Portable saddle-shaped cutting machine

A saddle-shaped, cutting machine technology, used in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve problems such as affecting the quality and performance of equipment, prone to offset, and circular deformation of cutting, and achieve a wide range of cutting objects. , The effect of high cutting precision and rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution and structure of the present invention will be described below in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

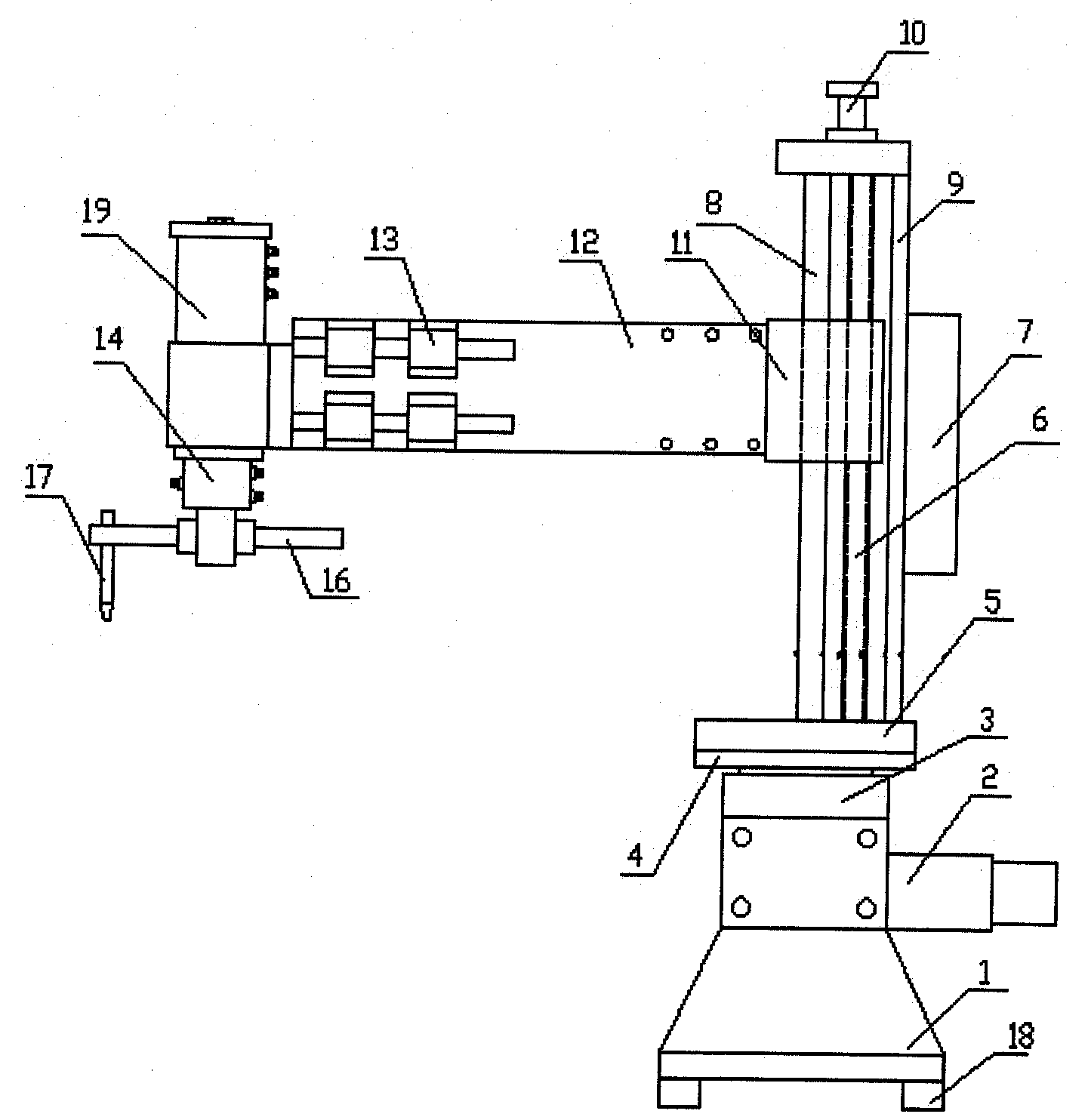

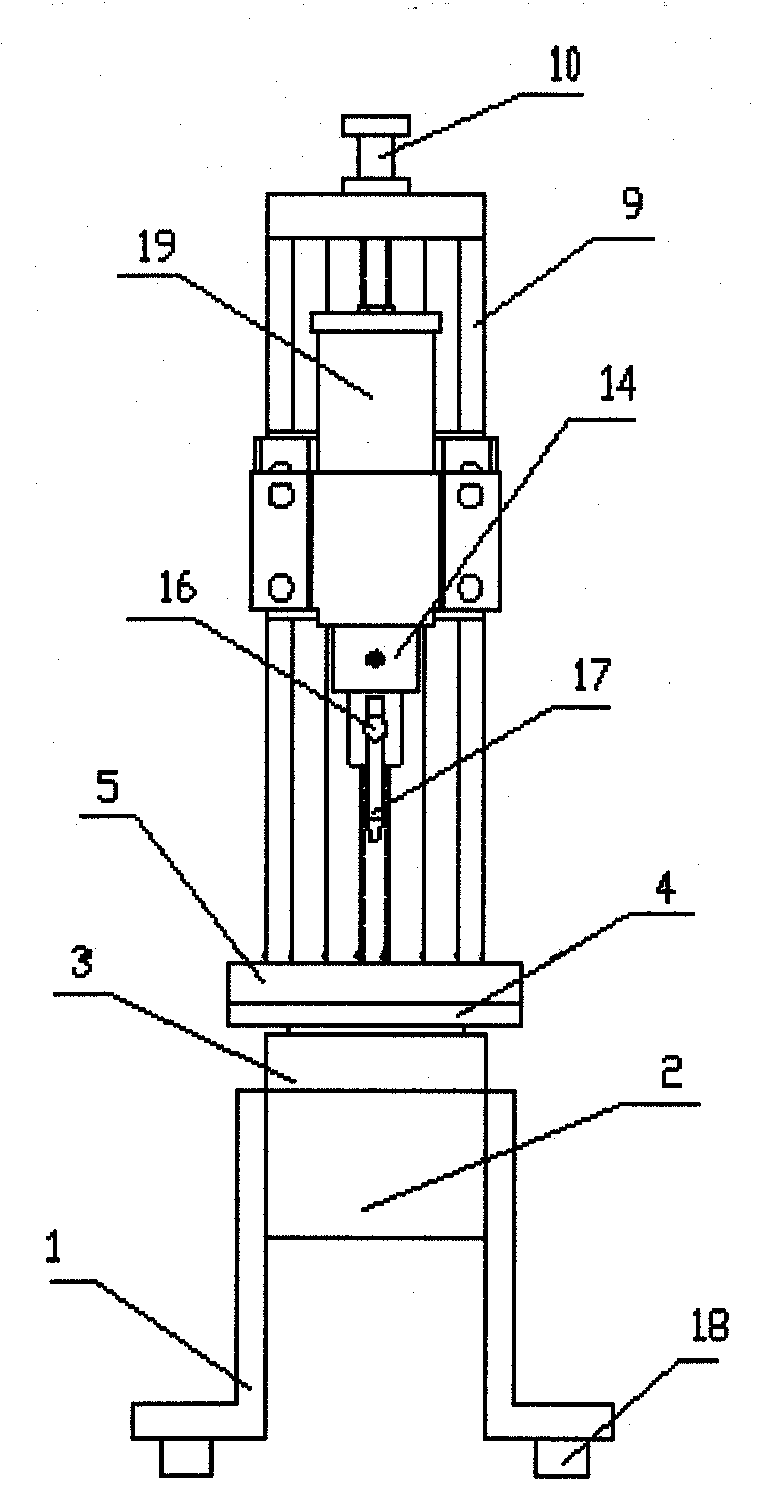

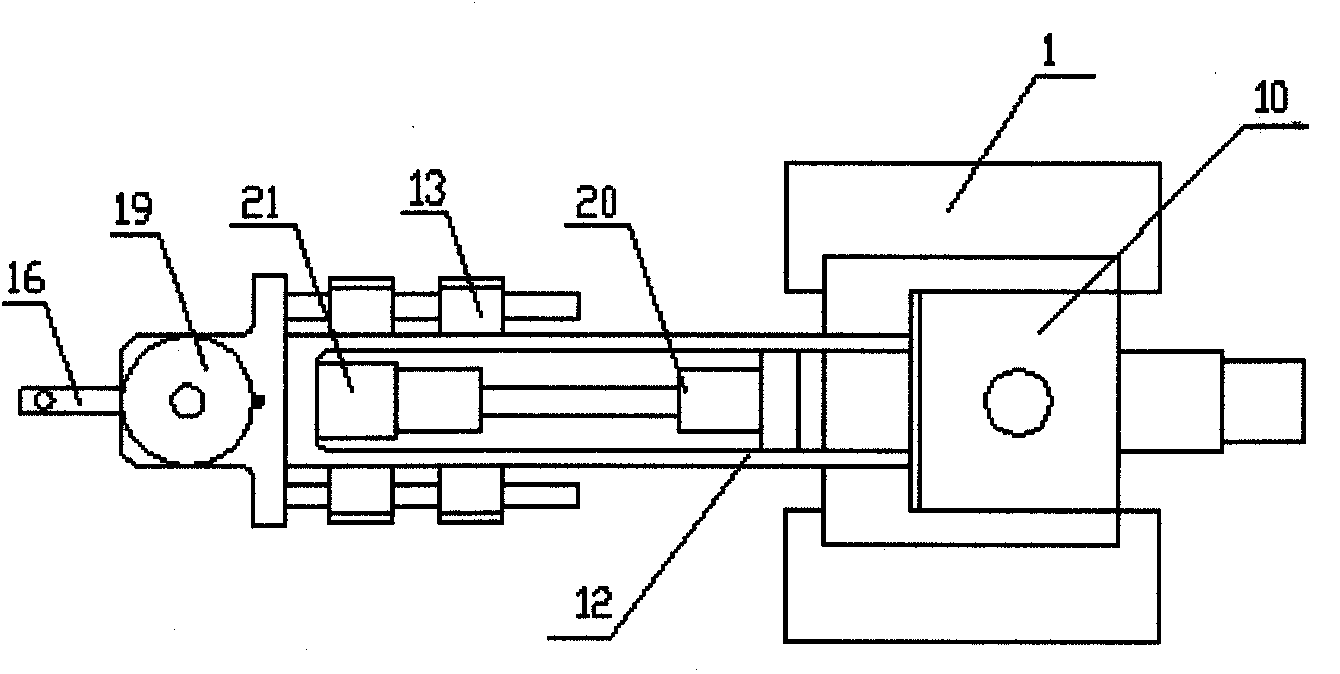

[0025] Such as figure 1 , figure 2 and image 3 As shown, a portable saddle-shaped cutting machine includes a fixed base 1, a large circle cutting mechanism, and a small circle cutting mechanism. The main shaft is provided with a lifting slide 11 that can move up and down, and the lifting slide 11 is connected with a detachable lifting arm 12 in a horizontal direction. The lift arm 12 is provided with a small circle cutting mechanism away from the lifting slide 11. The mechanism includes a telescopic mechanism 13 connected to the lifting arm 12. A rotary air distribution assembly 19 is provided at the end of the telescopic mechanism 13 away from the lifting arm 12, and a cutting nozzle assembly 17 is provided at the bottom of the rotary air distribution assembly 19.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com