Silicon alloy, alloy powder thereof, manufacturing apparatus, manufacturing process and sintered alloy thereof

a technology of alloy powder and silicon nitride, which is applied in the direction of manufacturing tools, heat treatment equipment, manufacturing tools, etc., can solve the problems of high cost of silicon nitride synthesis and processing, material cost, and the inability to use silicon in the form of a silicon alloy as industrial materials,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

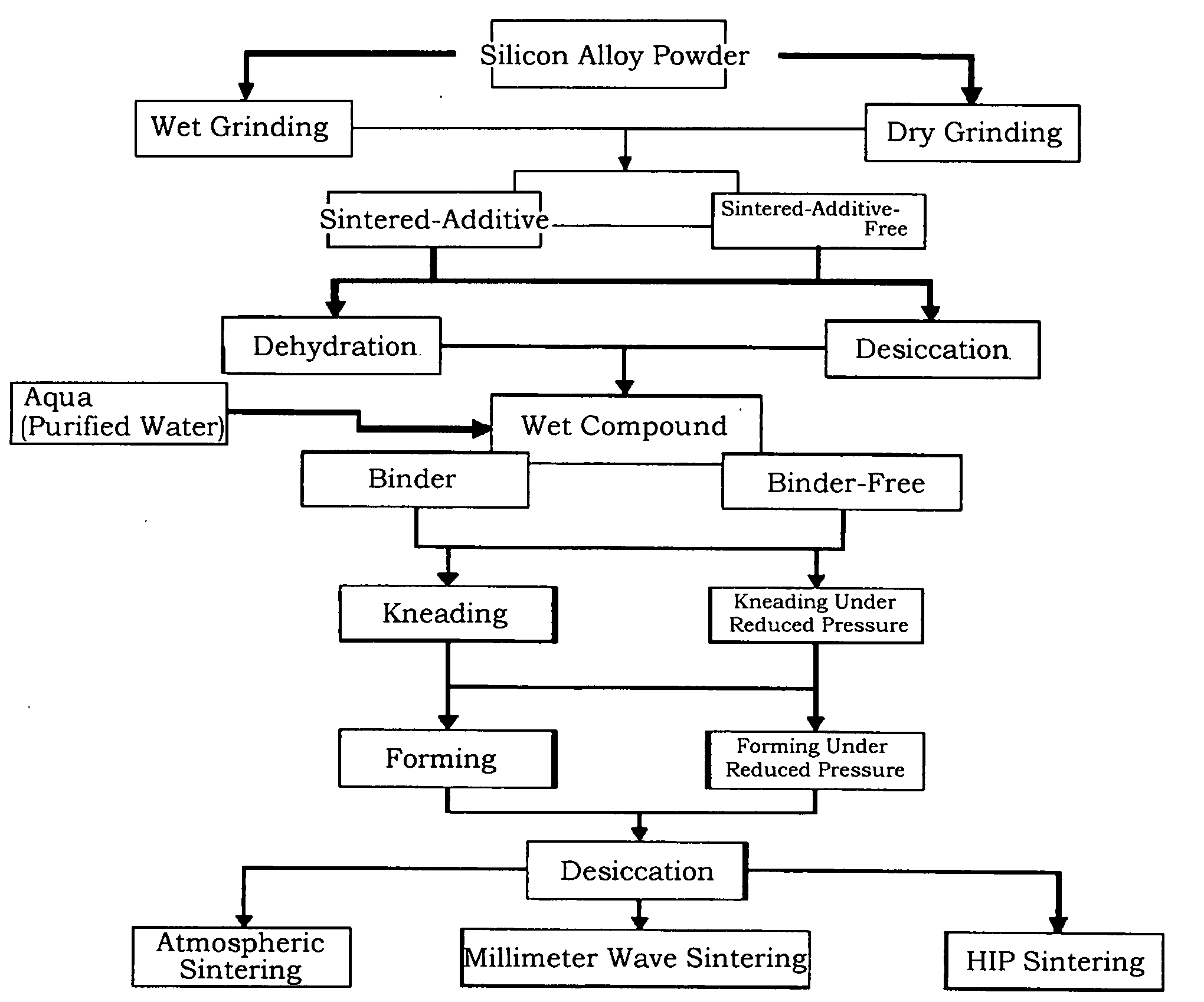

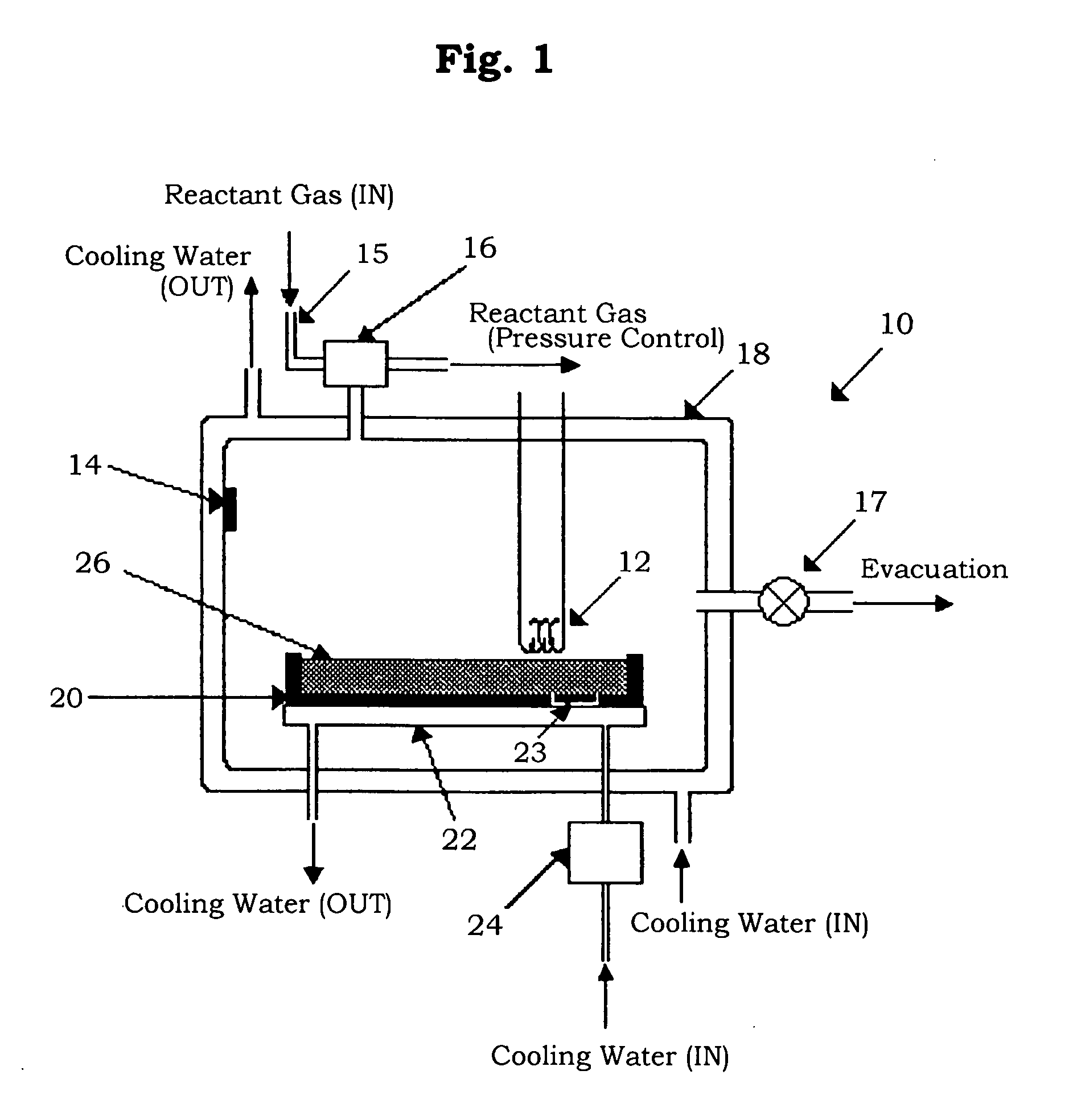

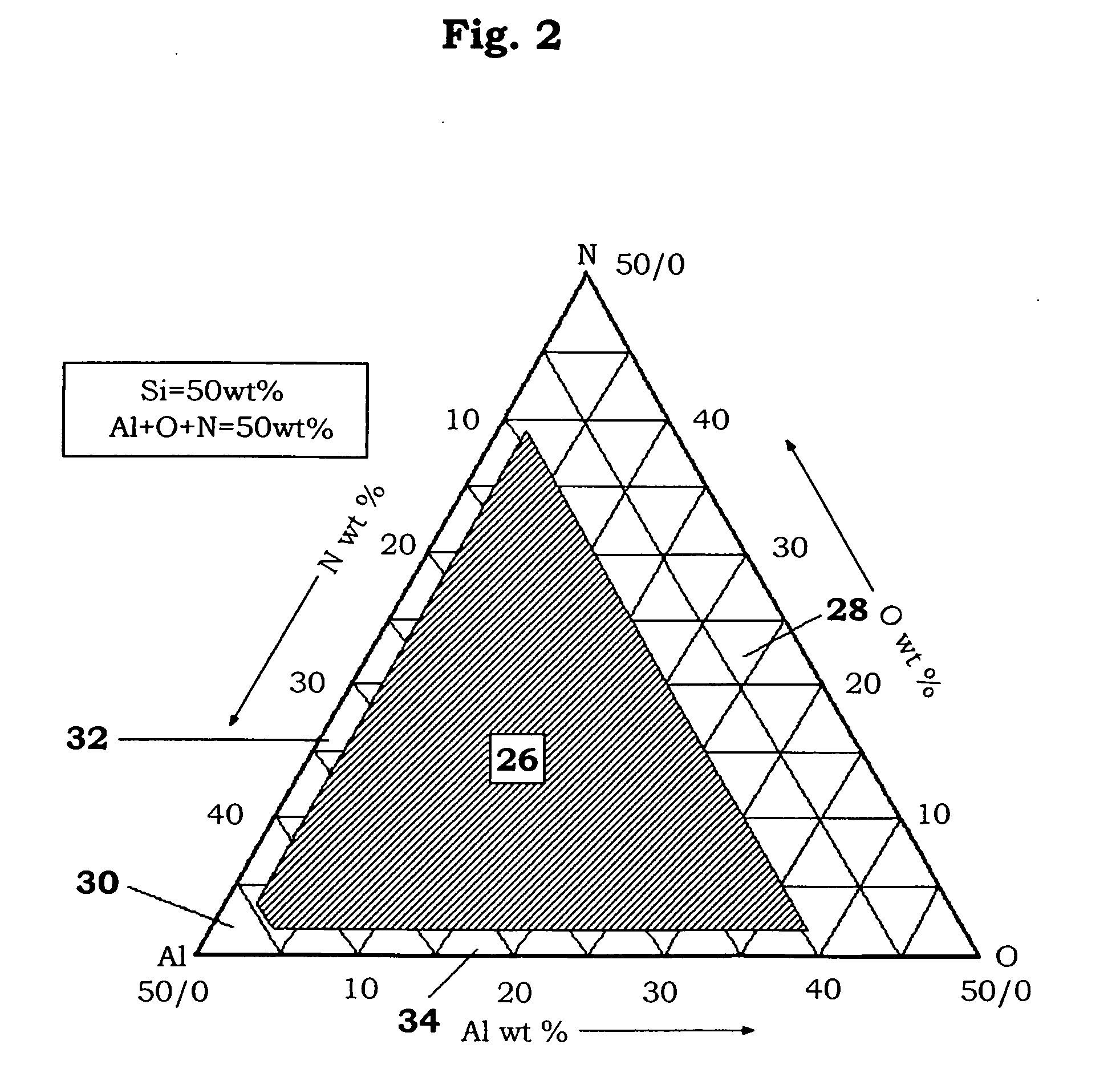

[0015]The silicon alloy of the invention can be obtained, by putting nitrogen, along with the specified quantities of silicon powder and aluminum powder as the basis, into a controlled combustion synthesis apparatus along with specified quantities of silicon oxide and / or aluminum oxide, and a specified suitable quantity of at least one element from the group consisting of iron, nickel, chromium, molybdenum, manganese, titanium, yttrium, magnesium, calcium, zirconium, vanadium, boron, tungsten and cobalt. The controlled combustion synthesis apparatus that we developed can supply nitrogen continuously, and optionally under pressure, when needed. It can control the pressure and the temperature of the reaction, and can also carry out controlled cooling in the apparatus following the combustion synthesis reaction.

[0016]Inexpensive metallurgical silicon, recycled silicon and / or recycled aluminum can be employed as the silicon and / or aluminum components.

[0017]The metallurgical silicon, whi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com