Jade fiber and flax fiber blended yarn and preparation method thereof

A technology of flax fiber and jade fiber, which is applied in the direction of yarn, textiles and papermaking, etc., can solve the problems of flax fiber containing a lot of impurities, unevenness, easy damage, etc., to reduce the impact force and the amount of noil, and improve the separation degree, improve the effect of spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

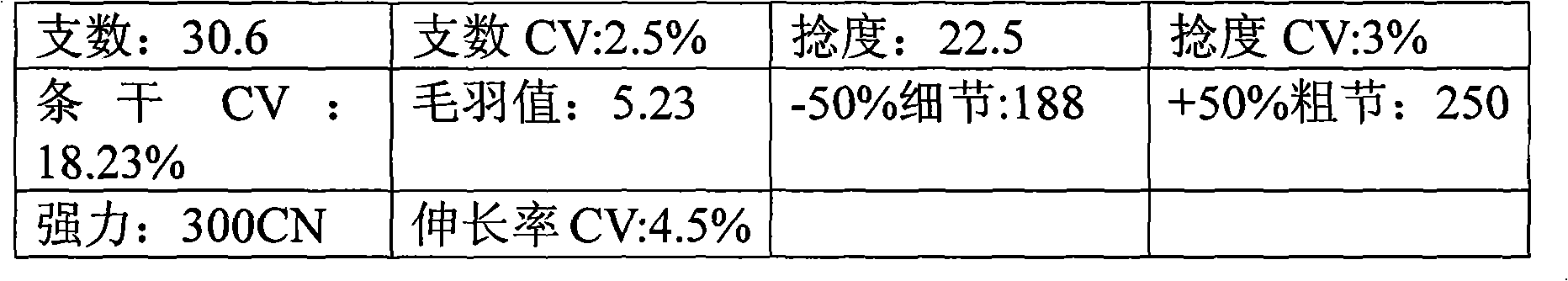

Image

Examples

Embodiment Construction

[0030] Raw material selection:

[0031] Jade fiber: select fiber with a fineness of 1.5dtex and a main body length of 38mm.

[0032] Flax fiber: select fibers with a dry strength of 3.3-4.0 cn / dtex, a wet strength of 3.5-5.2 cn / dtex, and a main body length of 20 mm.

[0033] The specific process is as follows:

[0034] 1. Raw material preparation process: The hemp fiber needs to be rehydrated in advance. The specific method of rehydration is to use water spray, and the specific rehydration time is preferably 72 hours.

[0035] 2. Opening and cleaning process: first of all, the specific ratio of feeding materials and the detailed weight of cotton blending must be determined. Here we use 78-80% of hemp and 20-22% of jade fiber for blending; in order to ensure the uniformity of blending, The first step is to manually mix the cotton on the cotton bed and spread the cotton layer by layer. Here we should pay attention to controlling the amount of noil, and implement the principle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powerful | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Body length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com