Servo drive mechanism of sewing machine

A servo-driven, sewing machine technology, applied in the field of sewing machines, can solve the problems affecting the torque and noise performance of the sewing machine, the difficulty of processing and assembling parts, and the high production cost, and achieve the effect of simple structure, easy processing of parts, and reduced difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

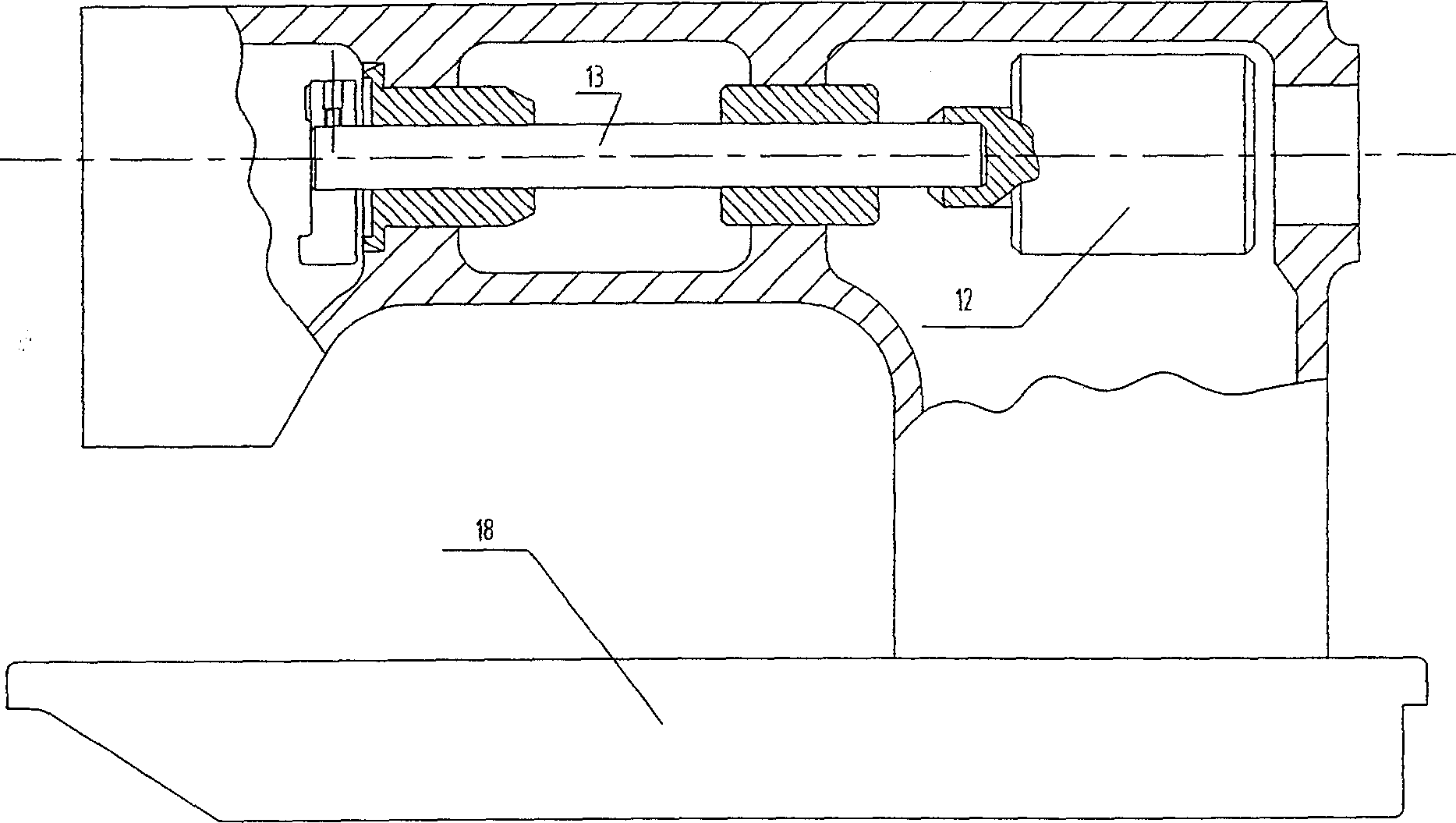

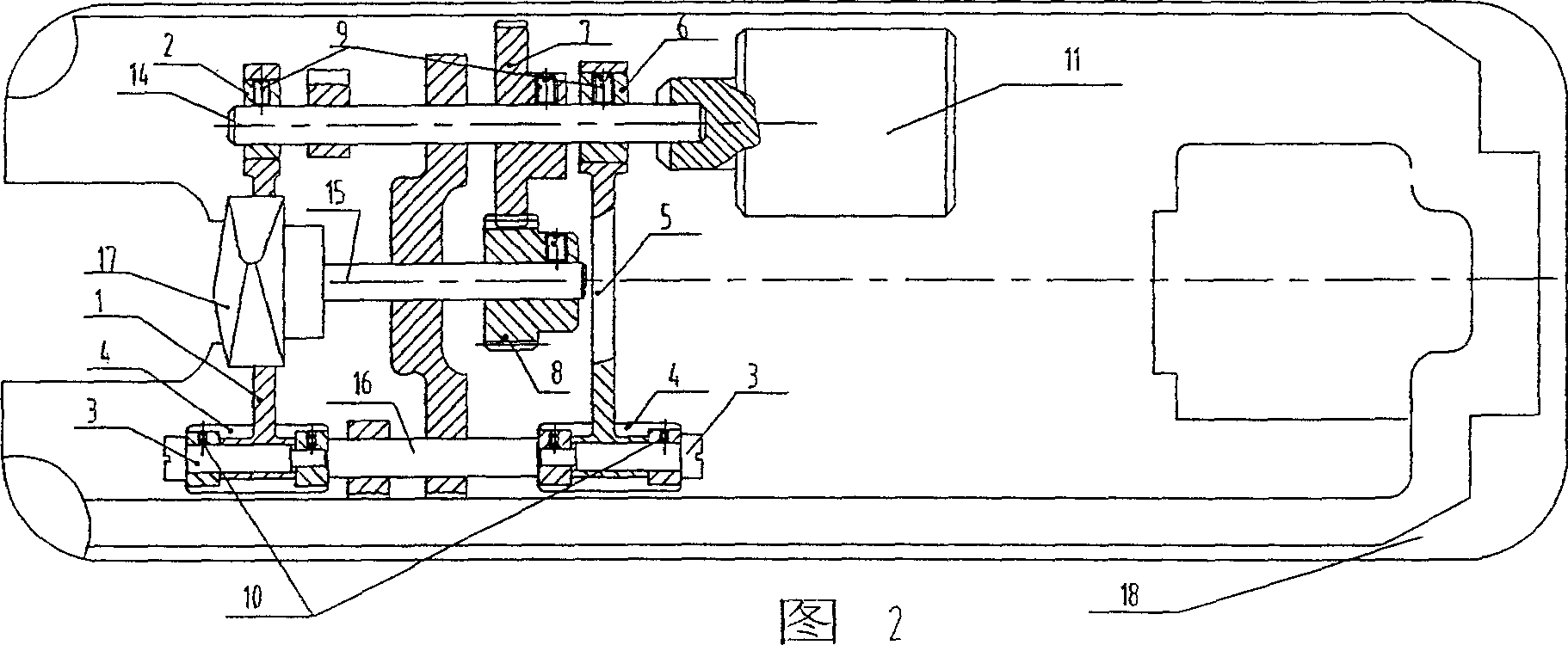

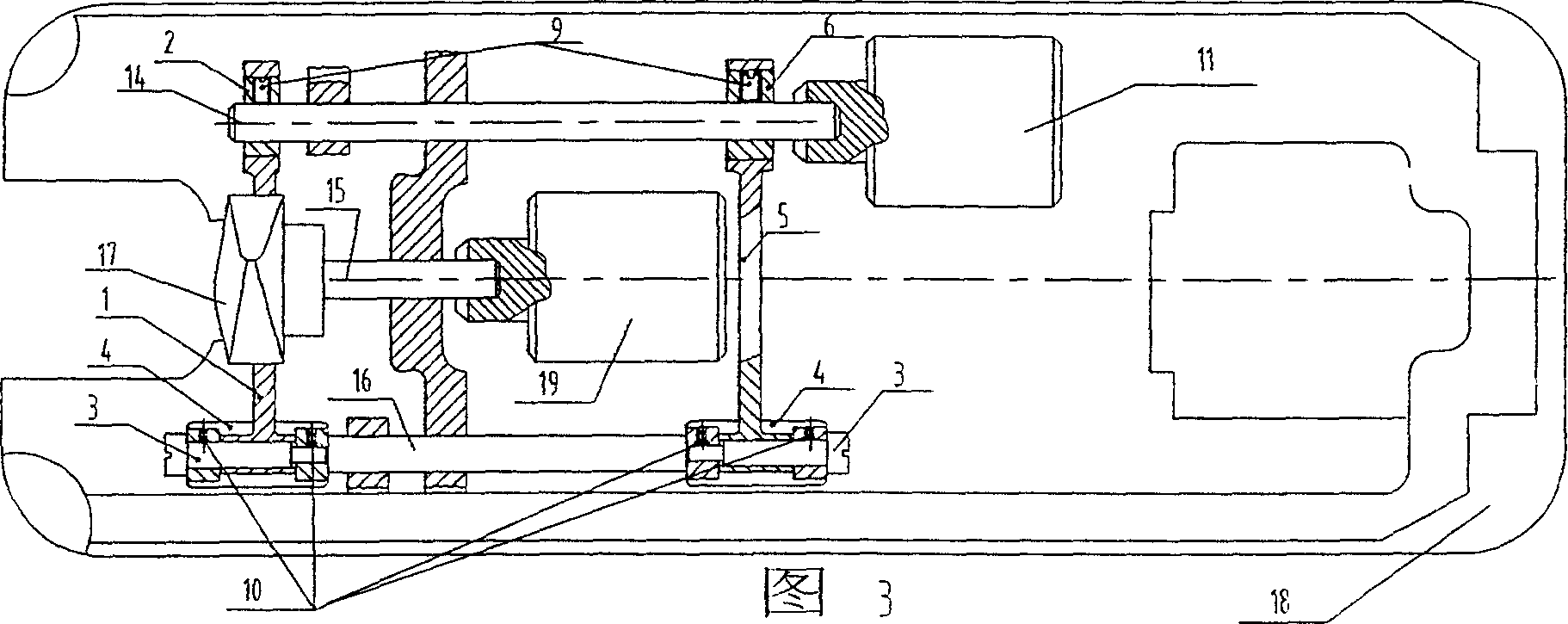

[0016] refer to figure 1 , Figure 2, the upper shaft 13 of the lockstitch machine is directly driven by the servo motor 12 and rotates; the tooth lifting shaft 14 is directly driven by the servo motor 11 and rotates. The right end of the lifting tooth shaft 14 is equipped with a feeding cam 6 and fixed with a set screw 9. The two ends of the feeding shaft 16 are respectively covered with a sleeve 4 and fixed by a set screw 10. The upper end of the feeding connecting rod 5 is sleeved on the feeding cam 6, and the lower end The pin shaft 3 is connected to the sleeve 4, so that the rotation of the feeding cam 6 is driven by the feeding connecting rod 5 to drive the feeding shaft 16 to swing back and forth; like Figure 4 As shown), the upper end is sleeved on the tooth-lifting cam 2, and the lower end is connected to the sleeve 4 mounted on the left end of the feeding shaft 16 through the pin shaft 3, so that the feeding shaft 16 swings back and forth to drive the tooth frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com