Welding track detection and control method of plate butt weld based on laser ranging

A technology of flat-plate docking and laser ranging, applied in welding equipment, digital control, electrical program control, etc., can solve problems such as high price, reduce work intensity, improve welding quality, and improve labor environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

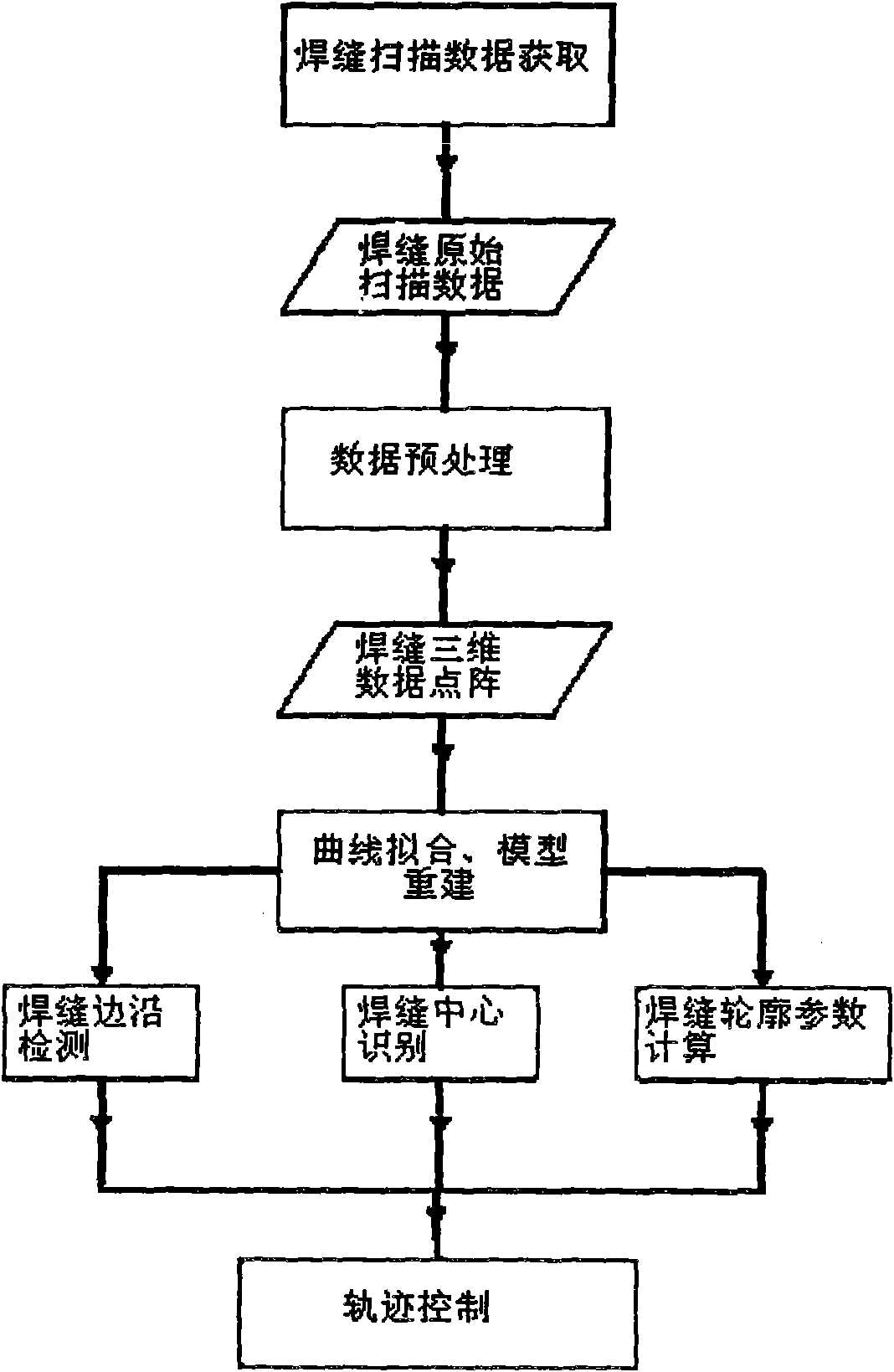

[0029] A method for detecting and controlling welding trajectory of flat butt weld seam based on laser ranging, comprising the following steps:

[0030] A. Carry out trajectory detection; after the system is initialized, the transverse scanning axis of the weld seam is started, and the cross-sectional profile of the flat butt weld is detected in real time through the laser precision displacement sensor, and is continuously fed along the direction of the weld seam; the detected weld seam contour information The data is transmitted to the industrial computer, and the collected data is filtered and stored;

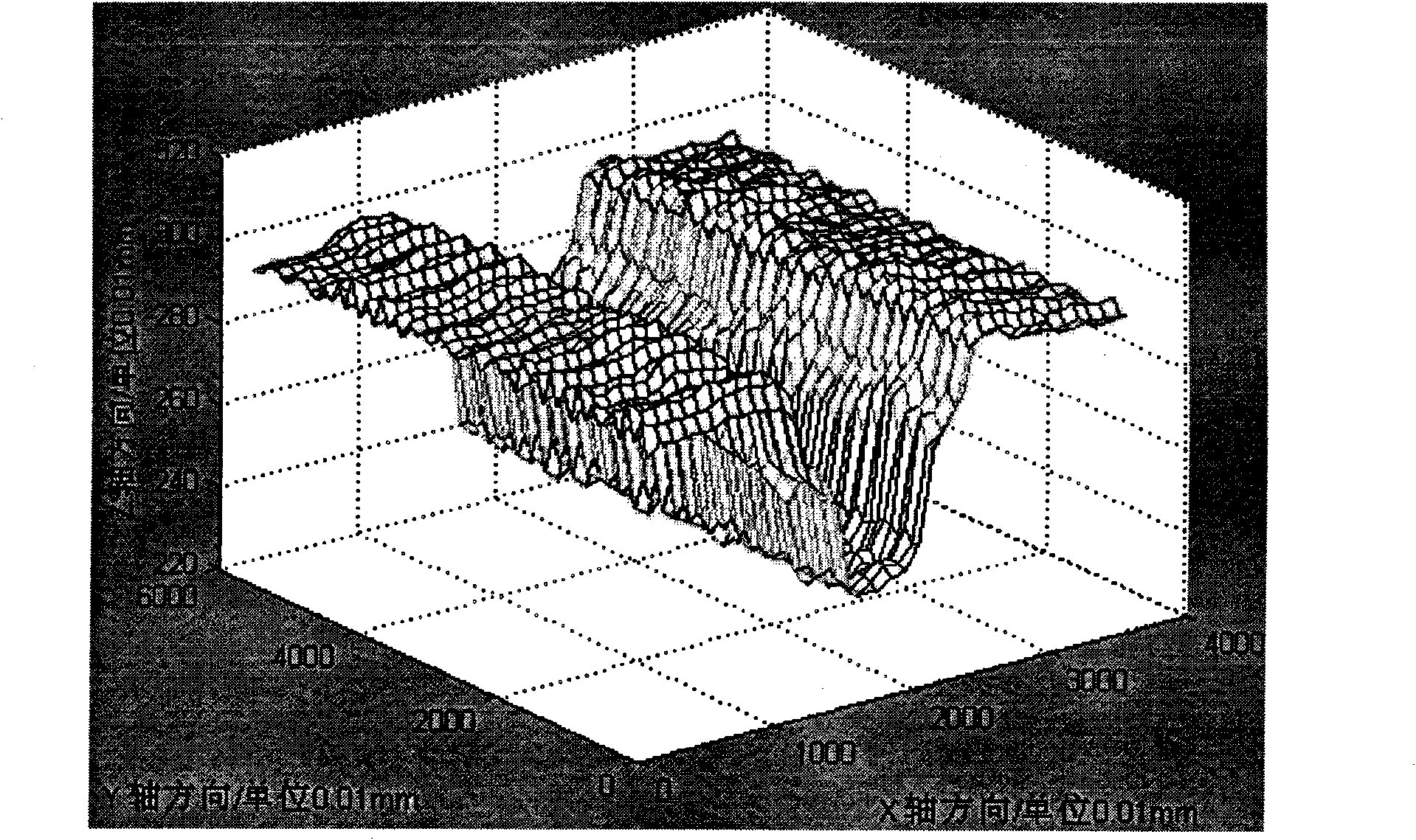

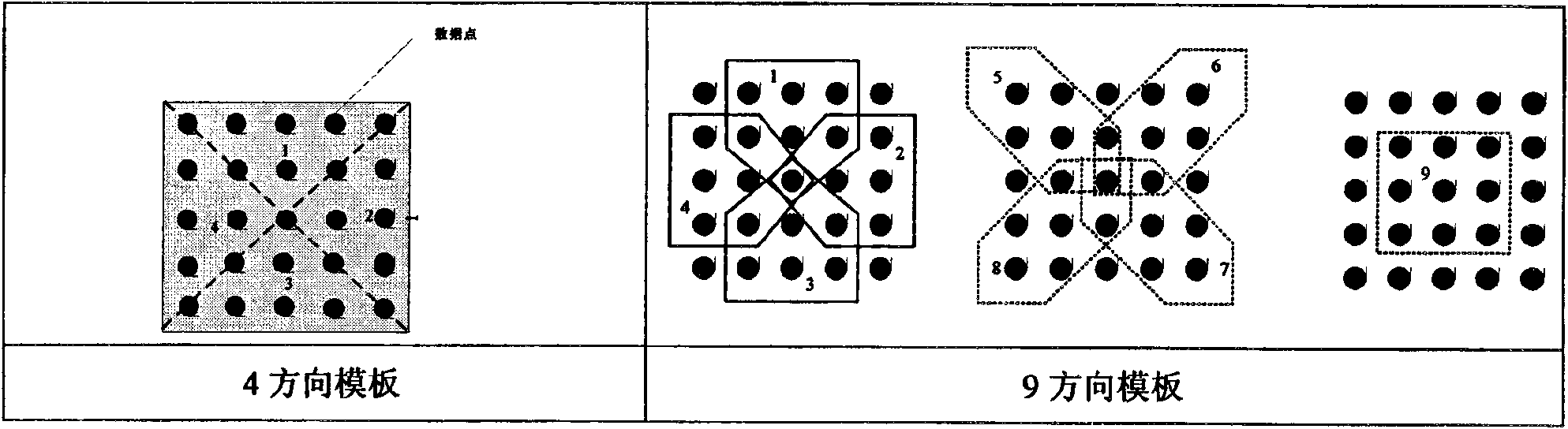

[0031] B. Carry out trajectory recognition; process the digital signal through the industrial computer, extract the information of the weld outline, and at the same time carry out the three-dimensional reconstruction of the weld, and obtain the paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com