High-pressure sintering combined die and high-pressure rapid sintering method for preparing nanometer ceramic thereof

A combined mold and high-pressure sintering technology, which is applied in the direction of ceramic molding machines and manufacturing tools, can solve the problems of low-temperature and rapid densification sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

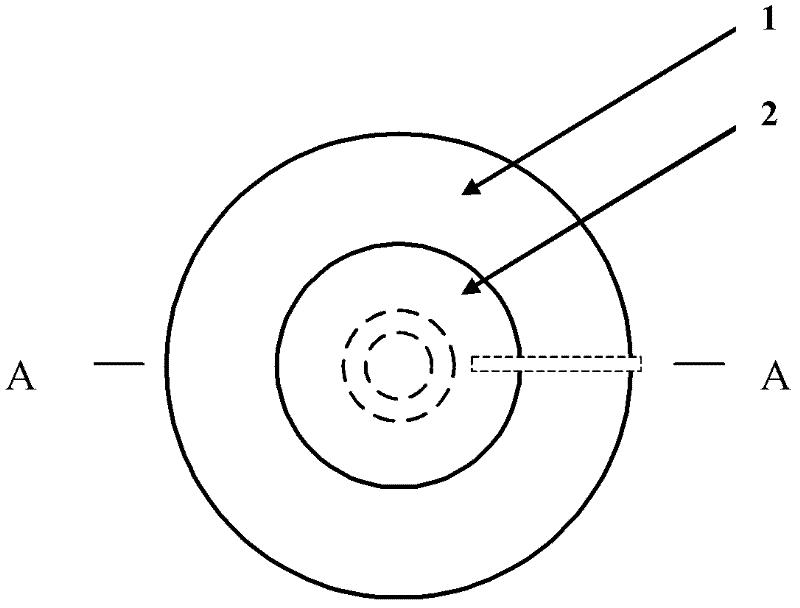

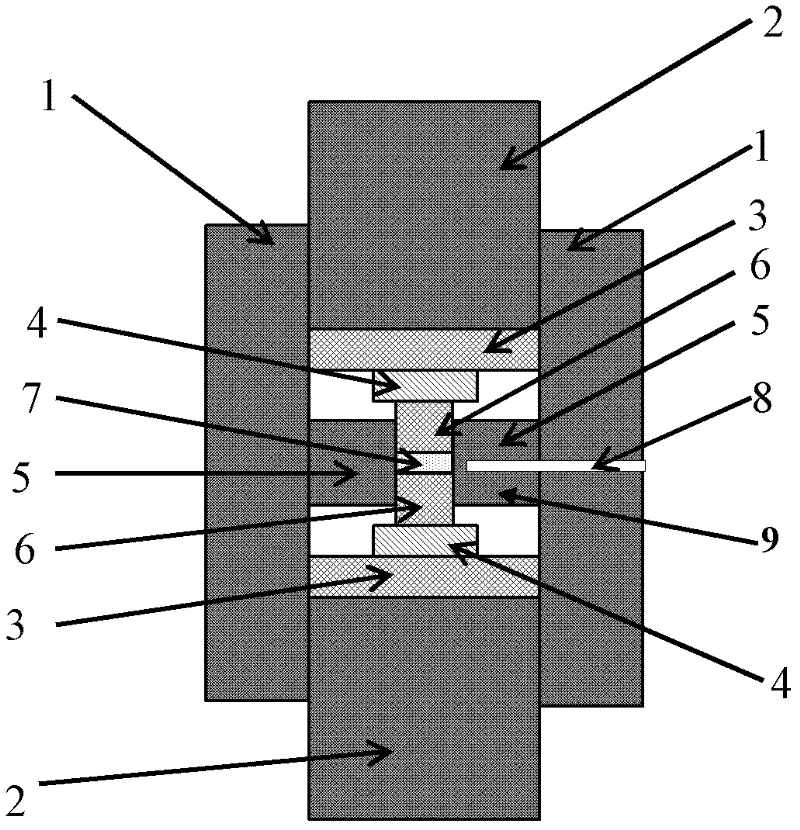

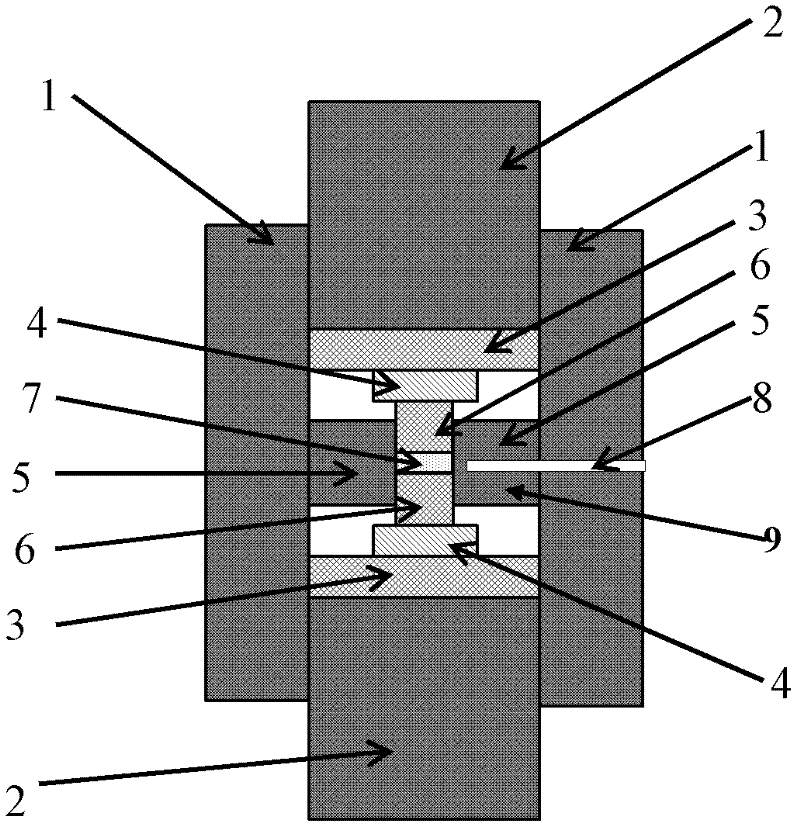

[0025] (1) Pre-preparation of high-pressure sintering composite mold

[0026] (1) The high-performance graphite material provided by Shanghai Toyo Carbon Co., Ltd. is processed into a through hole with a thermocouple inserted. The size is: The outer mold 1, the size is: The inner mold 5 and its dimensions are: The outer pressure head 2; the Ni-based ultra-high temperature alloy of model GH3030 is processed into a size of: metal laminations 4.

[0027] (2) SiC, AlN and Lu with a mass ratio of 80:15:5 after ball mill mixing by plasma activation sintering method 2 o 3 The powder is sintered under the sintering conditions of heating rate of 300°C / min, sintering temperature of 1600°C, sintering pressure of 40MPa, sintering holding time of 5min and vacuum degree of 12Pa to form the following sizes: with The discs are used as ceramic laminations 3 and internal pressure heads 6 respectively after grinding and flattening.

[0028] (2) High-pressure rapid sintering method o...

Embodiment 2

[0032] (1) Pre-preparation of high-pressure sintering composite mold

[0033] (1) The high-performance graphite material provided by Shanghai Toyo Carbon Co., Ltd. is processed into a through hole with a thermocouple inserted into the following dimensions: The outer mold 1, the size is: The inner mold 5 and its dimensions are: The outer pressure head 2; the Ni-based ultra-high temperature alloy of the model GH3030 is processed into a size of: metal laminations 4.

[0034] (2) Using hot pressing sintering method (equipment adopts High-Multi-5000 multi-functional furnace), SiC, AlN and Lu with a mass ratio of 80:15:5 after ball mill mixing 2 o 3 The powders were sintered at a sintering temperature of 1850°C, a holding time of 60min, a pressure of 40MPa and a nitrogen atmosphere to form the following sizes: with The wafers are used as ceramic laminations 3 and internal pressure heads 6 respectively after grinding and flattening.

[0035] (2) High-pressure rapid sinte...

Embodiment 3

[0039] (1) Pre-preparation of high-pressure sintering composite mold

[0040] (1) The high-performance graphite material provided by Shanghai Toyo Carbon Co., Ltd. is processed into a through hole with a thermocouple inserted into the following dimensions: The outer mold 1, the size is: The inner mold 5 and its dimensions are: The outer pressure head 2; the Co-based ultra-high temperature alloy of the model ECY768 is processed into a size of: metal laminations 4.

[0041] (2) SiC, AlN and Lu with a mass ratio of 80:15:5 after ball mill mixing by spark plasma sintering (SPS) method 2 o 3 The powder is sintered under the sintering conditions of heating rate of 300°C / min, sintering temperature of 1600°C, sintering pressure of 40MPa, sintering holding time of 5min and vacuum degree of 12Pa to form the following sizes: with The wafers are used as ceramic laminations 3 and internal pressure heads 6 respectively after grinding and flattening.

[0042] (2) High-pressure r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com