Carbonization wood finger-joint glued-laminated timber and its manufacturing method

A manufacturing method and technology of carbonized wood, applied in the direction of chemical instruments and methods, manufacturing tools, wood layered products, etc., can solve the problems of decay and moth, easy to change color, easy to deform size, etc., to achieve easy gluing and painting, reduce Hydrophilic properties, the effect of eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

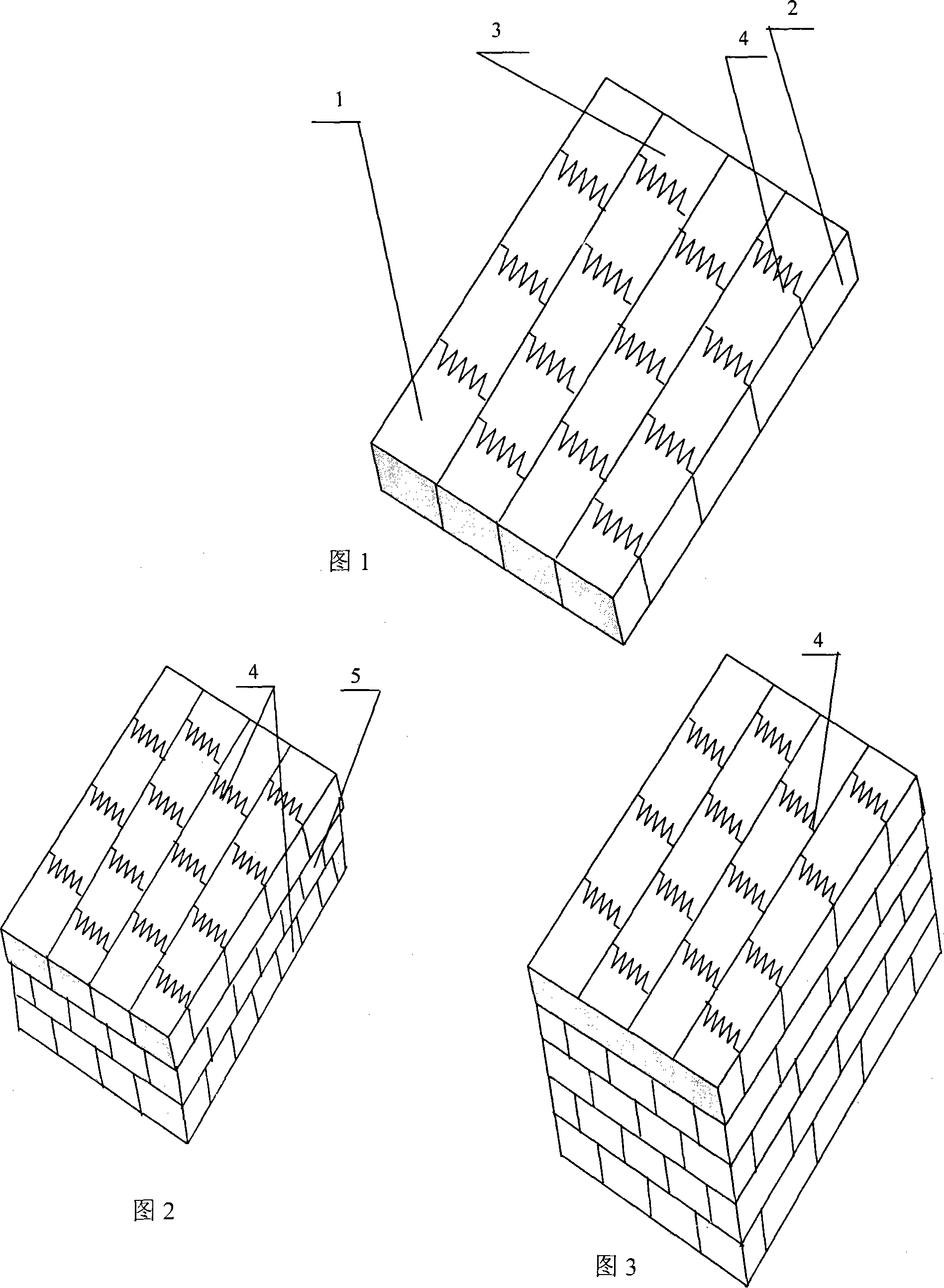

[0021] Referring to Figure 1, the structure of the carbonized wood finger-jointed integrated board: the carbonized finger-joined integrated board 4 is made of middle slats 1 with finger-jointed tenons processed at both ends after removing defects, and processed with finger-jointed tenons at one end The end slats 3 are lengthwise bonded by glue-coated mortises to a specified length and the sides of the slats 2 are glued to form a specified width. Its main purpose is to make solid wood furniture.

[0022] Manufacturing method:

[0023] a. Cutting and splitting: According to the bending condition, cut the log with medium and small diameter into 1-2m long wood section, and cut it into slats with a thickness of 20mm and a width of 30, 40, 50, 70mm according to the diameter with a band saw and a multi-blade saw .

[0024] b. Carbonization: Use spacers to stack the material carts supporting the carbonization equipment according to the requirements, place heavy objects on the top of...

Embodiment 2

[0030] Carbonized wood finger-joined glulam door frame structure: The structure of carbonized wood finger-joined glulam door frame is the same as that of integrated panels.

[0031] Manufacturing method: Saw logs into two specifications of slats with a thickness of 36mm, a width of 59mm and a width of 62mm. When using the above method for carbonization, the carbonization time should be extended appropriately; the planing, finger jointing, and paneling procedures are the same as the above method; according to the drawings, carry out post-processing such as pulling grooves, keyholes, and milling hinge grooves.

Embodiment 3

[0033] Referring to accompanying drawing 2, the structure of the carbonized wood finger-joined glulam concrete formwork: the carbonized wood finger-joined glulam concrete formwork is formed by gluing in the thickness direction two layers of integrated boards 4 laid vertically and one layer of integrated boards 5 laid horizontally.

[0034] Manufacturing method: use the same method as above a, b, c, d, e to manufacture carbonized wood finger joint integrated board (thickness about 11mm), the adhesive used is urea-formaldehyde resin or modified urea-formaldehyde resin or phenolic resin according to customer requirements . The three-layer integrated board is hot-pressed and glued to synthesize the concrete formwork (thickness 30mm), of which the second layer is double-sided coated with urea-formaldehyde or phenolic resin, and its fiber direction is perpendicular to the upper and lower laminates. The hot-pressing temperature is 140°C, the pressure is 1.0 MPa, the hot-pressing time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com