Overturn-resistant self-elevating platform pile shoe

A self-elevating platform and anti-overturning technology, which is applied in the field of self-elevating offshore platform equipment and spud shoes of jack-up offshore platforms, can solve the problems of reduced bearing capacity, poor spud shoe reliability, and reduced spud shoe strength, etc., to achieve The effect of overcoming the difference in bearing capacity, increasing the bearing area, and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

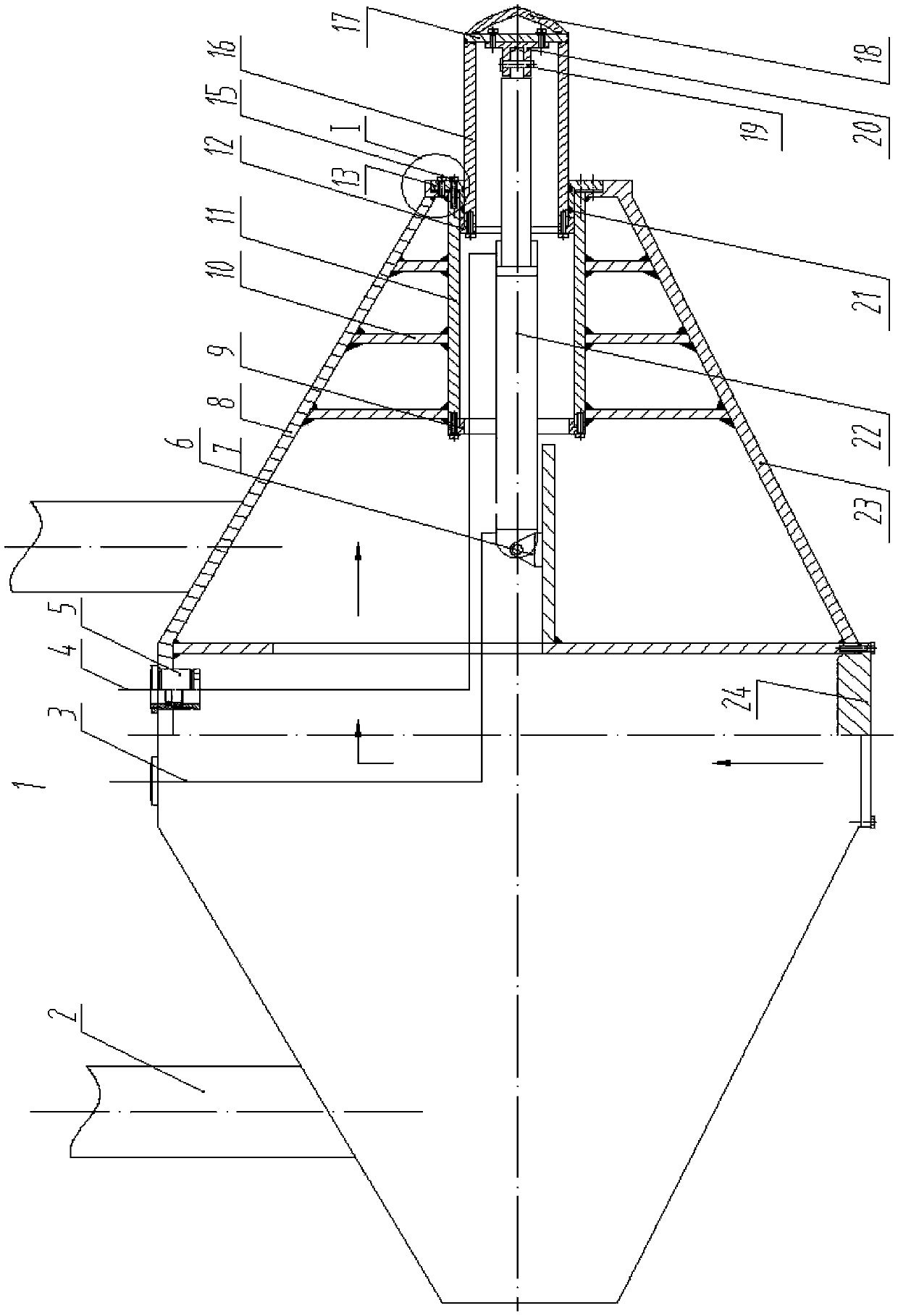

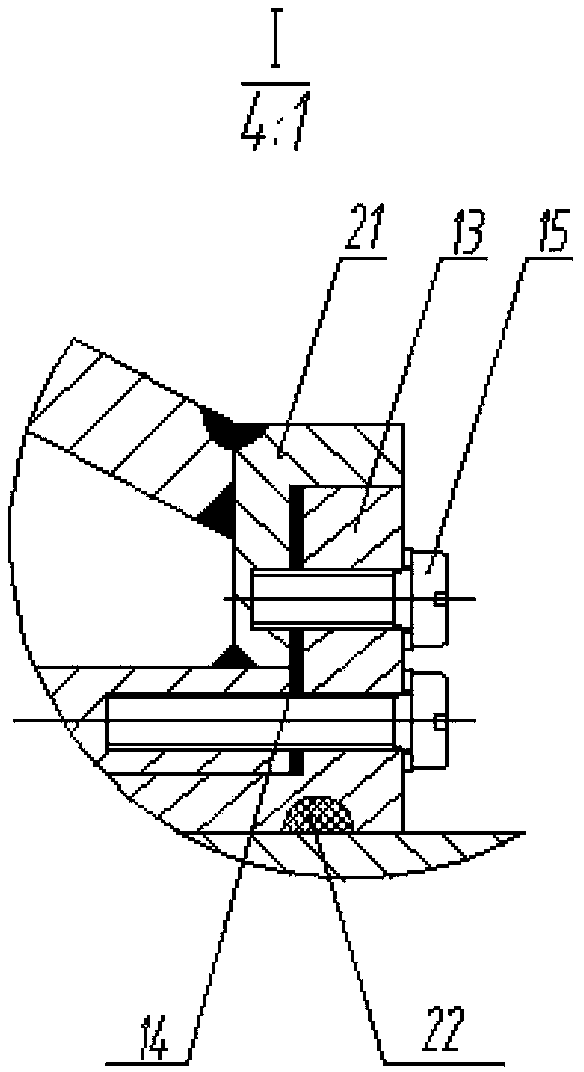

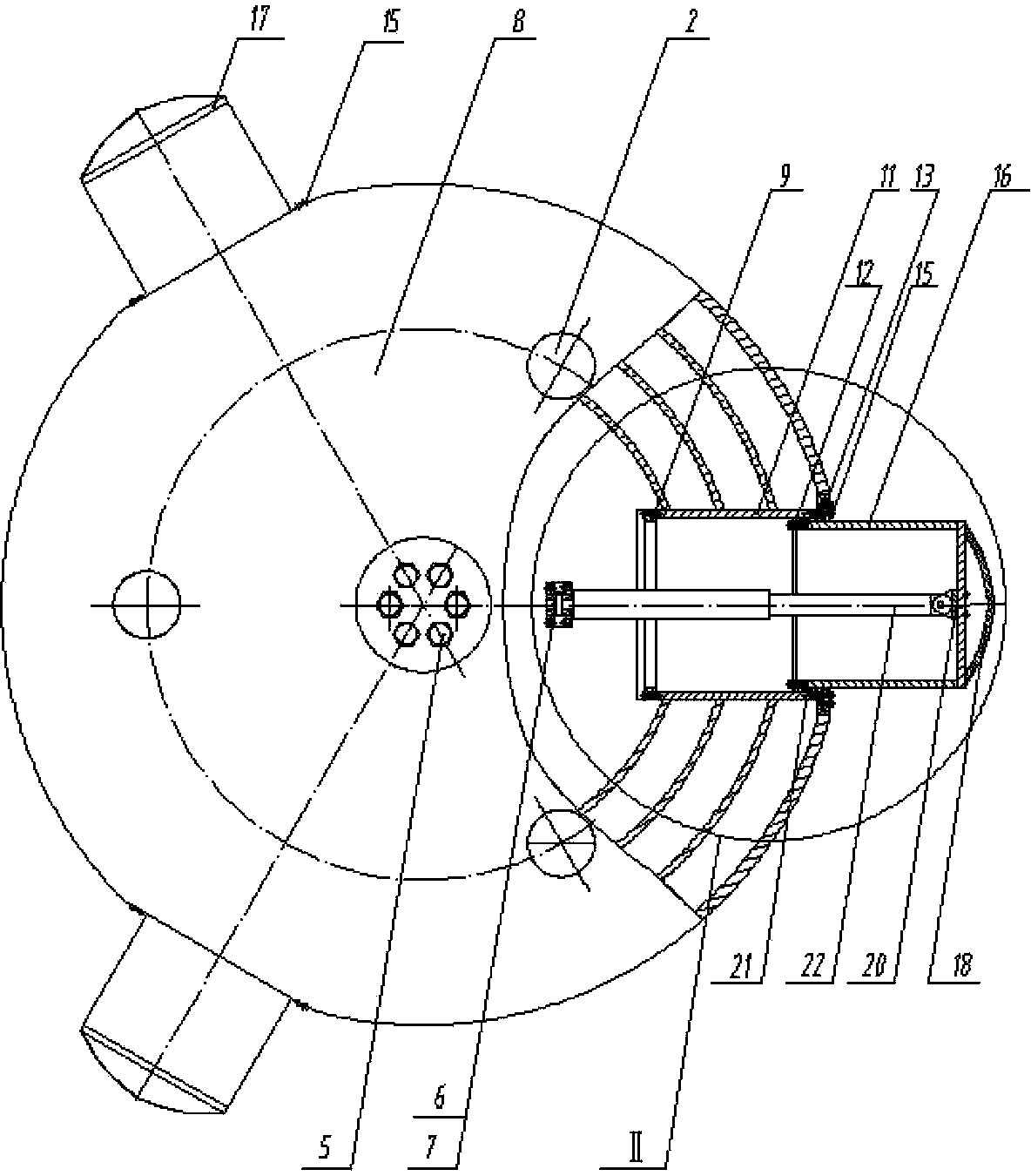

[0025] Such as figure 1 , 2 , 3, and 4, a spud shoe 1 of an anti-overturning self-elevating platform is fixedly connected to the lower end of the pile leg 2, and includes an upper top plate 8, a lower bottom plate 23, and internal circumferential and radial ribs 10. 'Discus-shaped' shell; the 'discus-shaped' shell contains at least three horizontal and radially placed along its circumferential side wall, and can be extended and retracted. The front end of the shell is closed, and the rear end has an outer stop. The telescopic tube 16 of the ring 12, and in the housing, the tubular slideway 11 for guiding the telescopic tube 16 and welding with the inner rib plate 10 of the housing; Blue ring 9,13, so that limit is provided when telescopic tube 16 stretches; The inner circumference of described limit flange 13 is provided with sealing ring 21, and the inner surface end that cooperates with sliding to outer mouth is equipped with rubber washer 14, uses To seal the gap between ...

Embodiment 2

[0033] Such as Figure 6 , On the basis of the first embodiment, a section of the telescopic tube 32 is added between the telescopic tube 16 and the tubular slideway 11 of the first embodiment. The rear end of the telescopic tube 32 is fixedly installed with a limit retaining ring 31, and the front end is installed with an elliptical spacer flange 34, and the telescopic tube 16 is sleeved inside, so as to ensure the smooth sliding of the telescopic tube 16 and provide the telescopic tube 16 with telescopic limit, to limit its sliding stroke; wherein, the inner peripheral surface of the limit flange 34 is provided with a sealing ring 35, and its function is the same as that of the limit flange 13 of the outer mouth of the tubular slideway 11 in the first embodiment and The function of its sealing ring 21 is the same. The present invention with one telescopic tube added has the same effect as the spud can with only one telescopic tube, and the length of the tubular slideway 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com