Rapid locking clamp

A clamping and fast technology, applied in the direction of clamping, manufacturing tools, support, etc., can solve the problems of wasting manpower and material resources, time, and cumbersome operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

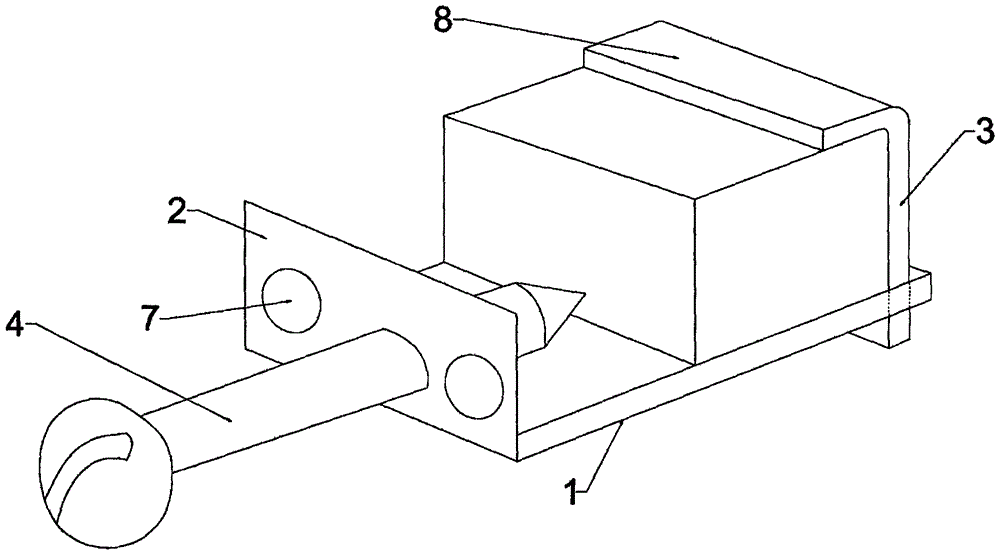

[0014] Depend on figure 1 It can be seen that a fast locking fixture of the present invention includes a bottom plate 1, a left side plate 2, a right side plate 3 and locking screws 4, the bottom plate 1 and the left side plate 2 are integrally structured, and the right side of the bottom plate 1 has A chute 5, the right side of the chute 5 is provided with a positioning bolt 6 threaded with the bottom plate 1, the right side plate 3 passes through the chute 5 from top to bottom, and the left side plate 2 is provided with a plurality of The through hole 7, the locking screw 4 is threadedly matched with the through hole 7, the upper cover 8 is provided on the 3 ends of the right side plate, the upper cover 8 is provided with a fastening bolt 9, and the upper cover 8 is provided with a fastening bolt 9. The cover 8 is integrated with the right side plate 3 , and the upper cover 8 and the right side cover 3 have an arc transition.

[0015] During the work of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com