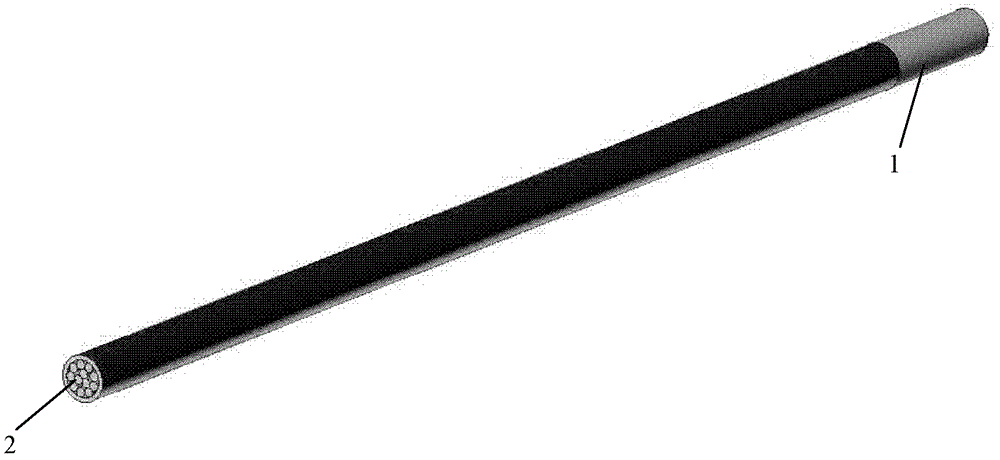

Underwater manual rapid cutting material

A technology for fast cutting and cutting of materials, applied in welding/cutting media/materials, manufacturing tools, metal processing equipment, etc. It can solve the problems of insufficient support for cutting materials and inability to meet cutting requirements, achieving high cutting efficiency and a wide range of cutting objects. , the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Wherein, the iron powder particle size is -80 to 200 mesh, the CuO powder particle size is -80 to 200 mesh, and the CuO powder particle size is -80 to 200 mesh. 2 The particle size of the O powder is -80-200 mesh, and the particle size of the rare earth cerium is -300 mesh.

[0050] Then, it is manufactured by multi-roller continuous rolling and multi-channel continuous wire drawing and diameter reduction through a multifunctional powder core wire forming machine. After strip cutting, strip rolling, powder filling, sealing, wire drawing, straightening and shearing processes, it can be obtained Cut the wire; the wire preparation speed is about 40m / min, and the straightening speed is about 5m / min.

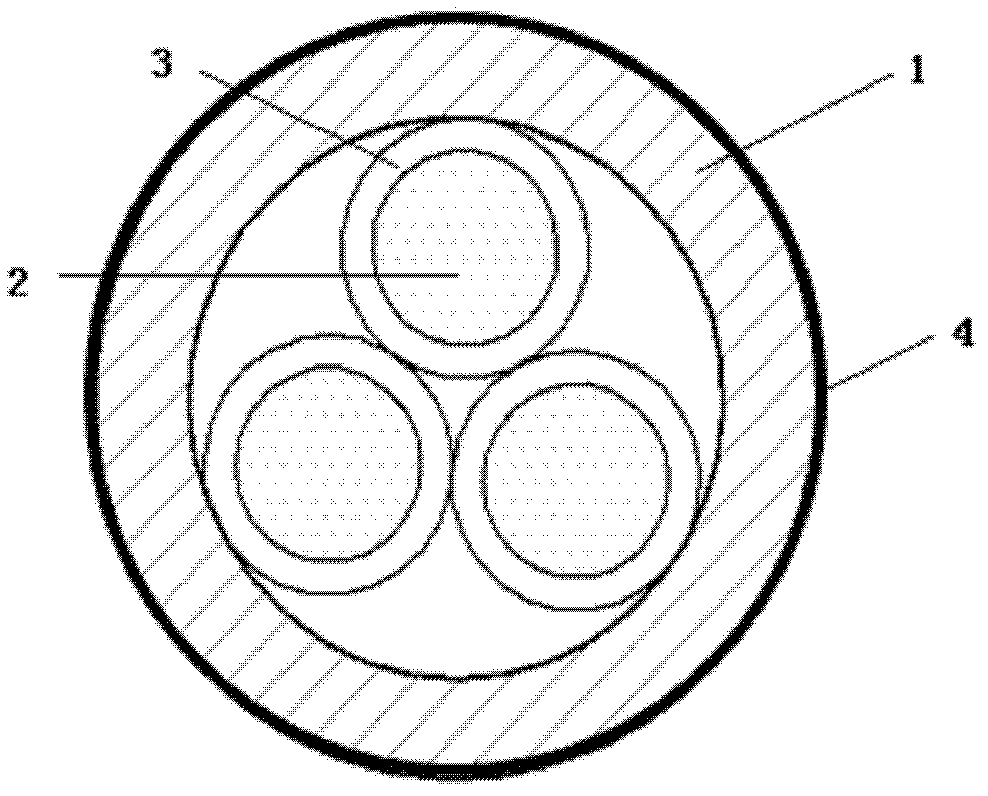

[0051] The steel pipe prepared by the forging process is used as the external cut pipe, and the inside and outside of the steel pipe are plated with a 0.1mm thick copper layer by electroplating process; the polyethylene tape is used to wrap the outside of the cut pipe as an in...

Embodiment 2

[0058] This embodiment is different from Example 1 in that: Al powder, Fe powder, Cu 2 O powder, CuO powder and rare earth alloy powder are mixed evenly according to the content ratio shown in Table 2, and 5 cutting wires are assembled in the inner cavity of the cutting pipe, wherein, 4 are steel sheaths, and 1 is aluminum sheath, The wire preparation speed is about 120m / min, and the straightening speed is about 22m / min.

[0059] Table 2

[0060] Powder core composition

% by weight

Cu 2 O powder

20%

CuO powder

5%

[0061] Aluminum powder

5%

rare earth cerium

7%

margin

[0062] The underwater manual rapid cutting material prepared by the above method was tested on a 45# steel plate with a thickness of 20 mm at a water depth of 1 meter, and the cutting speed was 1.4 mm / s.

[0063] Wherein, the cutting pipe can also use the above-mentioned copper-iron-copper three-layer co...

Embodiment 3

[0065] This embodiment is different from Example 1 in that: Al powder, Fe powder, Cu 2 O powder, CuO powder and rare earth alloy powder are mixed evenly according to the content ratio shown in Table 3. When there are 7 wires in the pipe, 1 to 3 wires can be covered with metal powder on aluminum skin, and the rest are iron wires. For metal powder wrapped in leather, the wire preparation speed is about 80m / min, and the straightening speed is about 18m / min.

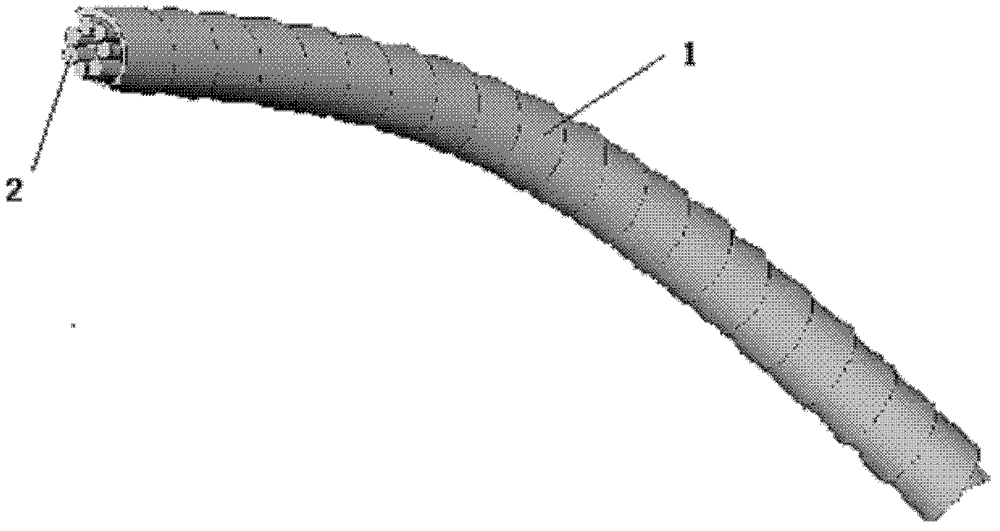

[0066] Wherein, the cutting pipe can also use the above-mentioned copper-iron-copper three-layer composite pipe, and the cutting pipe wound by the composite metal strip can realize the flexible bending of the cutting pipe, and is coiled together like a soft rope.

[0067] table 3

[0068] Powder core composition

% by weight

Cu 2 O powder

10%

CuO powder

25%

Aluminum powder

2%

rare earth cerium

7%

margin

[0069] The underwater m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com