Hard alloy mold material for fastener formed through cold upsetting and preparation method of hard alloy mold material

A technology of cold heading and cemented carbide, which is applied in the field of cemented carbide to achieve high strength, ensure wear resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

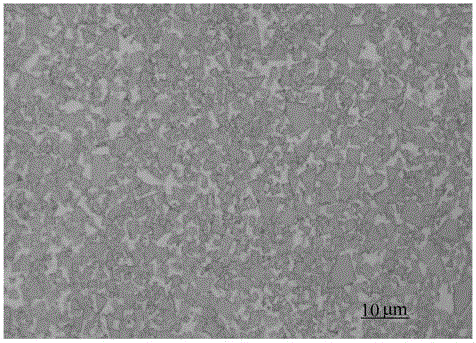

[0042] Using WC powder with Fsss particle size of 2.5 μm and 4.5 μm, the mass fraction of 2.5 μm WC powder is 60%, and the mass fraction of 4.5 μm WC powder is 40%, by weight ratio WC:Co:Ni:Cr 3 C 2 : WC-TiC-NbC solid solution = 77: 22: 0.5: 0.3: 0.2 Formula powder, the mass ratio of wet grinding balls to the mixture is 1.5:1, the grinding medium is alcohol, and the ratio of alcohol to mixture is 1L: 2Kg, The molding agent is paraffin wax, the addition amount is 2% of the weight of the mixture, ball milled for 13 hours, the powder after ball milling is spray-dried and granulated, and pressed into shape, and finally put into a 6MPa low-pressure sintering furnace at 1380°C for 60 minutes and sintered After the furnace is cooled to room temperature, the sintered alloy product is obtained, and the sintered alloy is cryogenically treated with liquid nitrogen at -180°C to -190°C, kept for 2 hours, and then tempered at 200°C to 300°C, kept for 30 minutes. The test results are shown ...

Embodiment 2

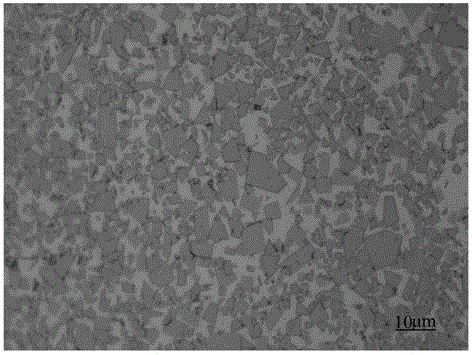

[0048] Using WC powder with Fsss particle size of 3.5 μm and 5.5 μm, the mass fraction of 3.5 μm WC powder is 60%, and the mass fraction of 5.5 μm WC powder is 40%, by weight ratio WC:Co:Ni:Cr 3 C 2 : (WC-TiC-NbC) solid solution = 72.4: 25: 0.8: 0.8: 1 Formula with powder, the mass ratio of wet grinding balls to the mixture is 1.5:1, the grinding medium is alcohol, and the ratio of alcohol to mixture is 1L: 2Kg, the molding agent is paraffin, the addition amount is 2% of the weight of the mixture, ball milled for 13 hours, the powder after ball milling is spray-dried and granulated, and pressed into shape, and finally put into a 6MPa low-pressure sintering furnace and kept at 1380°C for 60min After the sintering furnace is cooled to room temperature to obtain alloy products, the sintered alloy is cryogenically treated with liquid nitrogen at -180°C to -190°C, kept for 2 hours, and then tempered at 200°C to 300°C for 30 minutes. The test results are shown in Table 2. The prod...

Embodiment 3

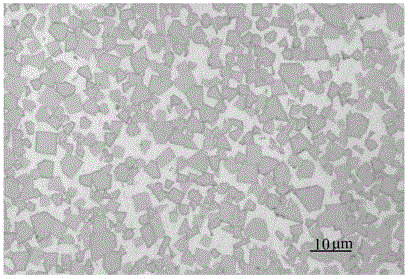

[0054] Using WC powder with Fsss particle size of 4.5μm, by weight ratio WC:Co:Ni:Cr 3 C 2 : (WC-TiC-NbC) solid solution = 74.4: 23: 0.8: 0.8: 1 Formula with powder, the mass ratio of wet grinding balls to the mixture is 1.5:1, the grinding medium is alcohol, and the ratio of alcohol to mixture is 1L: 2Kg, the molding agent is paraffin, the addition amount is 2% of the weight of the mixture, ball milled for 10 hours, the powder after ball milling is spray-dried and granulated, and pressed into shape, and finally put into a 1MPa low-pressure sintering furnace and kept at 1370°C for 60min After the sintering furnace is cooled to room temperature to obtain alloy products, the sintered alloy is cryogenically treated with liquid nitrogen at -180°C to -190°C, kept for 1 hour, and then tempered at 200°C to 300°C for 30 minutes. The test results are shown in Table 3. The product upsets more than 800,000 pieces of stainless steel nuts.

[0055] Table 3 Example 3 alloy physical and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com