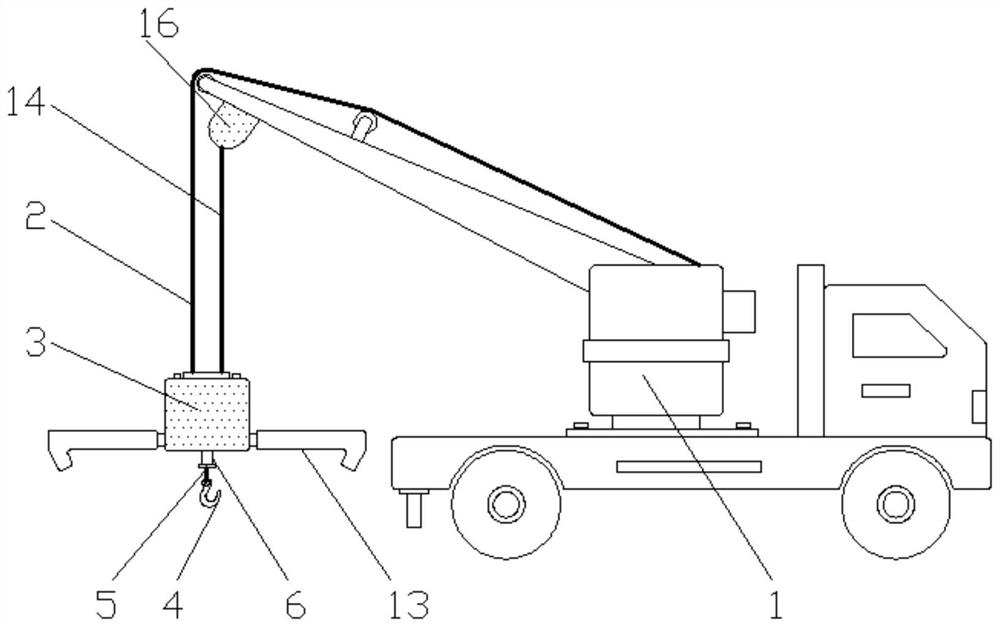

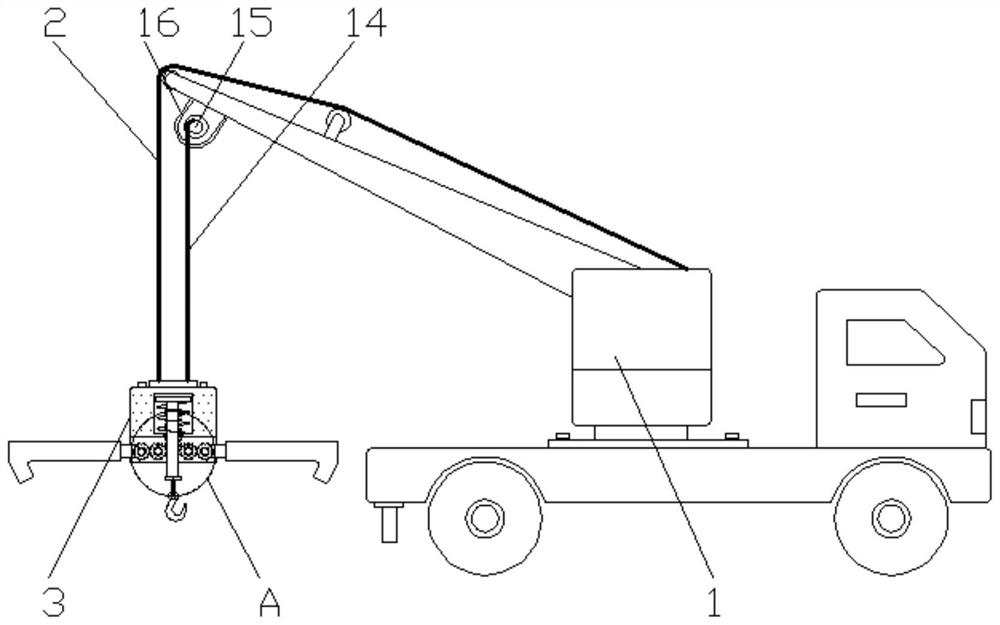

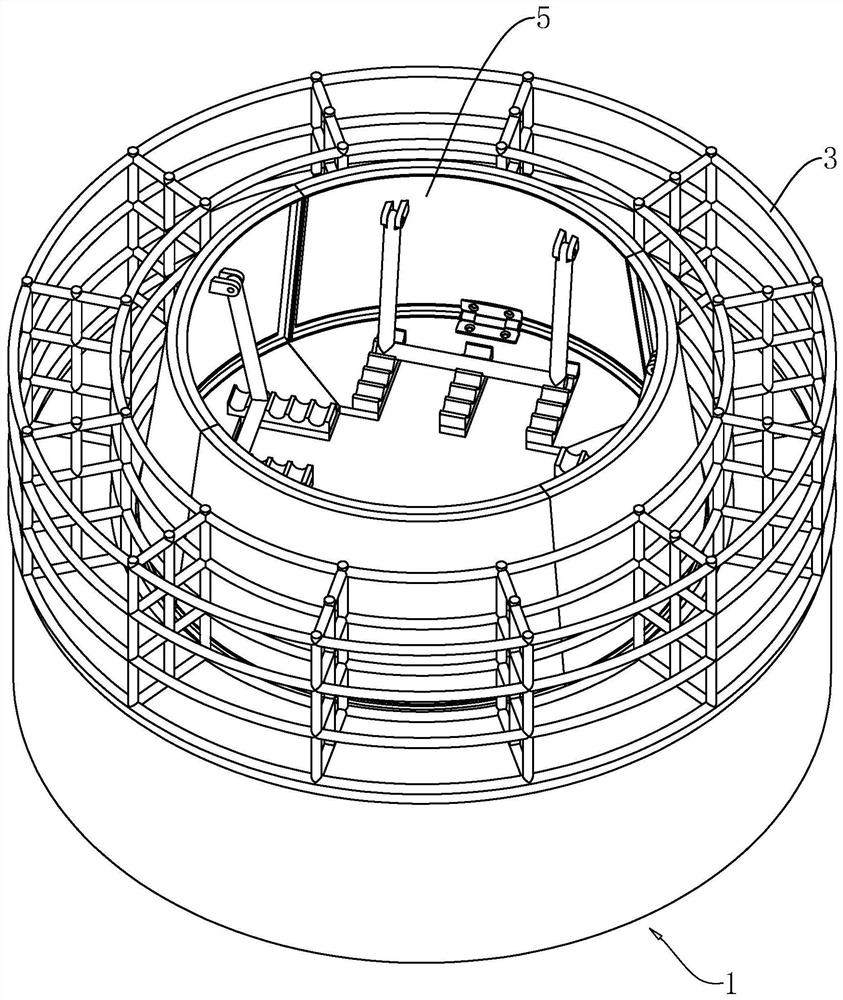

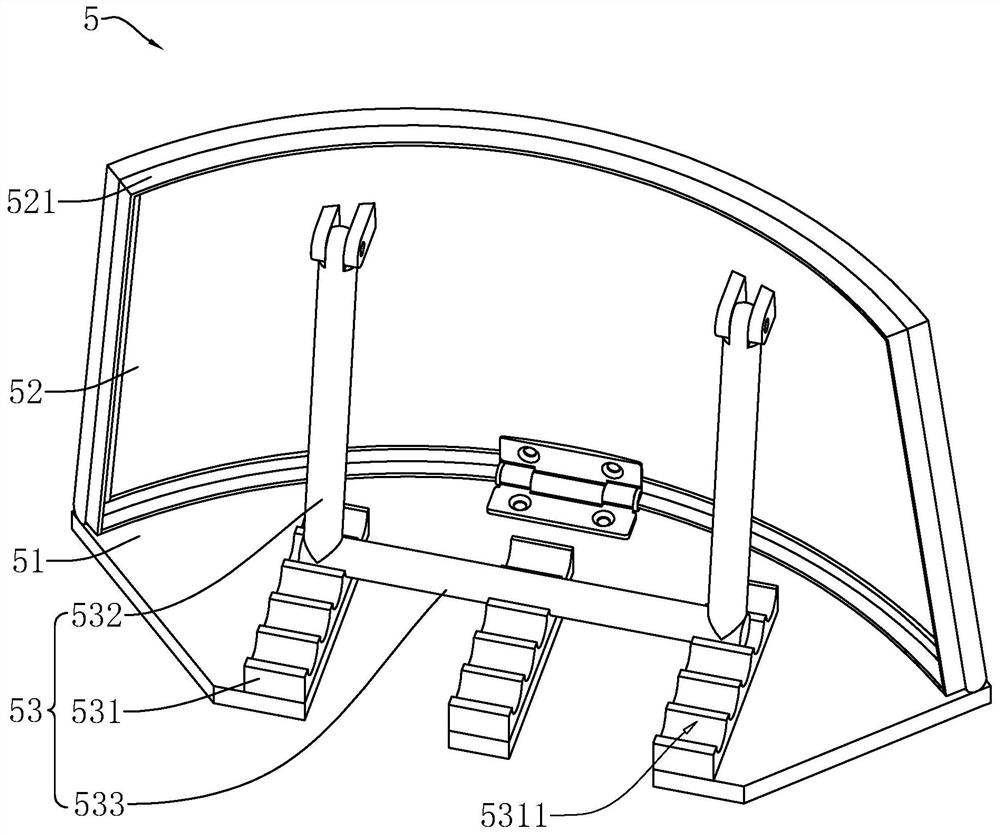

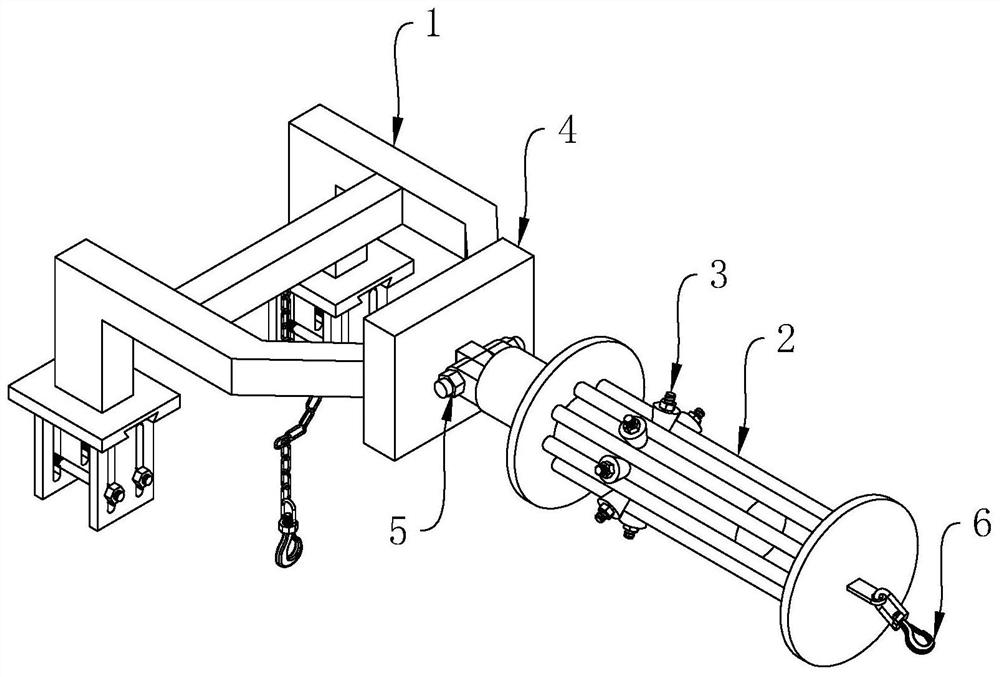

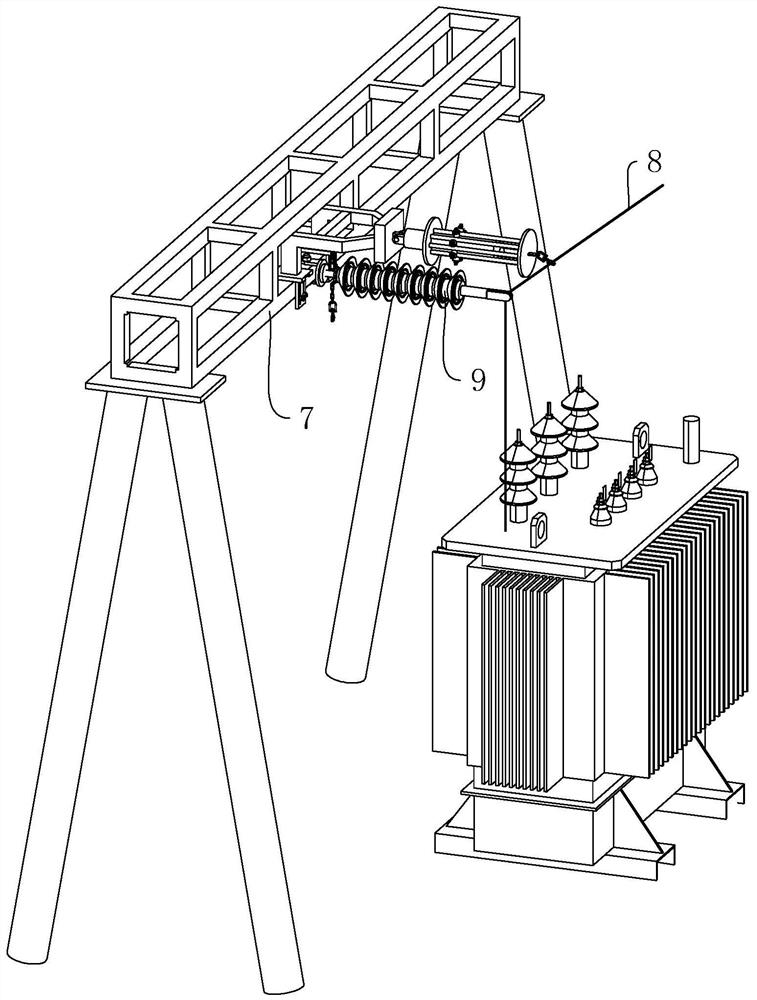

Self-adaptive fixed prefabricated building steel hoisting device

InactiveCN112551391AStable tensionImprove the safety of useCranesSafety gearArchitectural engineeringHoist device

Owner:姜婧

Solar support

ActiveCN105305939APrecise positioningImprove bearing capacityPhotovoltaic supportsPhotovoltaic energy generationEngineeringMechanical engineering

Owner:YANGZHONG YANGZILV PROCESSING CO LTD

Lithium niobate substrate blackening mehtod

InactiveCN108374201AShort timeEasy accessPolycrystalline material growthAfter-treatment detailsArgon atmosphereReaction temperature

The invention discloses a lithium niobate substrate blackening method. A reducing reagent utilized in the method is prepared by mixing iron powder and lithium carbonate powder. The lithium niobate substrate blackening method comprises the steps: 1, putting an iron powder and lithium carbonate mixture into a square corundum crucible; 2, flatly putting and burying a lithium niobate substrate into the mixture; 3, putting the square corundum crucible into a thermal treatment furnace and treating in the argon atmosphere; 4, putting into a diluted hydrochloric acid solution to be soaked when a temperature reduces to be close to a room temperature and then washing and spin drying. The method has short reaction time, small consumed time in a lithium niobate substrate blackening process and suitability for large-scale production; by means of high temperature resistance and acid-base resistance, the square corundum crucible can be used for a long time; furthermore, the square corundum crucible brings convenience to taking and putting wafers, and the square corundum crucible is stabler in a furnace tube of the thermal treatment furnace and is not prone to inclining. The method has the advantages of convenience, simpleness and easiness in operation, safety and reliability. By adjusting conditions of a mixture proportion, reaction time, reaction temperature and the like, the lithium niobatesubstrates of different blackened degrees can be obtained.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

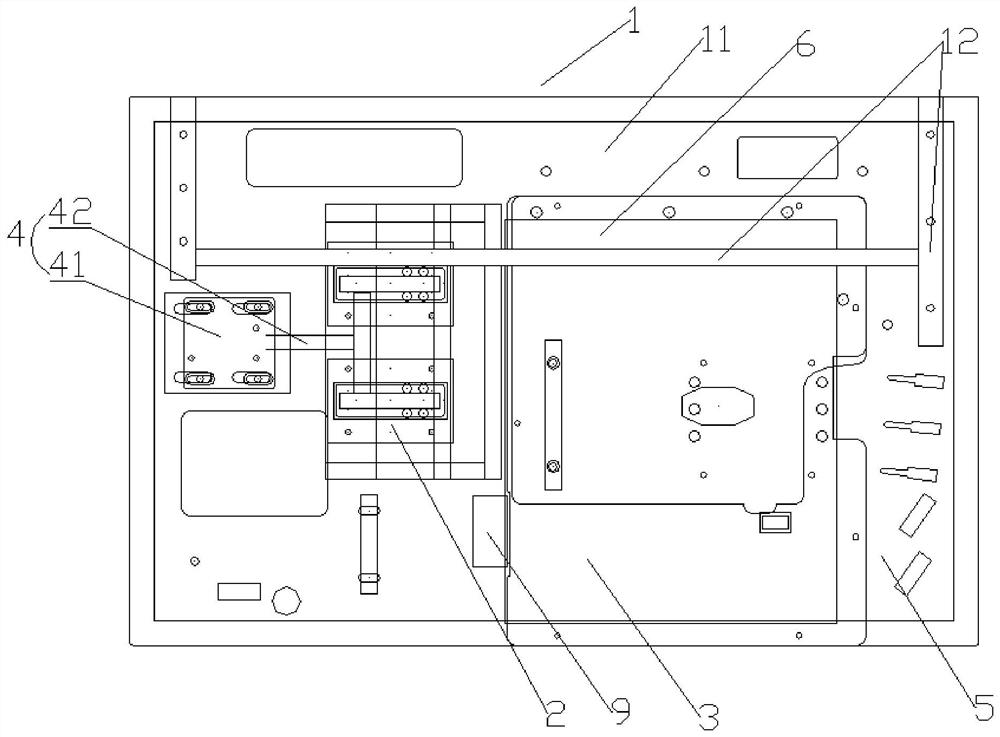

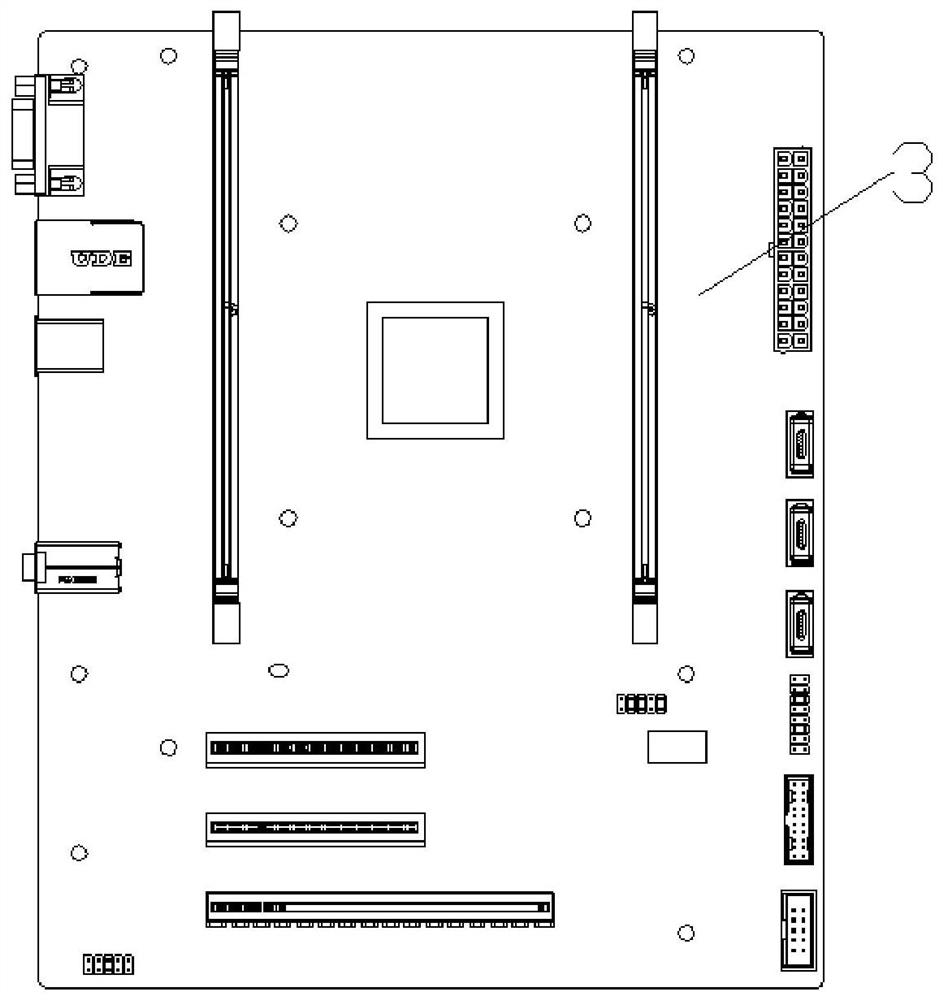

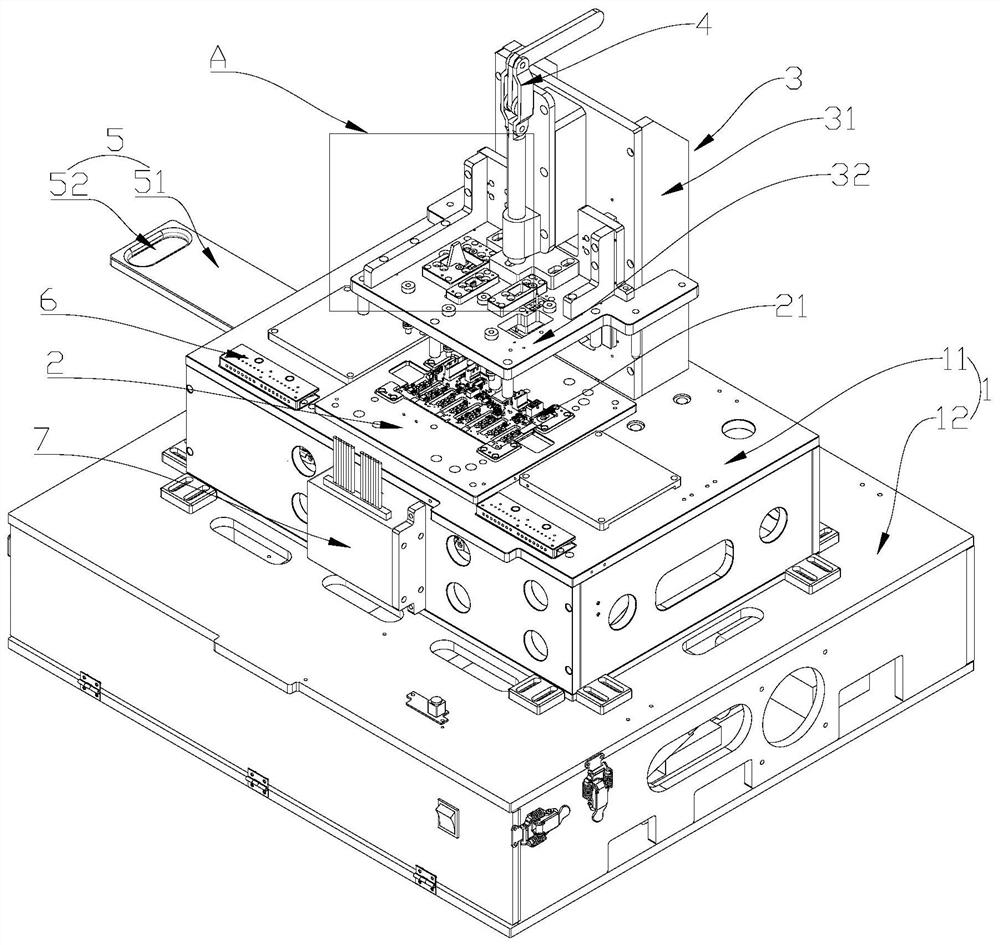

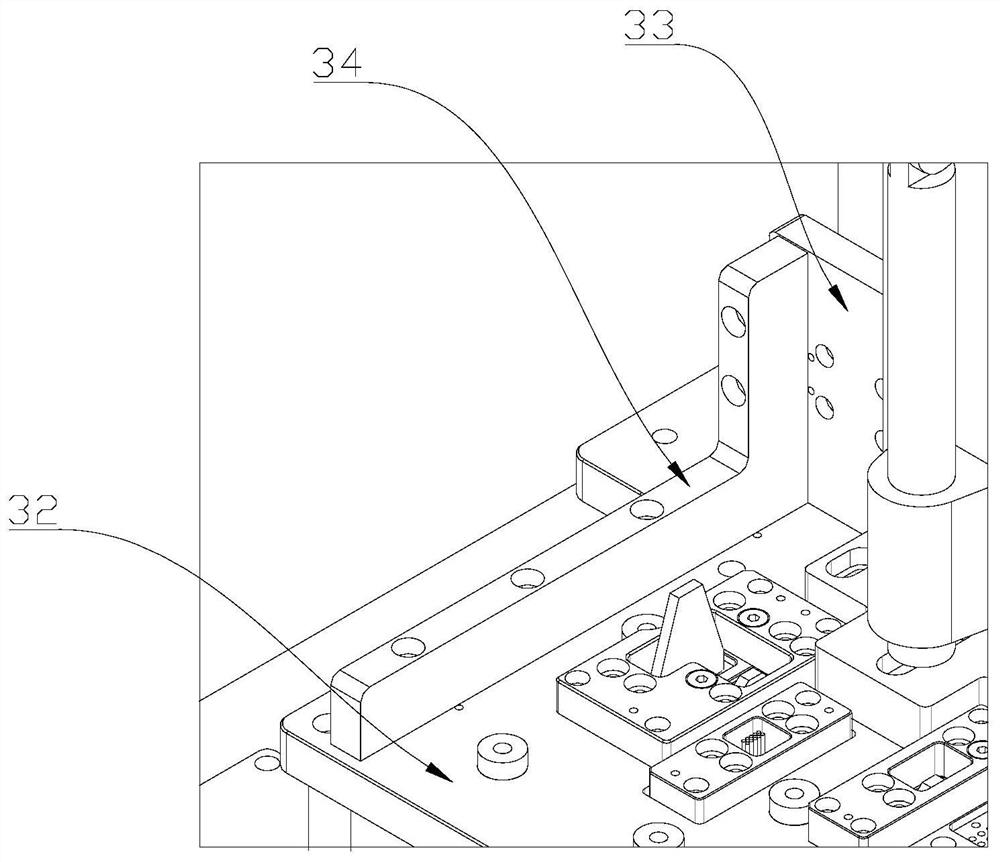

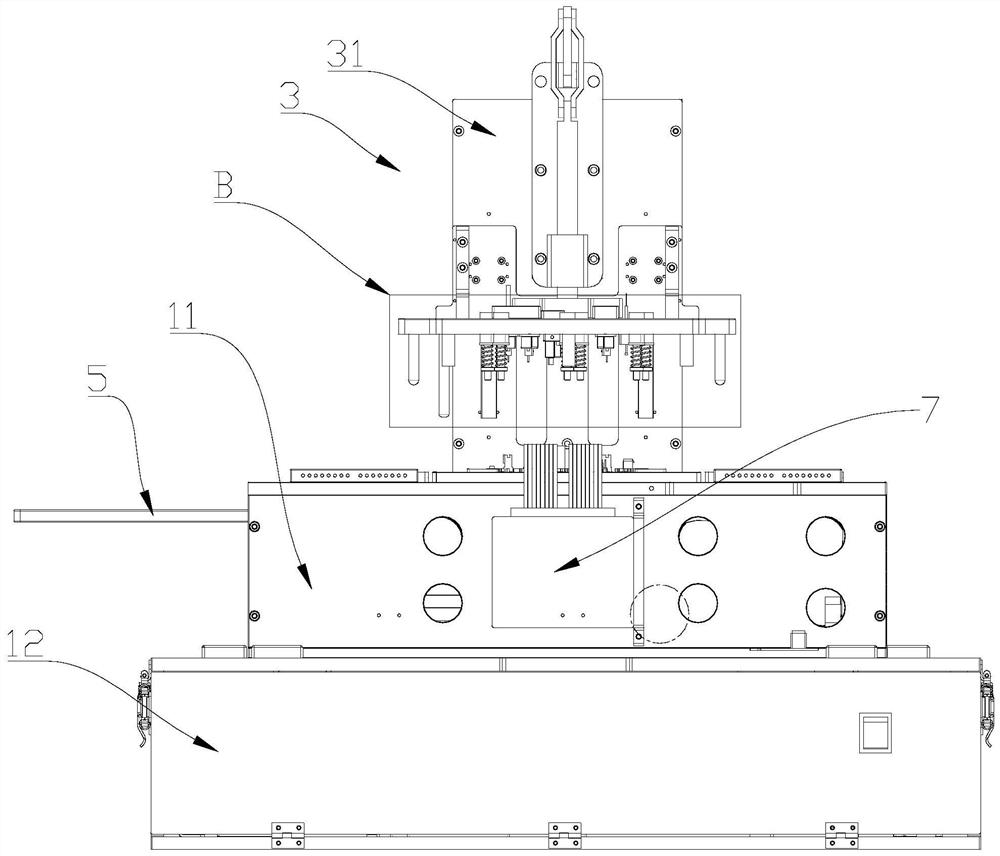

Mainboard testing device

PendingCN113866599ASame direction of plugging and unpluggingSimplified installation stepsPrinted circuit testingSoftware engineeringMechanical engineering

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

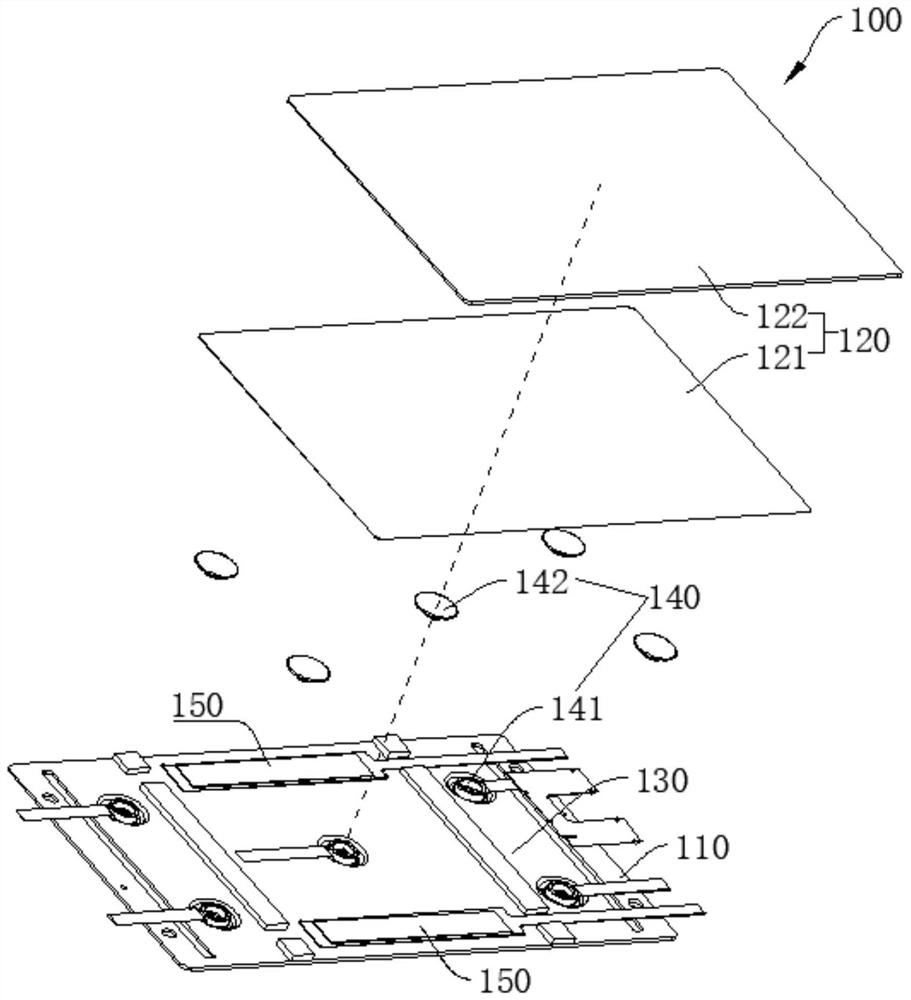

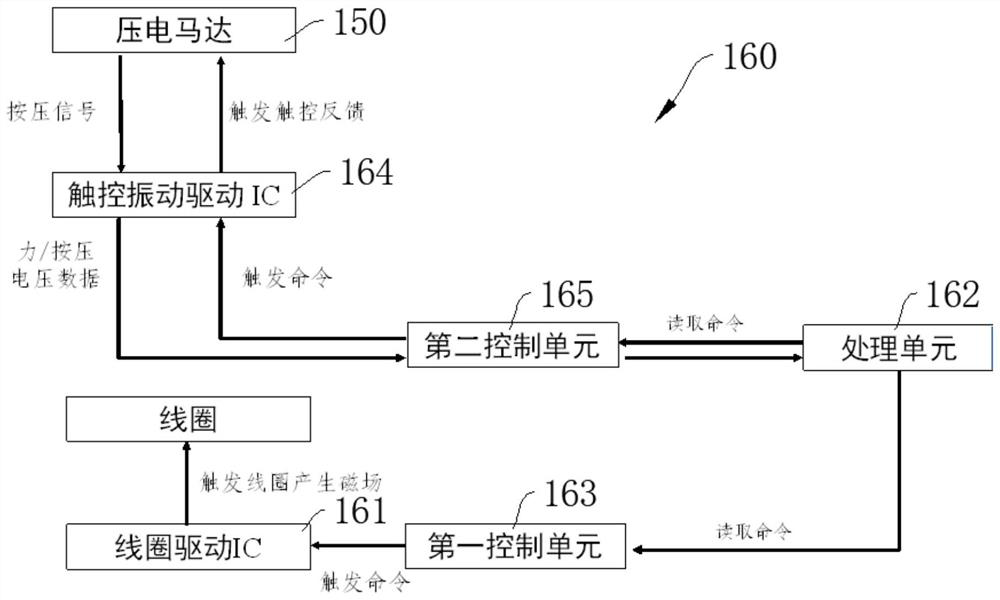

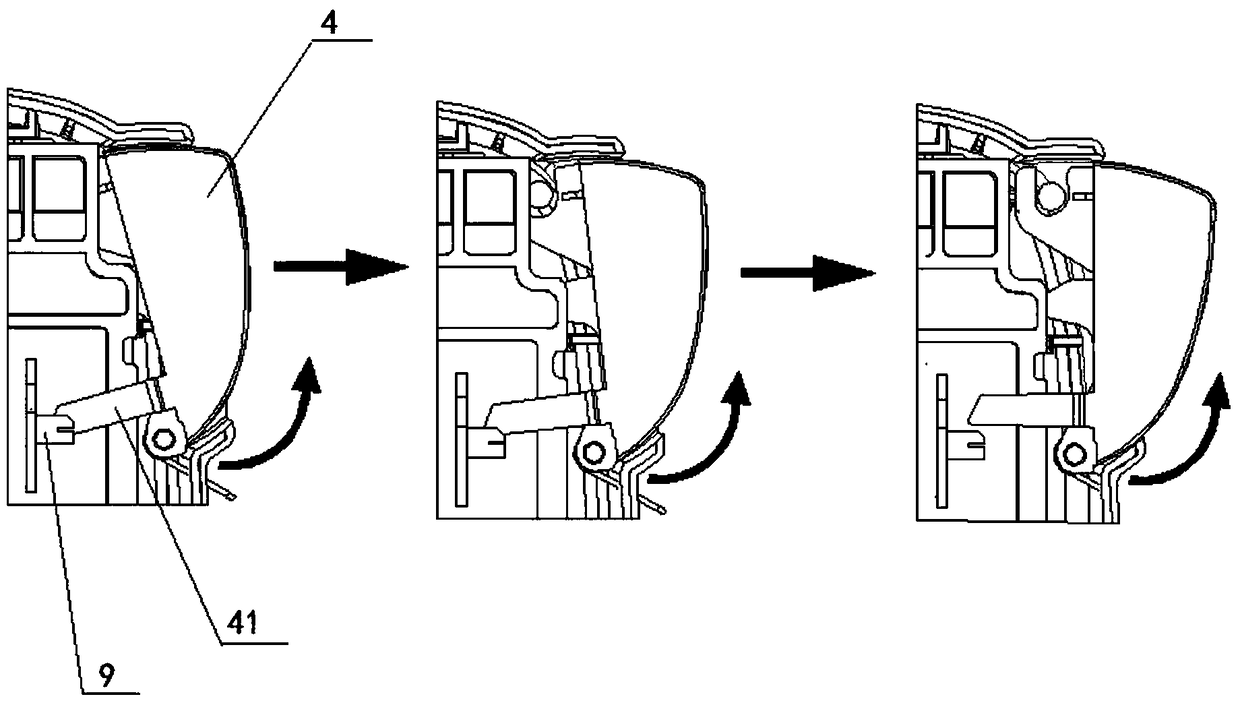

Touch feedback module and electronic equipment

InactiveCN112558780AReduce displacementImprove experienceInput/output for user-computer interactionGraph readingTouchpadEngineering

The embodiment of the invention discloses a touch feedback module and electronic equipment. The touch feedback module comprises a support plate; a touchpad arranged on one side of the supporting plate; a force transmission structure, wherein one end of the force transmission structure is connected with the supporting plate, and the other end of the force transmission structure is connected with the touchpad; a plurality of magnetic assemblies which are arranged between the supporting plate and the touchpad, and each magnetic assembly comprises a first part and a second part which can attract or repel each other, wherein the first part is arranged on the supporting plate, the second part is arranged on the touchpad, one of the first part and the second part is a magnet, the other one of thefirst part and the second part is a coil, part of the structure of the magnet extends into the coil, and the multiple magnetic assemblies are arranged between the supporting plate and the touchpad ina scattered mode. The effects of reducing the displacement of the touchpad caused by pressing the touchpad by a user and improving the user experience are achieved.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

Manual label making machine with continuous printing function

PendingCN109227703AControlled start and stopRealize no blank printingTypewritersMetal working apparatusPulp and paper industryPaper sheet

The invention discloses a manual label making machine with a continuous printing function. The manual label making machine comprises a housing, a full cutting button is installed on the housing, the full cutting button is connected with a full cutting knife assembly, an extension arm is connected to the full cutting button, and a photoelectric detection switch area is arranged in the housing; whenthe full cutting button is pressed to start label paper cutting, the extension arm enters the photoelectric detection switch area under the driving of the full cutting button; when the full cutting button resets after label paper cutting, the extension arm leaves the photoelectric detection switch area under the driving of the full cutting button. In the manual label making machine, through the cooperation of the extension arm arranged on the full cutting button and the photoelectric detection switch area, start and stop of a paper feeding mechanism and a printing head of the label marking machine can be controlled according to signals sent when the extension arm enters and exits from the photoelectric detection switch area, then, the label marking machine can perform printing without blanks, and the waste of the label paper can be reduced. Besides, through structural improvement on the full cutting knife assembly, cutting is facilitated, the phenomena of skew, deckle edges and the like of cuts of the label paper do not occur easily, and the manual label making machine is suitable for application and popularization.

Owner:BEIJING SUPVAN ELECTRONIC TECH CO LTD

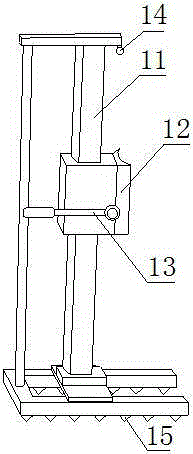

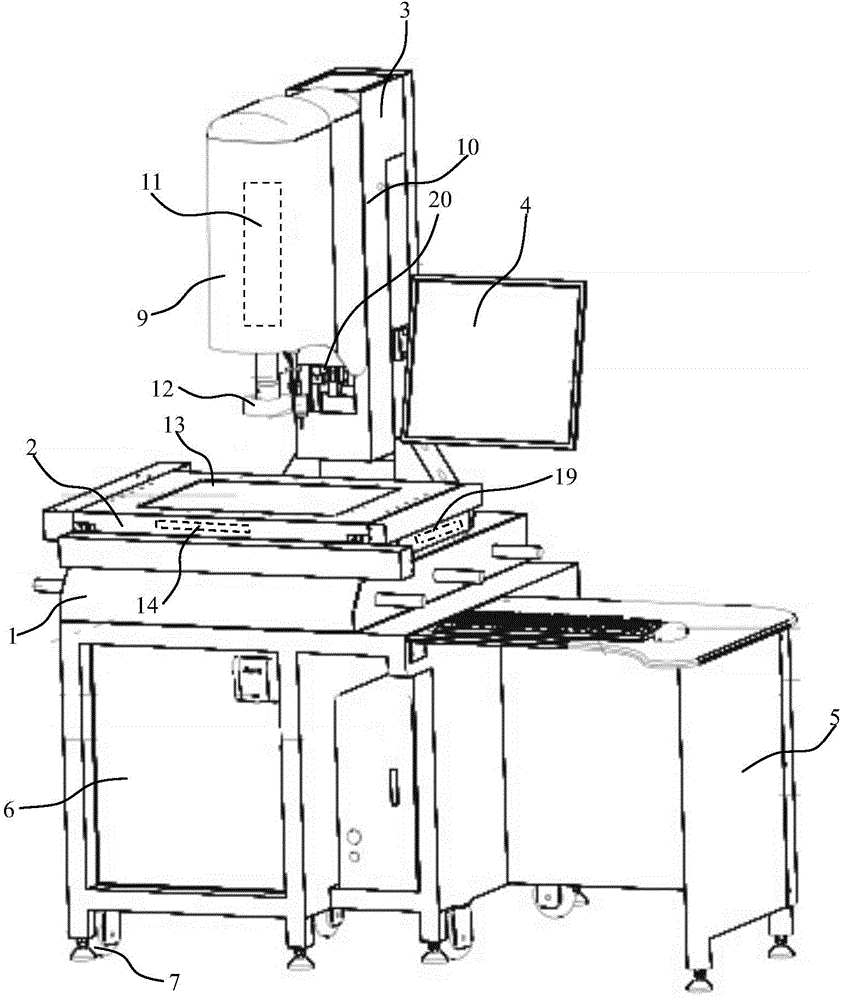

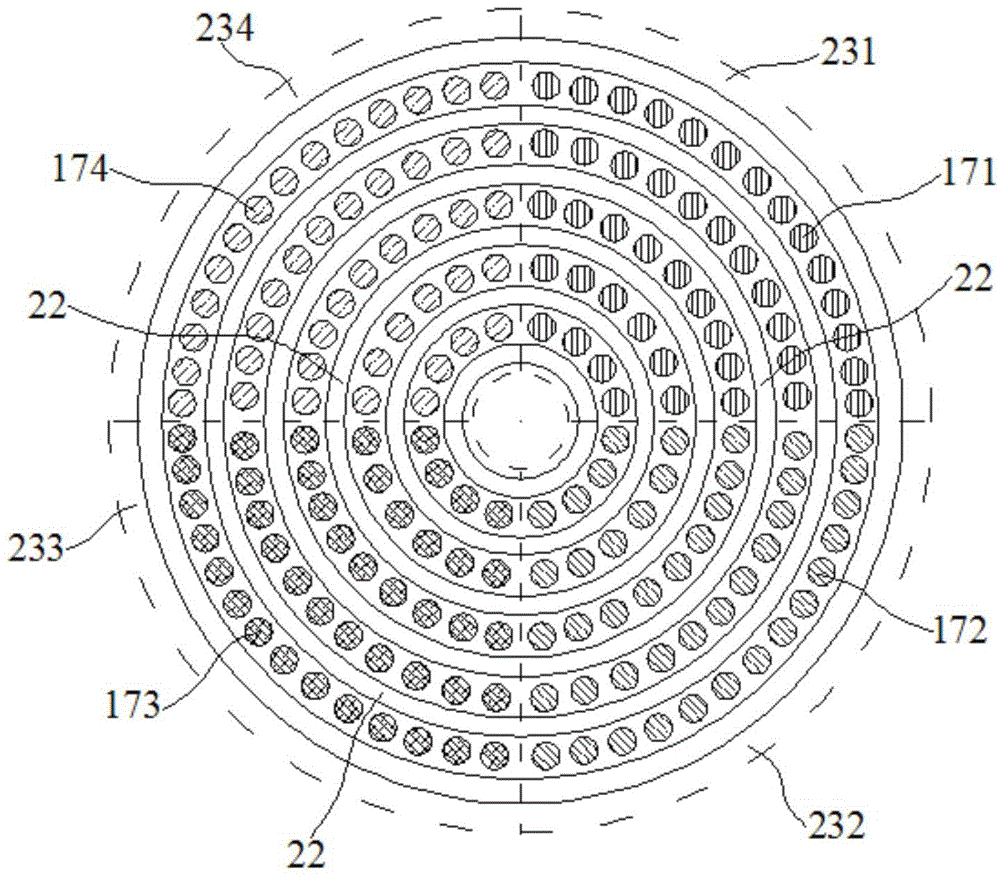

High definition image type measurement instrument

InactiveCN104375265AThe imaging effect is clearImprove image qualityMicroscopesUsing optical meansEngineeringContrast enhancement

The invention discloses a high definition image type measurement instrument which comprises a base, an LED upper lamp light source, an image lens sleeve and a measurement worktable. A coder and a transmission system formed by sequentially meshing a first gear, a second gear and a third gear are arranged in the image lens sleeve. The first gear is arranged on an output shaft of a motor, the second gear is arranged on a rotating shaft of the coder, and the third gear is arranged on the image lens sleeve. A plurality of red LED lamp beads, yellow LED lamp beads, blue LED lamp beads and green LED lamp beads are embedded in a plurality of inclined holes formed in a lamp plate, and the inclined holes form acute included angles with the axis of the lamp plate. The red LED lamp beads, the yellow LED lamp beads, the blue LED lamp beads and the green LED lamp beads are arranged from inside to outside to form at least four LED lamp rings. The high definition image type measurement instrument greatly improves the contract influencing the edge and enhances the image boundary so as to improve the measurement precision, is convenient to operate, and greatly improves the working efficiency.

Owner:SUZHOU EASSON OPTOELECTRONICS

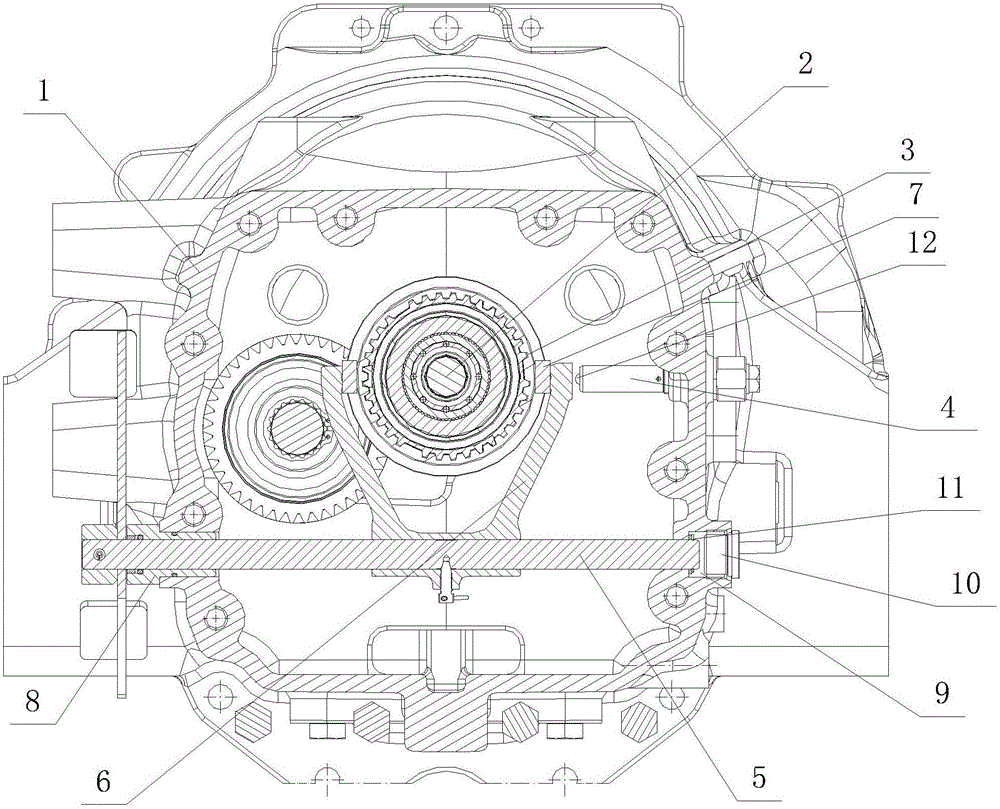

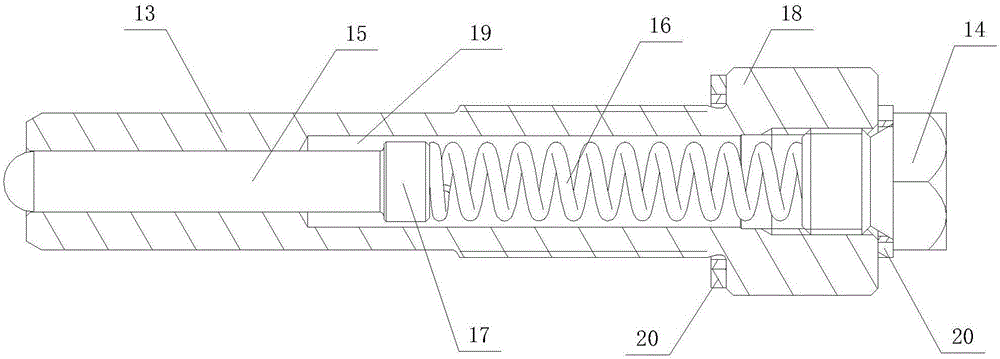

Synchronizer shifting fork gear shift mechanism for tractor

InactiveCN106499806AReduce wearCompact structureControlled membersGearing controlEngineeringSelf locking

The invention relates to a synchronizer shifting fork gear shift mechanism for a tractor, and belongs to the field of tractor gear shift. The synchronizer shifting fork gear shift mechanism is located in a gearbox shell and comprises a gear shaft, a shifting fork shaft, a shifting fork and a gear self-locking device. The gear shaft is perpendicular to the shifting fork shaft, and the gear shaft is sequentially sleeved with a first shifting gear, a synchronizer and a second shifting gear. The synchronizer is in sliding connection with the gear shaft through a spline and can be in hitching connection with the first shifting gear or the second shifting gear. The outer edge of the synchronizer is provided with an annular groove. The shifting fork is provided with a shifting block corresponding to the annular groove. The gear self-locking device is provided with a spring positioning pin abutting against the shifting fork. A first positioning hole, a middle positioning hole and a second positioning hole are formed in the outer side of the shifting fork at intervals. According to the synchronizer shifting fork gear shift mechanism, the product structure is compact, operation is easy and convenient, the shifting fork shaft rotates only under the effect of external force, the gear shifting performance is more stable, gear shifting and hitching connection are easier, more convenient and smoother, and the problem that the synchronizer is likely to be damaged or be out of gear in the gear shifting process can be effectively solved.

Owner:LOVOL HEAVY IND CO LTD

Bag and suitcase cloth roll separating device facilitating cutting

PendingCN108439001ALess prone to skewGuaranteed winding effectWebs handlingEngineeringMechanical engineering

The invention discloses a bag and suitcase cloth roll separating device facilitating cutting. The device comprises a cutting table, a cloth feeding mechanism, a length counter, a deviation rectifyingroller, a deviation measuring roller, a first installation frame, a rolling mechanism, a cutting device and a control device. The cloth feeding mechanism, the cutting table, the length counter, the deviation rectifying roller, the deviation measuring roller and the rolling device are sequentially arranged from left to right. The cutting device is located above the cutting table, the cutting tableis provided with a through groove adapting to the cutting device, two pressing plates are arranged above the cutting table and located on the left side and the right side of the through groove correspondingly, first lifting devices are fixed to the tops of the pressing plates, the deviation rectifying roller is installed on the first installation frame, an installation table is arranged below thefirst installation frame, a stand column is fixed to the installation table, and the top of the stand column is hinged to one end of the first installation frame. Since the deviation rectifying rolleris arranged between the length counter and the deviation measuring roller, a bag and suitcase cloth is not likely to be deviated in the rolling process, and the rolling effect is ensured.

Owner:嘉兴市布雷塑胶新材料股份有限公司

Automatic labeling assembly line

ActiveCN112644827AFirmly connectedNot easy to wearLamination ancillary operationsLaminationStructural engineeringAssembly line

The invention provides an automatic labeling assembly line. The automatic labeling assembly line comprises a first connecting device, a second connecting device, a cutting device and a storage device. The second connecting device comprises a first sizing device, a first conveying device, a pressing device and a sewing device. A trademark is protected through a plastic film, so that a connecting body single body is not prone to abrasion after being connected to an umbrella cover, the four edges of an adsorbed plastic film single body and the four edges of a trademark single body are kept flush with the four edges of a connecting belt all the time through an adsorption device, inclination is not prone to occurring, the attractive effect is kept after the connecting body single body is made into an umbrella belt, and a user can check the trademark more easily. Meanwhile, the trademark single body and the connecting belt are machined together in order, the good feeling of a client can be gained more easily, the connecting body single body is automatically produced and serves as the umbrella belt to be connected to the umbrella cover, the umbrella belt manufacturing efficiency is greatly improved, the labor cost is reduced, and the machining precision is improved.

Owner:海峡(晋江)伞业科技创新中心有限公司

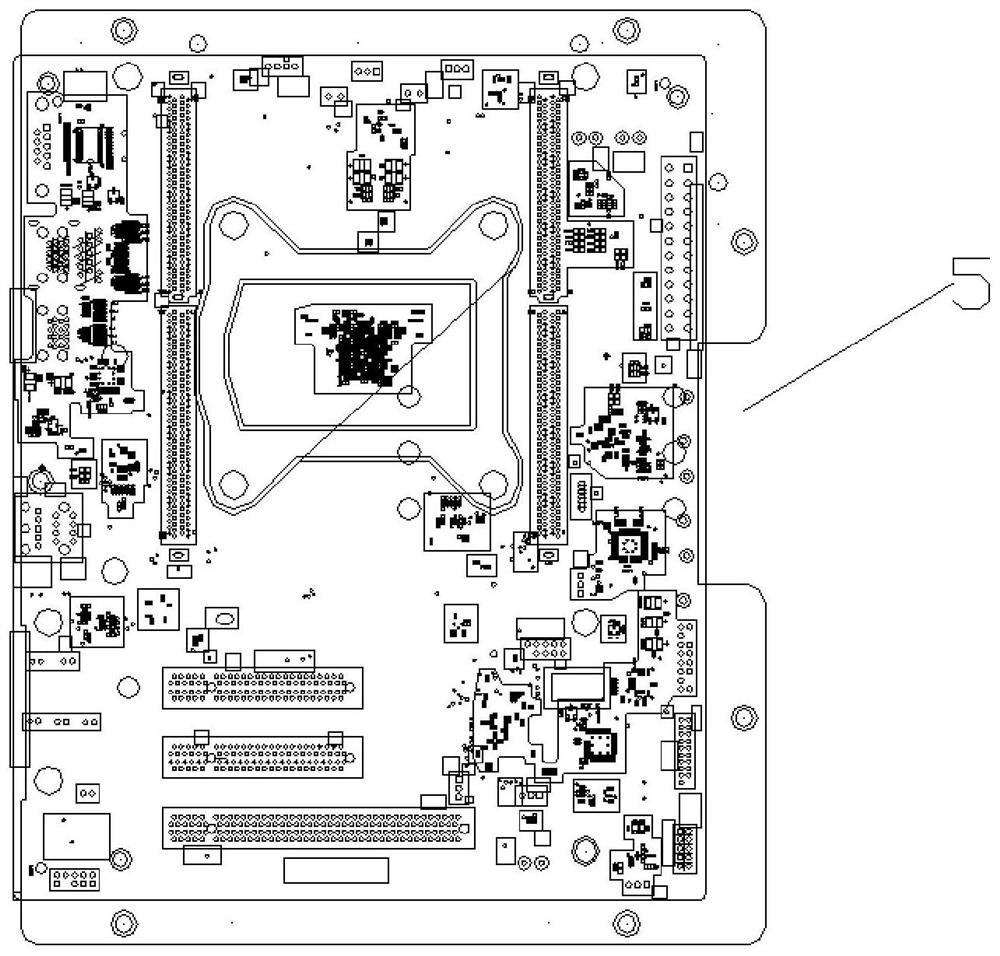

Hard disk backboard testing device

PendingCN113963742AQuick matingReduce damage rateCoupling device detailsDetecting faulty computer hardwareMechanical engineeringTest set

The invention relates to a hard disk backboard testing device, which comprises a testing box, a bearing structure, a fixing structure, a pressing jig and a first driving structure, and is characterized in that the testing box comprises a first box body; a bearing structure is arranged at the top of the first box body and is suitable for bearing a hard disk backboard; the fixing structure is arranged in the first box body, is suitable for being connected with the hard disks, and is used for vertically fixing the plurality of hard disks at positions corresponding to mounting ports of a hard disk backboard at intervals; the pressing jig comprises a supporting assembly and an insulating pressing plate, one end of the supporting assembly is connected with the top of the first box body, and the other end of the supporting assembly extends upwards in the vertical direction; the insulating pressing plate is slidably connected to the supporting assembly and can move in the vertical direction. The insulating pressing plate is positioned above the bearing structure and is suitable for pushing the hard disk back plate to be inserted into the hard disk; the first driving structure is arranged on the supporting assembly, and the output end is connected with the insulating pressing plate. According to the hard disk backboard testing device, time and labor are saved, and the damage probability of the hard disk and the hard disk backboard is reduced.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Efficient and accurate labeling mechanism

ActiveCN112644829AFirmly connectedEasy to connectAffixing tagsLabelling machinesStructural engineeringPlastic film

The invention provides an efficient and accurate labeling mechanism. The efficient and accurate labeling mechanism comprises a first connecting device, a second connecting device, a cutting device and a conveying device for conveying single connecting bodies. The first connecting device comprises a film supply device, an adsorption device for adsorbing single plastic film bodies, a first gluing device for gluing the lower surfaces of the single plastic film bodies, and a supply device for supplying single trademark bodies. The plastic films are connected to the upper surfaces of the single trademark bodies in a covering manner, and then the single trademark bodies protected by the plastic films are connected to connecting belts, so that the single connecting bodies protected by the plastic films are not easy to damage after being subsequently connected to umbrella covers, the adsorption device always keeps the four edges of the adsorbed single plastic film bodies and the single trademark bodies flush with the four edges of the connecting belts respectively, inclination is not likely to happen, the attractive effect is kept after the single connecting bodies are made into umbrella belts, a user can check the single connecting bodies more easily, meanwhile, the single trademark bodies and the connecting belts are machined together in order, and the good feeling of a client is gained more easily.

Owner:海峡(晋江)伞业科技创新中心有限公司

Yoga mat winding device

The invention relates to a yoga mat winding device. Bend-winding work positions and a clamping part conveying mechanism are arranged on a support (1) of the device. The bend-winding work positions are located between two supporting sheets (2) and each provided with a bend-winding restraining mechanism (3). The clamping part conveying mechanism comprises a sliding rod (5) and a driving mechanism (6) moving along the sliding rod (5). A bend-winding stepping motor (71) is arranged on the driving mechanism (6) and connected with a clamping sleeve pipe. The clamping sleeve pipe comprises an outer bend-winding pipe (81) and an inner bend-winding pipe (82) which are circularly sleeved together. Strip-shaped gaps (83) allowing a yoga mat to be clamped therein are formed in the outer bend-winding pipe (81) and the inner bend-winding pipe (82). A follow-up stepping motor (72) capable of being connected with the molded surface of the end of the inner bend-winding pipe (82) is arranged on the supporting sheet (2) on the outer side. According to the technical scheme, winding is fast, the winding rework rate is low, and the layers of the wound yoga mat are dense.

Owner:HUZHOU TEACHERS COLLEGE

Heat-sealing positioning control method of battery

ActiveCN102765593BLess prone to skewPrecise positioningFinal product manufactureControl devices for conveyorsPosition controlElectrical and Electronics engineering

The invention discloses a heat-sealing positioning control method of a battery, which comprises the steps that a motor is in transmission connection with a conveying belt, a sensor, a material level stopping cylinder and a clamping cylinder are respectively connected with a controller, and the battery is conveyed by the conveying belt; the battery on the conveying belt is detected by the sensor to obtain sensing signals and transmit the sensing signals to the controller; and after receiving the sensing signals, the controller controls the material level stopping cylinder to stop the battery, controls the clamping cylinder to start to clamp the battery, and controls the motor to delay and stop operation so as to make the conveying belt delay and stop operation. The heat-sealing positioning control method of the battery disclosed by the invention effectively solves the problem that positioning deviation is prone to occur during heat sealing of the battery in the prior art, and enhances the heat-sealing efficiency and the product qualification rate.

Owner:ANHUI LEOCH POWER SUPPLY

Integrated advertising street lamp

InactiveCN108119856ASolve the problem of simple structure and not stable enoughStable structureMechanical apparatusElectric circuit arrangementsEngineeringSolar cell

The invention discloses an integrated advertising street lamp. The street lamp comprises a lamp pole, a base, a lamp cap and a storage battery; the lamp pole is fixed on the ground through the base, the position, close to the top end, of the lamp pole is connected with the lamp cap through a supporting rod, a rectangular embedding groove is formed in the part, below the lamp cap, of the lamp pole,and a multimedia display screen is embedded in the rectangular embedding groove; and a solar cell panel is connected to the top end of the lamp pole, the solar cell panel is connected with the storage battery arranged in the base through a wire, and the storage battery is connected with the display screen in series through a wire. According to the street lamp, the rectangular embedding groove isformed in the part, below the lamp cap, of the lamp pole, and the multimedia display screen is embedded in the rectangular embedding groove so that the multimedia display screen can still be quite stable even in strong wind weather; and the design of the street lamp is ingenious, the design of an integrated structure is achieved, the structure is very stable, and skewing and falling are not proneto happen.

Owner:宁波蔚燃文化传播有限公司

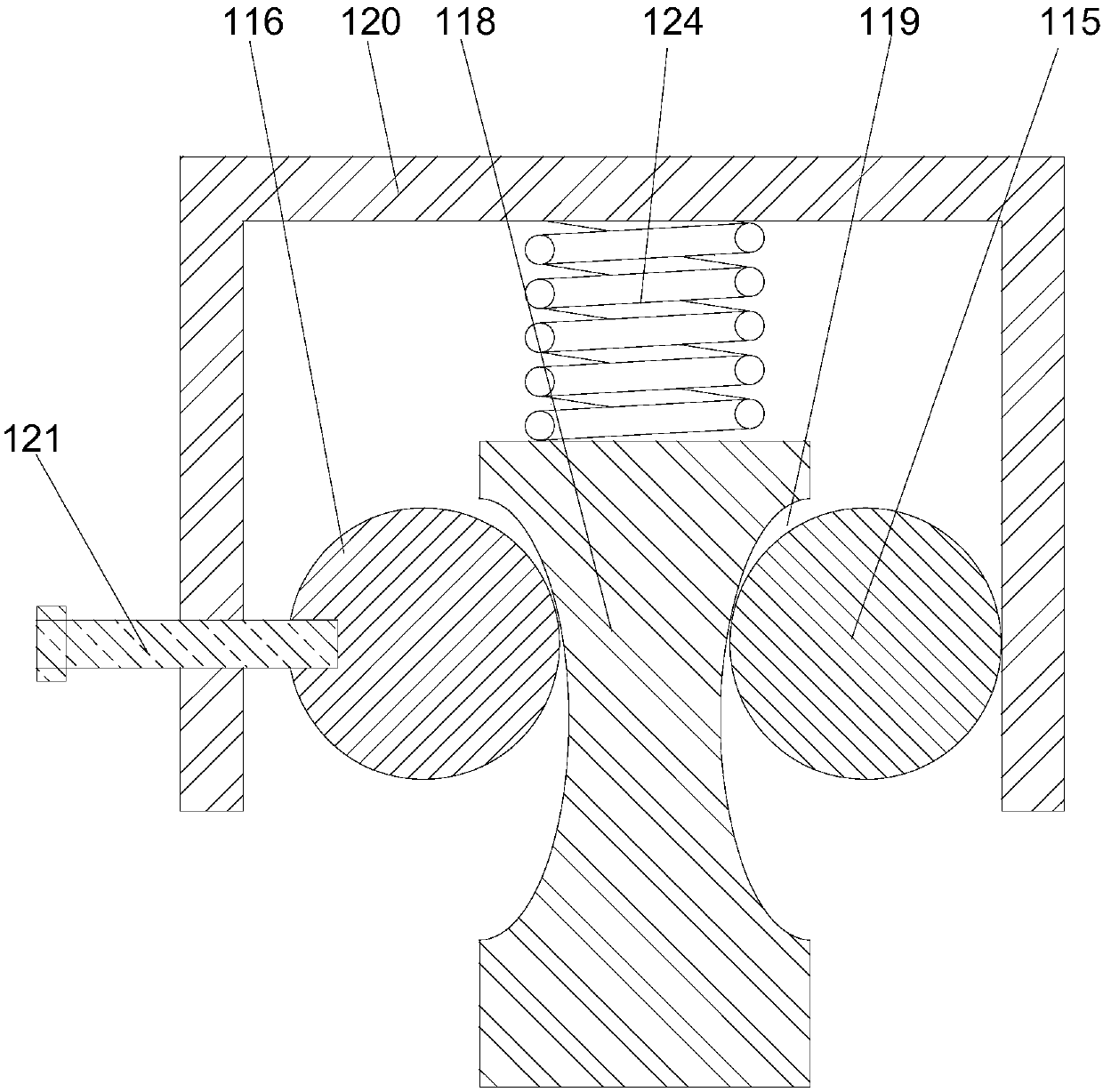

A road surface power generation mechanism arranged in a speed bump and its application in melting ice and snow

ActiveCN104481823BEfficient use ofOvercome the disadvantage of only using a single tripPaving detailsMachines/enginesSpeed bumpElectricity

The invention discloses a pavement power generating mechanism for use in speed bumps and application thereof in snow and ice thawing. A transmission structure is provided by using a bump pressure plate as a drive member. The pavement power generating mechanism is characterized in that the bump pressure plate is supported by springs to be higher than a pavement; pressure applied by an automobile running by drives the bump pressure plate to move down, achieving a downward stroke; after relief of the pressure, the bump pressure plate returns to the supported height, achieving an upward stroke; a transmission gear is fixed on a transverse transmission spindle and drives the same to rotate, thereby outputting torque from the transverse transmission spindle; an upper stroke drive structure and a lower stroke drive structure are identical in structure and are disposed on the left and right sides of the transmission gear, respectively; the upper stroke drive structure and the lower stroke drive structure alternately drive the transmission gear to rotate in a single same direction. The pavement power generating mechanism has the advantages that compression and return processes of a speed bump are bot made effective use, the transmission gear can keep rotating in the single direction, the limitation that upper and lower strokes are short is overcome, and electricity is continuously generated.

Owner:ANHUI HIGHWAY ENG CORP

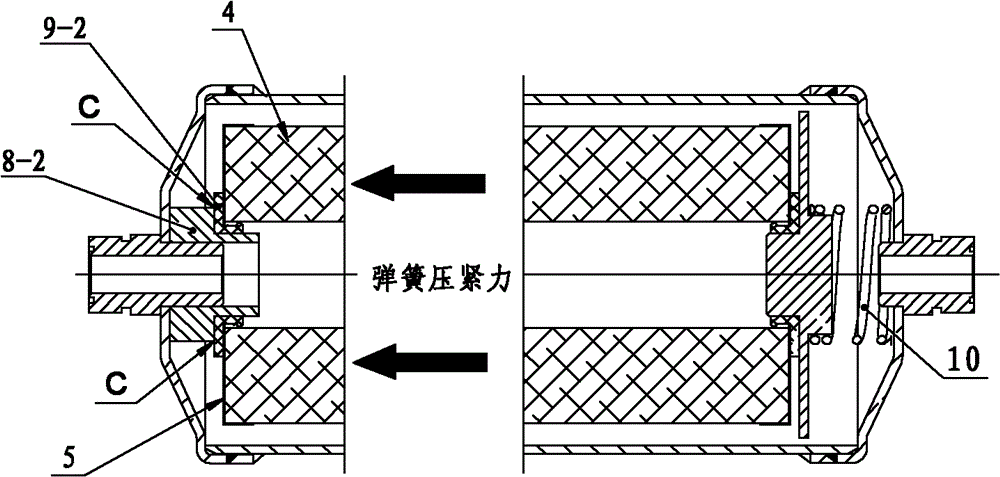

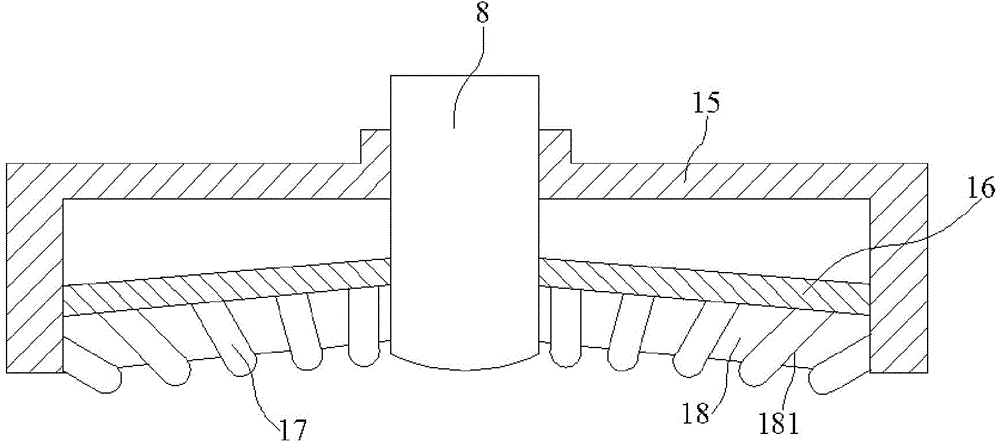

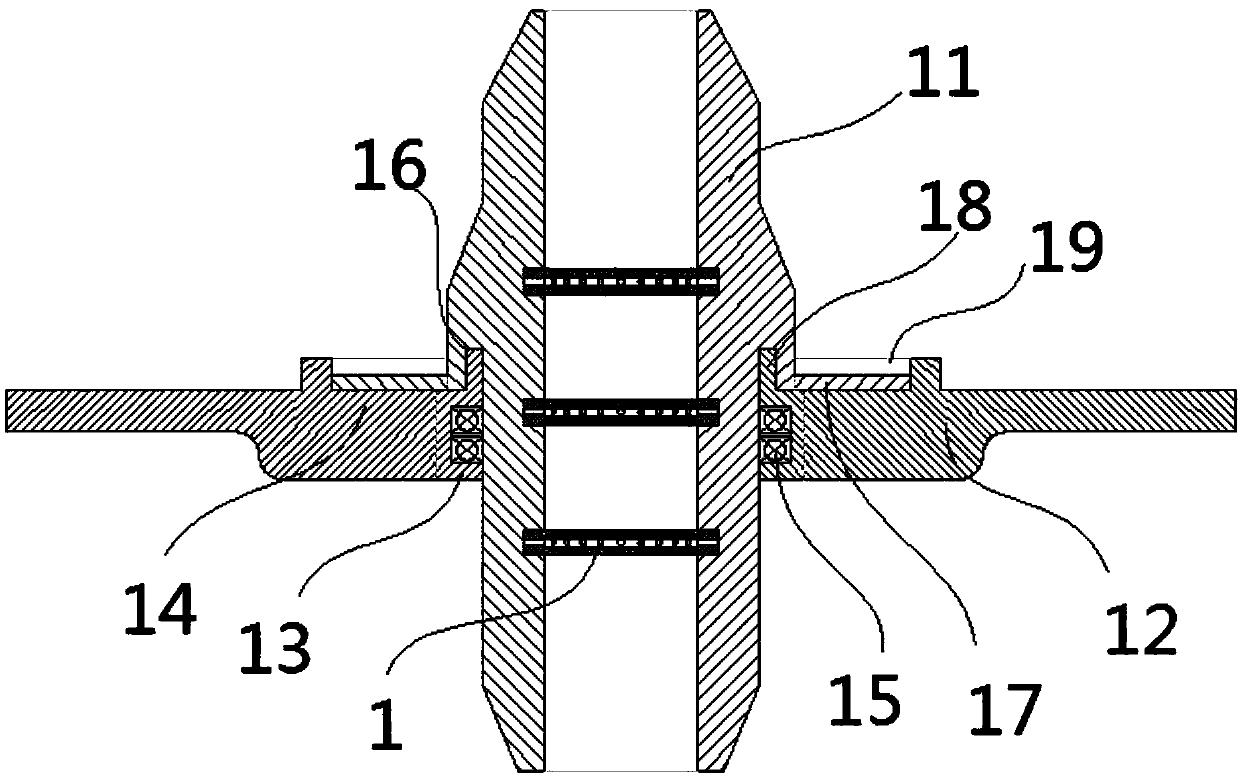

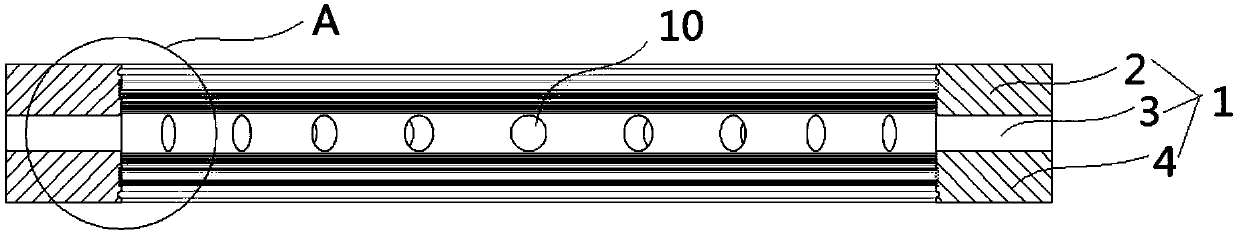

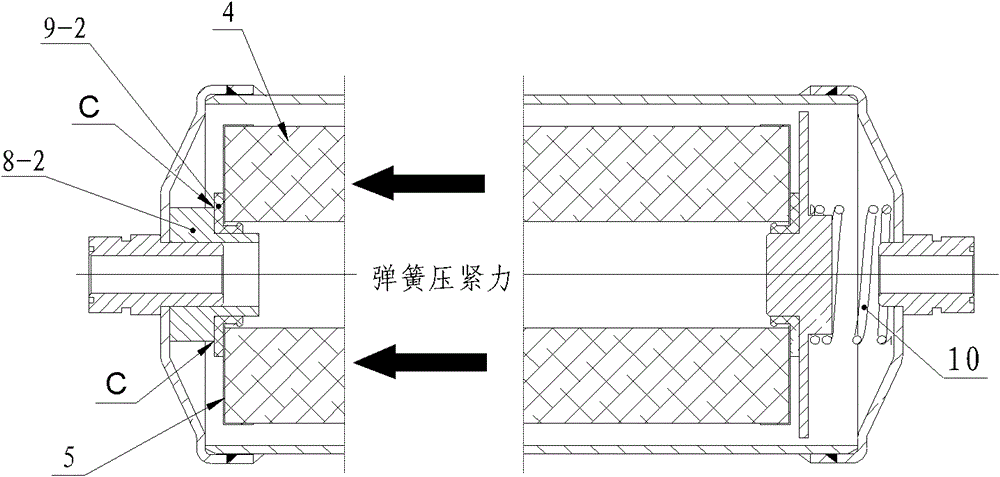

High-performance sealing shaft sleeve for spiral centrifugal pump

InactiveCN107906038AGuaranteed uptimeAxial stabilityPump componentsPumpsEngineeringMechanical engineering

The invention provides a high-performance sealing shaft sleeve for a spiral centrifugal pump. The high-performance sealing shaft sleeve for the spiral centrifugal pump comprises an inner shaft sleeveand an outer shaft sleeve; multiple sealing rings are arranged in the inner shaft sleeve; the outer shaft sleeve comprises a sleeve and a connecting plate; the inner shaft sleeve is provided with a ring groove and a positioning plate; the sleeve is provided with a ring plate; the connecting plate is provided with a positioning groove; the sealing rings comprise sealing upper parts, sealing middleparts and sealing lower parts; the sealing upper parts and the sealing lower parts are provided with symmetrical sealing structures; the sealing middle parts are provided with multiple elastic throughholes; and the sealing structures consist of two sets of airtight grooves and line sealing grooves. The high-performance sealing shaft sleeve for the spiral centrifugal pump is simple in structure, reasonable in design, stable in axial direction and not easy to incline; meanwhile, through arrangement of elastic through holes, the elastic stress of the sealing rings can be effectively improved toguarantee the sealing persistence; and line sealing, face sealing and air sealing are combined to greatly improve the sealing effect so as to guarantee efficient and stable operation of the spiral centrifugal pump.

Owner:ZHENJIANG FUTAIKE FLUID TECH CO LTD

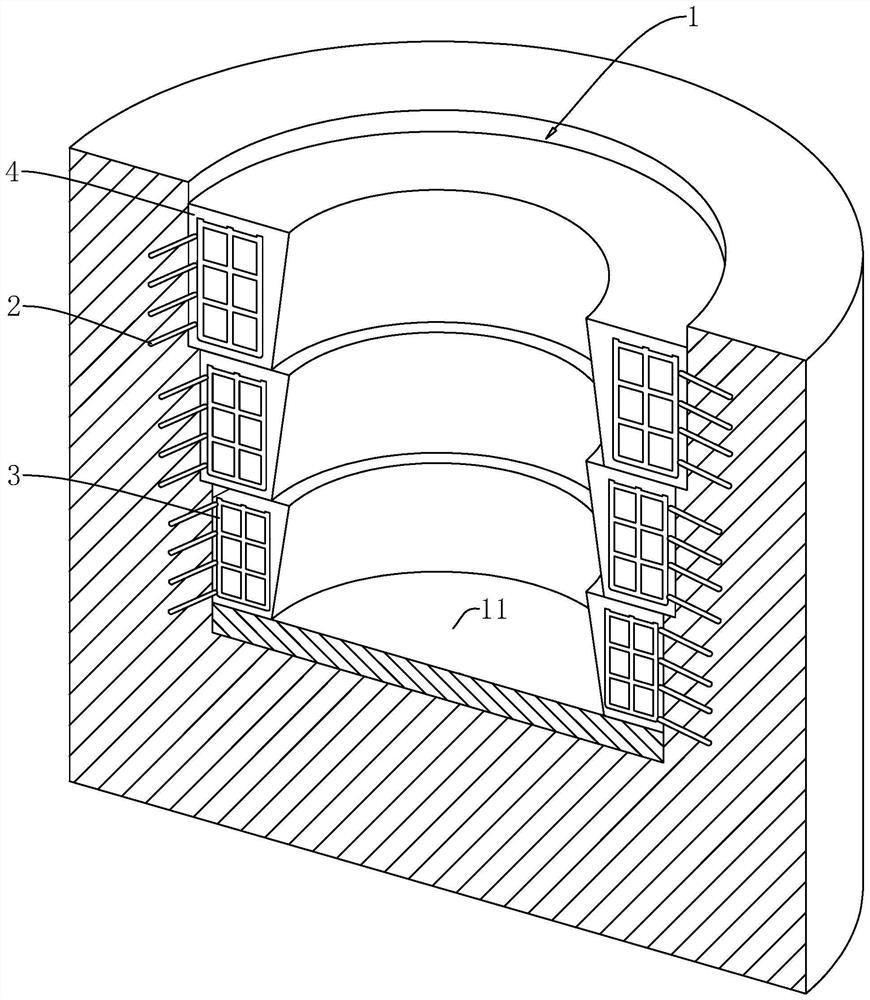

Open caisson structure applied to narrow zone and construction method of open caisson structure

ActiveCN113802608AEasy constructionGood structural stabilityArtificial islandsUnderwater structuresRebarCaisson

The invention relates to the technical field of open caisson construction, in particular to an open caisson structure applied to a narrow zone and a construction method of the open caisson structure. The open caisson structure comprises open caisson foundation pits formed by excavating downwards layer by layer, wherein each layer of open caisson foundation pit is an open caisson foundation pit unit, anchoring parts are evenly arranged on the pit wall of each open caisson foundation pit unit, steel reinforcement cages distributed annularly are arranged on the inner circumferential side of each open caisson foundation pit unit, the steel reinforcement cages are fixedly connected with the anchoring parts, annular concrete well walls poured outside the anchoring parts and the reinforcement cages are further arranged on the inner circumferential sides of the open caisson foundation pit units, the annular concrete well walls on the upper layer and the lower layer which are adjacent to each other are stacked up and down, and a concrete sealing bottom is arranged at the bottom of the lowermost open caisson foundation pit unit. The open caisson construction method comprises the steps of positioning, open caisson foundation pit unit excavation, anchoring part installation, reinforcement cage binding, pouring and bottom sealing. Reverse construction is carried out in a layer-by-layer downward mode, construction is more convenient, the structural stability is good, and deflection is not prone to occurring.

Owner:武汉市武昌市政建设(集团)有限公司

A replacement device and replacement method for tension insulator strings used in substations

ActiveCN112467615BEasy to operateNot easy to skewApparatus for overhead lines/cablesMechanical engineeringElectric power industry

This application relates to the technical field of the electric power industry, and in particular to a tension insulator string replacement device for a substation, which includes a fixing assembly for fixing the cross arm and a stretching assembly capable of stretching along a fixed direction, and the stretching assembly stretches Finally, the locking assembly is used for locking and fixing. The fixed assembly and the brace assembly are connected through a rotating seat. As for the position limiting component, the end of the stay component away from the rotating seat is provided with a self-locking hook for connecting with the power line. The application has the effect of facilitating the replacement of the tension insulator string during the maintenance process of the transmission line.

Owner:重庆巨鹏电力安装工程有限公司

Particleboard sawing tooling and sawing process

The invention discloses a shaving board saw cutting fixture which comprises a rack and a saw cutting motor arranged on the rack, wherein brackets are respectively arranged above two ends of the rack; a sliding support for mounting the saw cutting motor is arranged at the bottom of the rack; a supporting plate platform is arranged above the saw cutting motor; the sliding support can move along the lengthwise direction of the supporting plate platform; side plates are respectively arranged on two sides of the sliding support; the upper ends of the side plates are respectively bent towards the inner sides and are attached to the upper end surfaces of the brackets; an upper beam is arranged between the two side plates; the upper end surfaces of the two side plates are connected with each other through a bottom frame; a saw web supporting plate is arranged on the bottom frame; and a main rotating shaft for mounting a saw web is arranged on the saw web supporting plate. The shaving board saw cutting fixture can be used for improving the problem that existing shaving board machining equipment is inconvenient for locating the saw cutting saw web and a shaving board to be subjected to saw cutting, thus realizing rapid saw cutting for the shaving board.

Owner:SICHUAN J&F FOREST IND CORP

A kind of oil filter and refrigeration system

ActiveCN102743915BSimple structureReduce manufacturing costRefrigeration componentsStationary filtering element filtersEngineeringRefrigeration

The present invention relates to the technical field of filter, and especially discloses an oil filter with a stably and reliably positioned filter component. The oil filter comprises a shell, a front end cover, a rear end cover and a filter component. The front end cover is provided with an inlet joint; the rear end cover is provided with an outlet joint; and end face of an outlet end of the filter component abuts against an inner side surface of the rear end cover; and the outlet joint and the outlet of the filter component form a socket cooperation. The oil filter can realize stability and reliability of positioning of the filter component; deflection is not likely to happen; and during a welding process of the front end cover and the shell, failure of the filter component caused by local high temperature and heating will not happen. A second supporting seat between the outlet joint and the filter component, and a welding process on the second supporting seat and the outlet joint are canceled, so as to realize simple process, simple structure of the oil filter and low manufacturing cost. The invention also discloses a refrigerating system with the oil filter.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Sealing machine for medical plastic packaging bags

PendingCN111959886ALess prone to skewImprove seal qualityWrapper twisting/gatheringPlastic packagingEngineering

The invention provides a sealing machine for medical plastic packaging bags. The sealing machine comprises a shell, a material frame, a feeding mechanism, a sealing mechanism and a cutting mechanism,wherein the material frame, the feeding mechanism, the sealing mechanism and the cutting mechanism are arranged on the shell; the feeding mechanism comprises a bracket and a feeding roller and a pressing roller which are rotationally connected to the bracket, and a channel for allowing the plastic packaging bags to penetrate is formed between the feeding roller and the pressing roller; one end ofa discharging roller is connected with a material roller driving part, and the material roller driving part is used for driving the feeding roller to rotate; and the feeding mechanism is arranged in front of the sealing mechanism, so that the plastic packaging bags penetrate through the gap between a heating plate and a bottom plate, and after the sealing of the plastic packaging bags is completed, the cutting mechanism cuts the plastic packaging bags. Due to the fact that the remaining plastic packaging bags are still under the clamping of the feeding roller and the pressing roller, the plastic packaging bags can be fed into the gap between the heating plate and the bottom plate only by driving the feeding roller when the plastic packaging bags are sealed next time, the operation is simple, and the efficiency is high; and moreover, due to the clamping effect of the feeding roller and the pressing roller, the sealing of the plastic packaging bags is not prone to skewing, and the sealing quality is improved.

Owner:NINGBO LIFE MEDICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com