A kind of molecular sieve catalyst applied in seaweed liquefaction reaction and preparation method thereof

A catalyst and molecular sieve technology, which is applied in the direction of molecular sieve catalysts, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve the problems of low stability and limited use of metal molecular sieve catalysts, and achieve excellent hydrothermal stability. Effect of deactivation and high fuel yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

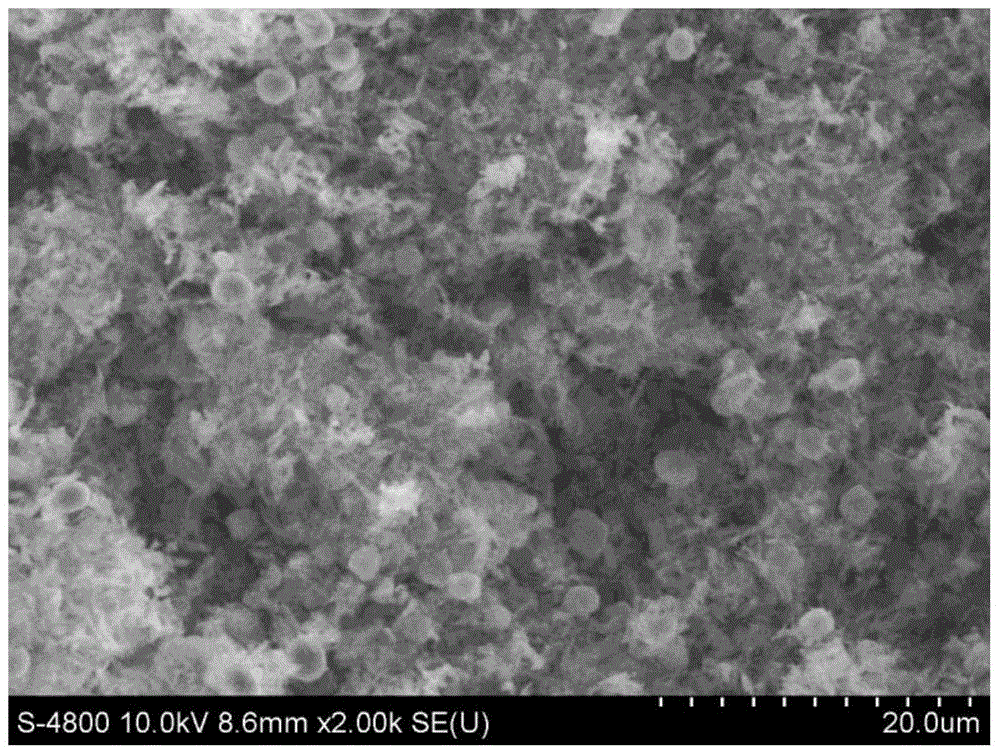

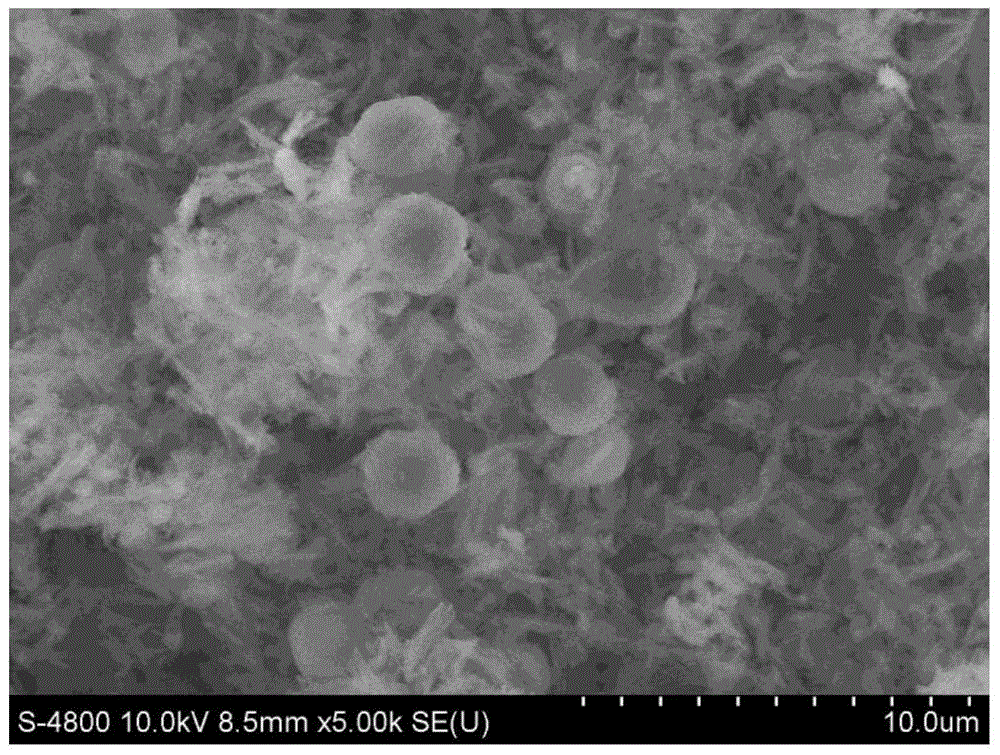

[0048] A method for preparing a metal-modified microporous-mesoporous composite molecular sieve catalyst modified by chemical liquid phase deposition, comprising the following steps:

[0049] (1) Take 10g of ZSM-5 molecular sieve and grind it into a particle size of 0.03mm, and treat it with 300mL of 0.8mol / L NaOH solution at 90°C for 1.5h to obtain an alkali-treated zeolite slurry; add sixteen Alkyltrimethylammonium bromide (CTAB) 3g, deionized water 1500mL until dissolved, then add 6g ethyl orthosilicate and continue stirring for 1h to obtain a solution. Add the prepared zeolite slurry to this solution, adjust the pH of the mixed solution to 10 with 1mol / L nitric acid, put the evenly stirred solution into a high-pressure reactor, crystallize at 170°C for 48h, and roast at 550°C for 6h Then ZSM-5 / MCM-41 composite molecular sieve is obtained.

[0050] (2) 1mol / L Ni(NO 3 ) 2 The solution was mixed with the composite molecular sieve catalyst prepared in the previous step at a...

Embodiment 2

[0053] (1) Take 9g of ZSM-5 molecular sieve and grind it into a particle size of 0.03mm, and treat it with 300mL of 1mol / L NaOH solution at 80°C for 2h to obtain an alkali-treated zeolite slurry; add hexadecyl to the beaker under stirring conditions Trimethylammonium bromide (CTAB) 3g, deionized water 2000mL until dissolved, then add 10g ethyl orthosilicate and continue stirring for 1.5h to obtain a solution. Add the prepared zeolite slurry to this solution, adjust the pH of the mixed solution to 9 with 1mol / L nitric acid, put the evenly stirred solution into a high-pressure reactor, crystallize at 180°C for 48 hours, and roast at 500°C After 8 hours, the ZSM-5 / MCM-41 composite molecular sieve was obtained.

[0054] (2) 0.5mol / L of Fe(NO 3 ) 2 Mix the solution with the composite molecular sieve catalyst prepared in the previous step at a mass ratio of 1:1, stir evenly, impregnate at room temperature for 12 hours, dry and roast at 500°C for 8 hours to obtain a modified compos...

Embodiment 3

[0057] (1) Take 5g of ZSM-5 molecular sieve and grind it into a particle size of 0.04mm, and treat it with 200mL of 1mol / L NaOH solution at 85°C for 1.8h to obtain an alkali-treated zeolite slurry; add hexadecane to the beaker under stirring conditions Trimethylammonium bromide (CTAB) 3g, deionized water 1500mL to dissolve, then add 9g ethyl orthosilicate and continue to stir for 1h to obtain a solution. Add the prepared zeolite slurry to this solution, adjust the pH of the mixed solution to 10 with 1mol / L nitric acid, put the evenly stirred solution into a high-pressure reactor, crystallize at 160°C for 60 hours, and roast at 525°C After 7 hours, the ZSM-5 / MCM-41 composite molecular sieve was obtained.

[0058] (2) 0.8mol / L Co(NO 3 ) 2 The solution was mixed with the composite molecular sieve catalyst prepared in the previous step at a mass ratio of 1:1, stirred evenly, impregnated at room temperature for 11 hours, dried and calcined at 5250°C for 7 hours to obtain a modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com