Preparation method of high-strength nano-porous nickel film

A nanoporous nickel, high-strength technology, applied in the field of high-strength nanoporous nickel membranes, can solve the problems of high production cost, product size limitation, pore size distribution and pore size influencing factors that are difficult to control, and achieve the effect of low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

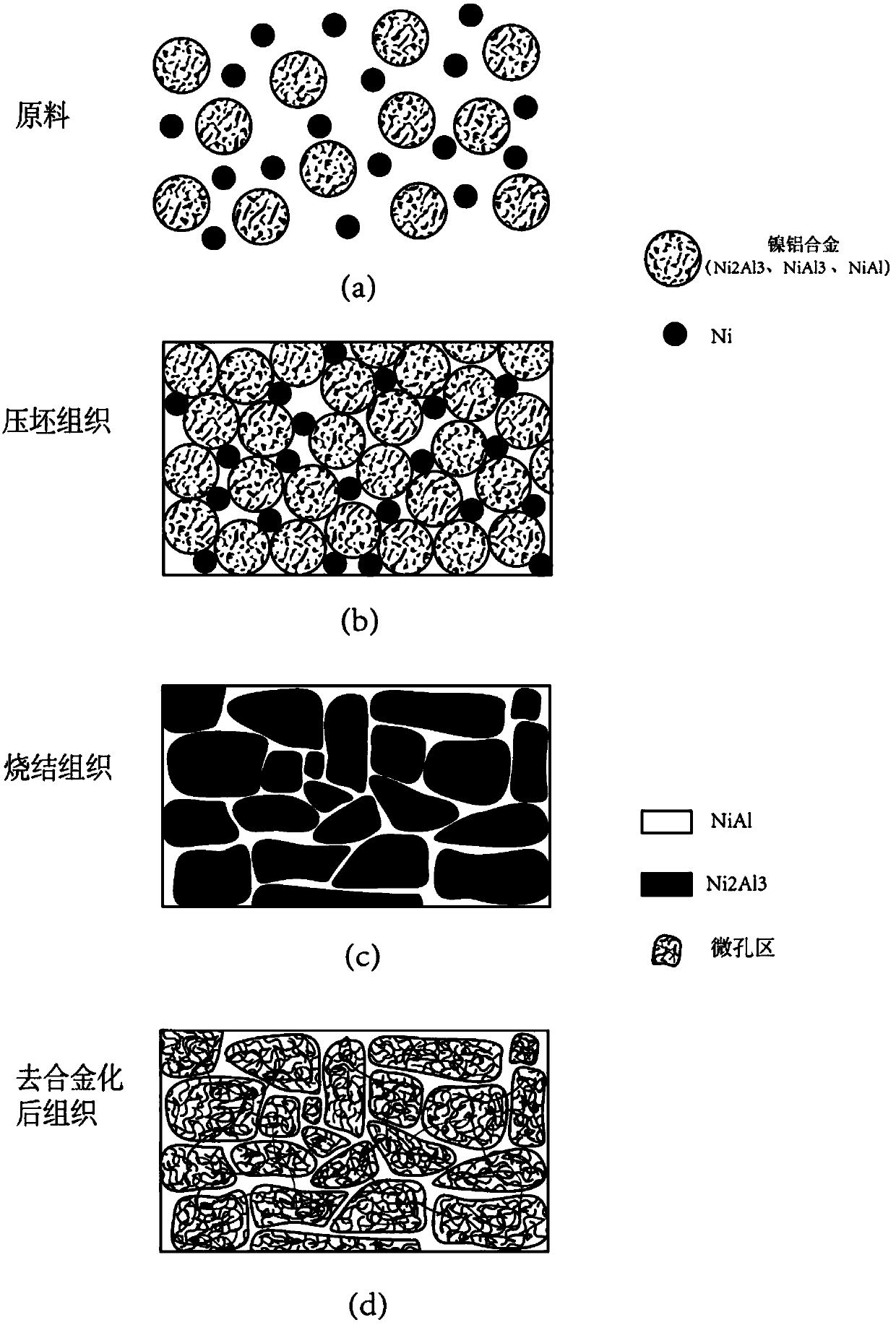

Method used

Image

Examples

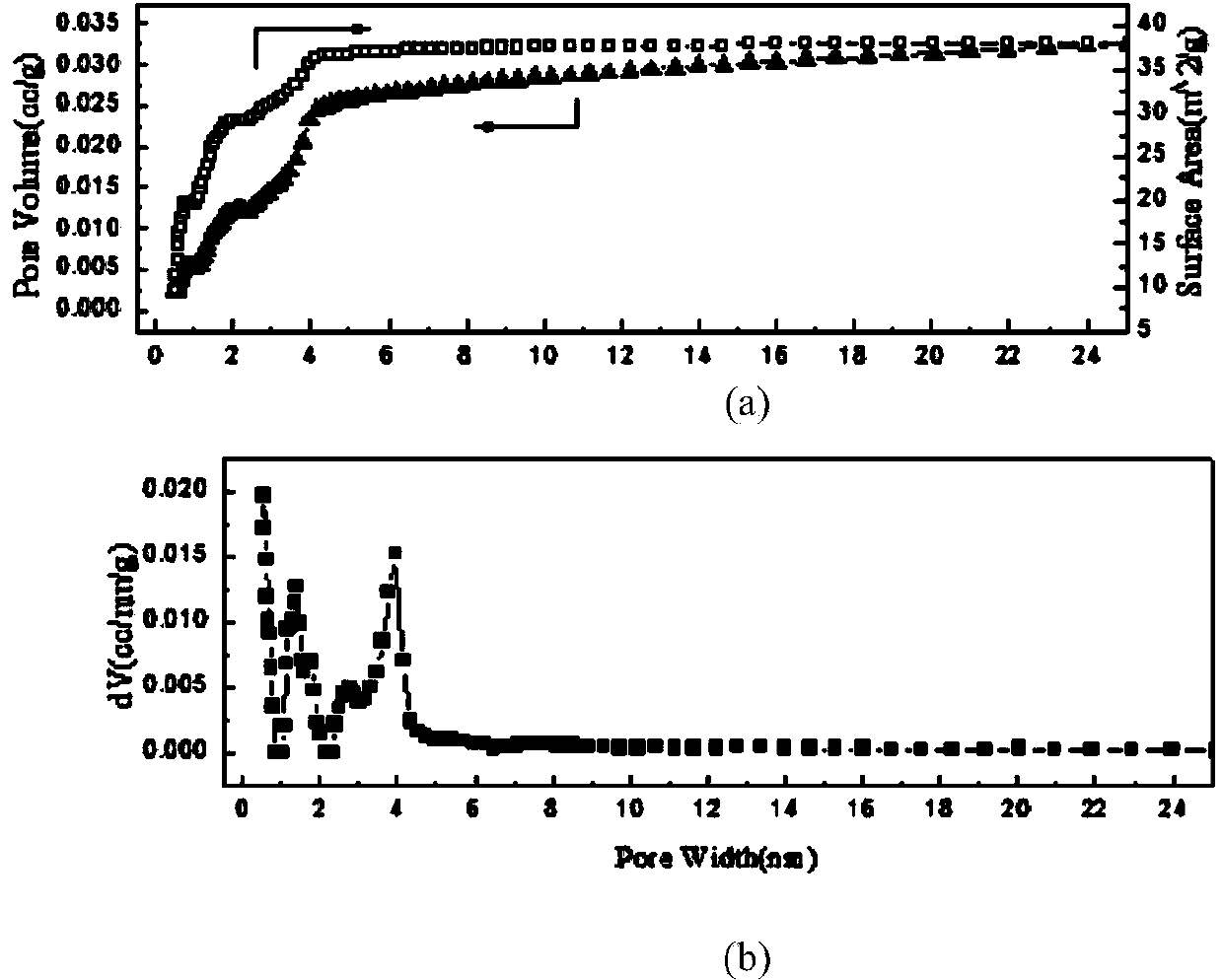

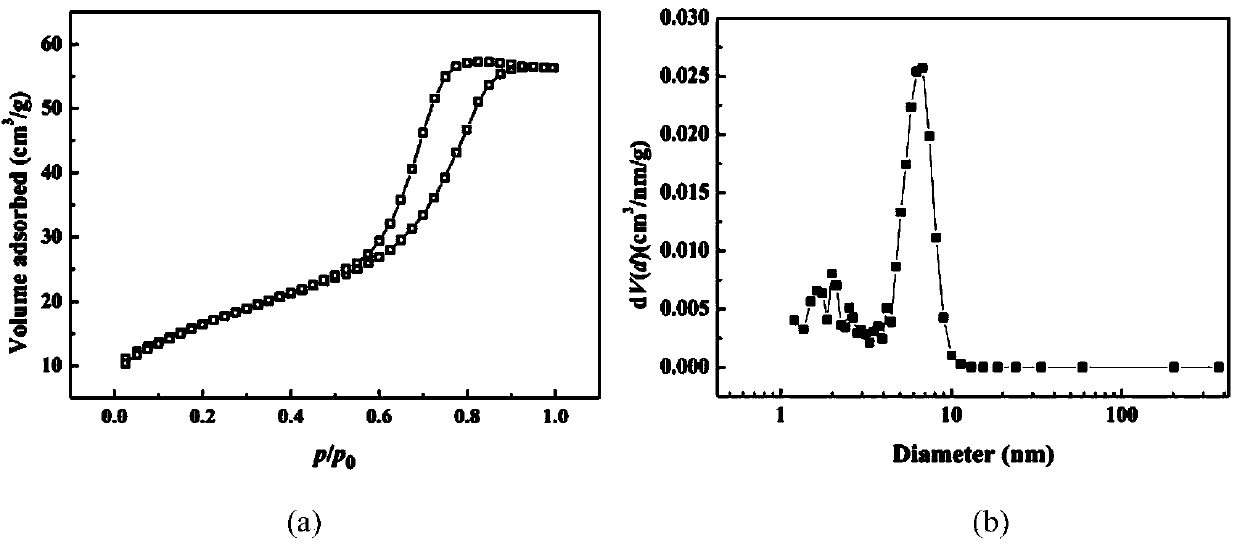

Embodiment 1

[0039] Weigh 1.6g of nickel powder and 2.4g of nickel-aluminum alloy powder (the particle size of nickel powder and nickel-aluminum alloy powder are both 300 mesh, and nickel-aluminum alloy powder contains 40at.% nickel), put them in the same container and put the mixture Mix the materials by machine for 2 hours to obtain a uniformly mixed powder material, pour 0.05g of the mixed powder into a φ8mm circular cavity mold, and use a powder tablet machine to press the green body at 946MPa; In the quality ark, place the porcelain ark in the middle area of the tubular muffle furnace, first pass argon to exhaust the air, then raise the temperature to 850 ℃ in a hydrogen atmosphere, and calcine at this temperature for 2 hours, and then reduce to room temperature with the furnace , powder metallurgy nickel-aluminum alloy sheet is obtained. Prepare a 6mol / L NaOH solution with a beaker, soak the alloy flakes in the NaOH solution for free corrosion and de-alloying, and then put the beak...

Embodiment 2

[0041]Weigh 0.8g of nickel powder and 3.2g of nickel-aluminum alloy powder (the particle size of nickel powder and nickel-aluminum alloy powder are both 300 mesh, and nickel-aluminum alloy powder contains nickel: 30at. After mixing the material with the feeder for 2 hours, after obtaining a uniformly mixed powder material, take 0.05g of the mixed powder and pour it into a φ8mm circular cavity mold, and use a powder tablet machine to press the green body at 946MPa; take the formed green body and put it into In the porcelain ark, place the porcelain ark in the middle area of the tubular muffle furnace, first pass argon to exhaust the air, then raise the temperature to 850 ℃ in a hydrogen atmosphere, and calcine at this temperature for 2 hours, and then drop to 850 °C with the furnace. At room temperature, powder metallurgy nickel-aluminum alloy sheets are prepared. Prepare a 1mol / L NaOH solution with a beaker, soak the alloy flakes in the NaOH solution for free corrosion and d...

Embodiment 3

[0043] Weigh 0.4g of nickel powder and 3.6g of nickel-aluminum alloy powder (the particle size of nickel powder and nickel-aluminum alloy powder are both 300 mesh, nickel-aluminum alloy powder contains nickel: 30at. After mixing the material with the feeder for 2 hours, after obtaining a uniformly mixed powder material, take 0.05g of the mixed powder and pour it into a φ8mm circular cavity mold, and use a powder tablet machine to press the green body at 946MPa; take the formed green body and put it into In the porcelain ark, place the porcelain ark in the middle area of the tubular muffle furnace, first pass argon to exhaust the air, then raise the temperature to 900 ℃ in a hydrogen atmosphere, and calcine at this temperature for 2 hours, and then decrease to 900 °C with the furnace. At room temperature, powder metallurgy nickel-aluminum alloy sheets are prepared. Use a beaker to prepare a 4mol / L NaOH solution, soak the alloy sheet in the NaOH solution for free corrosion and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com