Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

A polyisocyanate, water-based polyurethane technology, used in polyurea/polyurethane coatings, applications, chemical treatment of small raw hides/large raw hides/leather hides/furs, etc. Physical and chemical properties, the effect of superior water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

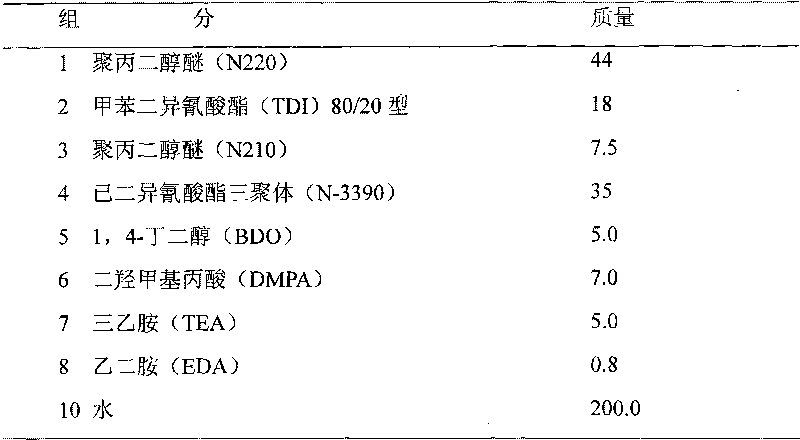

[0039] A polyisocyanate curing agent was used to modify the waterborne polyurethane dispersion, and its formulation components were listed in Table 1 to prepare a polyisocyanate curing agent modified waterborne polyurethane dispersion (PUD1).

[0040] Table 1

[0041]

[0042] Weigh according to the formula in Table 1. Dehydrate polyether polyols N220, N210 and BDO at a temperature of 120°C and a vacuum of 0.07Mpa for 3 hours, so that the water content is lower than 0.05%wt; under the protection of dry nitrogen, polyether polyols Add polyols N210 and N220, TDI (80 / 20 type) and hexamethylene diisocyanate trimer (N3390) into a four-neck flask equipped with a thermometer, stirring and reflux device, heat to 60°C while stirring, and drop 0.3g Catalyst (dibutyltin laurate) and react for 2 hours, then add BDO dropwise, add DMPA after keeping warm for 30 minutes, react at 70°C until the weight percentage of NCO groups in the system is below 5.0%, and generate about 116g of polyure...

Embodiment 2

[0044] Using the polyisocyanate curing agent prepared in Example 1 to modify the aqueous polyurethane dispersion, prepare the wood coating formulation as shown in Table 2.

[0045] Table 2 Waterborne Polyurethane Wood Coating Formulation

[0046] serial number

[0047] The preparation method is as follows: firstly add raw materials No. 2-7 into the stirring tank, disperse with a high-speed disperser for 10-30 minutes, then slowly add the PUD emulsion into the stirring tank, stir at a medium speed for 30-60 minutes, use AMP-95 Adjust the pH value of the coating. When the pH is > 7.0, slowly add No. 9 raw material, stir at a medium speed for 10 minutes, measure the viscosity of the coating system, filter, discharge and pack after the viscosity is qualified. Properties of the prepared wood coating: Appearance: Milky white slightly transparent liquid without mechanical impurities; PH=7-9; solid content 30-32%, viscosity 30-200cps. Wood coating film performance: Pencil h...

Embodiment 3

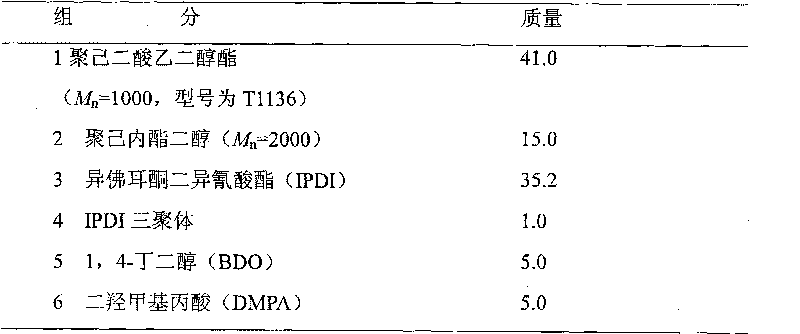

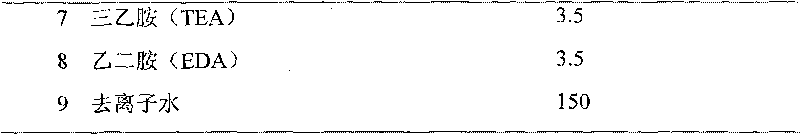

[0049] Polyethylene adipate and aliphatic diisocyanate were reacted to prepare polyisocyanate curing agent modified water-based polyurethane dispersion (PUD2). The raw material formulations used are listed in Table 3. m n is the number average molecular weight.

[0050] table 3

[0051]

[0052]

[0053] Weigh the polyethylene adipate, polycaprolactone diol and BDO at a temperature of 120°C and a vacuum of 0.09Mpa for 4 hours to dehydrate the polyethylene adipate, polycaprolactone diol and BDO according to the formula in Table 3, so that the water content is all lower than 0.05%wt;

[0054] Under the protection of dry nitrogen, polyethylene adipate and polycaprolactone diol, IPDI and IPDI trimer were added to a four-necked flask equipped with a thermometer, stirring and reflux devices, and heated to At 90°C, add 0.2g of catalyst (dimethylcyclohexylamine) dropwise and react for 2h, then add BDO dropwise, add DMPA after keeping the temperature for 30min, and react at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com