Tungsten aluminum-copper alloy sintered body and preparation thereof

A sintered body and copper alloy technology, applied in the field of tungsten-aluminum-copper alloy sintered body and its manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

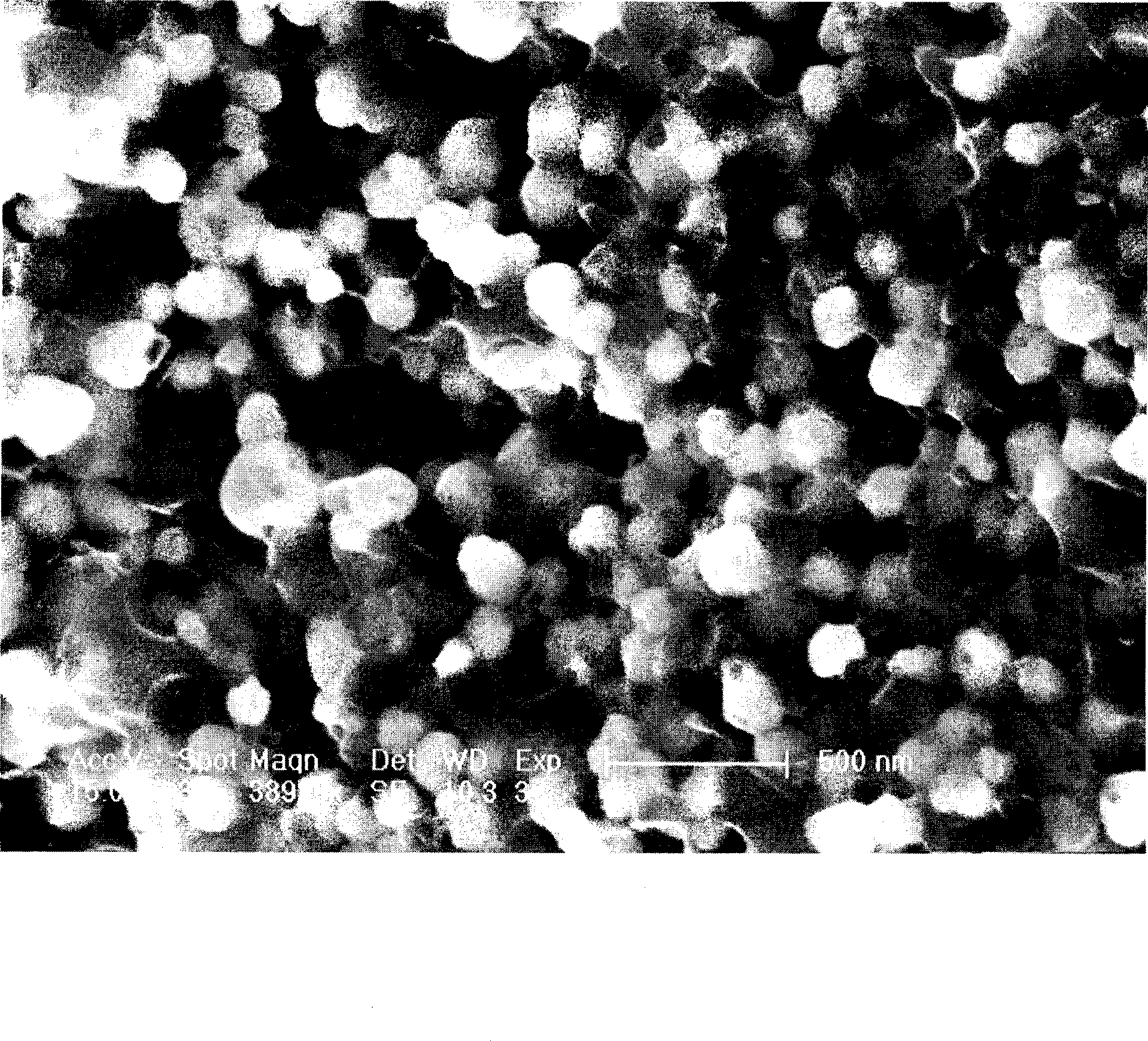

Image

Examples

Embodiment 1

[0011] Embodiment 1: 30 grams (W 0.9 Al 0.1 ) alloy and 3.33 grams of copper powder are mixed and cold-pressed, put into a graphite mould, put into a vacuum hot-press sintering machine, at 10 -2 Hot-pressing sintering under Pa vacuum condition, sintering temperature is 1400°C, pressure is 40MPa, and sintering time is 30 minutes to obtain tungsten-aluminum-copper alloy sintered body. The relative density is 99%. Conductivity 23.3MS / m -1 , microhardness 4.13GPa, bending strength 784MPa.

Embodiment 2

[0012] Embodiment 2: will be 25 grams, (W 0.75 Al 0.25 ) alloy and 2.78 grams of copper powder are mixed and cold-pressed, put into a graphite mold, put into a vacuum hot-press sintering machine, -2 Hot-pressing sintering under Pa vacuum condition, sintering temperature is 1400°C, pressure is 40MPa, and sintering time is 30 minutes to obtain tungsten-aluminum-copper alloy sintered body. The relative density is 99%. Conductivity 24.4MS / m -1 , microhardness 4.31GPa, bending strength 791MPa.

Embodiment 3

[0013] Embodiment 3: 20 grams (W 0.5 Al 0.5 ) alloy and 2.22 grams of copper powder are mixed and cold-pressed, put into a graphite mould, put into a vacuum hot-press sintering machine, at 10 -2 Hot-pressing sintering under Pa vacuum condition, sintering temperature is 1400°C, pressure is 40MPa, and sintering time is 30 minutes to obtain tungsten-aluminum-copper alloy sintered body. The relative density is 99%. Conductivity 24.8MS / m -1 , microhardness 4.50GPa, bending strength 850MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com