Mechanical seal device

A technology of mechanical sealing device and sealing ring, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of poor fluidity of sealing fluid, complex overall structure, thermal deformation of sealing surface, etc., and achieve the goal of improving the sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

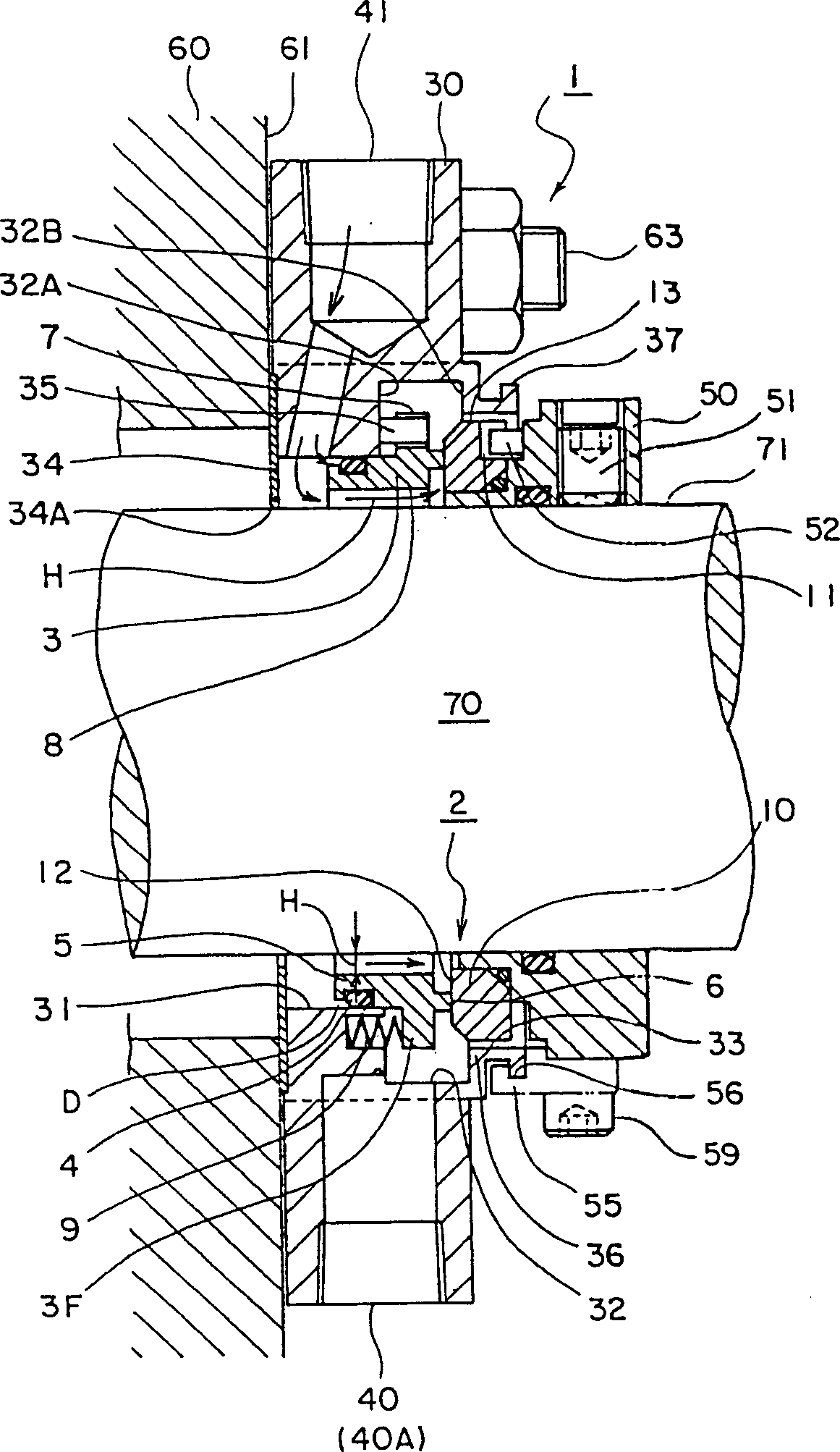

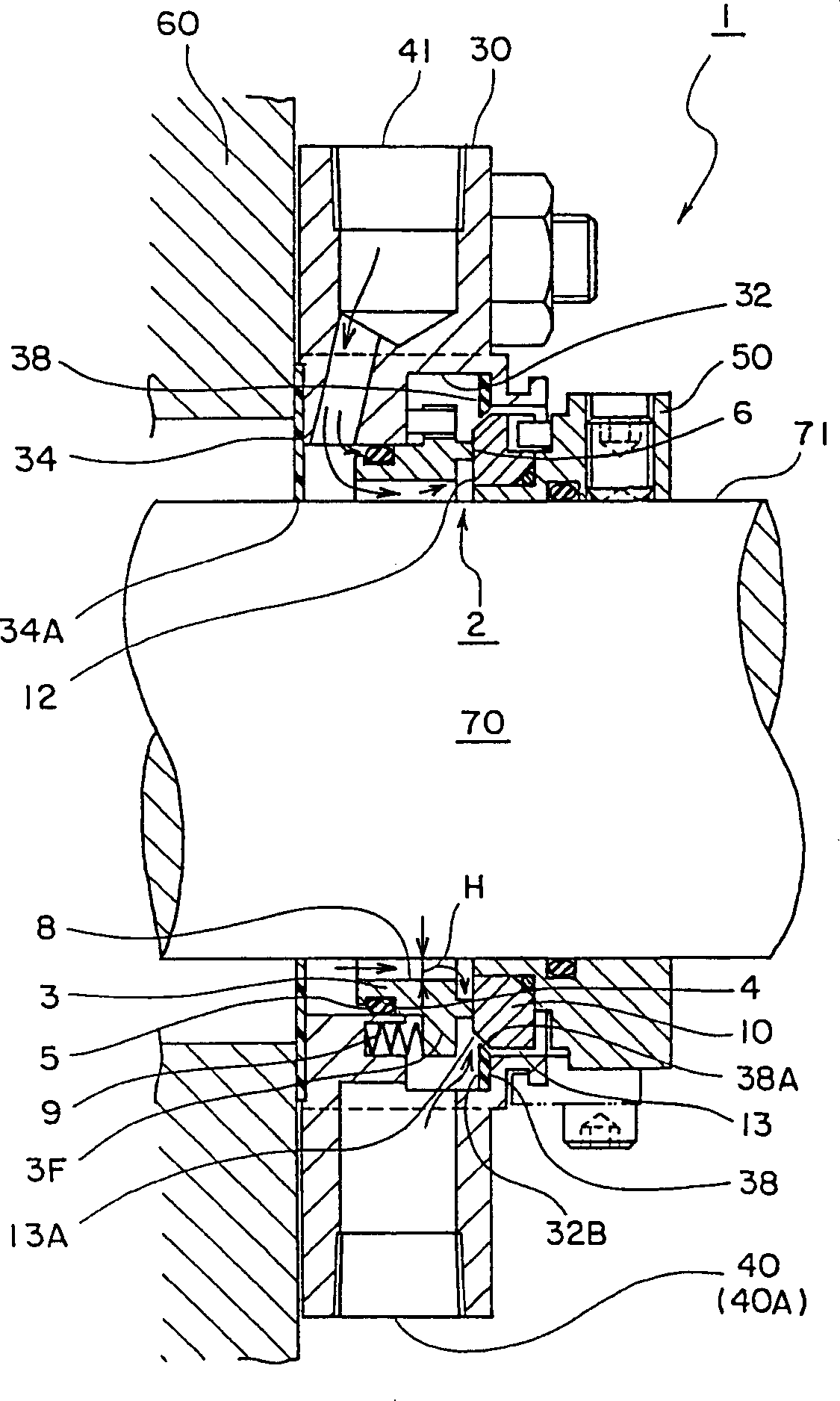

[0039] Hereinafter, the mechanical seal device 1 according to the embodiment of the present invention will be described in detail with reference to the accompanying drawings. In addition, the following drawings are not conceptual drawings for patent use, but are design drawings with accurate dimensional relationships based on experimental data.

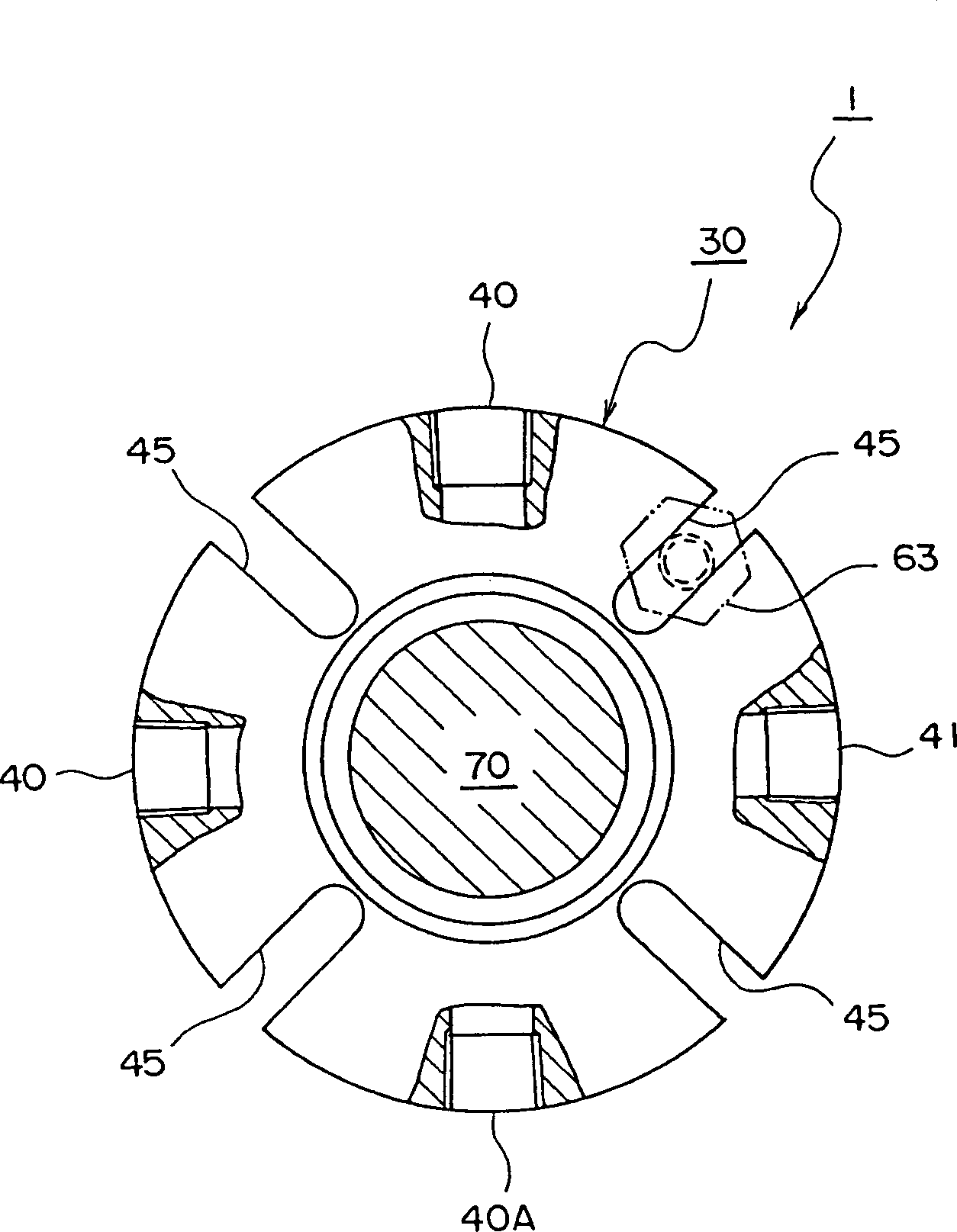

[0040] figure 1 This is a cross-sectional view of the mechanical seal device 1 of the present invention as a clip fitted to the outside of the device main body (stuffing box) 60 and the rotating shaft 70 . figure 2 Yes figure 1 The axial plan view of the mechanical seal device 1 after being fitted on the rotating shaft 70 .

[0041] figure 1 The mechanical seal device 1 according to the first embodiment of the present invention is shown. Should figure 1 The mechanical sealing device 1 is installed after positioning the sealing flange 30 mounted on the outer surface 61 of the device main body 60 and the sealing collar 50 embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com