Method for preparing aluminum oxynitride transparent ceramic

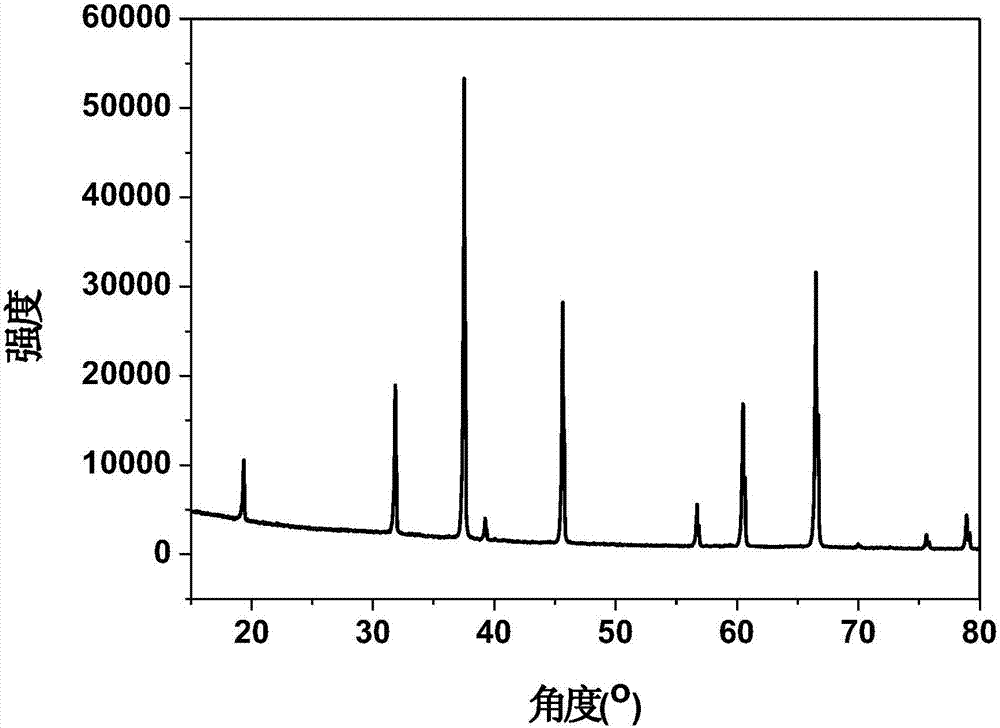

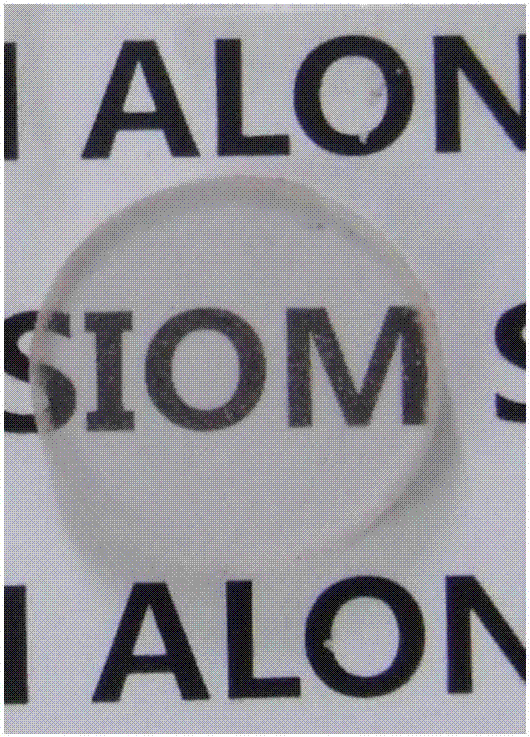

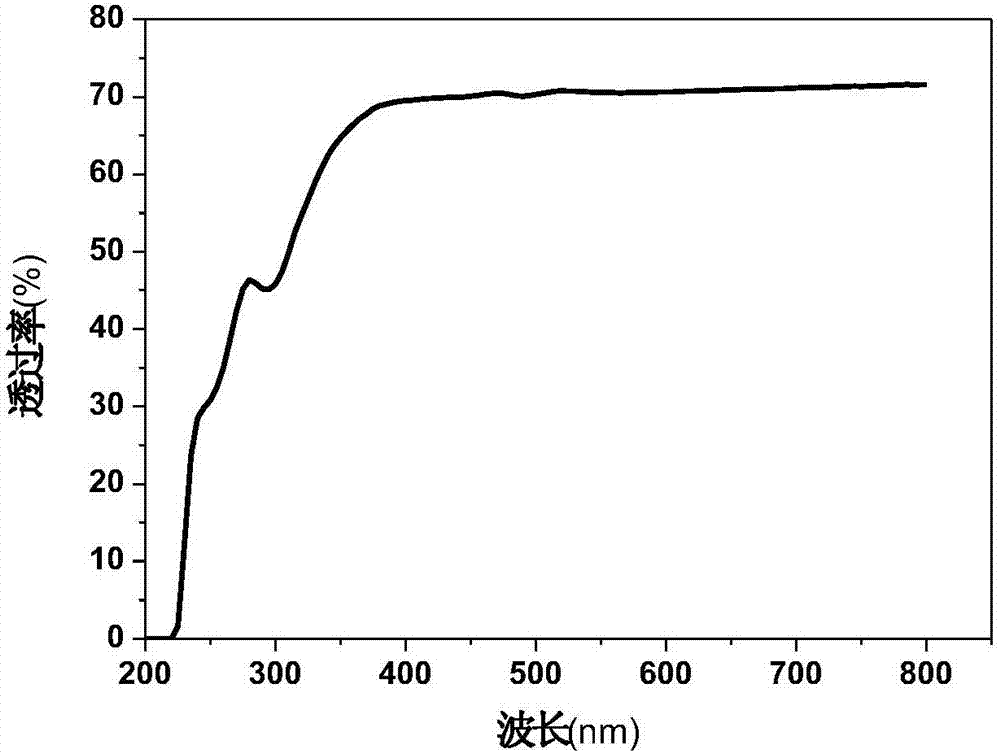

A technology of transparent ceramics and aluminum oxynitride, which is applied in the field of preparation of aluminum oxynitride transparent ceramics, and can solve problems such as low transmittance, high AlON phase synthesis temperature, and blackened sample color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Powder mixing: high-purity alumina and aluminum nitride are weighed at a mass ratio of 70:30, and sintering aids MgO and Y 2 o 3 The added amounts of are respectively 0.04wt% and 0.08wt%. The mixed powder with a mass of 80g was mixed with 60ml of absolute ethanol and 300g of high-purity alumina balls and ball milled at a speed of 250 rpm. The milled powder was dried at 70°C for 8 hours, and then passed through a 200-mesh sieve;

[0033] 2) Pretreatment: put the mixed powder sieved in step 1) in a muffle furnace for pre-calcination treatment to remove organic matter: the pre-calcination temperature is 800°C, and the holding time is 3h;

[0034] 3) Abrasive tooling: Put 5g of decarbonized powder in a Φ20 graphite mold. Before loading, a layer of graphite paper should be placed between the indenter and the powder and the inner wall of the mold, and the inner wall of the mold needs to be coated with a layer of boron nitride, which is convenient for demoulding after sin...

Embodiment 2

[0040] 1) with step 1) in embodiment 1);

[0041] 2) with step 2) in embodiment 1;

[0042] 3) with step 3) in embodiment 1;

[0043] 4) Spark plasma sintering

[0044] Place the assembled mold in an SPS sintering furnace for rapid sintering under the following conditions: the pressure is 50MPa, the temperature is 1450°C, and the temperature is kept for 5 minutes to obtain a dense AlON ceramic phase.

[0045] 5) Pressureless sintering

[0046] Put the AlON ceramics obtained in step (4) into a pressureless sintering furnace for pressureless sintering, the condition is nitrogen atmosphere, the sintering temperature is 1700 ° C, and the temperature is kept for 3 hours to remove the carbon infiltrated in the SPS rapid sintering, and further improve the Density increases the transmittance of AlON ceramics.

[0047] 6) The ceramic sample sintered in step 5) is processed and polished to 2mm with a surface grinder and diamond grinding paste.

Embodiment 3

[0049] 1) Powder mixing: high-purity alumina and aluminum nitride are weighed at a mass ratio of 73:27, sintering aids MgO and Y 2 o 3 The addition amounts of are respectively 0.04wt% and 0.06wt%. The mixed powder with a mass of 80g was mixed with 60ml of absolute ethanol and 300g of high-purity alumina balls for ball milling, the milling speed was 250rpm, and the milled powder was dried at 70°C for 8 hours, and then passed through a 200-mesh sieve;

[0050] 2) with step 2) in embodiment 1;

[0051] 3) with step 3) in embodiment 1;

[0052] 4) Spark plasma sintering

[0053] Place the assembled mold in an SPS sintering furnace for rapid sintering under the following conditions: the pressure is 100MPa, the temperature is 1700°C, and the temperature is kept for 5 minutes to obtain a dense AlON ceramic phase.

[0054] 5) Pressureless sintering

[0055] Put the AlON ceramics obtained in step (4) into a pressureless sintering furnace for pressureless sintering, the conditions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com