Hybrid adhesive and the use thereof in engineered wood boards

An adhesive, hybrid technology, used in the field of manufacturing wood panels, can solve the problems of incompatibility, poor process performance, etc., to achieve the effect of improved ecology and compatibility, improved requirements, excellent workability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0083] Example 1: Manufacture of the first hybrid adhesive

[0084] Provides a urethane matrix in which OH groups or unincorporated cyanamide groups are also present. SiO 2 The granules are mixed into the urethane matrix in the desired amount. Subsequently, isocyanopropyltriethoxysilane and the possible initiator dibutylisotin dilaurate are added for the case where the polyurethane does not yet contain an initiator. The mixture was heated to 50°C and maintained at this temperature for about 30 minutes. After cooling to room temperature, glycidoxypropyltriethoxysilane and an acid such as phosphoric acid as catalyst are added and stirring is continued for 60 minutes. Subsequently, the polyurethane-silane-SiO thus prepared 2 The mixture is mixed with melamine resin.

example 2

[0085] Example 2: Manufacture of a Second Hybrid Adhesive

[0086] An ethanol / water mixture was provided to which was added a mixture of glycidoxypropyltriethoxysilane and ethyl orthosilicate. Subsequently, the aqueous silica sol solvent, that is to say nano-scale SiO 2 The particles are added to water, and an acid such as acetic acid or p-toluenesulfonic acid is added as a catalyst. After 5 minutes of stirring time, the melamine resin mixture was added and after an additional 20 minutes of stirring time, the polyurethane adhesive was added.

example 3

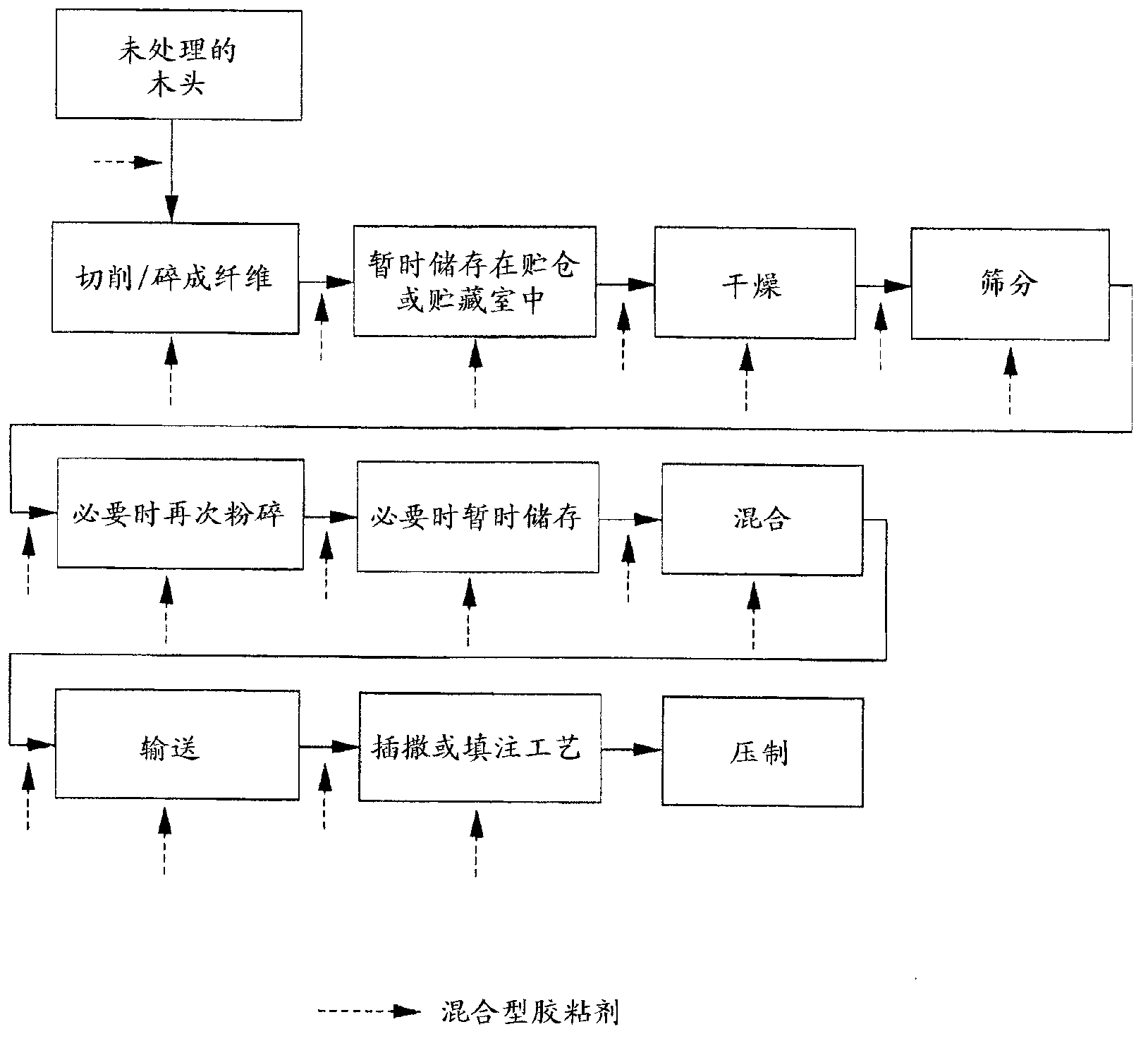

[0087] Example 3: Particle Board Manufacturing

[0088] Chip shape and chip size have a decisive influence on the quality of the chipboard. The middle layer is made of larger wood chips that give the board stability, the covering layer (outer layer) should be made of smaller wood chips in order to get a flat and regular surface. Depending on the raw material the shape and size of the chips can be influenced for better or for worse. Therefore, in order to manufacture a product of good quality, modern chipboard processes always use a certain proportion of fine-grained wood chips for a flat, uniform covering layer, and a major proportion of stable wood chips under the covering board. , layered structures, chipped new and old wood with chips of different lengths (new logs or sawn waste, e.g. bark, firewood, old wood).

[0089] The lumberyard is the entry point for raw materials. In this case, the different types of wood (quality of wood, storage capacity, quantity determinati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com