Method for manufacturing underwater manual quick cutting material

A rapid cutting and manual technology, applied in the direction of welding/cutting media/materials, metal processing equipment, manufacturing tools, etc., can solve the problems of insufficient support for cutting materials and unsatisfactory cutting, and achieve high cutting efficiency, wide range of cutting objects, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step 1, the mixing mixer will Al powder, Fe powder, Cu 2 O powder, CuO powder and rare earth cerium are composed of Cu 2 O powder 3-20%, CuO powder 5-25%, Al powder 2-10%, rare earth cerium 1-7%, and the balance is Fe powder and mix evenly; prepare steel strip and aluminum strip, the steel The strip is SPCC-SD type cold-rolled steel strip, and its chemical composition is: by weight percentage, C≤0.15%, Mn≤0.60%, P≤0.1%, S≤0.025%, and the rest is iron and unavoidable impurities;

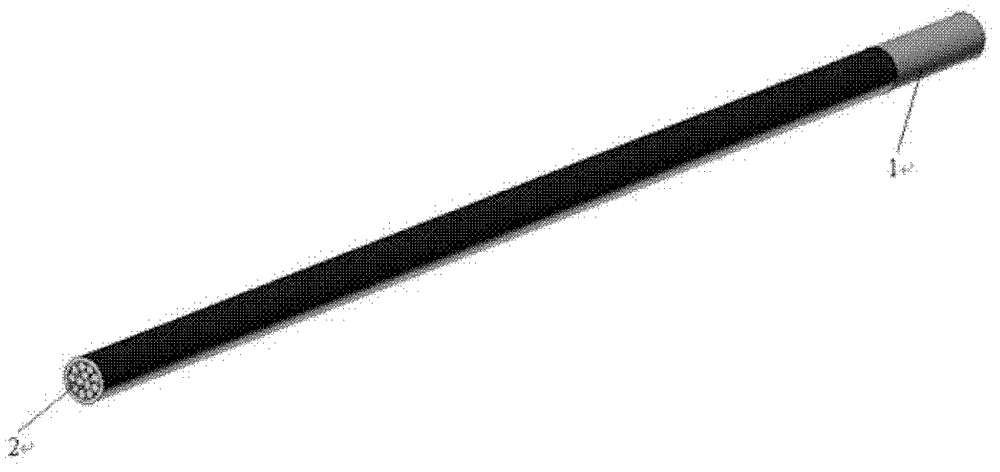

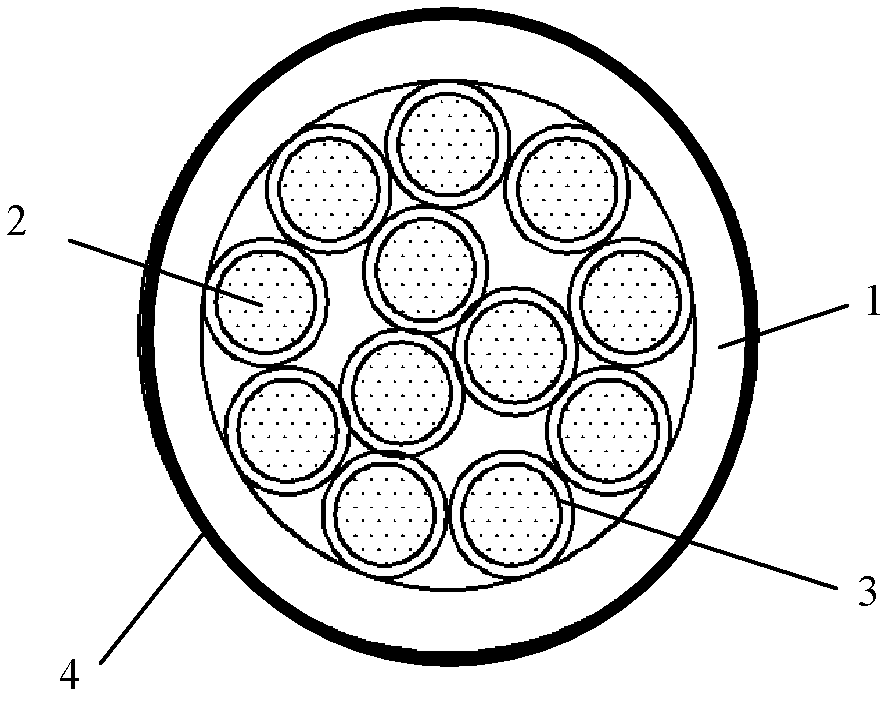

[0045] Step 2. Using a multi-functional powder core wire forming machine, using steel strips and aluminum strips, it is manufactured by multi-roll continuous rolling and multi-channel continuous wire drawing and diameter reduction. After strip cutting, strip rolling, powder filling, sealing, wire drawing, Straightening and shearing processes to produce cutting wires coated with steel strips and aluminum strips respectively;

[0046] Step 3. The steel pipe prepared by the forging process is us...

Embodiment 2

[0055] This embodiment is different from Example 1 in that: Al powder, Fe powder, Cu 2 O powder, CuO powder and rare earth cerium are mixed evenly according to the content ratio shown in Table 2, and 5 cutting wires are assembled in the inner cavity of the cutting pipe, of which 4 are steel sheaths and 1 is aluminum sheaths. The wire speed is about 120m / min and the straightening speed is about 22m / min.

[0056] Table 2

[0057] Powder core composition

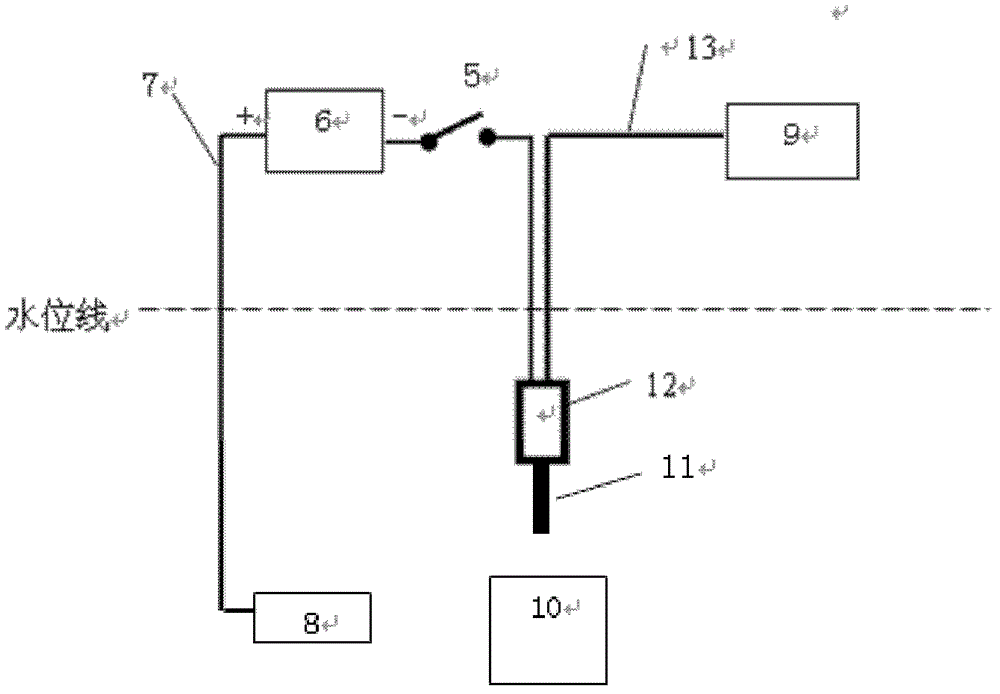

[0058] The underwater manual rapid cutting material prepared by the above method was tested on a 45# steel plate with a thickness of 20 mm at a water depth of 1 meter, and the cutting speed was 1.4 mm / s.

Embodiment 3

[0060] This embodiment is different from Example 1 in that: Al powder, Fe powder, Cu 2 O powder, CuO powder and rare earth cerium are mixed evenly according to the content ratio shown in Table 3. When there are 7 wires in the pipe, 1 to 3 wires can be covered with aluminum sheath and metal powder, and the rest are iron sheathed wires. For leather-wrapped metal powder, the wire preparation speed is about 80m / min, and the straightening speed is about 18m / min.

[0061] table 3

[0062] Powder core composition

% by weight

Cu 2 O powder

10%

CuO powder

25%

Aluminum powder

2%

rare earth cerium

7%

margin

[0063] The underwater manual rapid cutting material prepared by the above method was tested on a 45# steel plate with a thickness of 20 mm at a water depth of 1 meter, and the cutting speed was 2.5 mm / s.

[0064] The material of the present invention can be applied to the cutting of underwater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com