Method for preparing apatite type composite solid electrolyte ceramic material by ultrasonic-assisted sol-gel method

A technology of sol-gel method and solid electrolyte, which is applied in the field of preparation of solid electrolyte ceramic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of an apatite type composite solid electrolyte ceramic sheet, the steps are as follows:

[0028] ①, according to the target sample Ba x / 3 La 10-x / 3 Si 6-y Ti y o 27±δ The stoichiometric ratio of La(NO 3 ) 3 ·6H 2 O, Ba(NO 3 ) 2 、C 8 h 20 o 4 Si, C 16 h 36 o 4 Ti, add 100ml of distilled water, then add citric acid and ethylene glycol.

[0029] There are a total of 10 groups in the experiment, corresponding to the two cases where y is taken from 0 and 0.5, and x is taken from 0, 1, 2, 3 and 4 respectively. For each set of experiments, the molar mass of citric acid was 1.5 times the amount of metal ions contained in the components, and the weight of ethylene glycol was 1.2 times the weight of citric acid.

[0030] ②. Stir continuously with a glass rod to fully dissolve the solid particles in the solution, then add an appropriate amount of ammonia water to adjust the pH value to 4-6.

[0031]③. Put the prepared solution in an ultrasonic...

Embodiment 2

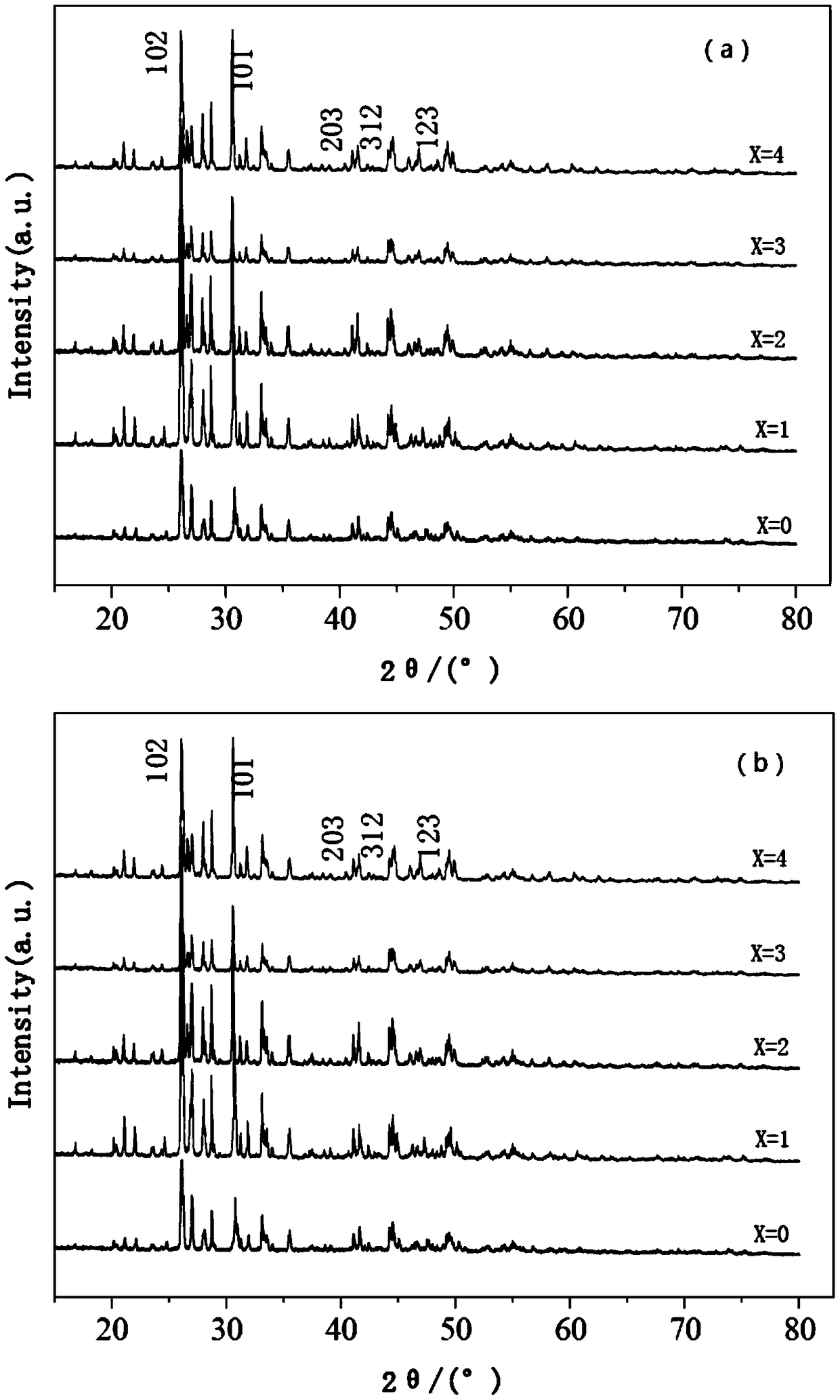

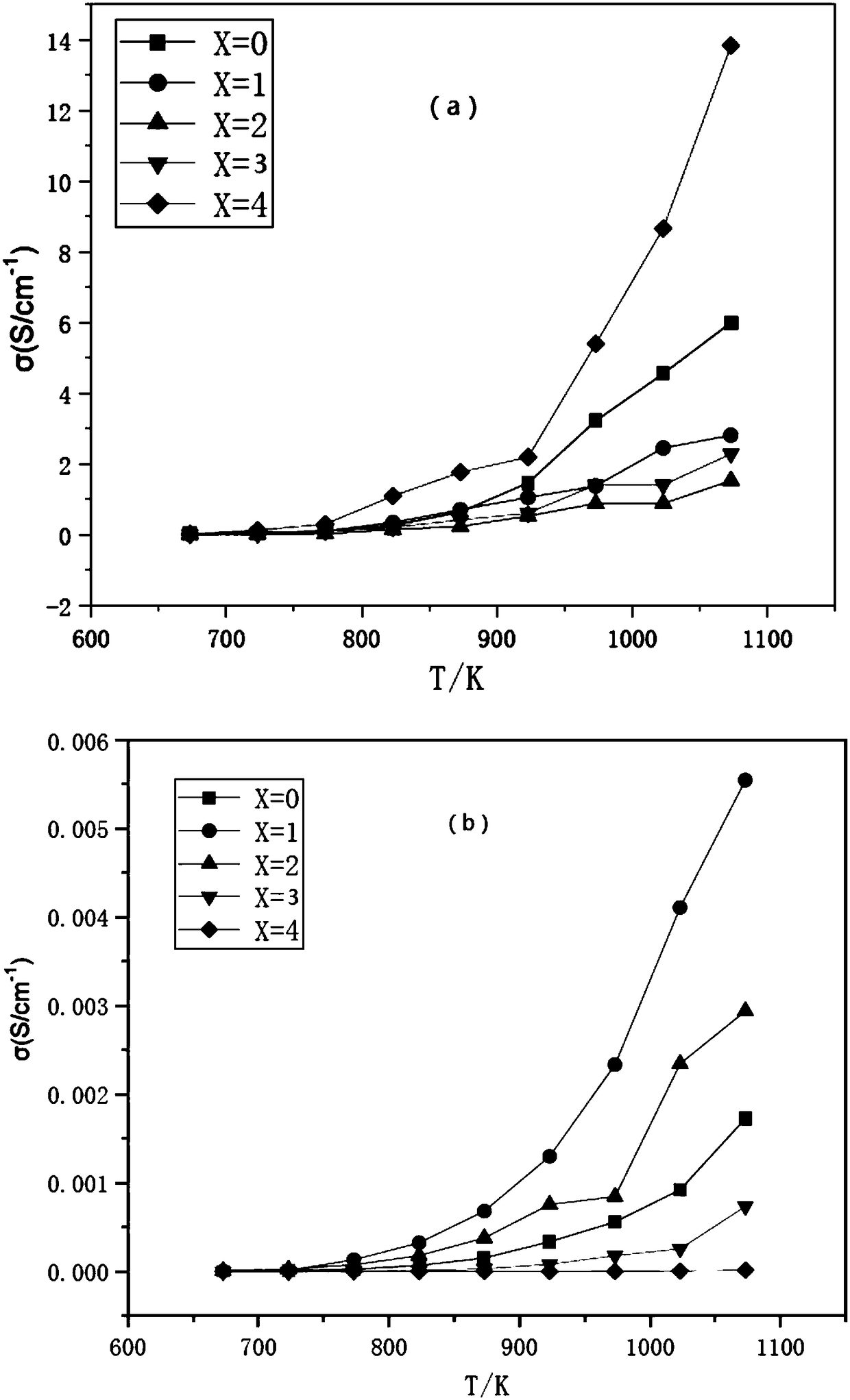

[0038] Ba x / 3 La 10-x / 3 Si 6-y Ti y o 27±δ Performance Characterization of Electrolyte Powder and Ceramic Sheet

[0039] In the preparation of Ba x / 3 La 10-x / 3 Si 6-y Ti y o 27±δ After the electrolyte powder and ceramic sheets, samples are required for analysis. In the process of experimental preparation, a part of the powder needs to be reserved before firing the ceramic sheet to test the XRD data, infrared spectrum and thermogravimetric analysis. Part of the fired ceramic sheet is used for SEM scanning electron microscope analysis, and the other part of the ceramic sheet is used to test the impedance after silver plating. It should be noted that the silver plating on the side of the ceramic sheet needs to be ground with sandpaper before measuring the impedance. avoid short circuit

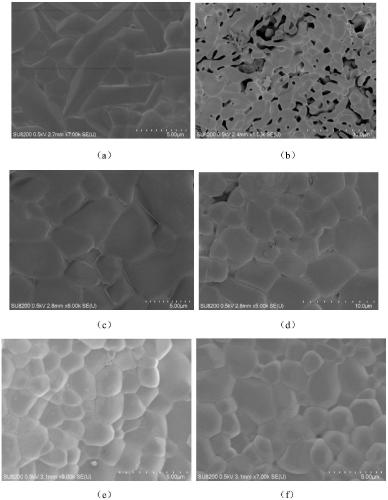

[0040] 1. SEM test analysis

[0041] After the preparation of the test sample is completed, various performance tests are started, among which the scanning electron microscope (SEM) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com