Raw material cleaning and decontaminating device for photoelectronic device production

A technology of optoelectronic devices and raw materials, applied in the field of optoelectronics, can solve problems such as lack of cleaning devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

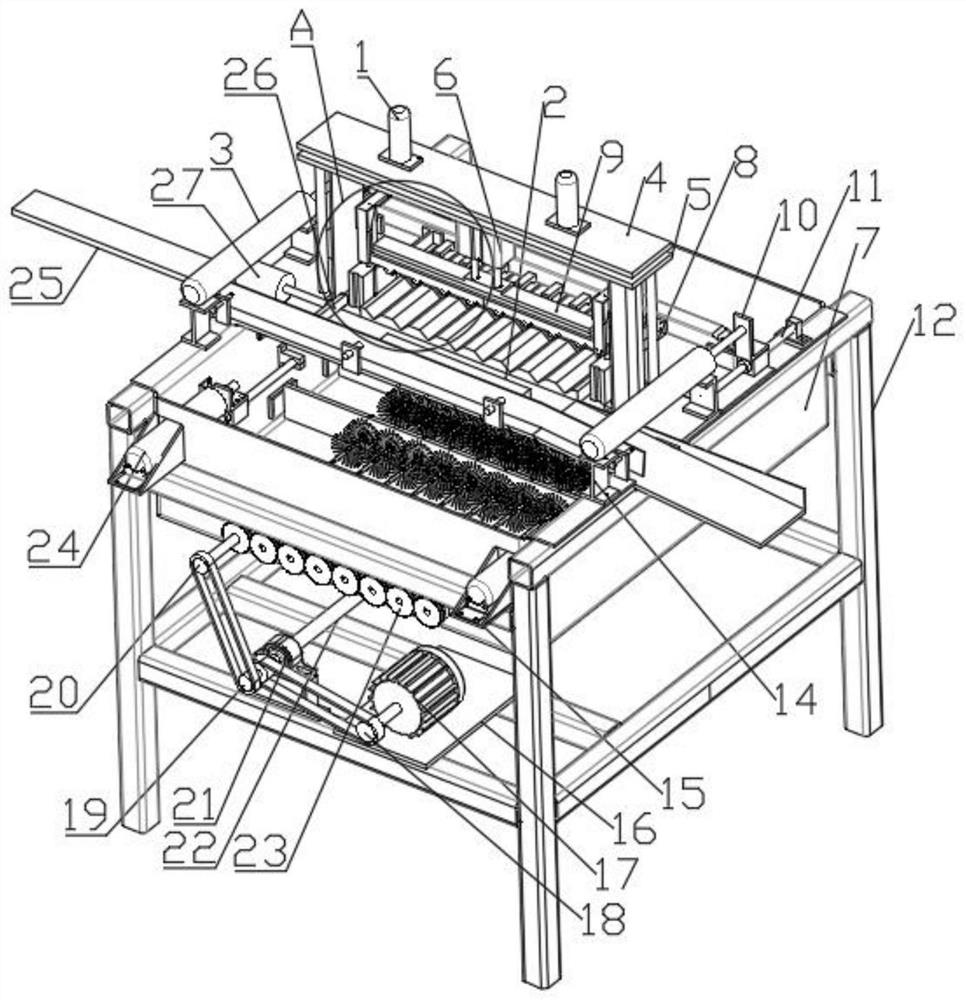

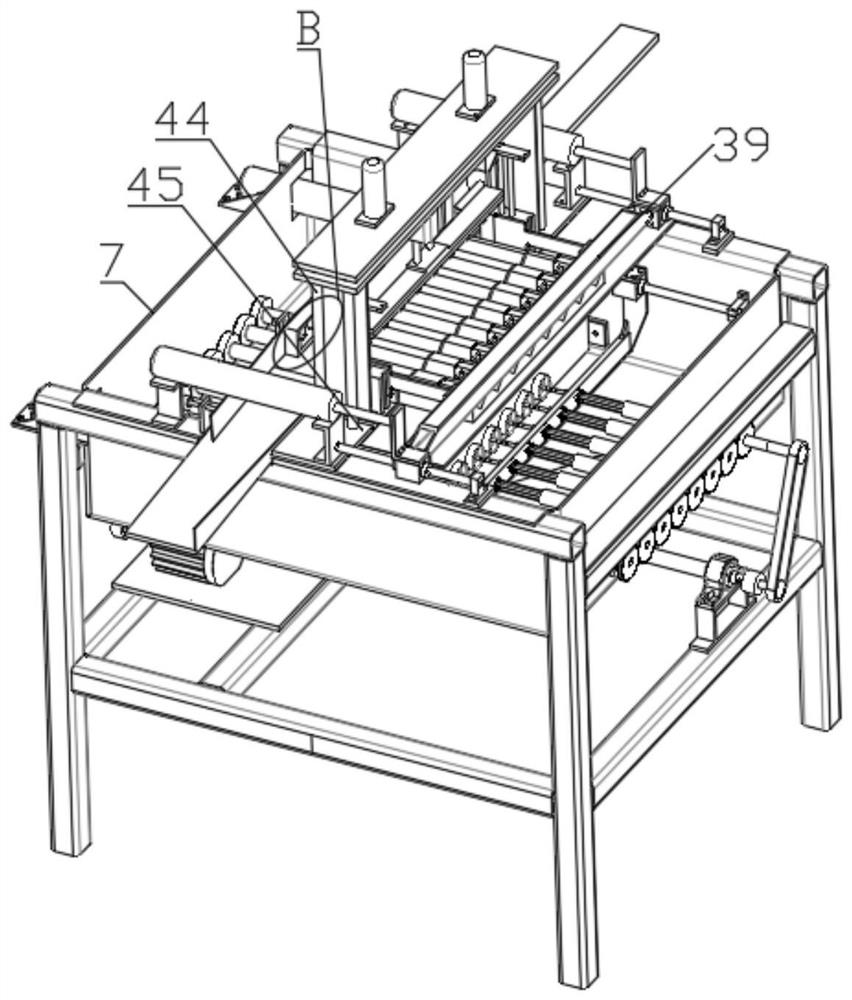

[0027] see Figure 1-6 , in an embodiment of the present invention, a raw material cleaning and decontamination device for optoelectronic device production mainly includes a mounting frame 12 .

[0028] The upper side crossbeam of described installation frame 12 is divided into left crossbeam and right crossbeam, and water tank 7 is arranged between described left crossbeam and right crossbeam, and the upper side of described water tank 7 is provided with feeding chute 25, and described feeding trough No. 5 telescopic motor 27 and scraping box 2 are arranged on the upper side of 25. A plurality of friction rollers 13 are arranged in the scraping box 2. A layer of water-absorbent cotton material, the telescopic part of the No. 5 telescopic motor 27 is connected with a support plate 26, the left beam and the right beam are all provided with a receiving plate 45, and the upper side of the receiving plate 45 is provided with a plurality of No. 1 Guide rod 8, on the No. 1 guide ro...

Embodiment 2

[0033] On the basis of the raw material cleaning and decontamination device for optoelectronic device production described in embodiment 1, the differences between this embodiment and embodiment 1 are:

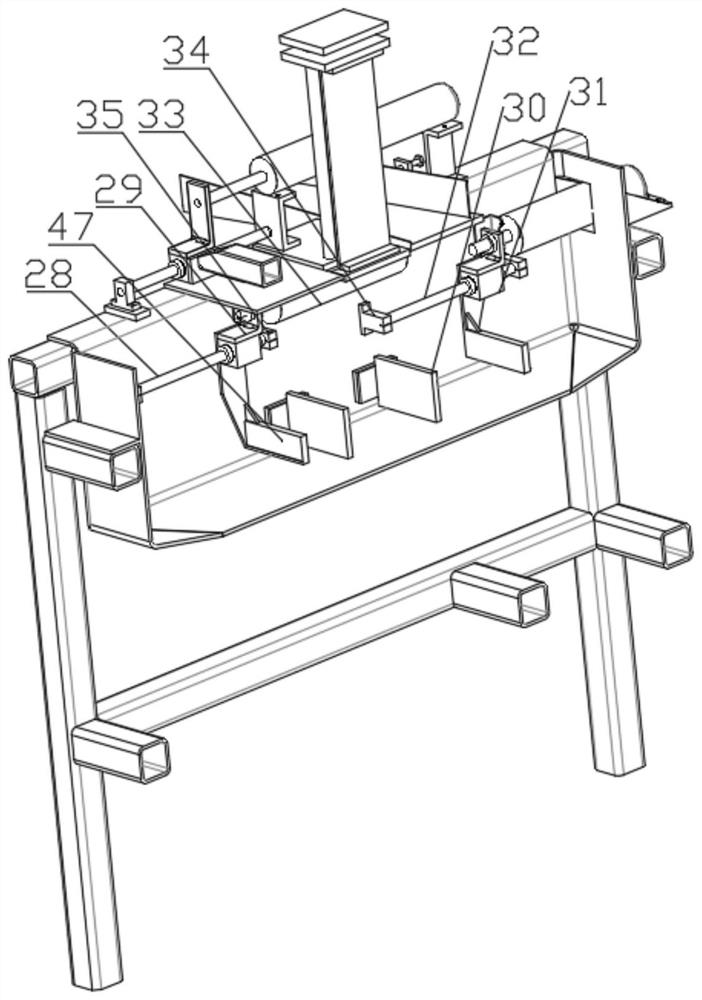

[0034] In this embodiment, a plurality of baffles 30 are fixedly connected between the left and right inner walls of the water tank 7, and a plurality of guide sleeves 36 are sleeved on the baffles 30, and the guide sleeves 36 have elastic Plastic material, two sets of brushes 38 are arranged between the two adjacent baffle plates 30, and the back-to-back ends of the adjacent two brushes 38 are connected with connecting rods 40, the connecting rods 40 The radius is smaller than the opening radius of the guide sleeve 36, and the other end of the connecting rod 40 is connected with a strut, and the strut is fixedly connected with the transverse splint 47 and the strut is connected with the transverse splint 47, and the other end of the strut is connected There is a rotating rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com