Expanded type fireproof coating and preparation method thereof

A fire retardant coating and intumescent technology, used in fire retardant coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor water resistance, poor high temperature resistance, poor aging resistance, etc., to improve hydrolysis resistance and overcome poor water resistance. and poor aging resistance, the effect of improving the fireproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The specific preparation process of novel intumescent fireproof coating in the present embodiment is:

[0025] 15% microencapsulated ammonium polyphosphate, 4.5% microencapsulated pentaerythritol, 10.5% microencapsulated melamine, 2% montmorillonite and 28% deionized Water is placed in a basket grinder and ground to a fineness of less than 90 microns; then add 32% acrylic emulsion, 1% alkylphenol polyoxyethylene ether, 1% carboxymethyl cellulose and 1% hexadecimal Sodium phosphate is placed in a stainless steel dispersion tank and dispersed with a disperser to obtain an intumescent fireproof coating.

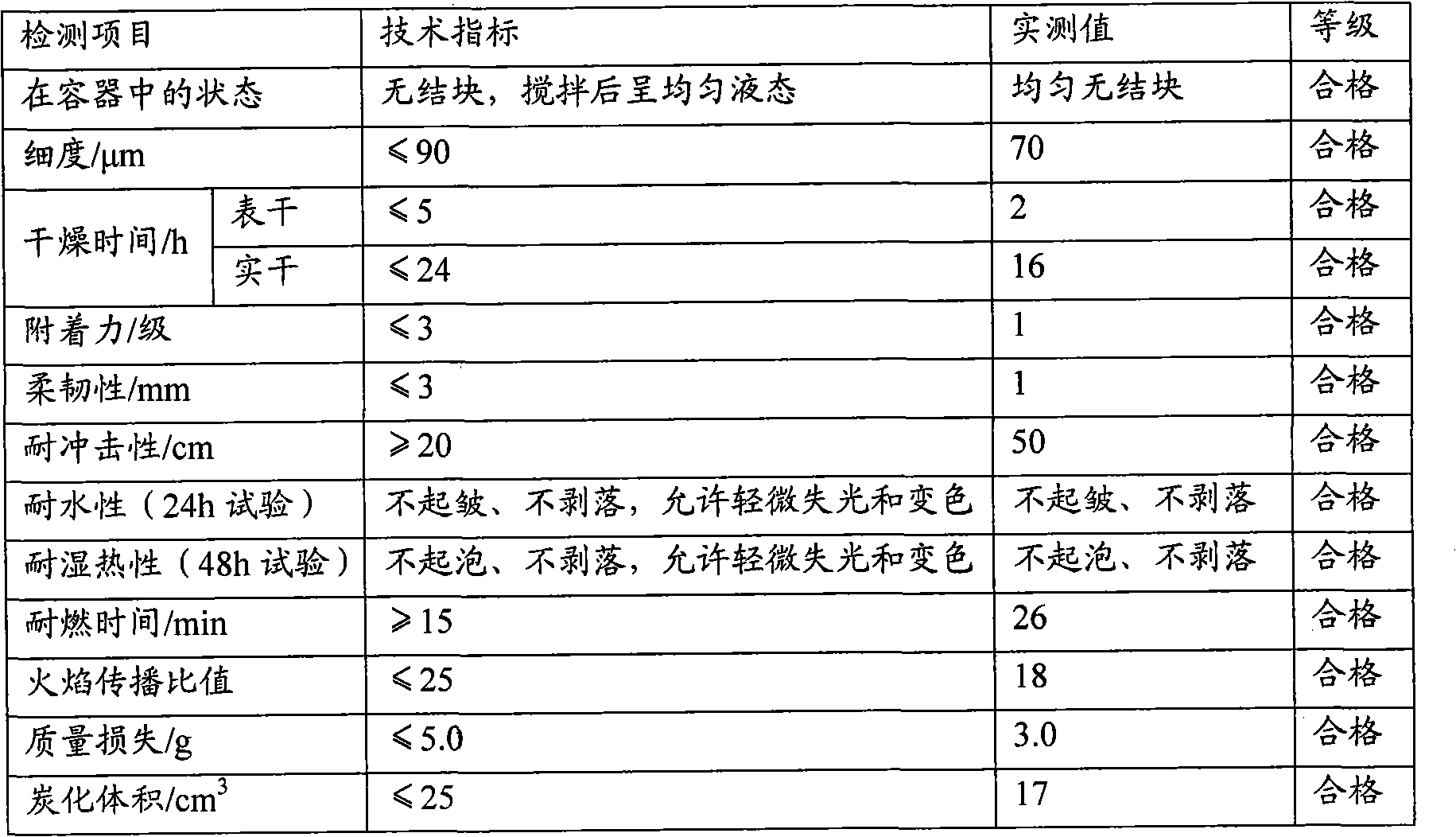

[0026] The physical and chemical performance test is carried out according to the national standard GB 12441-2005, and the test results can be seen in Table 1:

[0027] Table 1

[0028]

[0029] As can be seen from the technical indicators and measured values listed in Table 1: the intumescent fireproof coating prepared in this embodiment is uniform and has no caki...

Embodiment 2

[0031] The specific preparation process of novel intumescent fireproof coating in the present embodiment is:

[0032] 12% microencapsulated diammonium hydrogen phosphate, 6% microencapsulated starch, 12% microencapsulated urea, 5% zirconium phosphate and 25% deionized Water is placed in a basket grinder to grind and disperse to a fineness of less than 90 microns; then add 30% benzene-acrylic emulsion, 1% alkylphenol polyoxyethylene ether, 1% carboxymethyl cellulose and 2% Sodium hexametaphosphate is placed in a stainless steel dispersion tank and dispersed with a disperser to obtain an intumescent fireproof coating.

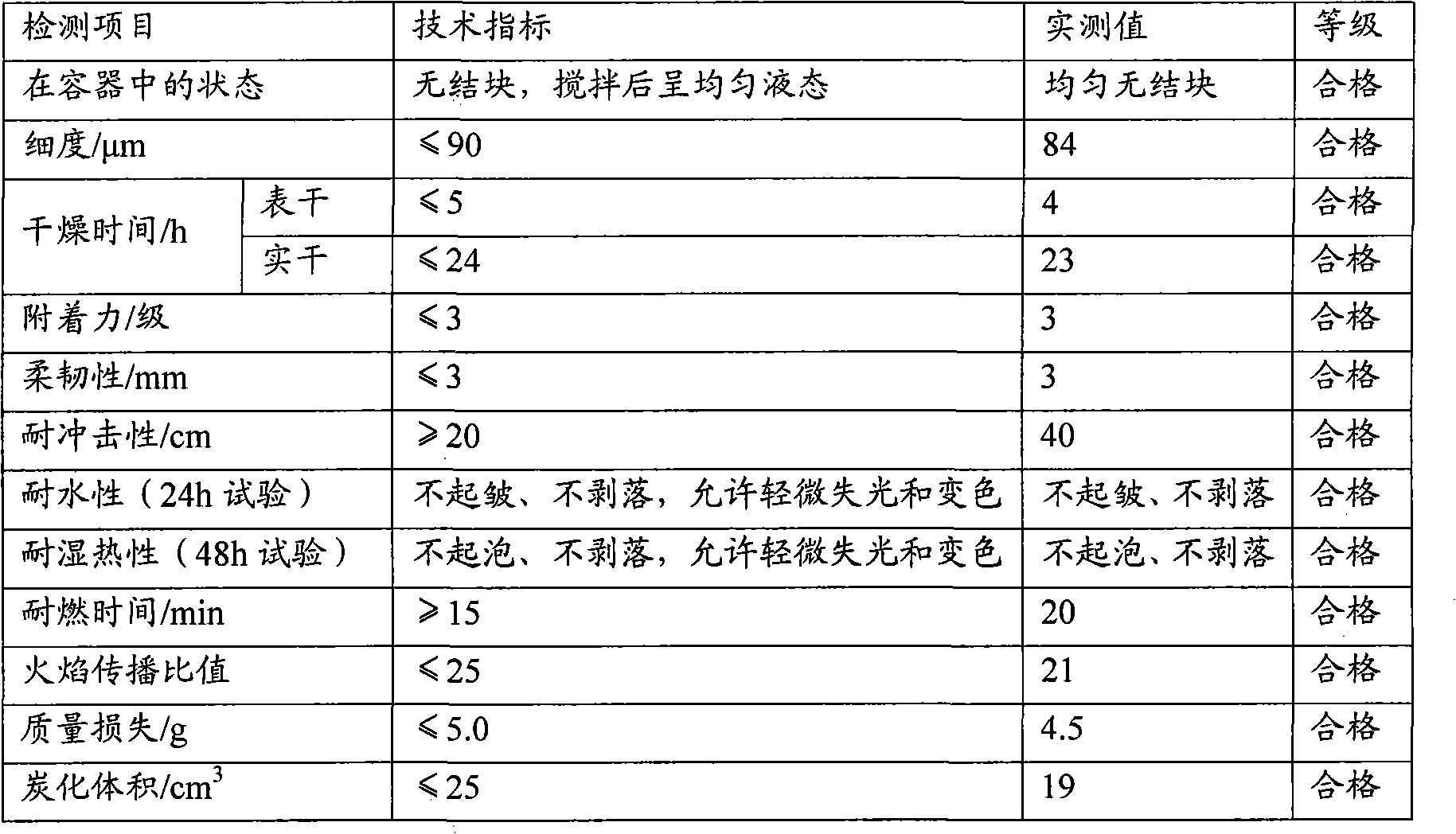

[0033] The physical and chemical performance test is carried out according to the national standard GB 12441-2005, and the test results can be seen in the following table 2:

[0034] Table 2

[0035]

[0036] As can be seen from the technical indicators listed in Table 2 and the measured values: the intumescent fireproof coating prepared in this embodiment i...

Embodiment 3

[0038] The specific preparation process of novel intumescent fireproof coating in the present embodiment is:

[0039] 18% microencapsulated ammonium dihydrogen phosphate, 3% microencapsulated starch, 9% microencapsulated melamine, 4% magnesium aluminum double hydroxide, 16 % xylene and 4% n-butanol are placed in a basket grinder to grind and disperse until the fineness is less than 90 microns; then add 30% epoxy resin, 7% melamine formaldehyde resin, 1% alkylphenol polyoxygen Vinyl ether, 1% carboxymethyl cellulose and 1% sodium hexametaphosphate are placed in a stainless steel dispersion tank and dispersed with a disperser to obtain an intumescent fireproof coating.

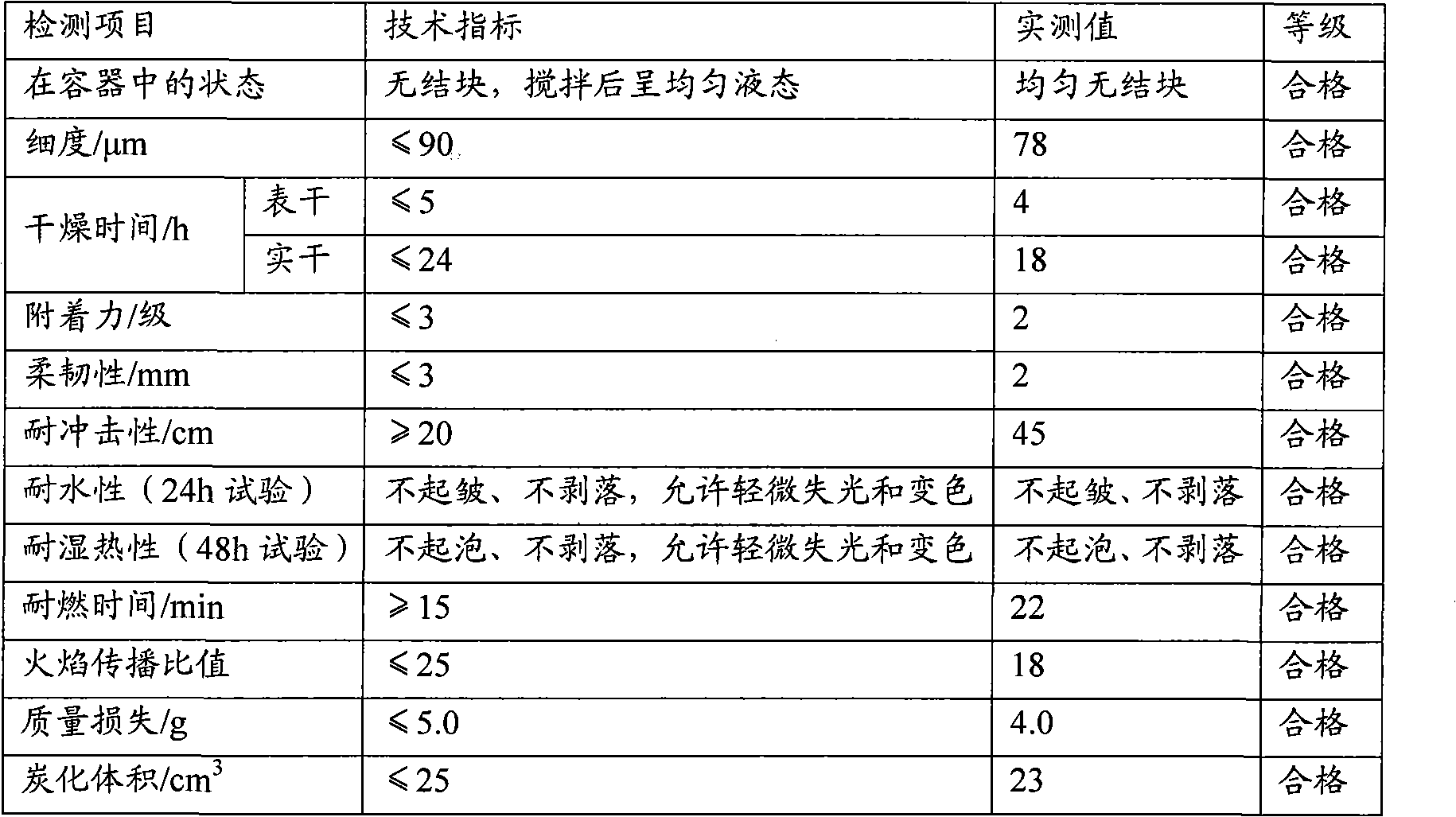

[0040] The physical and chemical performance test is carried out according to the national standard GB 12441-2005, and the test results can be seen in the following table 3:

[0041] table 3

[0042]

[0043] As can be seen from the technical indicators listed in Table 3 and the measured values: the intumes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com