Method for quickly preparing gamma aluminum nitride oxygen transparent ceramic powder

A technology of aluminum oxynitride and transparent ceramics, applied in the field of preparing γ-aluminum oxynitride ceramic powder, can solve the problems of large content of mixed impurities, high energy consumption, deterioration of optical properties of dense γ-AlON ceramics, etc. The effect of uniform diameter, high efficiency and easy crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

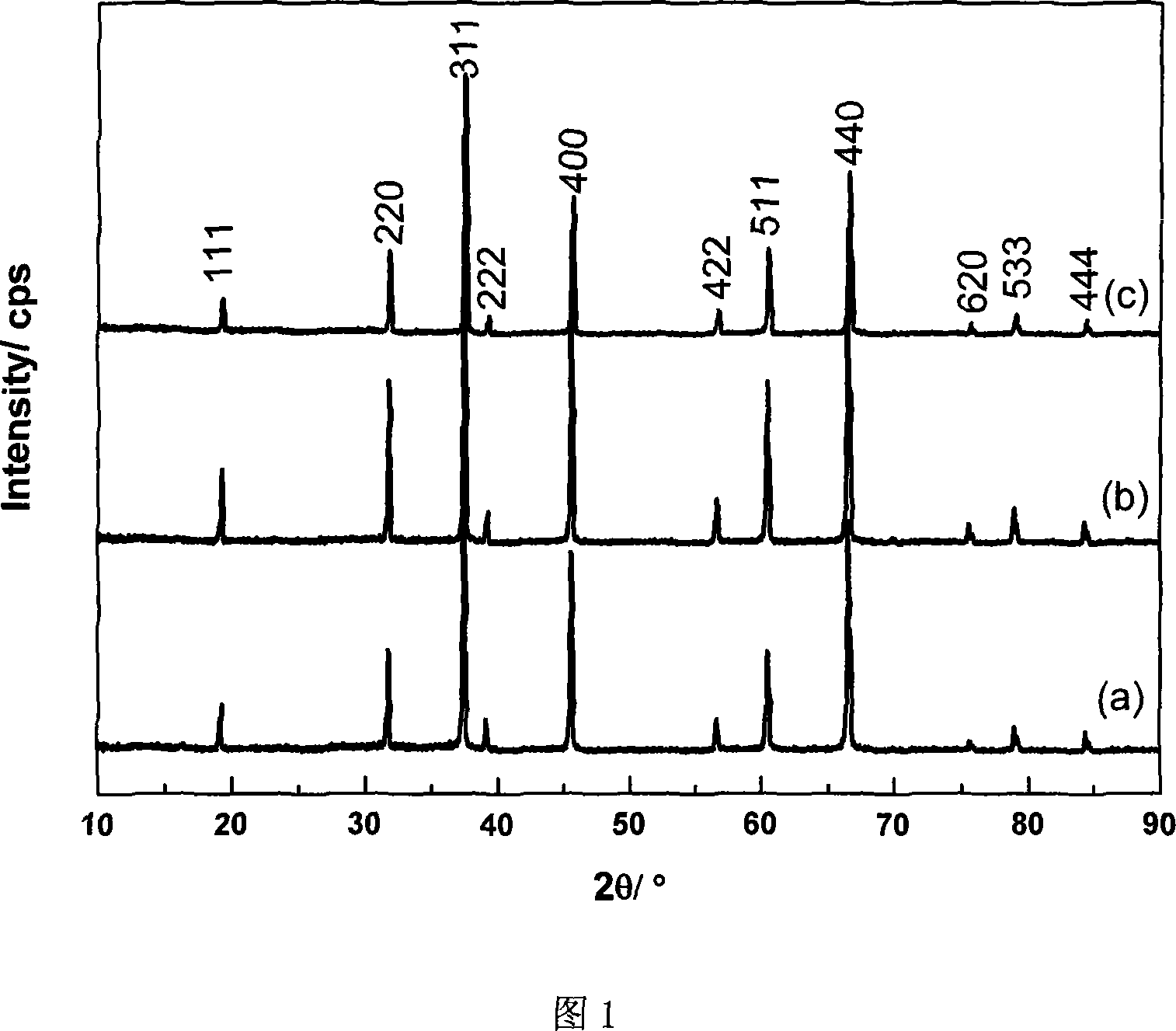

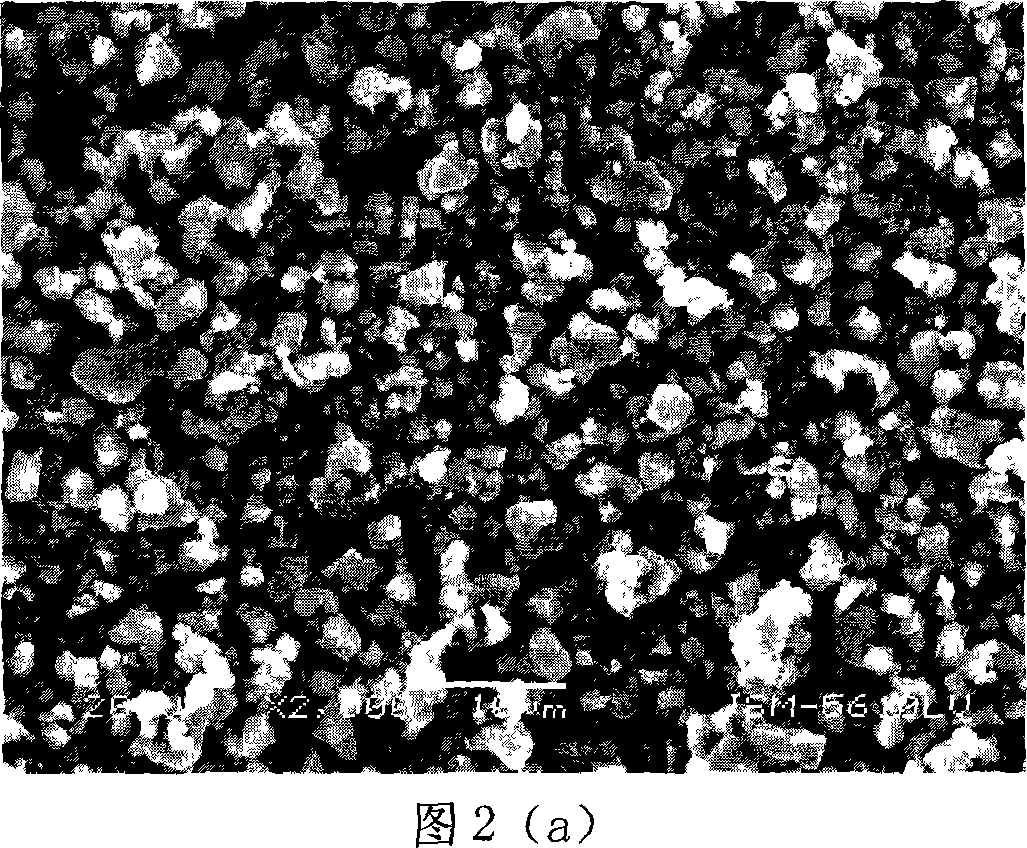

Embodiment 1

[0028] α-Al 2 o 3 Powder (purity greater than 99.99wt%, average particle size 0.5μm), AlN powder (purity greater than 99wt%, average particle size 0.05μm, specific surface area greater than 78m 2 / g) mixture is the raw material, where α-Al 2 o 3 The molar content of the powder was 72%, and the molar content of the AlN powder was 28%. Mix the materials by ball milling on a planetary ball mill for 10 hours, with absolute ethanol as the ball milling medium, high-purity Al 2 o 3 The ball is a milling ball, Al 2 o 3 Ball: Material (α-Al 2 o 3 powder and AlN powder): absolute ethanol mass ratio=2:1:3. The mixed material after ball milling was dried under vacuum at 83-87°C, and sieved through a 100-mesh sieve; 20 g of the dried mixed material was put into a circular graphite crucible whose inner wall was coated with boron nitride, and the inner diameter of the crucible was 40 mm. Placed in a graphite reactor, the inner diameter of the graphite reactor is 50mm. Put the grap...

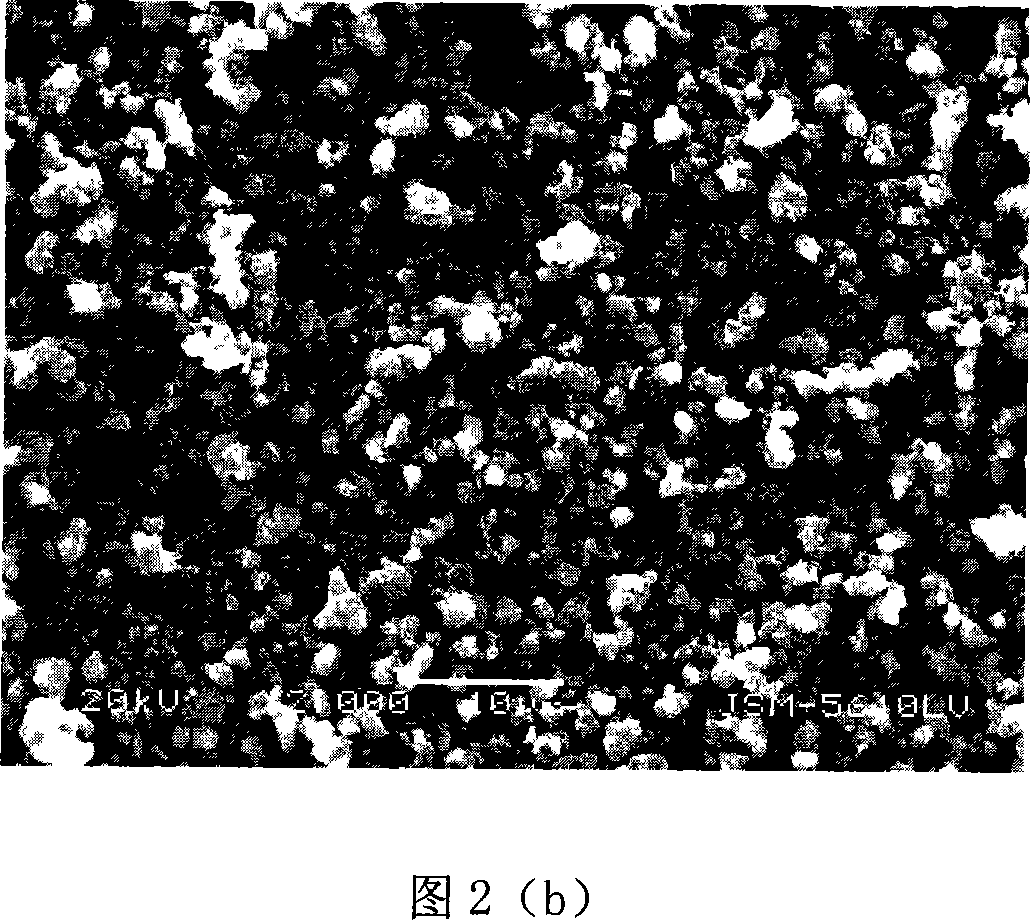

Embodiment 2

[0030] α-Al 2 o 3 Powder (purity greater than 99.99wt%, average particle size 0.5μm), AlN powder (purity greater than 99wt%, average particle size 0.05μm, specific surface area greater than 78m 2 / g) mixture is the raw material, where α-Al 2 o 3 The molar content of the powder is 60%, and the molar content of the AlN powder is 40%. Mix the materials by ball milling on a planetary ball mill for 10 hours, with absolute ethanol as the ball milling medium, high-purity Al 2 o 3 The ball is a milling ball, Al 2 o 3 Ball: Material (α-Al 2 o 3 powder and AlN powder): absolute ethanol mass ratio=2:1:3. The mixed material after ball milling was dried under vacuum at 83-87°C, and sieved through a 100-mesh sieve; 20 g of the dried mixed material was put into a circular graphite crucible whose inner wall was coated with boron nitride, and the inner diameter of the crucible was 40 mm. Placed in a graphite reactor, the inner diameter of the graphite reactor is 50mm. Put the graphi...

Embodiment 3

[0032] α-Al 2 o 3 Powder (purity greater than 99.99wt%, average particle size 0.5μm), AlN powder (purity greater than 99wt%, average particle size 0.05μm, specific surface area greater than 78m 2 / g) mixture is the raw material, where α-Al 2 o 3 The molar content of the powder was 66%, and the molar content of the AlN powder was 34%. Mix the materials by ball milling on a planetary ball mill for 10 hours, with absolute ethanol as the ball milling medium, high-purity Al 2 o 3 The ball is a milling ball, Al 2 o 3 Ball: Material (α-Al 2 o 3 powder and AlN powder): absolute ethanol mass ratio=2:1:3. The mixed material after ball milling was dried under vacuum at 83-87°C, and sieved through a 100-mesh sieve; 20 g of the dried mixed material was put into a circular graphite crucible whose inner wall was coated with boron nitride, and the inner diameter of the crucible was 40 mm. Placed in a graphite reactor, the inner diameter of the graphite reactor is 50mm. Put the grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com