Method for preparing high-heat-conductivity aluminum nitride ceramics by self-propagating powder

A self-propagating technology of aluminum nitride ceramics, applied in the field of preparation of aluminum nitride ceramic substrates, can solve the problems of high equipment requirements and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] A method for preparing high thermal conductivity aluminum nitride ceramics from self-propagating powder, comprising the following preparation steps:

[0020] (1) Pre-heat treatment of self-propagating powder: heat-treat commercial self-propagating aluminum nitride powder in a high-temperature graphite furnace, the heat treatment temperature is 1600-1700°C, the treatment time is 1-4h, and the protective atmosphere is nitrogen;

[0021] (2) Preparation of casting slurry: 100 parts by weight of self-propagating aluminum nitride powder treated in step (1), 3-8 parts by weight of Y 2 o 3 and 0.5-1 parts by weight of TiO 2 (Sintering additive), ball milling and mixing with 23 parts by weight of solvent (absolute ethanol / butanol mixture), 2.0 parts by weight of dispersant (fish oil) for 24 hours, and then mixed with 20 parts by weight of solvent (absolute ethanol / butanol mixture ), 10 parts by weight of binder (polyvinyl butyral), and 5 parts by weight of plasticizer (dibuty...

Embodiment 1~13

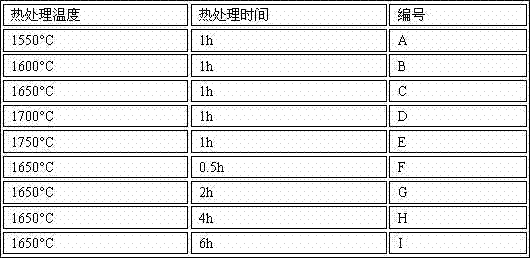

[0025] 1000g of self-propagating high-temperature synthetic aluminum nitride powders were respectively heat-treated in a high-temperature graphite furnace. The heat-treatment conditions are shown in Table 1, and the treated powders were used for later use.

[0026] Table 1

[0027]

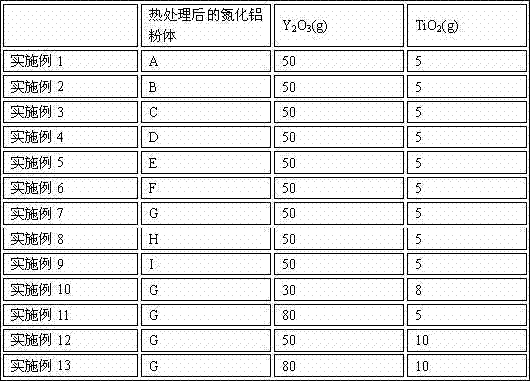

[0028] Respectively weigh 1000g of the above heat-treated powder, and then combine with Y 2 o 3 and TiO 2 (The amount of the two is shown in Table 2), 230g of absolute ethanol / butanol, 20g of fish oil and ball milled for 24 hours, then added 200g of absolute ethanol / butanol, 100g of polyvinyl butyral (PVB), 50g of ortho Dibutyl phthalate was mixed together for 12 hours, and the slurry was subjected to vacuum defoaming treatment for 5 hours to obtain a casting slurry with a viscosity near 20000 cps. Wherein the ratio of absolute ethanol / butanol is 1:2.

[0029] Table 2

[0030]

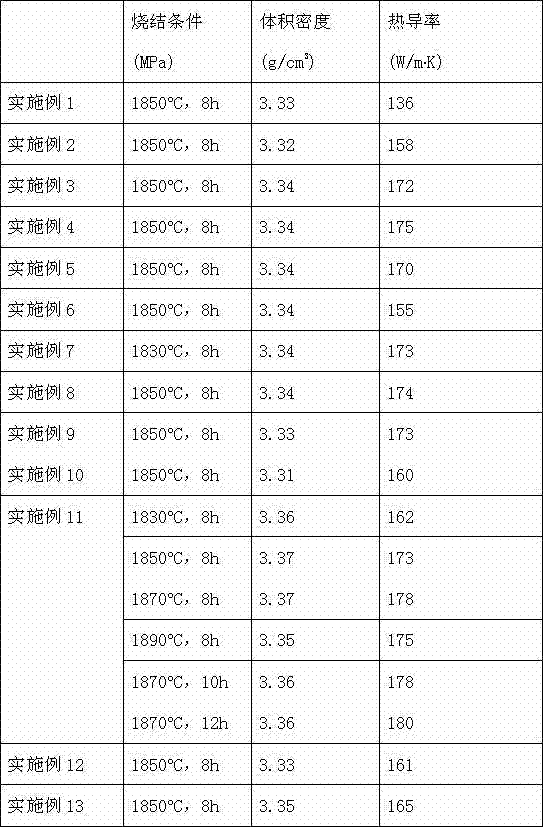

[0031]The slurry was passed through a tape casting machine to obtain a tape casting green body with a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com