Carbonization wood finger-joint glued-laminated timber and its manufacturing method

A manufacturing method and technology of carbonized wood, applied in chemical instruments and methods, manufacturing tools, wood-layered products, etc., can solve the problems of decay and moth-eaten, easy to discolor, easy to deform in size, etc., to achieve easy gluing and finishing, reduce Hydrophilic properties, the effect of eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

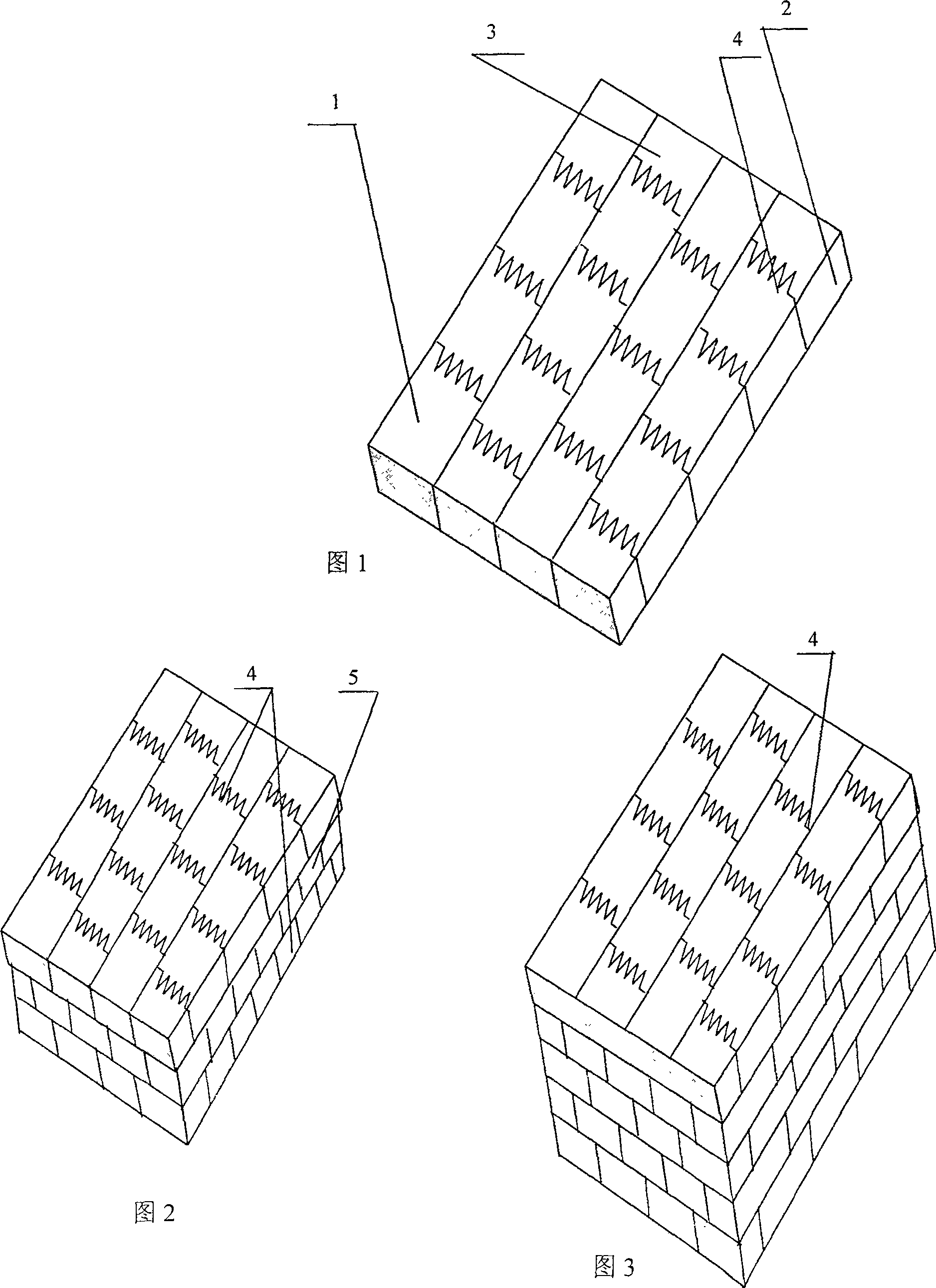

[0021] Referring to Figure 1, the structure of the carbonized wood finger-jointed integrated board: the carbonized finger-joined integrated board 4 is made of middle slats 1 with finger-jointed tenons processed at both ends after removing defects, and processed with finger-jointed tenons at one end The end slats 3 are lengthwise bonded by glue-coated mortises to a specified length and the sides of the slats 2 are glued to form a specified width. Its main purpose is to make solid wood furniture.

[0022] Manufacturing method:

[0023] a. Cutting and splitting: According to the bending condition, cut the log with medium and small diameter into 1-2m long wood section, and cut it into slats with a thickness of 20mm and a width of 30, 40, 50, 70mm according to the diameter with a band saw and a multi-blade saw .

[0024] b. Carbonization: Use spacers to stack the material carts supporting the carbonization equipment according to the requirements, place heavy objects on the top of...

Embodiment 2

[0030] Carbonized wood finger-joined glulam door frame structure: The structure of carbonized wood finger-joined glulam door frame is the same as that of integrated panels.

[0031] Manufacturing method: Saw logs into two specifications of slats with a thickness of 36mm, a width of 59mm and a width of 62mm. When using the above method for carbonization, the carbonization time should be extended appropriately; the planing, finger jointing, and paneling procedures are the same as the above method; according to the drawings, carry out post-processing such as pulling grooves, keyholes, and milling hinge grooves.

Embodiment 3

[0033] Referring to accompanying drawing 2, the structure of the carbonized wood finger-joined glulam concrete formwork: the carbonized wood finger-joined glulam concrete formwork is formed by gluing in the thickness direction two layers of integrated boards 4 laid vertically and one layer of integrated boards 5 laid horizontally.

[0034] Manufacturing method: use the same method as above a, b, c, d, e to manufacture carbonized wood finger joint integrated board (thickness about 11mm), the adhesive used is urea-formaldehyde resin or modified urea-formaldehyde resin or phenolic resin according to customer requirements . The three-layer integrated board is hot-pressed and glued to synthesize the concrete formwork (thickness 30mm), of which the second layer is double-sided coated with urea-formaldehyde or phenolic resin, and its fiber direction is perpendicular to the upper and lower laminates. The hot-pressing temperature is 140°C, the pressure is 1.0 MPa, the hot-pressing time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com