Method for preparing attapulgite/carbon adsorbent based on hydrothermal-activation coupling technology

A technology of attapulgite and carbon adsorbent, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of low specific surface area, low specific surface area of clay minerals, etc. Pure, low ash, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

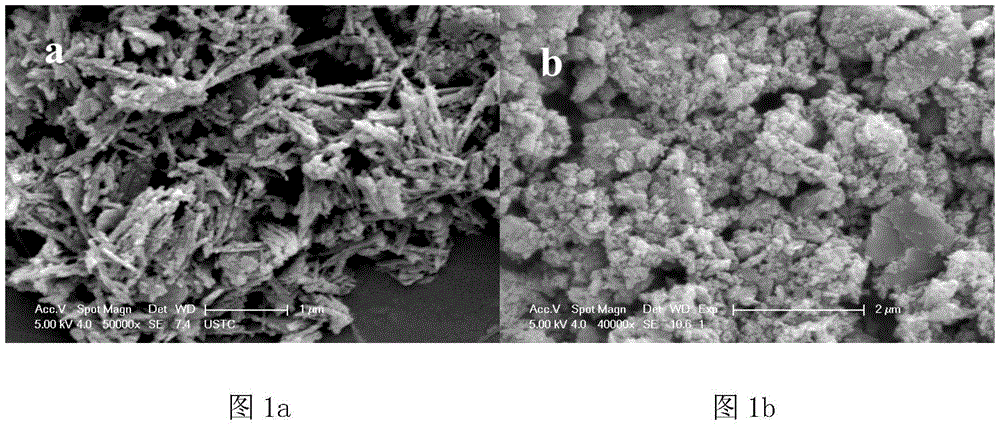

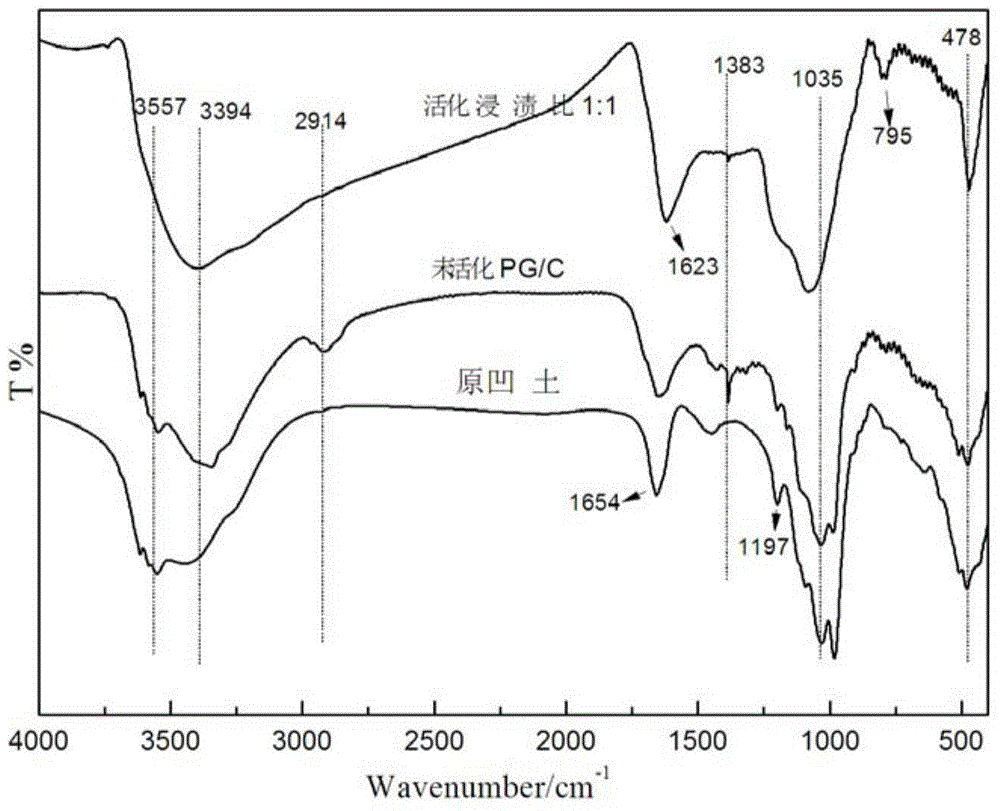

[0029] Take attapulgite 2.5g as it is, add 5g of cellulose, mix with 70mL of distilled water, then add 2.801g of ferrous ammonium sulfate, and ultrasonically disperse to obtain a mixed solution. At this time, the pH value of the mixed solution is 5; Transfer to a polytetrafluoroethylene hydrothermal kettle, keep the filling rate at 75%, react at 220°C, and carbonize for 12 hours; naturally cool to room temperature after the reaction, centrifuge, wash with water and ethanol alternately until neutral, and dry at 60°C A black product was obtained.

[0030] Weigh 2gZnCl 2 The solid is dissolved in water, and 1 g of the above hydrothermal product is added to the ZnCl 2 In the solution, stir or ultrasonically disperse evenly, dry after soaking for 24 hours.

[0031] The dried samples were placed in a horizontal tube activation furnace, N 2 Under the protection of the atmosphere, the temperature was raised to 500°C at 5°C / min and kept for 60min. After cooling to room temperature,...

Embodiment 2

[0035] The preparation method of the hydrothermal product is the same as in Example 1.

[0036] Weigh 1gZnCl 2 Dissolve the solid in water, take 1g of the above hydrothermal product and add it to ZnCl2 In the solution, stir or ultrasonically disperse evenly, immerse for 4 hours and then dry.

[0037] The dried samples were placed in a horizontal tube activation furnace under N 2 Under the protection of the atmosphere, the temperature was raised to 550°C at 5°C / min and kept for 30min. After cooling to room temperature, wash with 1.2mol / L hydrochloric acid solution, then wash with hot water at 70°C until the pH is 7, and dry at 60°C to obtain the activated product.

[0038] The measured BET specific surface area of the obtained sample is 799m 2 / g, which is higher than the specific surface area of attapulgite raw ore (see Table 1).

[0039] Take the methylene blue solution with an initial concentration of 100mg / L as the simulated organic wastewater, add the above-mention...

Embodiment 3

[0041] The preparation method of the hydrothermal product is the same as in Example 1.

[0042] Weigh 1gZnCl 2 Dissolve the solid in water, take 1g of the above hydrothermal product and add it to ZnCl 2 In the solution, stir or ultrasonically disperse evenly, immerse for 12 hours and then dry.

[0043] The dried samples were placed in a horizontal tube activation furnace under N 2 Under the protection of the atmosphere, the temperature was raised to 500°C at 5°C / min and kept for 60min. After cooling to room temperature, wash with 1.2mol / L hydrochloric acid solution, then wash with hot water at 70°C until the pH is 7, and dry at 60°C to obtain the activated product.

[0044] The measured BET specific surface area of the obtained sample is 1151m 2 / g, which is higher than the specific surface area of attapulgite raw ore and activated carbon (see Table 1).

[0045] Take the methylene blue solution with an initial concentration of 100mg / L as the simulated organic wastewat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com