Submicron grain Ti(C, N)-base cermet and its prepn process

A submicron, metal-based technology, applied in the field of cermet materials, can solve the problems of poor strength and toughness, limit the application range of cermets, etc., achieve the effect of improving hardness and toughness, and reducing tissue stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

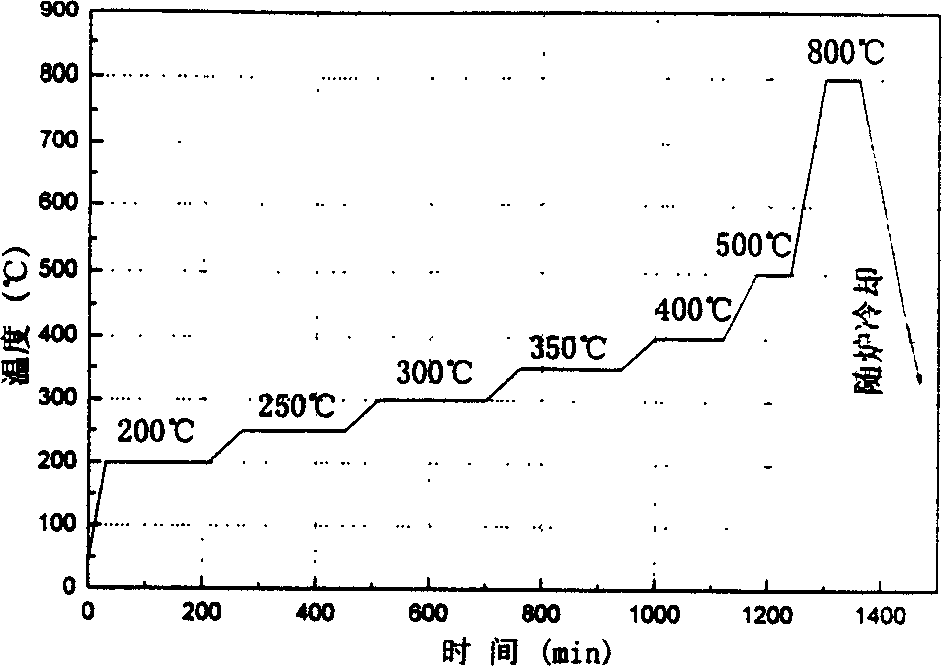

[0039] Select TiC, TiN, WC, Mo, and Ni in Table 2 as raw materials and add an appropriate amount of carbon powder, so that the atomic percentages of the components of the prepared Ti(C, N)-based cermet are approximately: Ti 38, Mo 4.5, W 1.3 , Ni 13, N 6.5, and the rest are C. The samples were prepared by stirring ball milling, sintering-hot isostatic pressing process or vacuum sintering. Stirring ball milling must make the linear velocity of the ball milling medium move above 0.5m / s; the ball-to-material ratio is 5:1; the ball milling time is 2, 6, 12, and 24 hours respectively. During the ball milling process of the mixed powder, an appropriate amount of forming agent is added, dried, molded, and then sintered. The sintering is carried out in a sintering-hot isostatic pressing integrated furnace, the sintering temperature is 1420°C, argon is used as the pressure transmission medium, and the atmospheric pressure is 1.7MPa. Vacuum sintering and ball milling were also carried...

example 2

[0043] The raw materials in Table 2 are selected for batching, so that the atomic percentages of the components of various Ti(C, N)-based cermets prepared are shown in Table 4. The samples were prepared by stirring ball milling, sintering-hot isostatic pressing process. Stirring ball milling must make the linear velocity of the ball milling medium move above 0.5m / s; the ratio of ball to material is 5:1; the time of stirring ball milling is 12 hours respectively. During the ball milling process of the mixed powder, an appropriate amount of forming agent is added, dried, molded, and then sintered. The sintering is carried out in a sintering-hot isostatic pressing integrated furnace, the sintering temperature is 1420°C, argon is used as the pressure transmission medium, and the atmospheric pressure is 1.7MPa. The performance and grain size of hard phase of each alloy are shown in Table 5.

[0044] match

party

Preface

No

Raw materials

...

example 3

[0060] Select TiC, TiN, WC, Mo, and Ni in Table 2 as raw materials and add an appropriate amount of carbon powder, so that the atomic percentages of the components of the prepared Ti(C, N)-based cermet are approximately: Ti 38, Mo 4.5, W 1.3 , Ni 13, N 6.5, and the rest are C. The samples were prepared by planetary ball milling, sintering-hot isostatic pressing process. The revolution speed of the turntable of the planetary ball mill was set at 450rpm. The ball milling time is 12; 24h respectively. After the mixed powder is ball milled, an appropriate amount of molding agent is added, dried, molded, and then sintered. The sintering is carried out in a sintering-hot isostatic pressing integrated furnace, the sintering temperature is 1420°C, argon is used as the pressure transmission medium, and the atmospheric pressure is 1.7MPa. Table 6 shows the performance of the alloy and the grain size of the hard phase after ball milling for 12 and 24 hours.

[0061] Table 6 Propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com