Flame cutting energy conservation device and operation method thereof

An energy-saving device and flame cutting technology, which is applied in the direction of gas flame welding equipment, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of frequent adjustment of explosion relief valves, inaccurate pressure setting, and complicated maintenance, etc. Wide range of varieties, safe use, scientific and effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

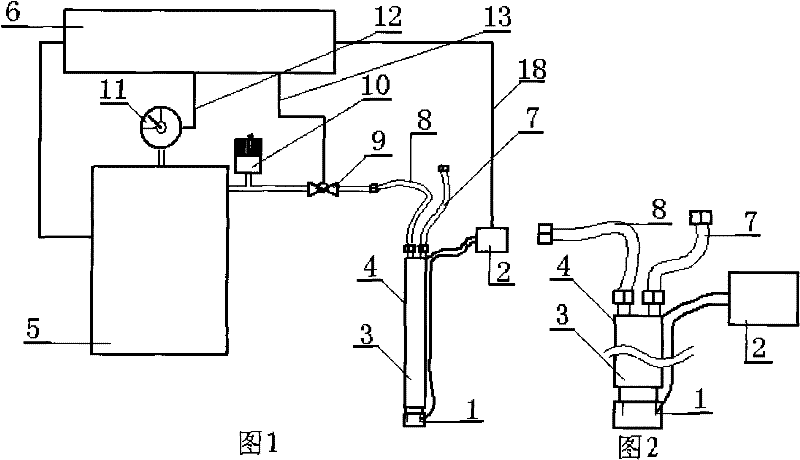

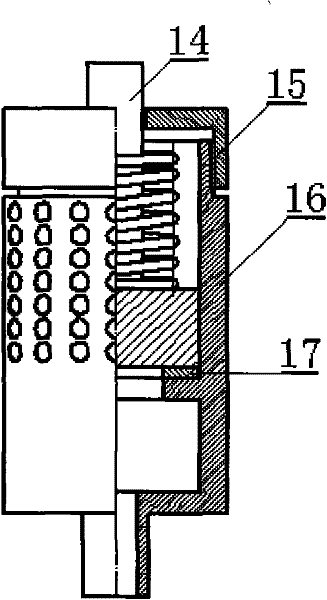

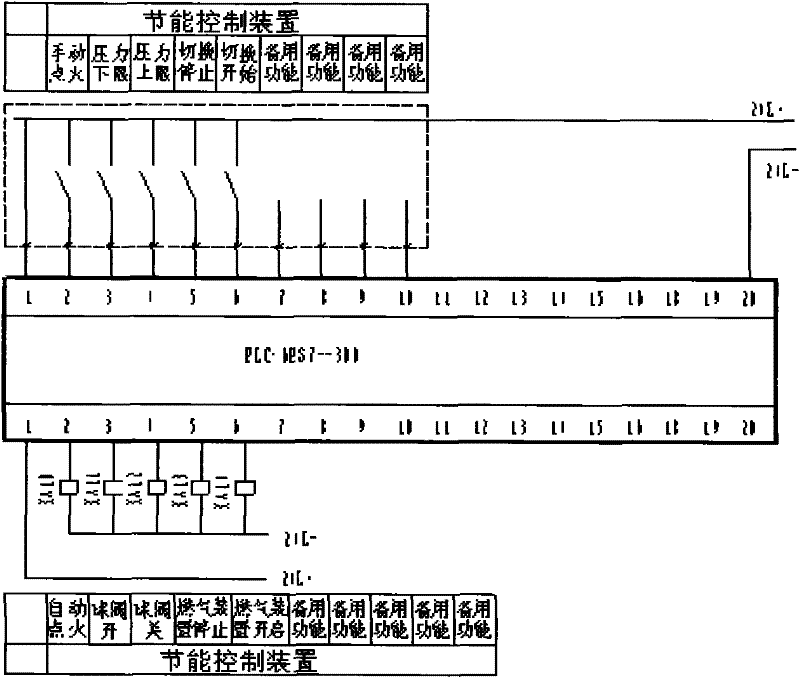

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific methods of the embodiments. The flame cutting energy-saving device of the present invention includes a pulse automatic ignition cutting torch 4 composed of a spark needle 1, a pulse electronic ignition control device 2 and a cutting torch body 3, a gas supply device 5, an energy-saving control device 6, and an oxygen tube 7 And the gas pipe 8 is characterized in that the gas pipe 8 is connected to the safety explosion relief valve 10 through the electric control ball valve 9, and the other end of the safety explosion relief valve 10 is connected to the gas supply device 5, and the gas supply device 5 is provided with an electric contact pressure controller 11 , the electric contact pressure controller signal line 12, the electric control ball valve signal line 13 and the pulse electronic ignition signal line 18 are respectively connected with the ene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com