Method for preparing manual fast cutting material

A rapid cutting and manual technology, applied in the direction of welding/cutting media/materials, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing cutting efficiency, paralyzing equipment and power facilities, delaying rescue time, etc., to achieve rapid cutting and cracking, Wide range of cutting objects and high cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

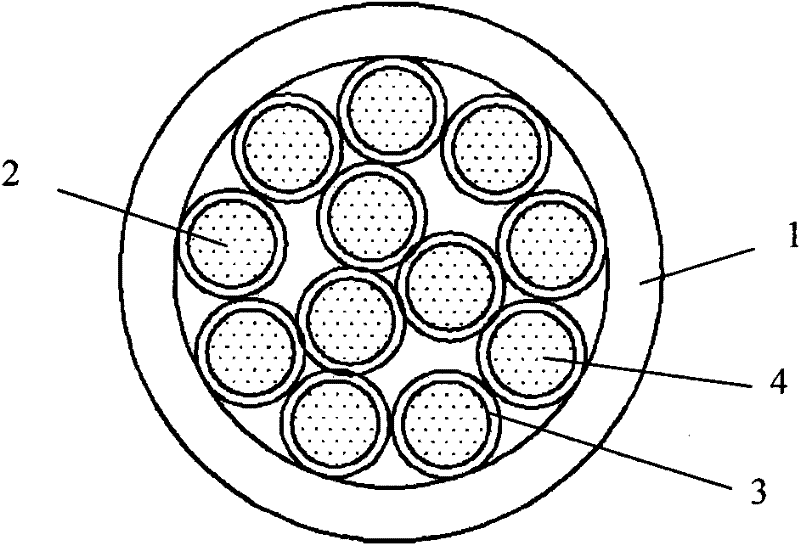

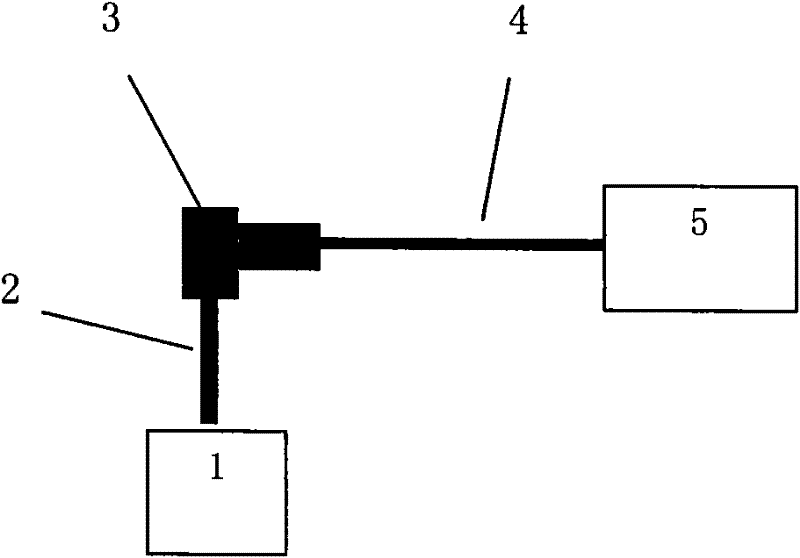

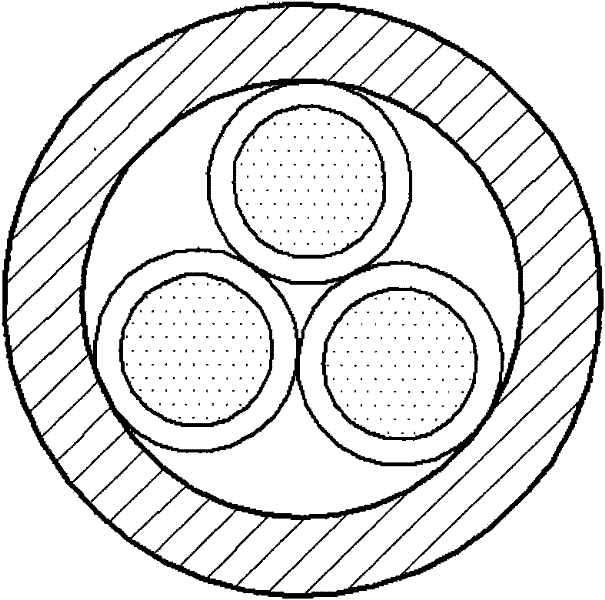

[0037] Iron powder, CuO powder and rare earth alloy powder are mixed uniformly by the content ratio as shown in table 1 earlier with mixing agitator, and prepare low-carbon steel 08F steel strip, described low-carbon steel 08F steel strip chemical composition is: In weight percentage, C0.05%~0.11%, Si≤0.03%, Mn 0.25%~0.50%, P≤0.035%, S≤0.035%, Ni≤0.25%, Cr≤0.10%, the rest is iron and non Avoid impurities; then through the multi-functional powder core wire forming machine, it is manufactured by multi-roll continuous rolling and multi-channel continuous wire drawing and diameter reduction, after strip cutting, strip rolling, powder filling, sealing, wire drawing, straightening and shearing The process is to cut the wire; the wire preparation speed is about 10m / min, and the straightening speed is about 5m / min.

[0038] The steel pipe prepared by the forging process is used as the external cutting pipe, and the inside and outside of the steel pipe are plated with a 0.1mm thick cop...

Embodiment 2

[0044] The difference between this embodiment and Example 1 is that iron powder, CuO powder and rare earth alloy powder are uniformly mixed according to the content ratio shown in Table 2, and five cutting wires are assembled in the inner cavity of the cutting pipe to prepare wire The material speed is about 30m / min, and the straightening speed is about 22m / min.

[0045] Table 2

[0046] Powder core composition % by weight CuO powder 5% rare earth cerium 1% iron powder margin

[0047] The manual quick-cutting material prepared by the above-mentioned method was used to conduct a cutting test on a 45# steel plate with a thickness of 20mm, and the cutting speed was 5.9mm / s.

Embodiment 3

[0049] The difference between this embodiment and Example 1 is that iron powder, CuO powder and rare earth alloy powder are uniformly mixed according to the content ratio shown in Table 3, and seven cutting wires are assembled in the inner cavity of the cutting pipe to prepare wire The material speed is about 15m / min, and the straightening speed is about 18m / min.

[0050] table 3

[0051] Powder core composition % by weight CuO powder 8% rare earth cerium 1.5% iron powder margin

[0052] The manual rapid cutting material prepared by the above method was used for cutting test on 45# steel plate with a thickness of 20mm, and the cutting speed was 8.27mm / s.

[0053] The beneficial effects brought by the manual rapid cutting material prepared by the preparation method provided by the invention are as follows:

[0054] 1) Portability, using carbon fiber oxygen cylinders for fire-fighting, the cutting system and cutting materials used are li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com