Wood-structure glued-laminated timber flexible machining production line and flexible machining method

A flexible processing and glulam technology, applied in wood processing appliances, manufacturing tools, multi-purpose machinery, etc., can solve the problems of low quality supervision of glulam production, high production cost, low efficiency of glulam production, etc. The product quality is guaranteed, the automation level is improved, and the utilization rate is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

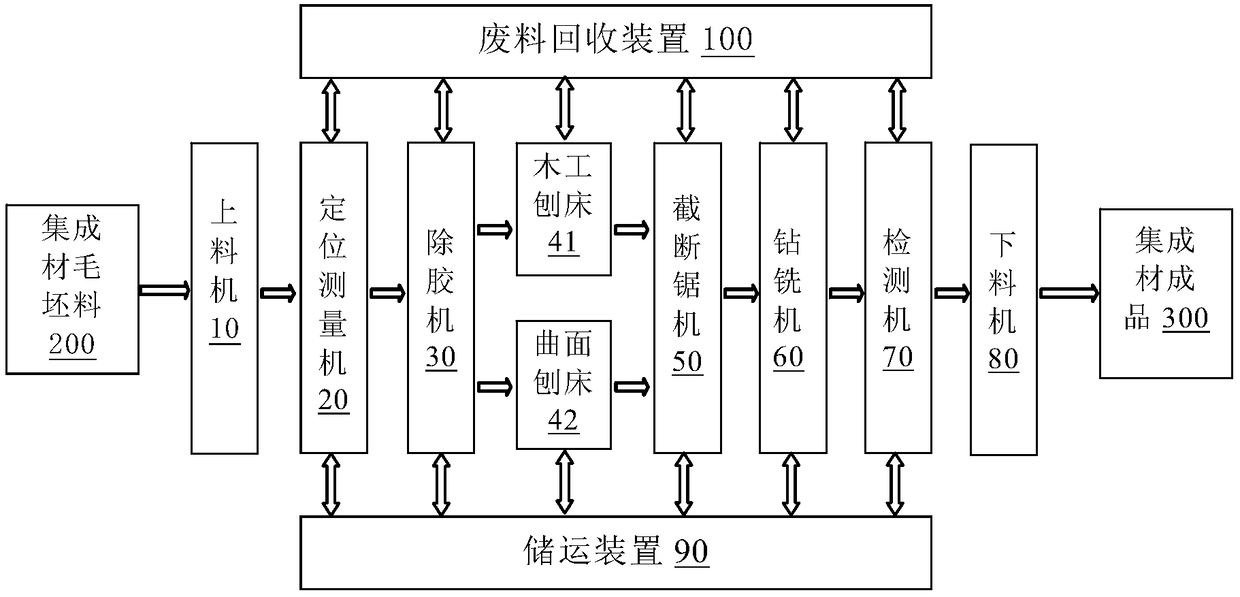

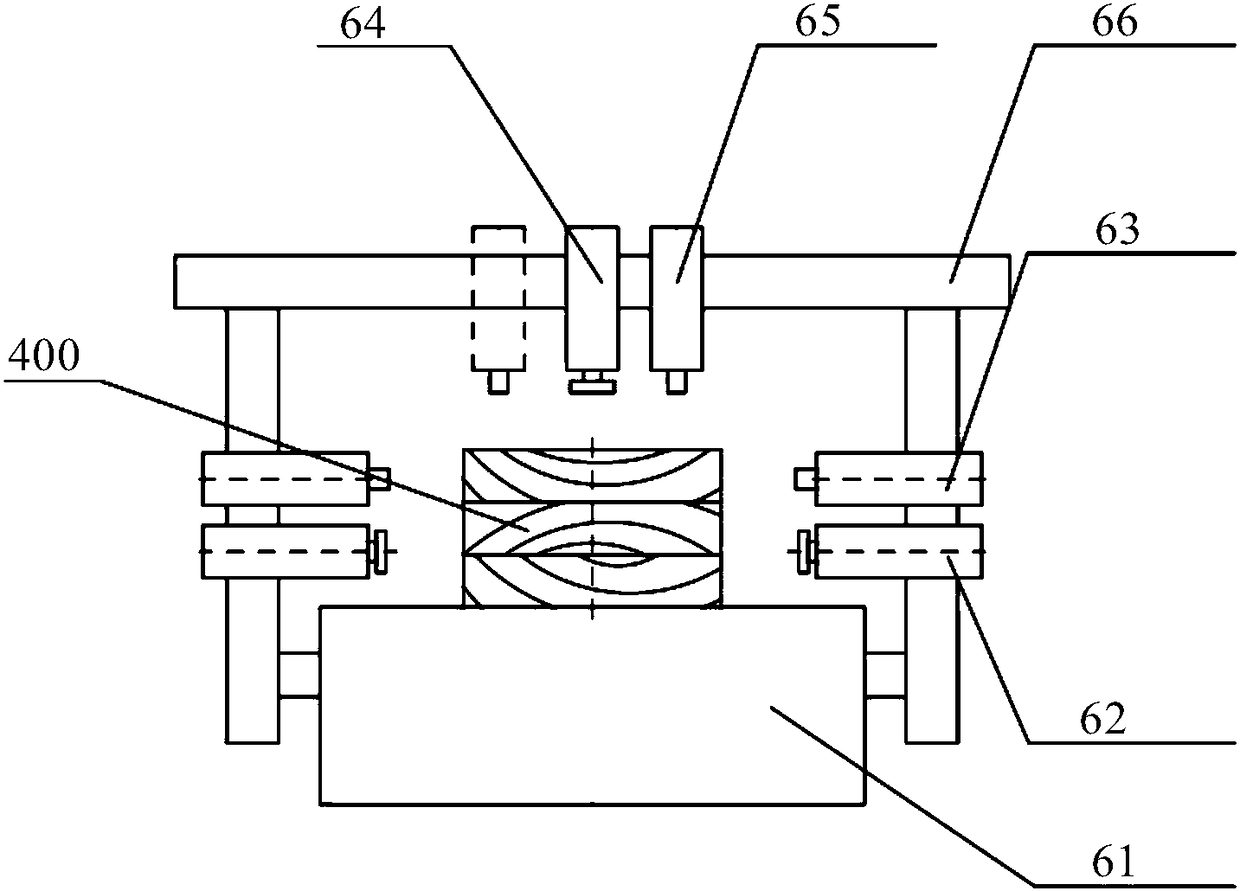

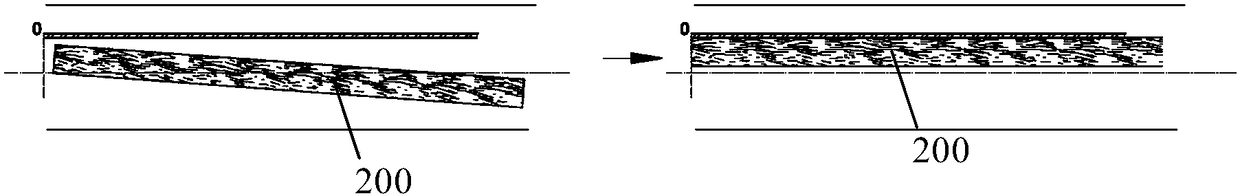

[0022] like figure 1 As shown, the wood-structured glulam flexible processing production line of the present invention includes a feeder 10, a positioning and measuring machine 20, a glue remover 30, a planer, a cutting saw 50, a drilling machine, which are arranged in the required order and connected end to end in the processing and production. Milling machine 60, testing machine 70 and blanking machine 80, wherein: the planer includes woodworking planer 41 and curved surface planer 42 arranged side by side, that is, according to processing and production needs, feeding machine 10 passes through positioning measuring machine 20, deglue machine 30, Woodworking planer 41, cut-off saw machine 50, drilling and milling machine 60, detection machine 70 are connected with blanking machine 80, or feeder 10 passes through positioning measuring machine 20, glue remover 30, curved surface planer 42, cut-off saw machine 50, The drilling and milling machine 60, the testing machine 70 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com