Synchronizer shifting fork gear shift mechanism for tractor

A technology of shifting mechanism and synchronizer, which is applied in the direction of instruments, controlled components, mechanical equipment, etc., to achieve the effect of flexible movement, stable and firm installation in the gear position self-locking device, and assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

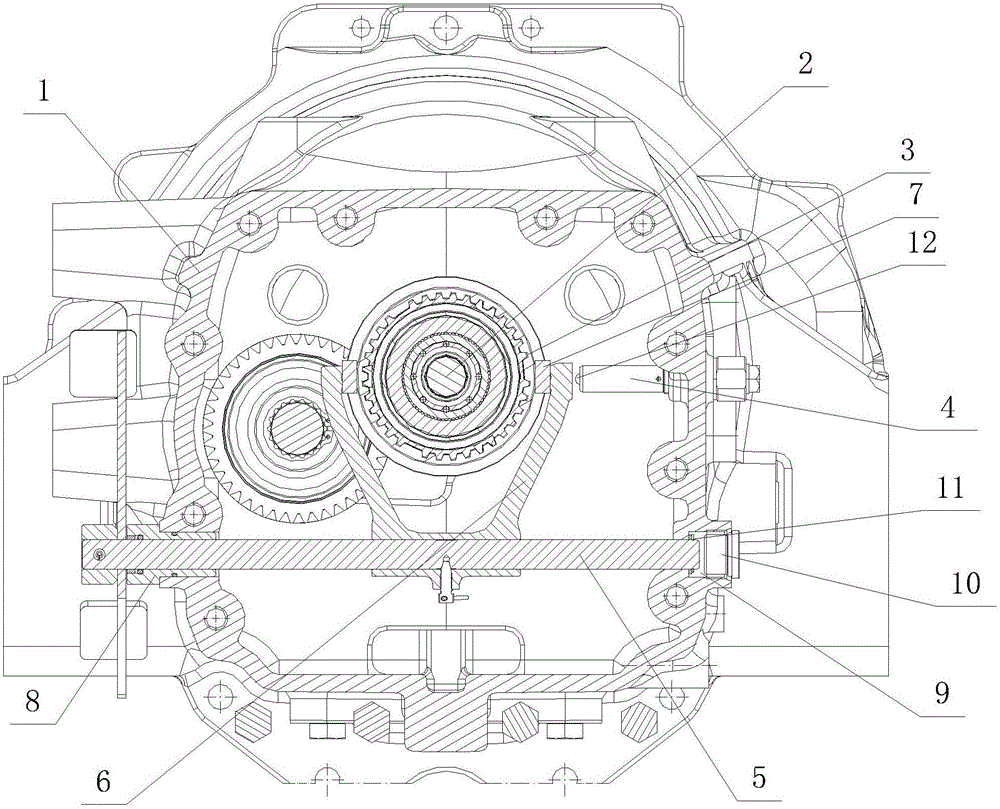

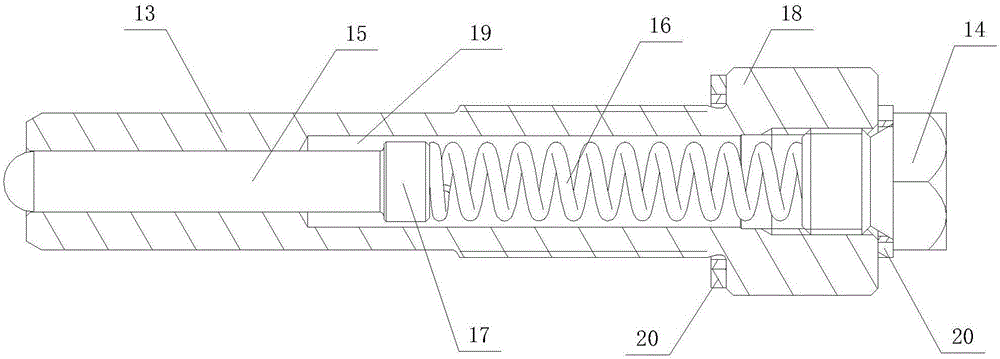

[0048] like Figure 1 to Figure 2 As shown, a synchronizer fork shift mechanism for a tractor is arranged in a gearbox housing 1 and includes a gear shaft 2 , a shift fork shaft 5 , a shift fork 6 and a gear self-locking device 4 . The shift shaft 2 and the shift fork shaft 5 are perpendicular to each other, and are respectively connected in rotation with the gearbox case 1 . The first gear, the synchronizer 3 and the second gear are sequentially set on the gear shaft 2; the first gear and the second gear are respectively connected in rotation with the gear shaft 2; Synchronizer 3 is slidably connected with gear shaft 2 through splines.

[0049] The outer edge of the synchronizer 3 is provided with an annular groove, and is located in the same plane as the shift fork 6 . One end of the shift fork 6 is fixedly connected to the shift fork shaft 5, and the other end is close to the outer edge of the synchronizer 3, and is provided with a shift block 7; the shift block 7 is inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com