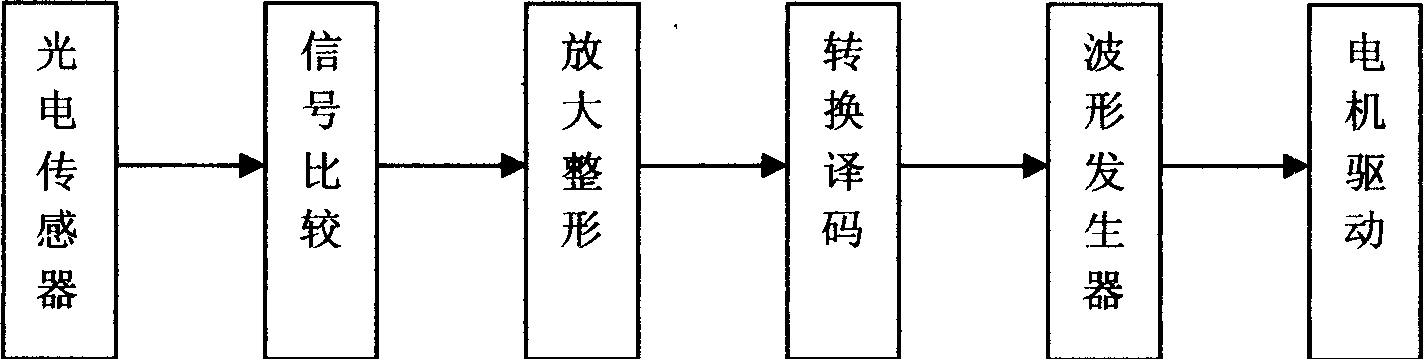

Photoelectric sensor type welding seam automatic tracing control method

A photoelectric sensor and automatic tracking technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of high cost, complex control system and calculation process, and achieve strong practicability, simplified calculation process and circuit structure, The effect of high system tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

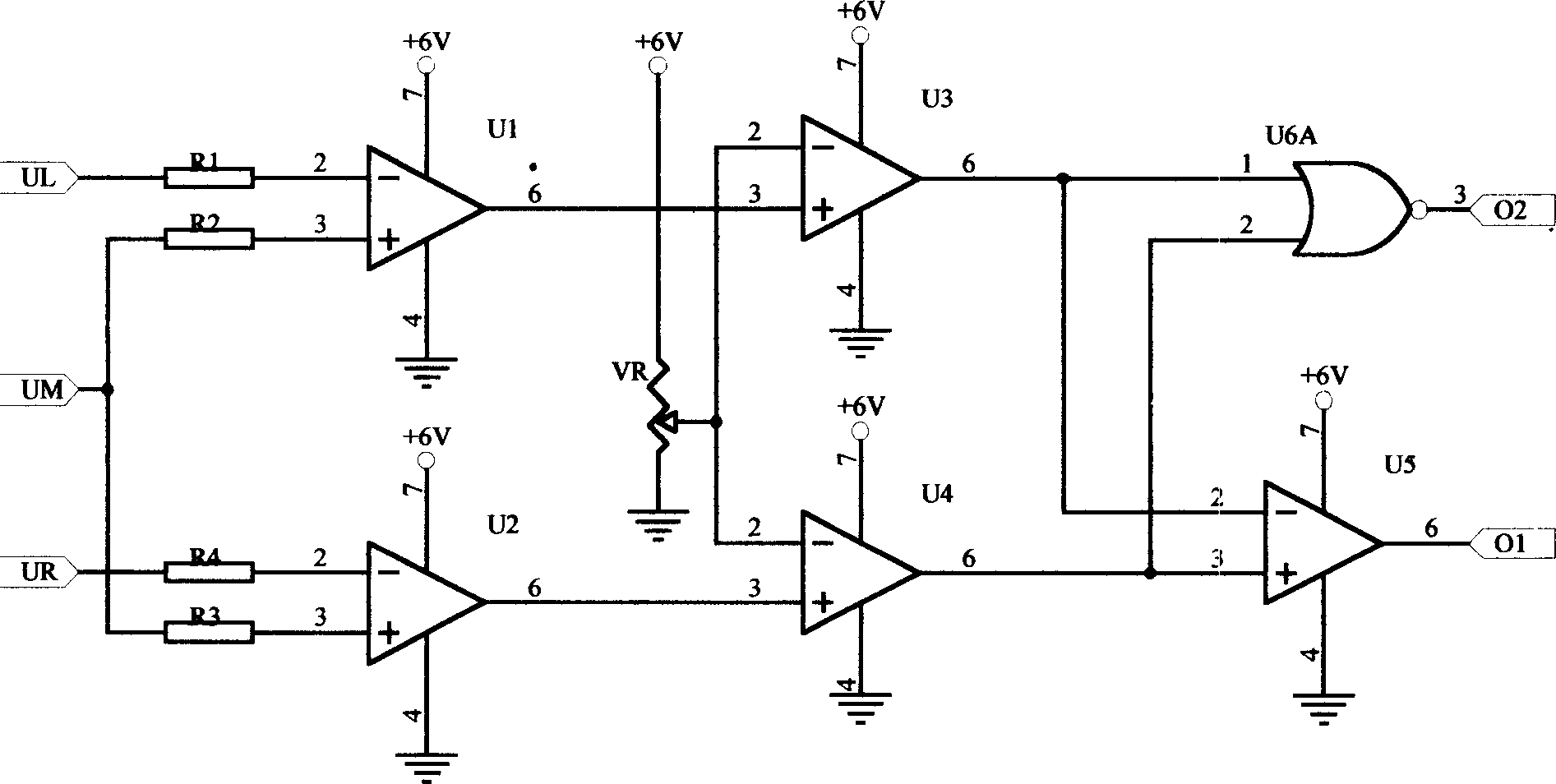

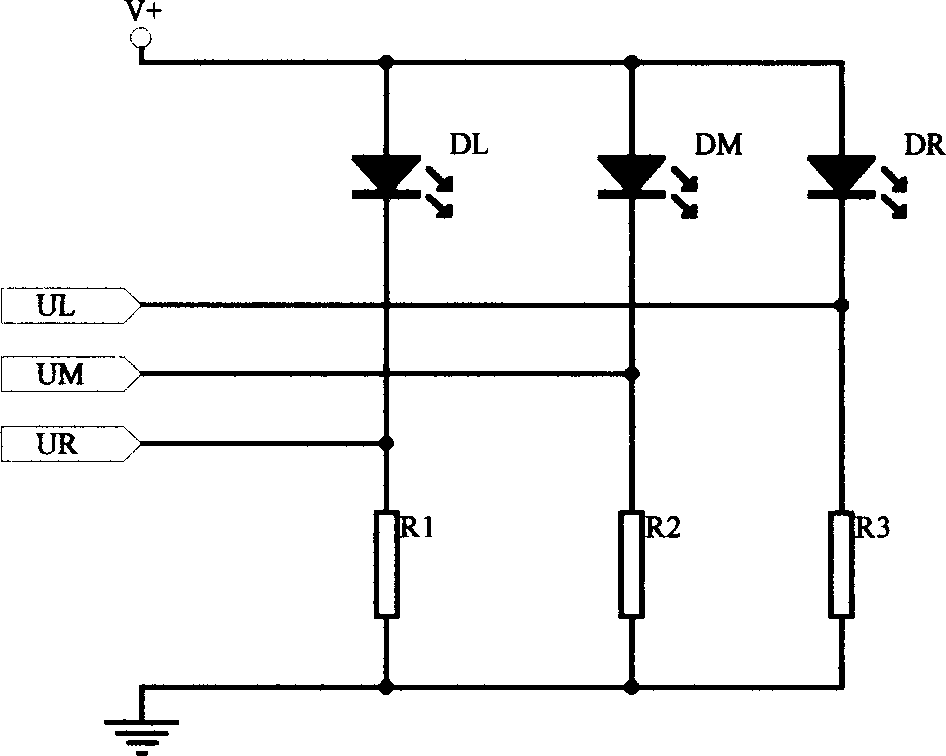

[0013] Depend on Figure 1 to Figure 2 It can be seen that the method of the present invention is to use the white line drawn on one side of the workpiece joint with a width of 2 to 4 mm as the tracking detection object. Its photoelectric sensor is composed of ordinary small electric beads, photosensitive transistor, photoelectric element screen, convex lens and concave lens, etc. The light source forms a rectangular light spot on the workpiece through the concave lens, and the light spot forms an enlarged light spot on the photoelectric element screen through the concave lens and convex lens. Reflective light spot: Three phototransistors are installed side by side on the photoelectric element screen, which are left photosensitive tube DL, middle photosensitive tube DM and right photosensitive tube DR. When the white line on the workpiece is at the center of the light spot, the middle photosensitive tube DM receives the most light. Strong, the output signal UM of the middle ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com