Engineering method for producing biochar soil from dredging sediment

A bio-carbon and engineering technology, applied in the preparation of organic fertilizer, biological organic part treatment, fertilizer mixture and other directions, can solve the problem of sediment disposal and other problems, achieve high added value, speed up the process of making bio-carbon soil, social Highly recognized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

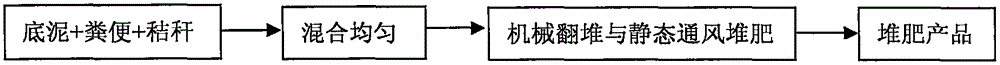

Method used

Image

Examples

Embodiment Construction

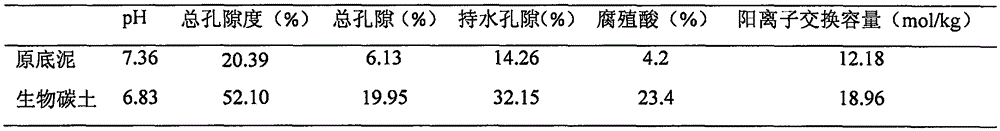

[0029] In this project, samples were taken in a watershed in the upper reaches of Taihu Lake in April, July, October, December and March 2015 respectively. There were 10 sampling points each time, and the surface samples and columnar samples were collected respectively (the columnar samples were divided into four layers, Each layer is 10cm), and make parallel samples, 100 samples each time, 5 times a total of 500 samples. The monitoring results show that the bottom mud of the Lianhuadang water system belongs to the type of high organic matter (the mass content of organic matter is more than 6%), and the concentrations of As, Cu, Hg, Cd, Cr, Zn, Pb, and Ni in the bottom mud range from 9.14 to 25.05 and 38.24, respectively. ~98.63, 0.14~0.46, 0.15~0.28, 34.94~110.20, 94.58~185.34, 23.62~110.29, 14.26~36.28mg / kg, the concentration of HCH and DDT in the sediment were 0.07~0.09, 0.06~0.10mg / kg, respectively kg, because the "Soil Environmental Quality Standard GB15618-1995" stipulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com