Free forging method of forge piece of rotary arms

A technology for forgings and swivel arms, which is applied in the field of free forging of swivel arm forgings, can solve the problems of increased production resource consumption, difficult to repair, and large forging allowances, so as to reduce the cost of forgings, ensure internal quality, and reduce forgings. The effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

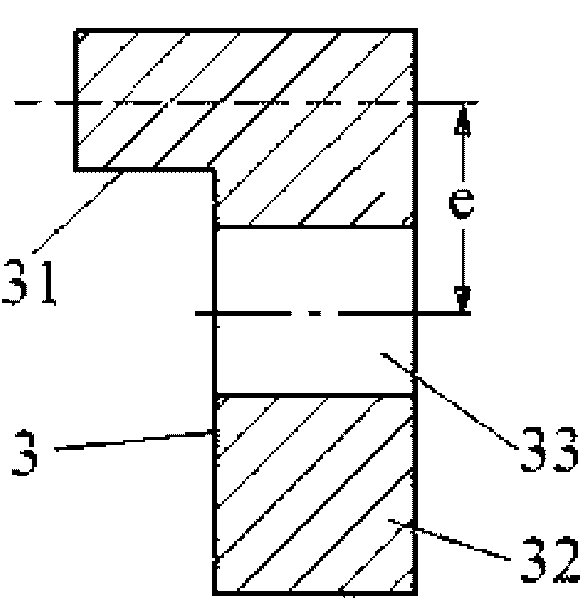

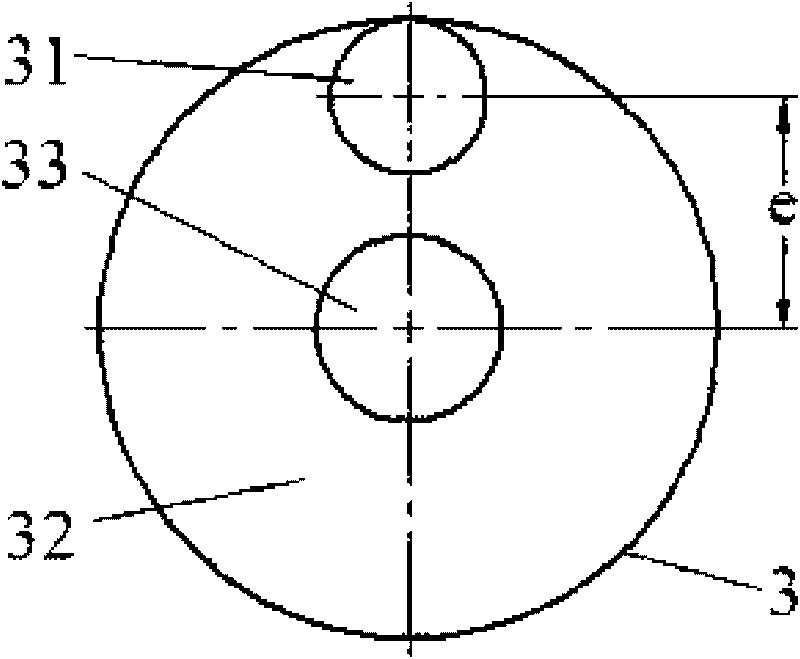

[0028] like figure 1 , 2 As shown, it is a structural schematic diagram of the forging of the arm type used by the method of the present invention. The structure of the forging 3 is to include a forging inner hole 33 on the axis of the large disk 32, an eccentric cylinder 31 is arranged at the eccentric position of the axis of the large disk 32, and the axis of the eccentric cylinder 31 is aligned with the forging inner hole. The distance between the axes of 33 is e.

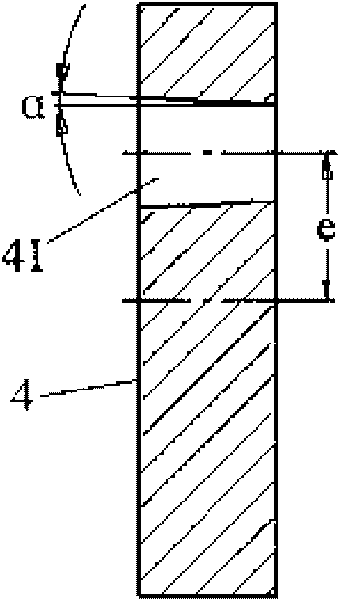

[0029] like image 3 , 4 As shown, it is a schematic view of the tire mold structure that adopts the method of the present invention to use. The tire mold hole 41 is eccentrically arranged on the tire mold 4, and the distance between the axis line of the tire mold hole 41 and the axis line of the tire mold 4 is e, The inner hole of the tire mold hole 41 is a conical surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com