Wood flooring composed of wpl, base and soundproof layer

A floor and substrate technology, applied in the field of laminated wood flooring, can solve problems such as not being able to meet various needs of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

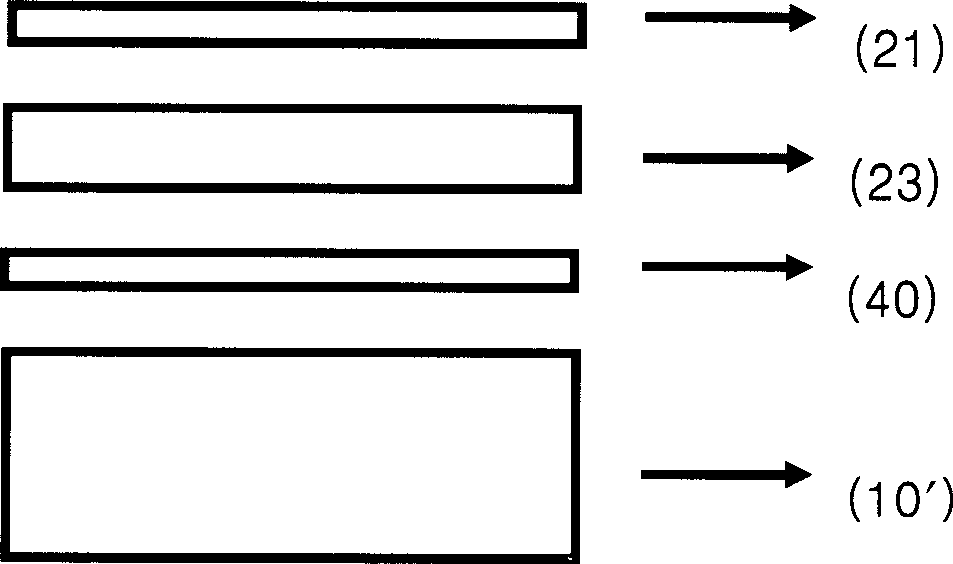

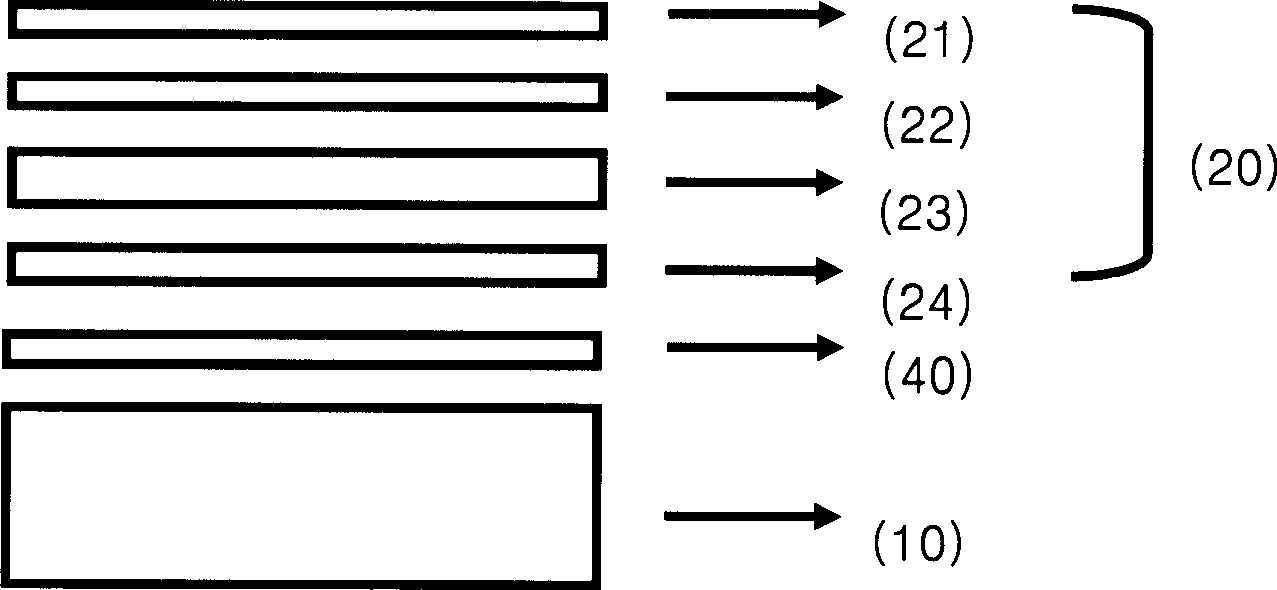

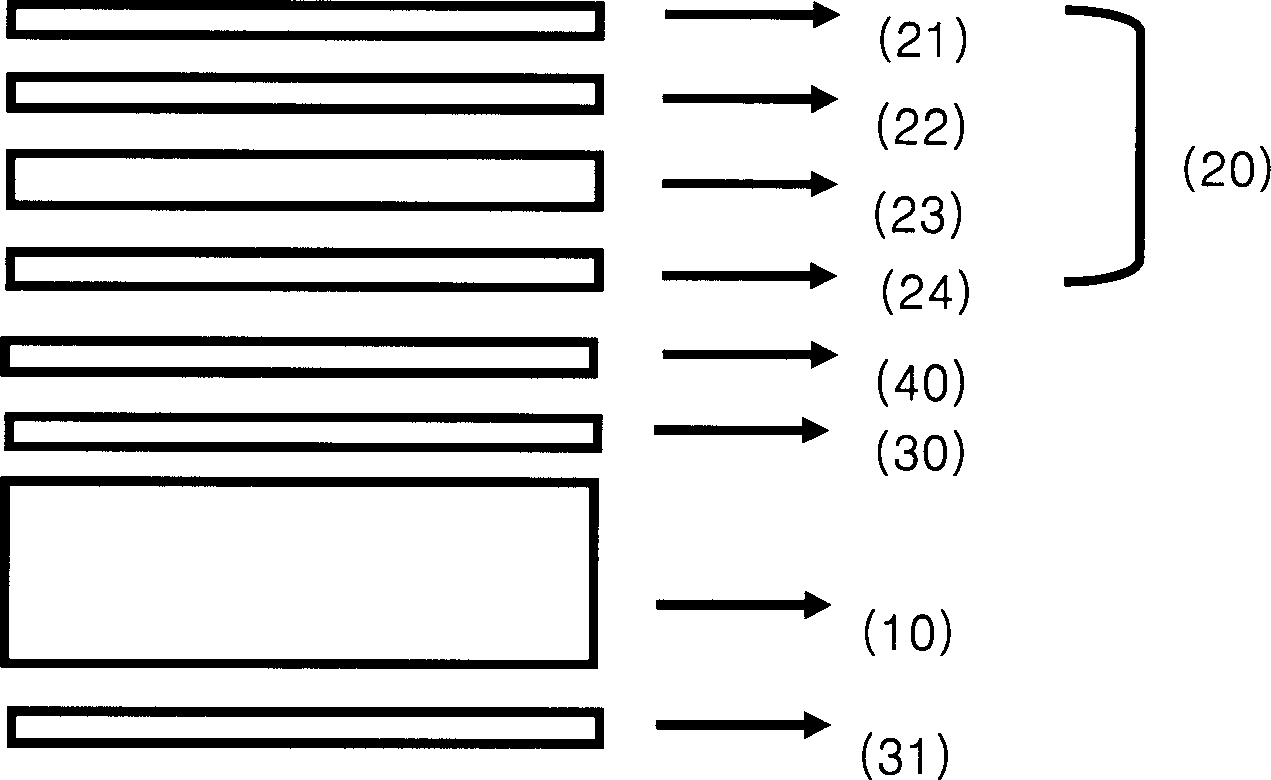

[0043] 1. Preparation of polyvinyl chloride resin layer, particle board, high-density fiberboard and waterproof plywood layer 10

[0044] A polyvinyl chloride resin layer with a thickness of 1.0-5.0 mm is prepared from a composition comprising PVC resin, plasticizer, filler and stabilizer.

[0045] Particleboard and high-density fiberboard are produced by pressing in melamine resin shavings or fibers or fibrous wood obtained by cutting and subsequently shaping them. The waterproof plywood layer 10 is prepared by laminating 5 to 7 layers of veneers using melamine resin such that the grain directions of the veneers are perpendicular to each other and applying pressure thereto.

[0046] 2. Preparation of upper WPL20

[0047] 1) Preparation of UV coating 21

[0048] In terms of surface protection and high-quality appearance, UV coating is carried out 6 to 10 times. For coverings impregnated in amino resins (urea, melamine or urea-melamine resins), UV coating is carried out af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com