Machining mechanism for automobile cylinder covers

A technology of machining and automobile cylinders, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome procedures, affecting milling efficiency, and repositioning of clamping, so as to improve processing efficiency and reduce processing The effect of increasing the duration and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

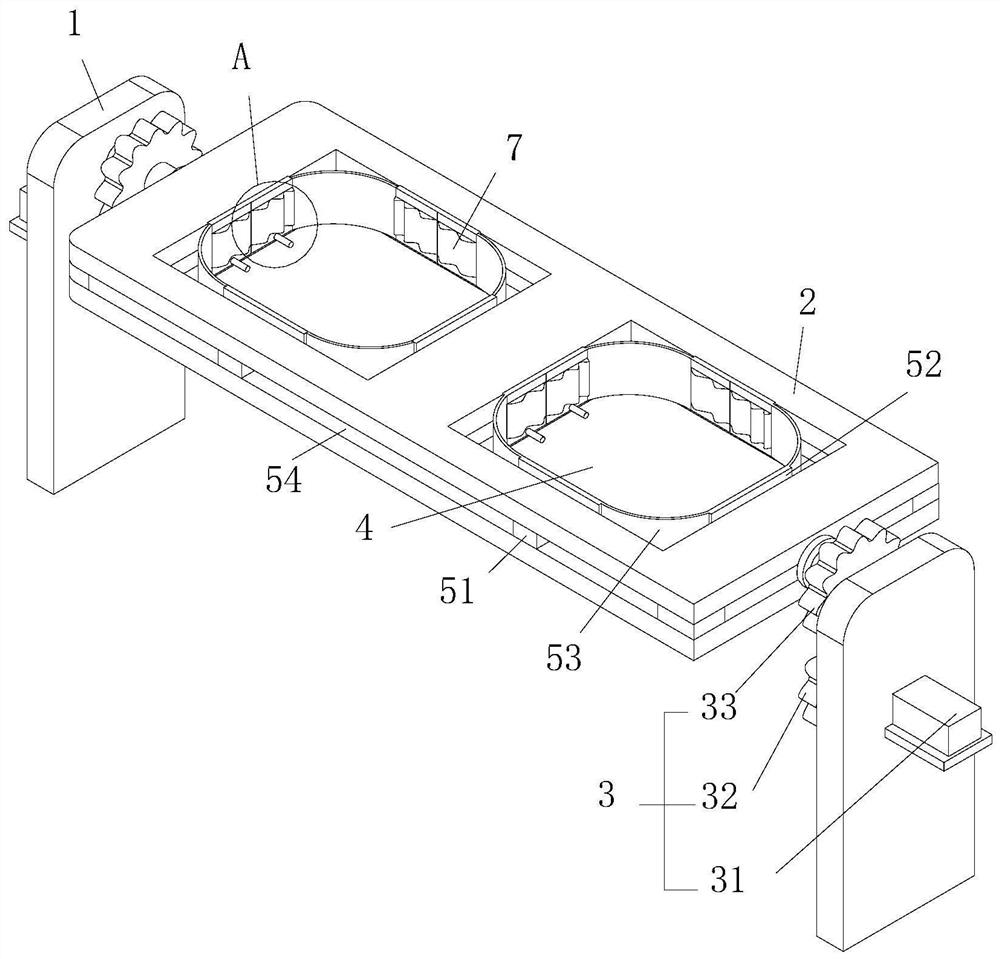

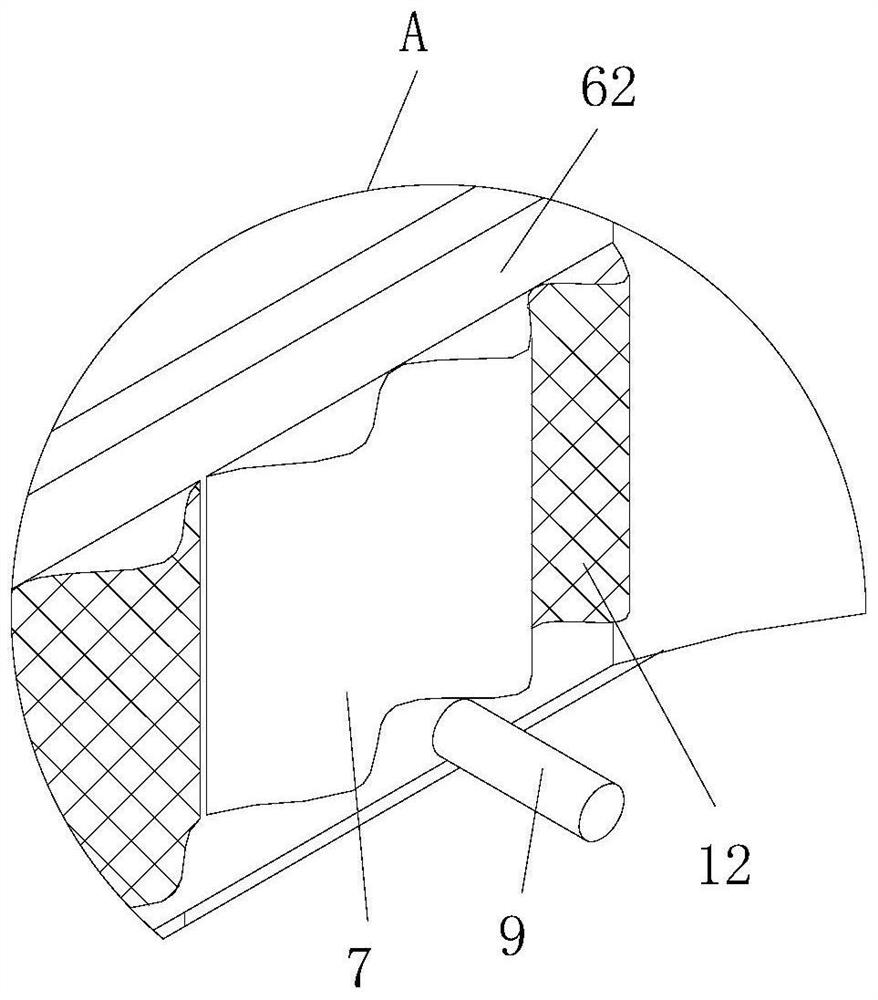

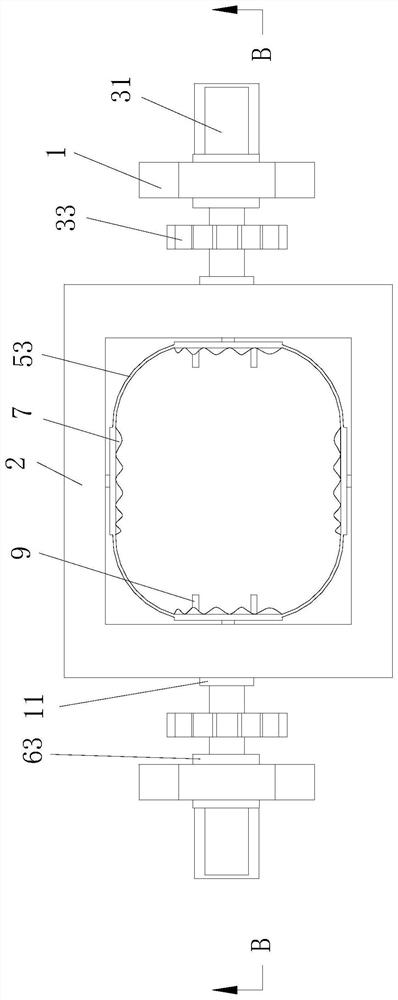

[0031] Attached below Figure 1-6 The present invention is further described with embodiment:

[0032] A machining mechanism for an automobile cylinder head, comprising a frame 1, a processing bed 2 and a processing groove 4, the frame 1 is symmetrically distributed on both sides of the processing bed 2, and the processing bed 2 is provided with several processing grooves 4, so The processing groove 4 is used to place the cylinder head 8 to be processed, the driving mechanism 3 is arranged between the processing bed 2 and the frame 1, the clamping mechanism 5 is arranged on the processing bed 2, and the processing bed 2 A lifting mechanism 6 is also arranged on the lower surface; the processing bed 2 is driven by the driving mechanism 3 to turn over a single angle of 180 degrees, and the processing bed 2 is initially in a horizontal state. When the present invention is machining the automobile cylinder head 8, by setting one or two processing grooves 4 on the processing bed 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com