Patents

Literature

33results about How to "To achieve the purpose of tracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding track detection and control method of plate butt weld based on laser ranging

InactiveCN101559512ATo achieve the purpose of seam trackingTo achieve the purpose of trackingArc welding apparatusNumerical controlLaser rangingField tests

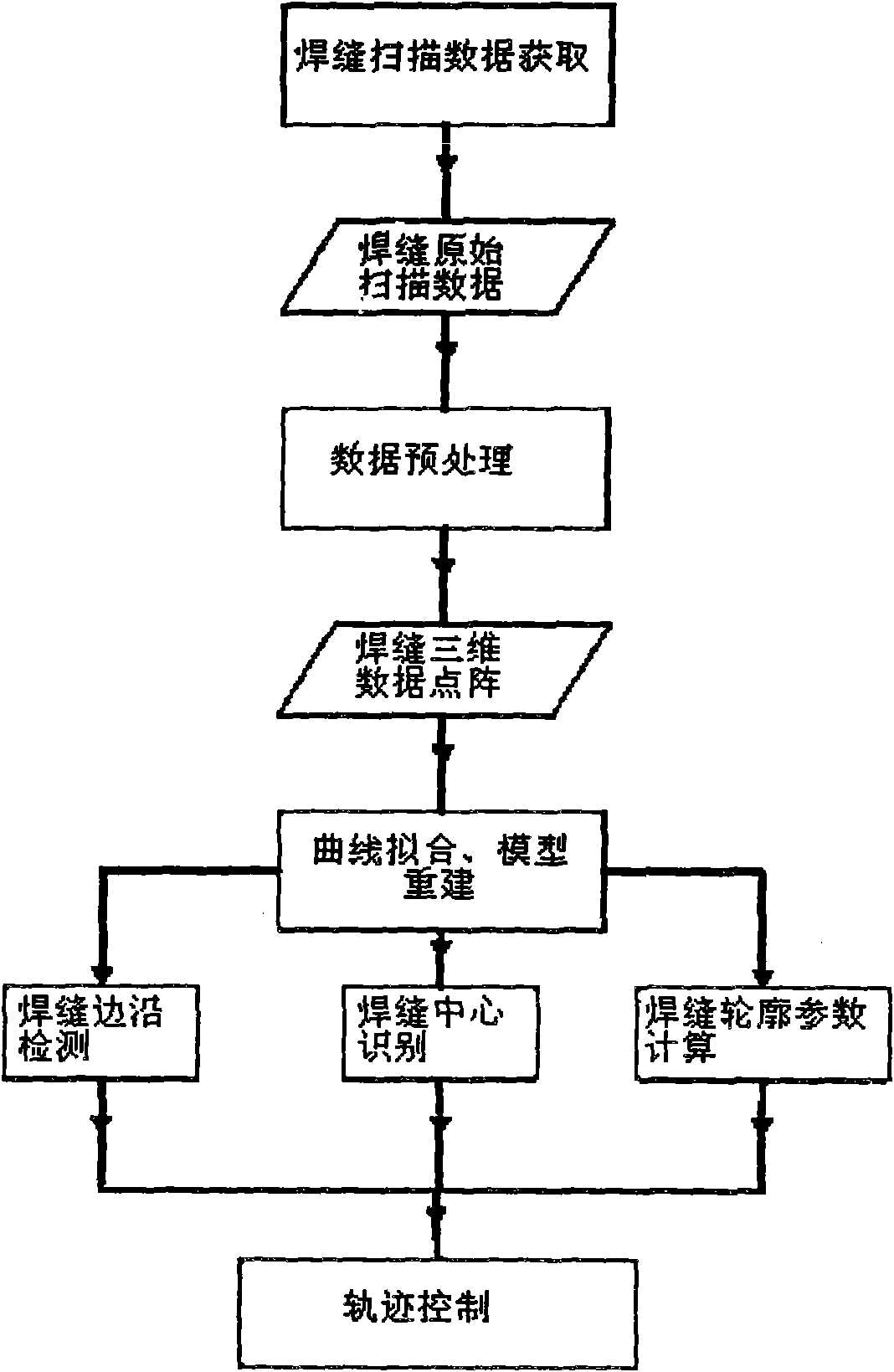

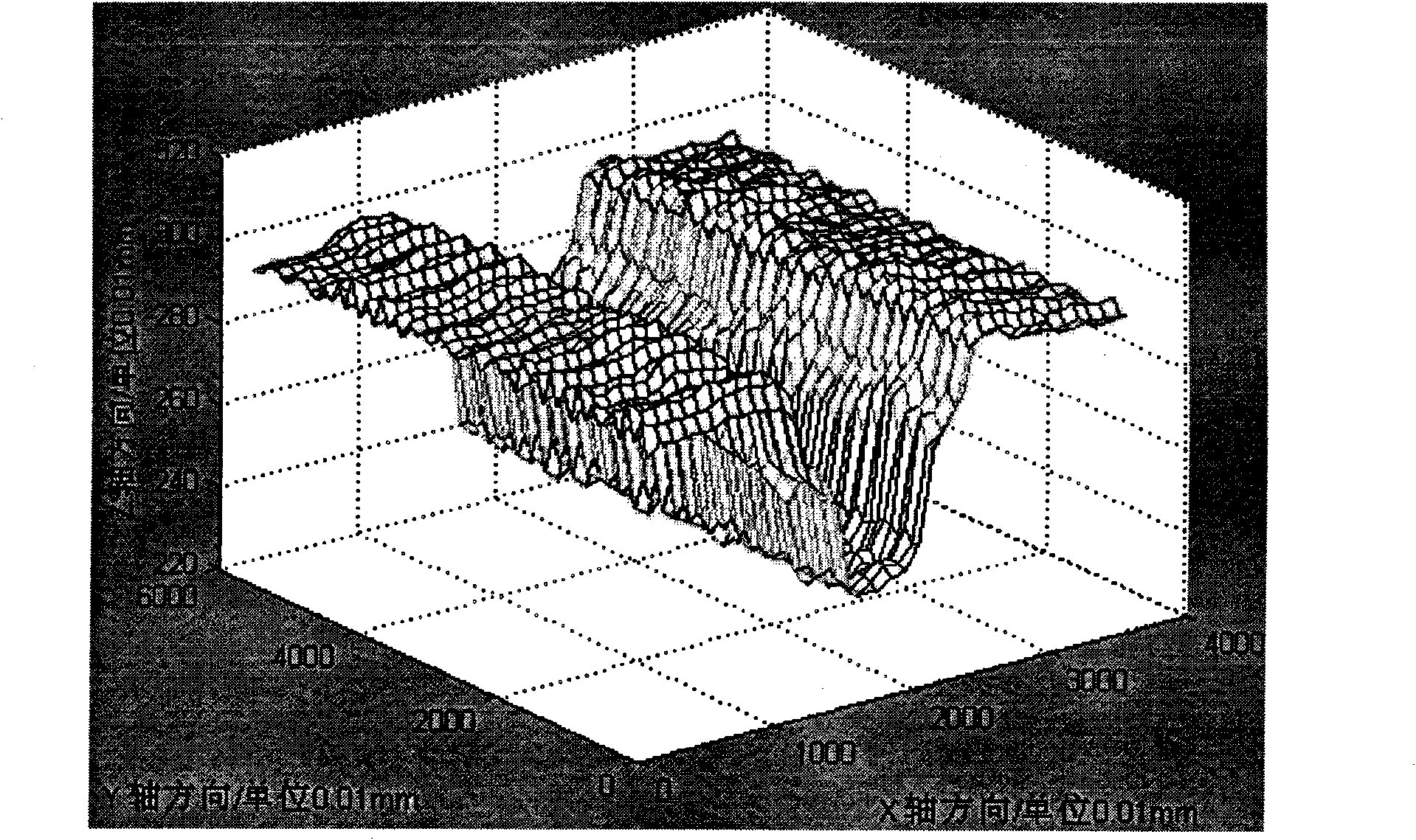

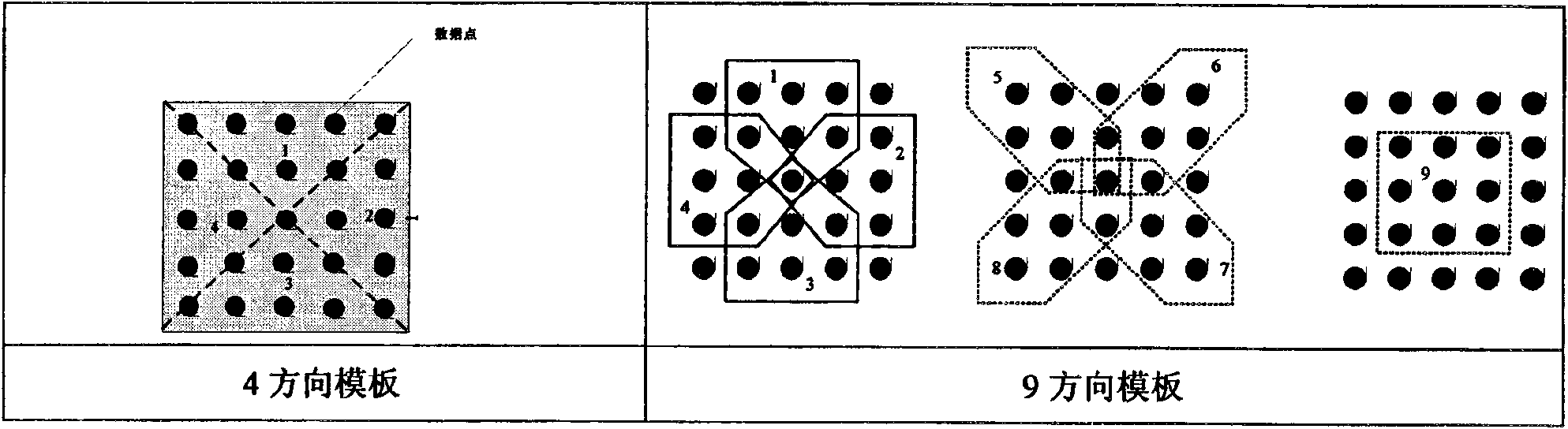

The invention relates to a welding track detection and control method of plate butt weld based on laser ranging, including the following steps: A. track detection is carried out; B. track identification and extraction are carried out; C. track control is carried out; D. the relative position relation between a welding gun and a welding seam is adjusted at last by performing mechanism actions. In the invention, the information of welding seam profile is obtained by transverse scanning of a laser sensor, and welding seam is rebuilt after effective wave filtering treatment to realize three-dimensional detection of the welding seam; simultaneously, the welding track curve is obtained by fit while detecting welding seam by using dynamic B spline fit algorithm, and the track control is carried out in combination with constant speed B spline track interpolation algorithm, thereby fundamentally solving the problem of track detection and control in automatic welding of plate butt weld. By using the method in the invention, the field test welding has welding profile identification precision of 0.15mm and welding track identification precision of 0.2mm, and the welding speed is more than four times of common manual welding.

Owner:SHANDONG UNIV

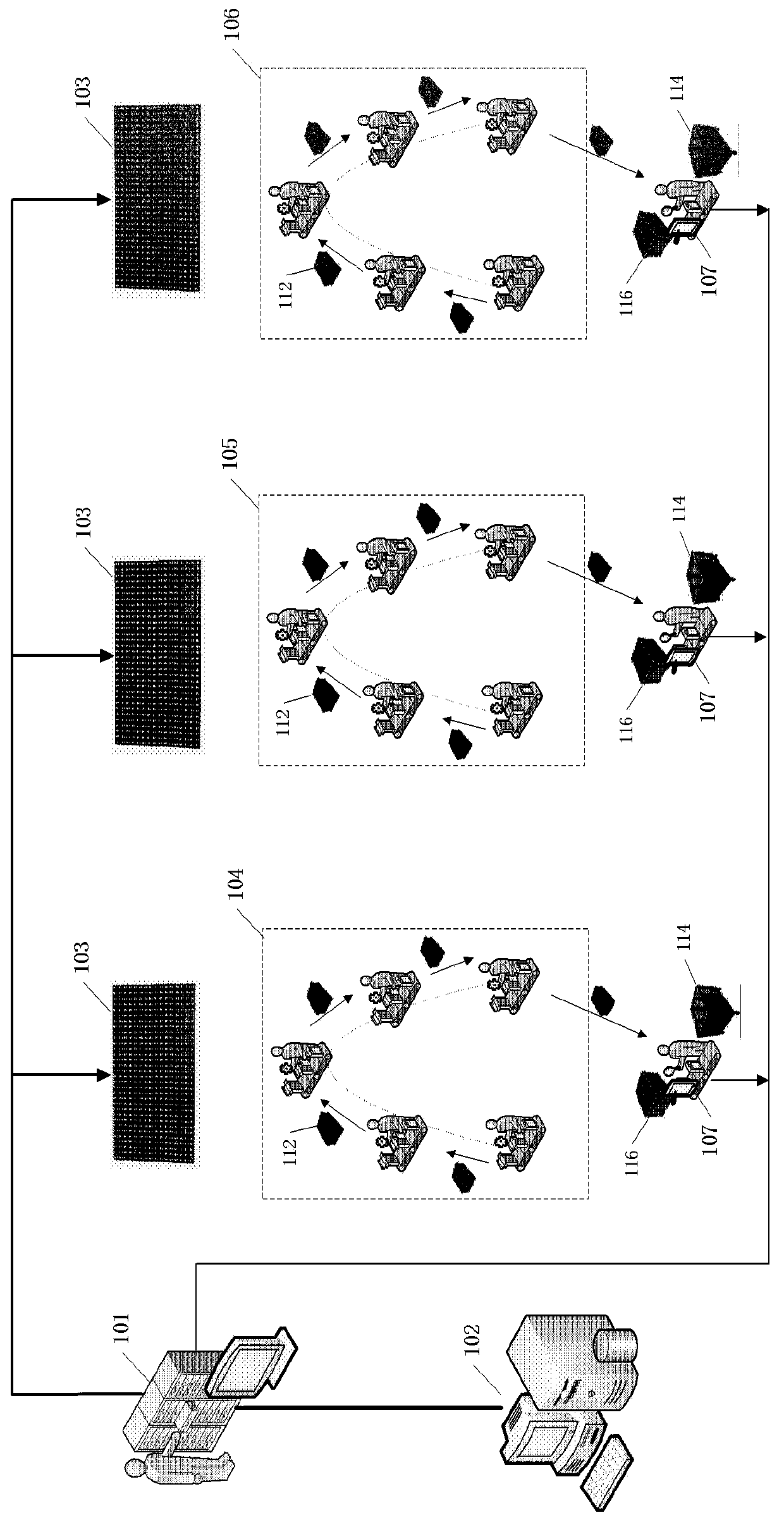

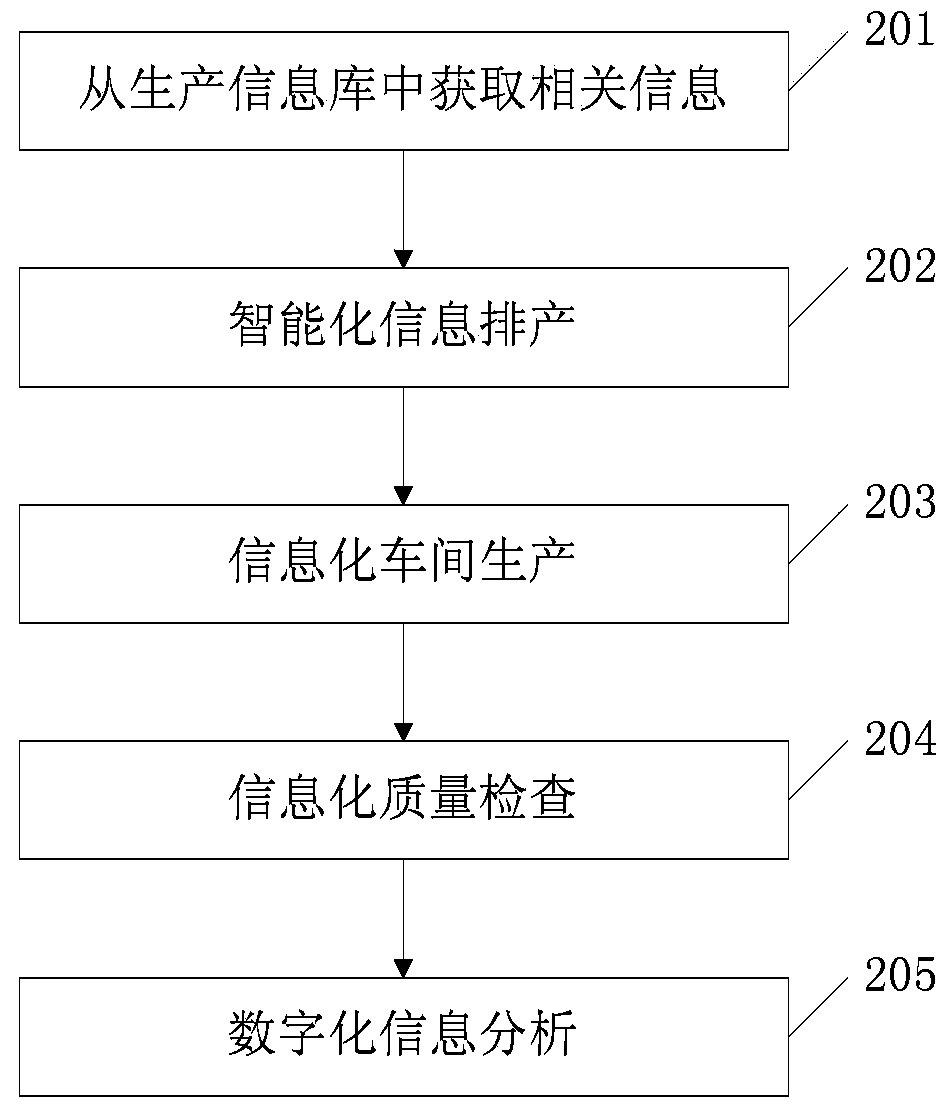

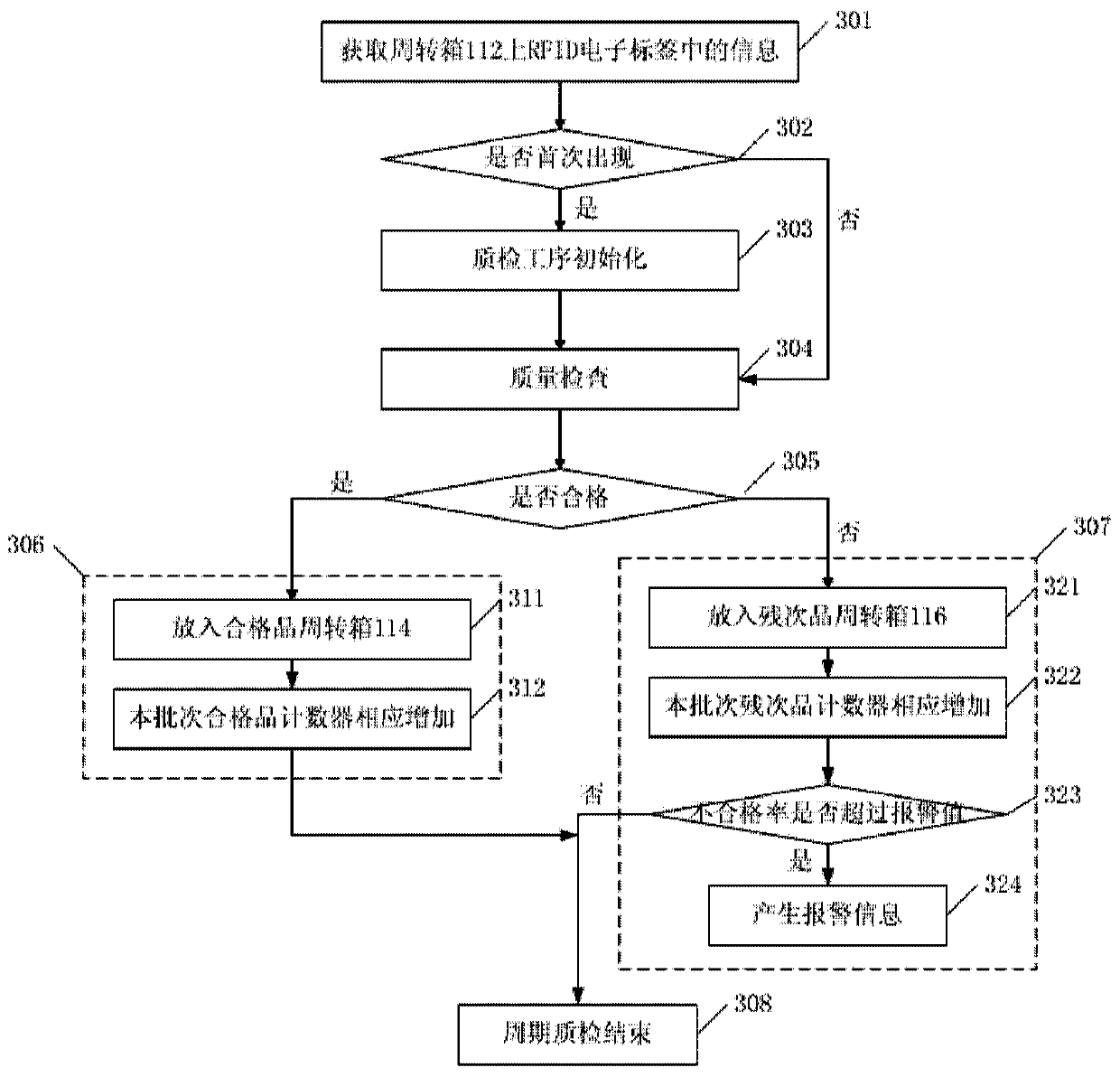

Motor producing quality monitoring and managing system and corresponding method

InactiveCN103440554ABest production statusTo achieve the purpose of trackingResourcesManufacturing computing systemsProduction lineDisplay board

The invention discloses a motor producing quality monitoring and managing system and a corresponding method. The system comprises a quality monitoring subsystem and a material circulating subsystem. The quality monitoring subsystem comprises a workshop control center, a master control center, a workshop electronic display board, producing lines and unit quality detecting points. The material circulating subsystem comprises turnover boxes of products in process on the producing lines, turnover boxes of qualified products of the detecting points and defective product turnover box. Batch processing of turnover boxes with pasted RFID electronic labels is used during the producing process, and products with the same model number in the same batch use the same turnover box. The RFID electronic labels on the turnover boxes at the working positions are read and written, so that production information of each procedure is recorded, and when product reject ratio exceeds an alarming value, alarming information is timely generated. After production, the producing record of a product of each model number of each worker during the producing process is analyzed, so that next production arrangement is helped to be optimized, productivity is arranged reasonably, and the fact that producing quality is improved stably is guaranteed.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

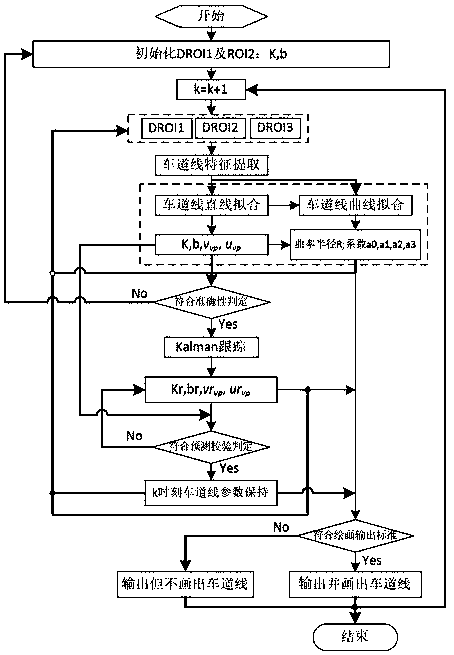

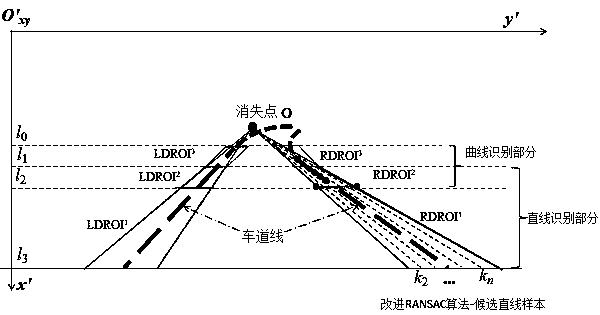

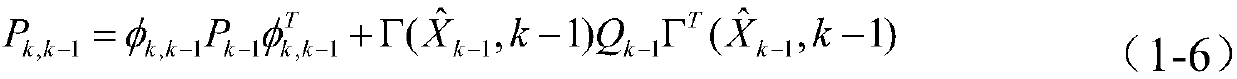

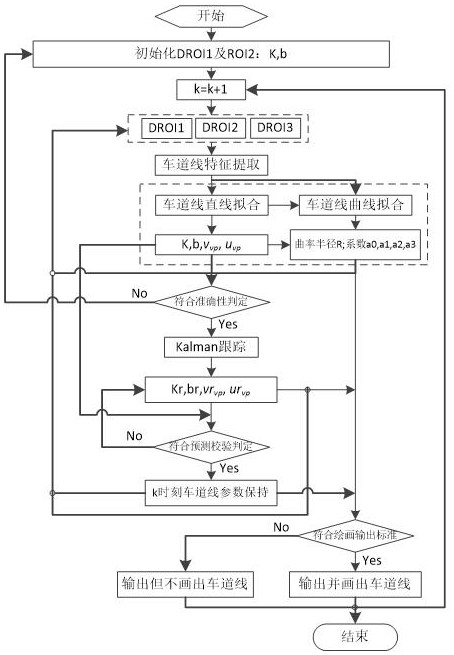

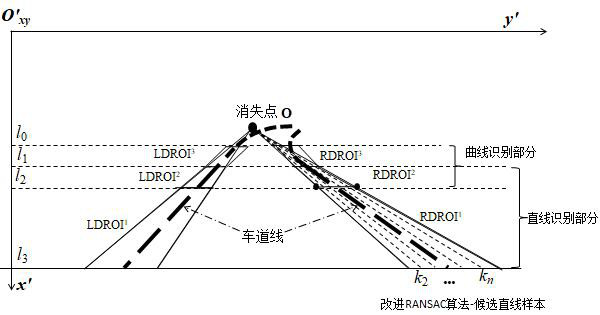

Robust lane detection method based on dynamic region of interest

ActiveCN109409202AEfficient extractionAnti-interference improvement and enhancementCharacter and pattern recognitionAnti jammingFitting algorithm

The invention relates to a robust lane line detection method based on a dynamic region of interest, comprising the following steps: S10, initializing a dynamic region of interest of the lane; S20, dividing the lane line interested region in the current frame from near to far into a straight line identifying region and a curve identifying region; S30, pre-extracting that characteristic point of thelane line edge for the straight line recognition area and the curve recognition area, obtaining the straight line lane parameter of the straight line recognition area and the curve lane parameters ofthe curve recognition area through a fitting algorithm, and drawing a fitting lane line; S40, according to the fitting lane line parameters of the current frame, the dynamic region of interest DROI in the next frame image is predicted by using the Kalman filter. The invention is based on DROI, adopts RANSAC algorithm, can effectively extract lane line inner side edge information under complex working conditions, and the anti-jamming performance and accuracy of the method are obviously improved and improved. At the same time, the real-time and robust lane tracking can be realized by using Kalman prediction and inter-frame correlation constraint.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

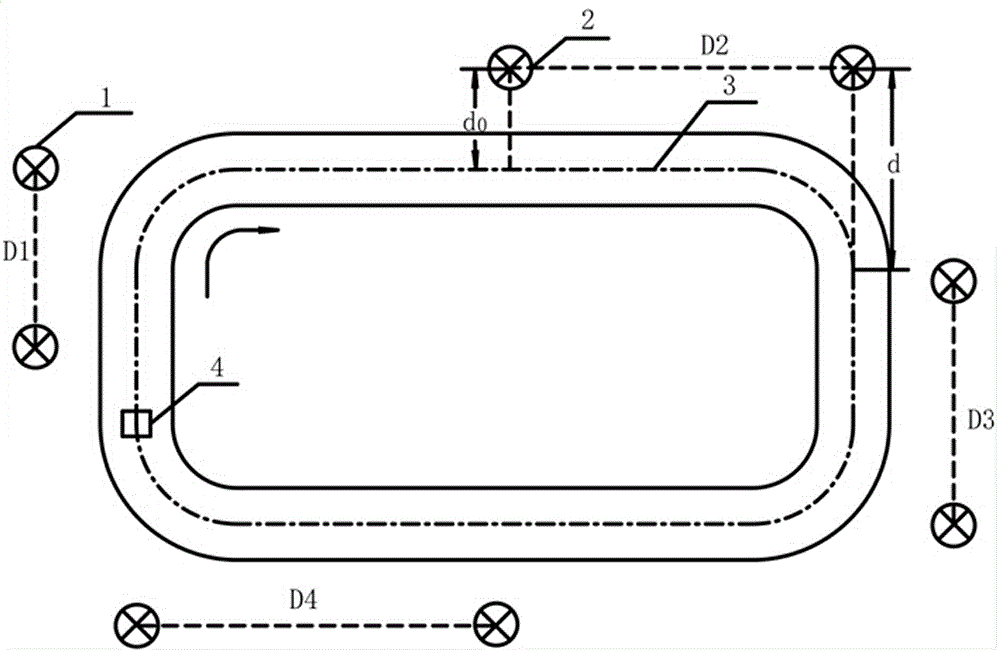

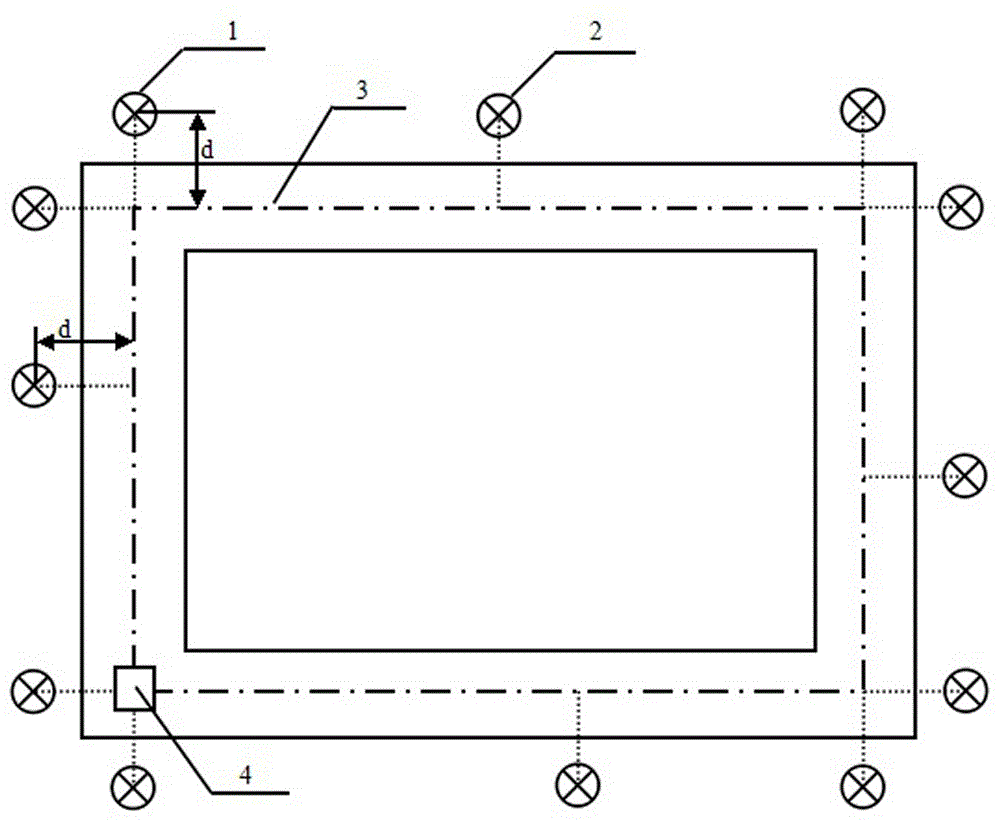

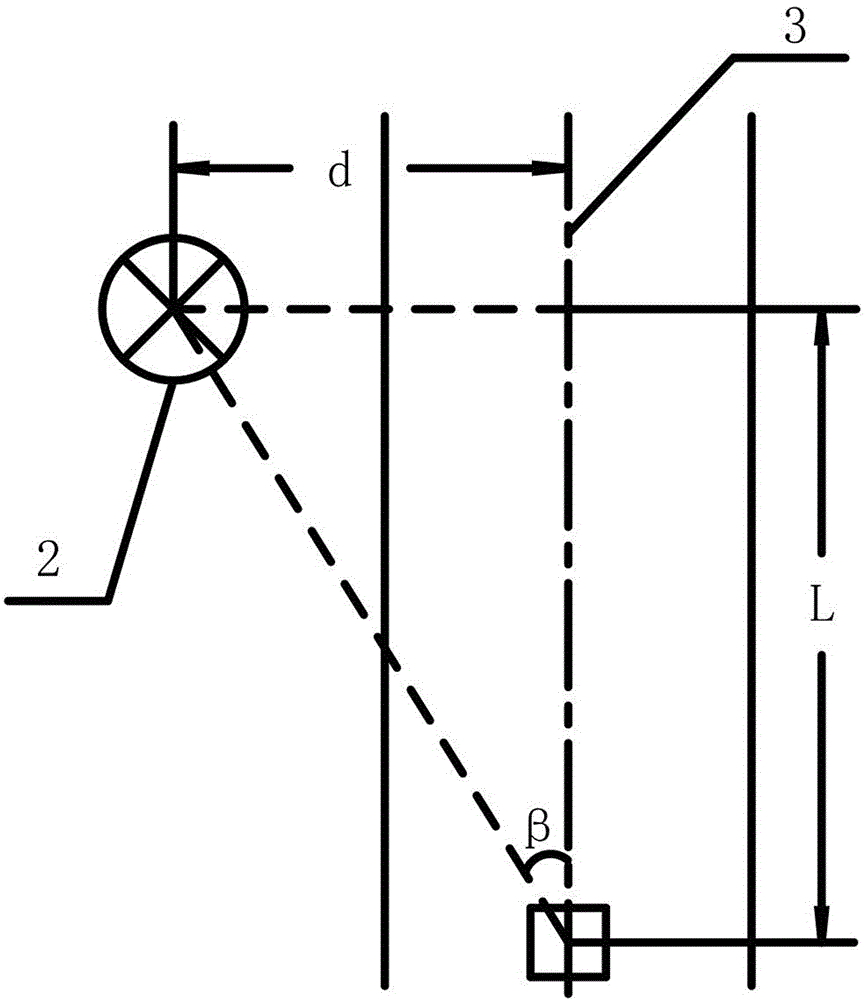

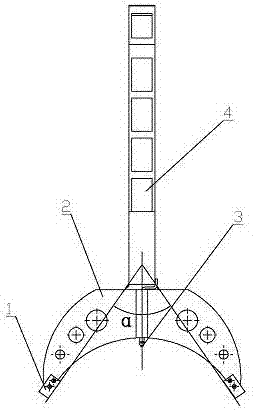

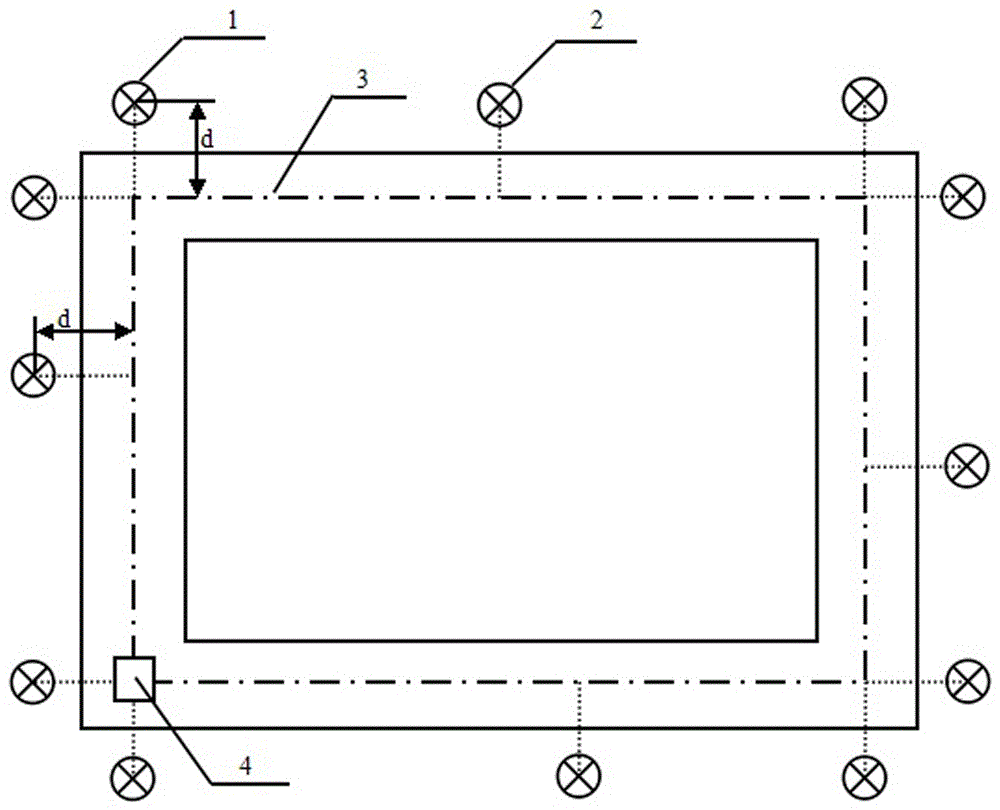

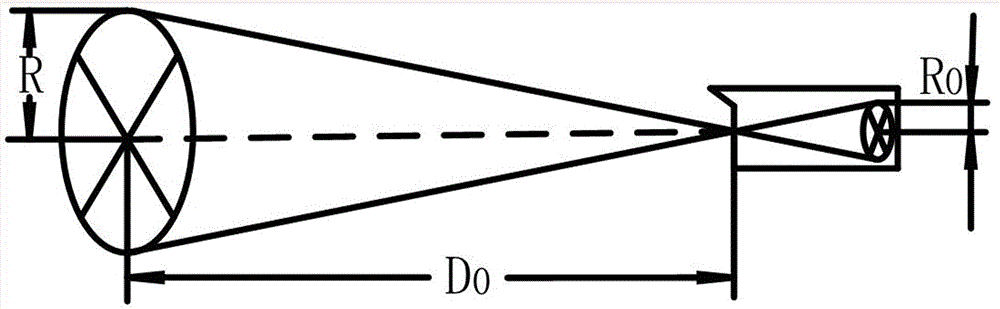

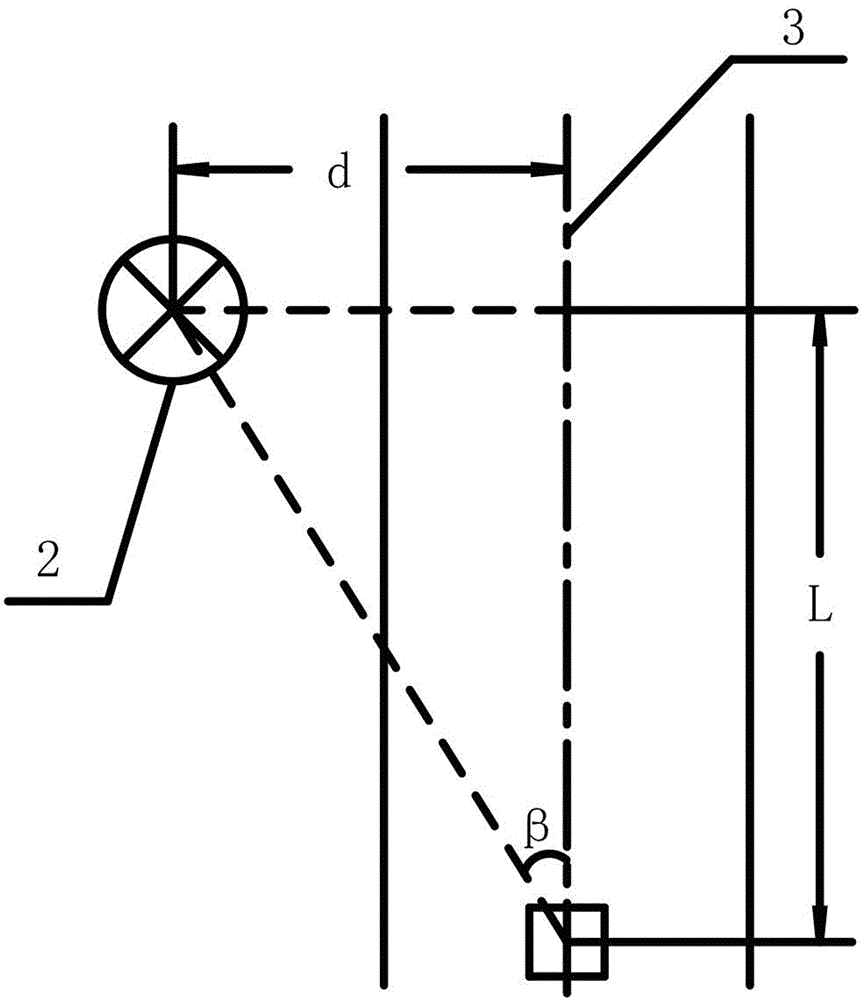

Navigation positioning method for tour inspection robot of transformer substation

ActiveCN104571103ATo achieve the purpose of trackingTo achieve the purpose of positioningPosition/course control in two dimensionsTransformerEngineering

The invention discloses a navigation positioning method for a tour inspection robot of a transformer substation. The imaging positions of tracking navigation lamps in an infrared thermal imager are detected, so that the moving direction of a trolley is determined, and the aim of tracking is fulfilled; in order to position the robot in a moving process, a cradle head is horizontally rotated until an image of a positioning navigation lamp in the infrared thermal imager is in the center, the distance to the next fixed point is calculated according to the horizontal rotating angle of the cradle head and the moving distance of the trolley is calculated according to the sizes of images of the tracking navigation lamps in the infrared thermal imager, so that the aim of positioning is fulfilled.

Owner:STATE GRID CORP OF CHINA +3

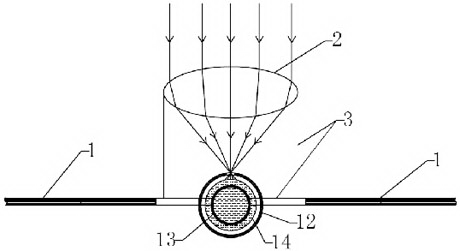

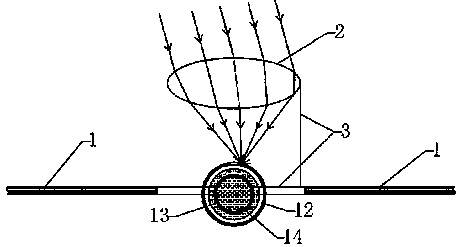

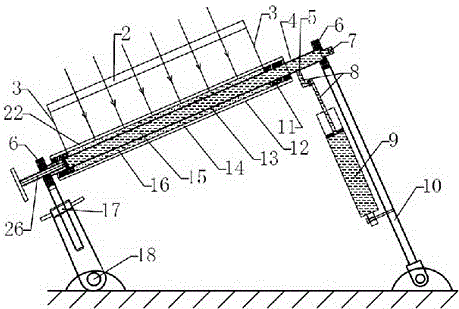

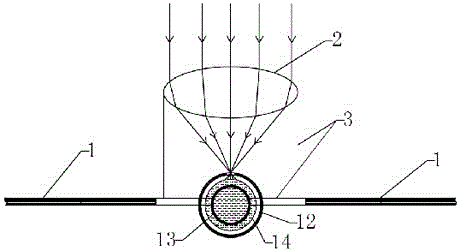

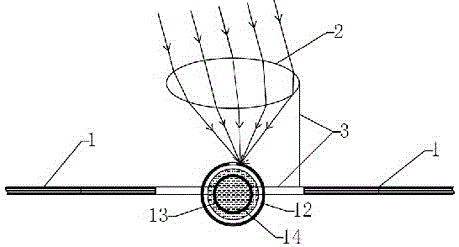

Solar concentration thermal drive automatic tracking device

InactiveCN104006546AMuch sunlight energyNo time lag effectSolar heating energySolar heat devicesHydraulic cylinderThermal dilatation

A solar concentration thermal drive automatic tracking device aims at tracking position changes of the sun through the device driven by energy provided by the sunlight, improving tracking accuracy and reducing tracking cost. A solar condenser (2) is arranged in the middle or the periphery of a solar receiver (1). A heat collection pipe (14) is arranged at the focal point position or the focal line position of the solar condenser (2). A thermal expansion pipe (13) is arranged inside the heat collection pipe (14). A reflecting layer (12) wraps the heat collection pipe (14). The position, facing right towards the solar condenser (2), of the reflecting layer (12) is provided with a small hole or a thin groove (22). The thermal expansion pipe (13) is communicated with an inner cavity of the hydraulic cylinder (9) through a pressure guide pipe (8). The thermal expansion pipe (13), the pressure guide pipe (8) and the inner cavity of the hydraulic cavity (9) are filled with a thermal expansion fluid medium (15). One end of the hydraulic cylinder (9) is connected with a second support (10), and the other end of the hydraulic cylinder (9) is connected with a displacement angle conversion device (5).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

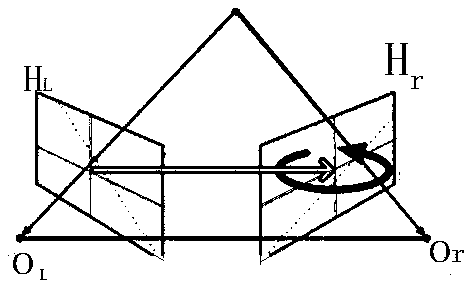

Transformer substation complex environment cross-field-of-view target tracking method based on three-dimensional digital model

PendingCN108038868ATo achieve the purpose of trackingImprove tracking accuracyImage enhancementImage analysisTransformerEquation of state

The invention discloses a transformer substation complex environment cross-field-of-view target tracking method based on a three-dimensional digital model. The technical scheme is that monitoring cameras are arranged in the area of a transformer substation requiring monitoring in a spaced way, the adjacent monitoring cameras photograph the position and the state of work personnel and maintenance equipment in a cross way, a nonlinear system is linearized by using extended Kalman filtering through Taylor series, and the original system model is converted into a station equation and an observation equation expressed in the form of error under the condition of neglecting high-order error; and the motion equation of the moving target is constructed under a transformer substation three-dimensional coordinate system by using a second-order kinetic model, multiple monitoring cameras are utilized to perform initial positioning and the result acts as the initial value of EKF tracking after the target is monitored for the first time, then the detection value of the corresponding image space target is utilized to convert the position error of the three-dimensional coordinates and substitute inthe state equation for iteration, and the filter estimates the position of the target in case of temporarily removing out of the field of view of the target or switching of the field of view so thathigh tracking precision can be acquired.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

Tracking method and related product

PendingCN110503662ATo achieve the purpose of trackingAccurate trackingImage analysisComputer visionComputer science

Owner:IFLYTEK (SUZHOU) TECH CO LTD

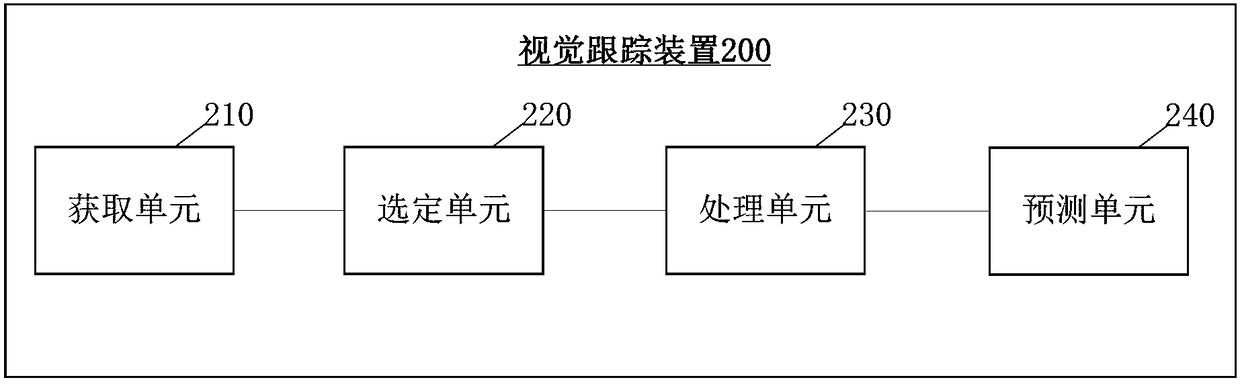

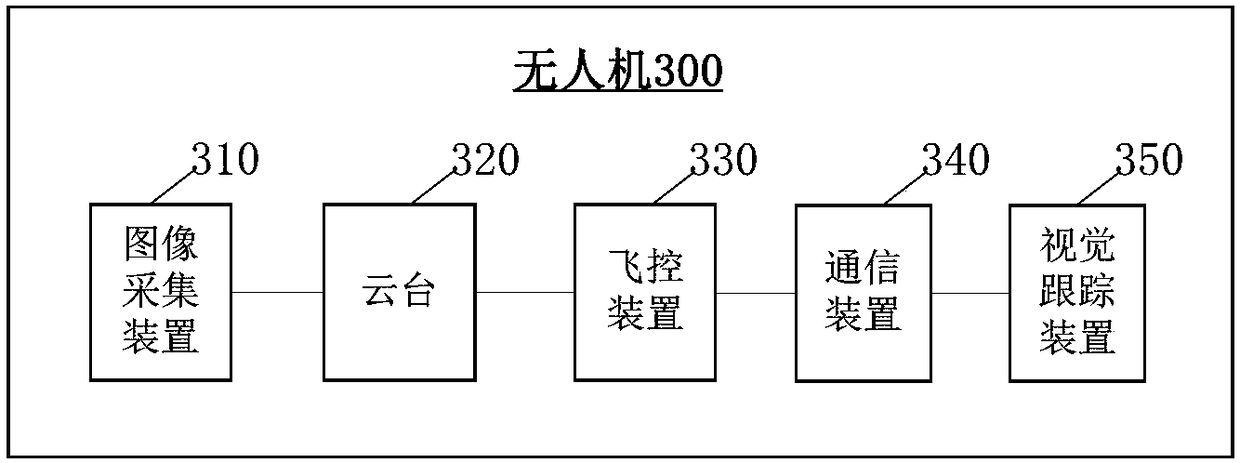

Visual tracking method, visual tracking device, UAV(unmanned aerial vehicle) and terminal device

InactiveCN108288281AChoose Fast and AccurateEasy to controlImage enhancementImage analysisObject basedUncrewed vehicle

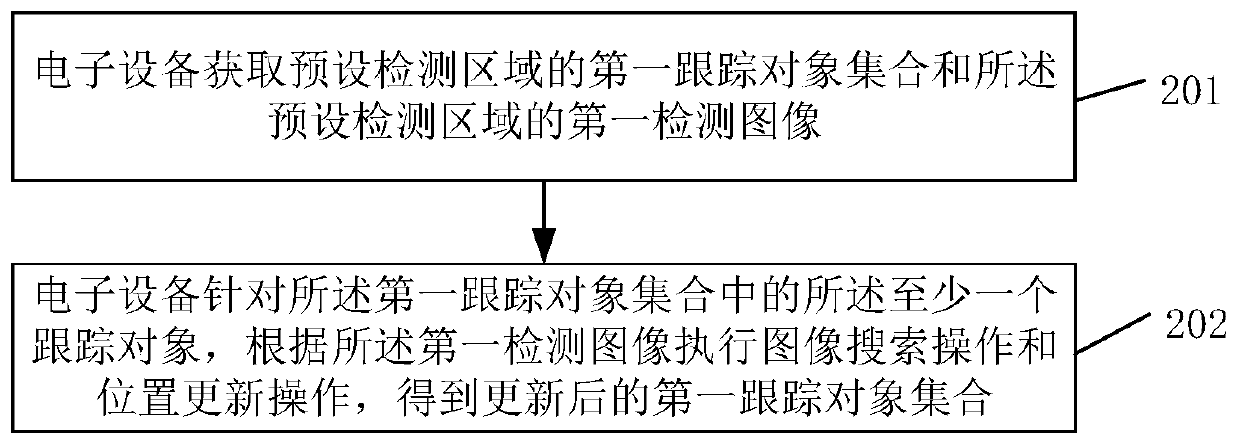

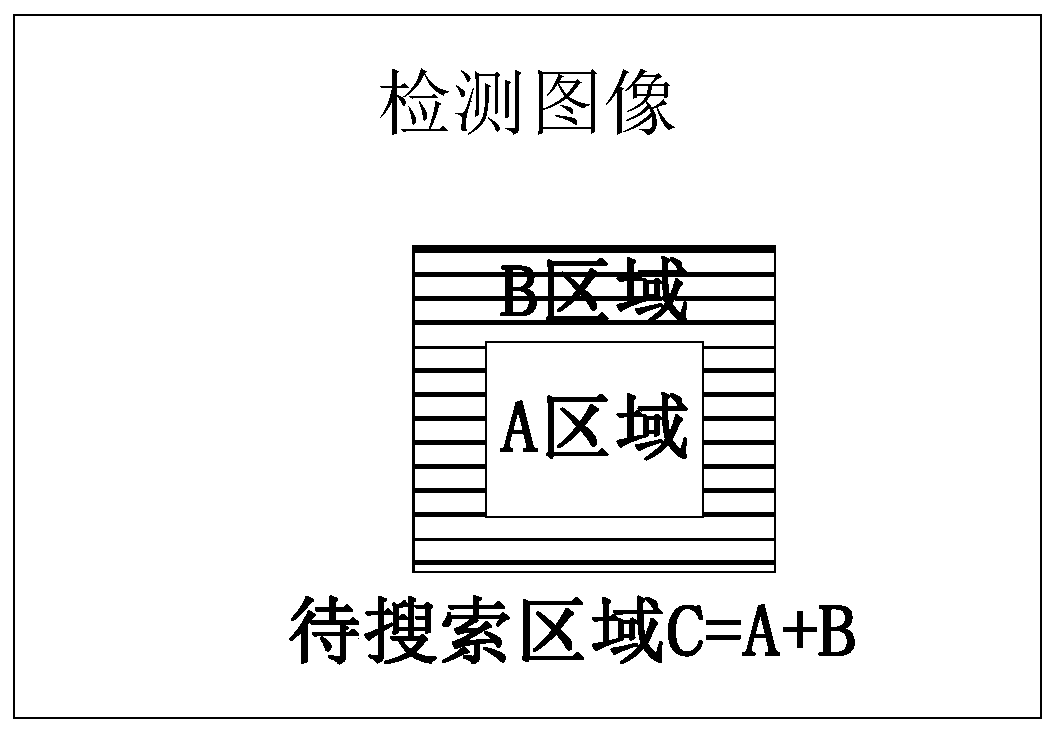

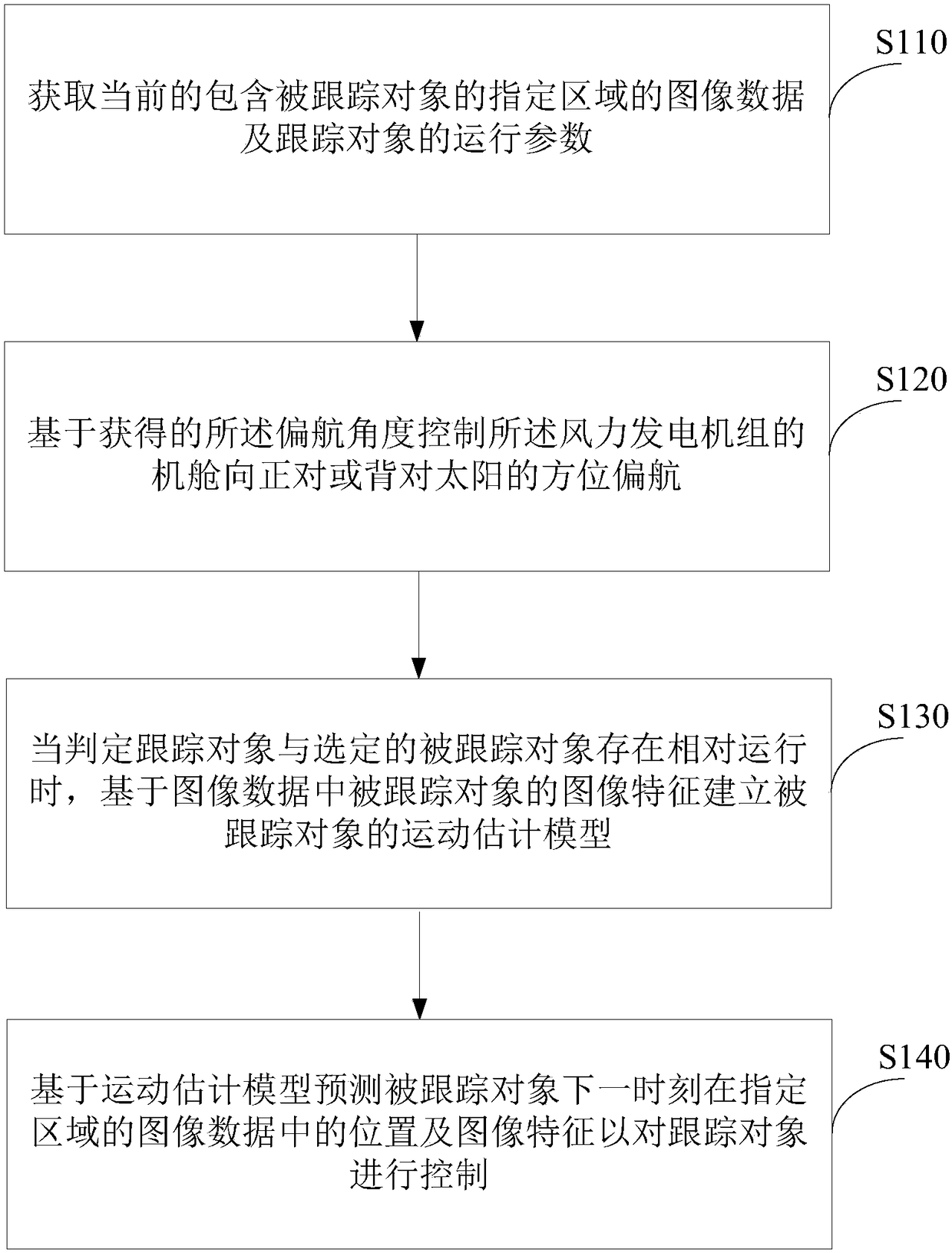

The invention discloses a visual tracking method, a visual tracking device, an UAV(unmanned aerial vehicle) and a terminal device. The method comprises the following steps: obtaining image data of a designated area comprising a tracked object at present and operating parameters of a tracking object; based on the obtained image data of the designated area comprising the tracked object at present, obtaining possible tracked objects in the designated area and generating a tracked object library to select the tracked object; when judging that the tracking object is in relative motion with the selected tracked object, establishing a motion estimation model of the tracked object based on image features of the tracked object in the image data; and based on the motion estimation model, predicatingthe position of the tracked object in the image data of the designated area at the next moment and image features to control the tracking object.

Owner:SHANGHAI HANG SENG ELECTRONICS TECH CO LTD

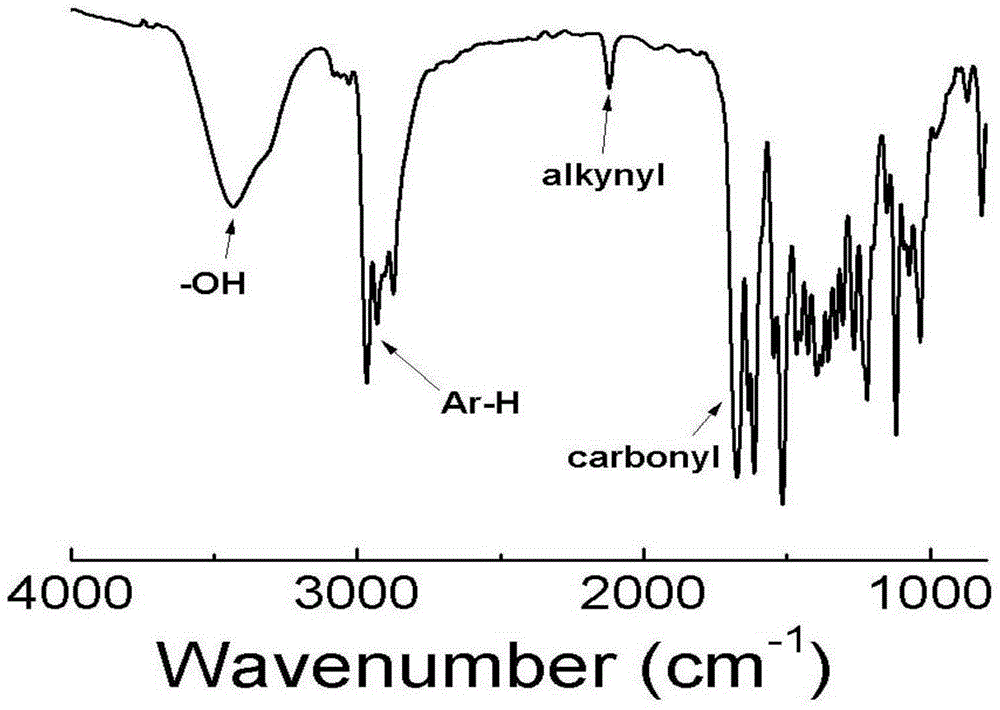

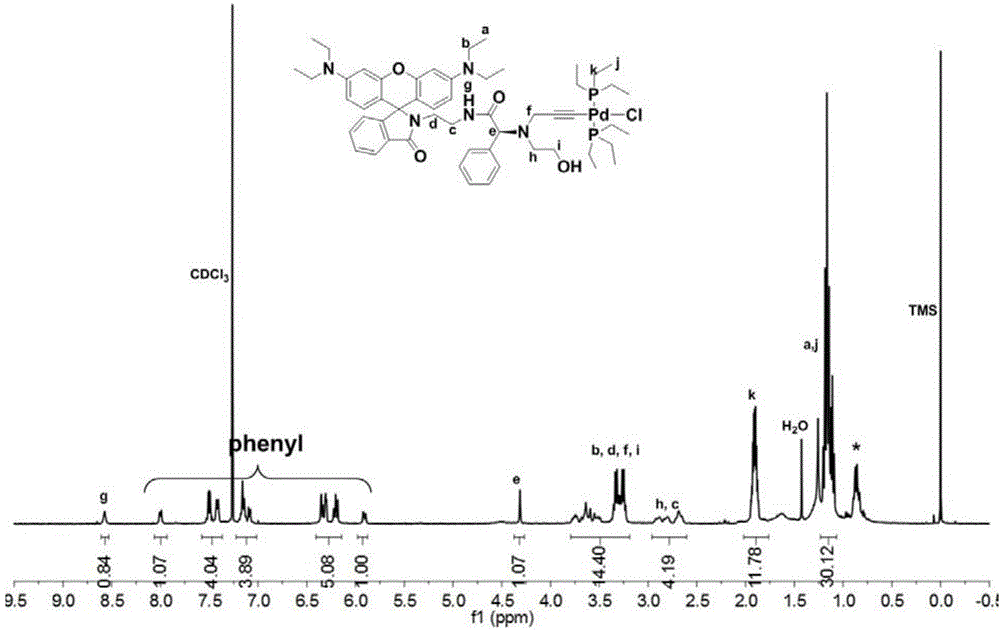

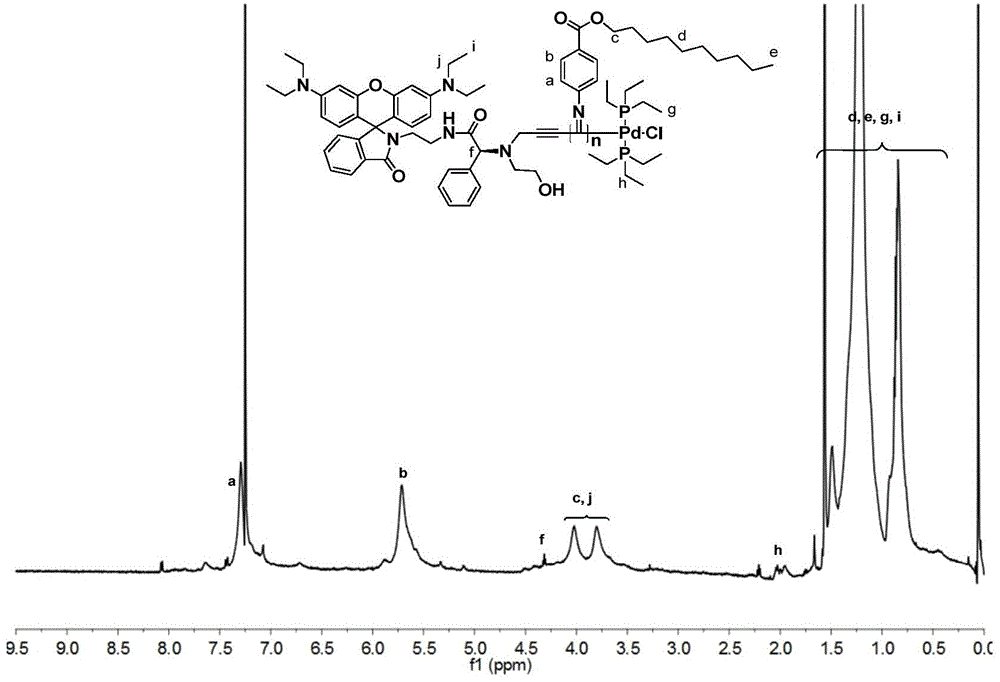

Chiral fluorescence self-sorting polymerization bifunctional initiator, and preparation method and application thereof

InactiveCN104628998AUniform molecular weightNarrow molecular weight distributionGroup 8/9/10/18 element organic compoundsIn-vivo testing preparationsFluorescenceLactide

The invention discloses a chiral-acid / alkali-stimulation-responsive difunctional fluorescence molecular initiator, and a preparation method and application thereof. The structure of the initiator is disclosed as the following general formula. The chiral center and chromophore are introduced into the initiator; the initiator can perform hybrid polymerization on isonitrile and lactide or epsilon-caprolactone monomers by a one-pot process, has the advantages of favorable self-sorting polymerizing power and high stability, and can be used for active / controllable polymerization of isonitrile, lactide, epsilon-caprolactone and other monomers; and the obtained polyisonitrile, polylactide homopolymer and block copolymers thereof have controllable molecular weight and narrow molecular weight distribution.

Owner:HEFEI UNIV OF TECH

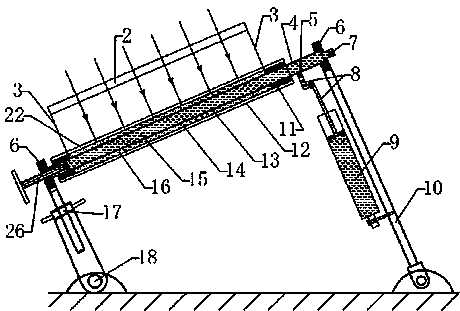

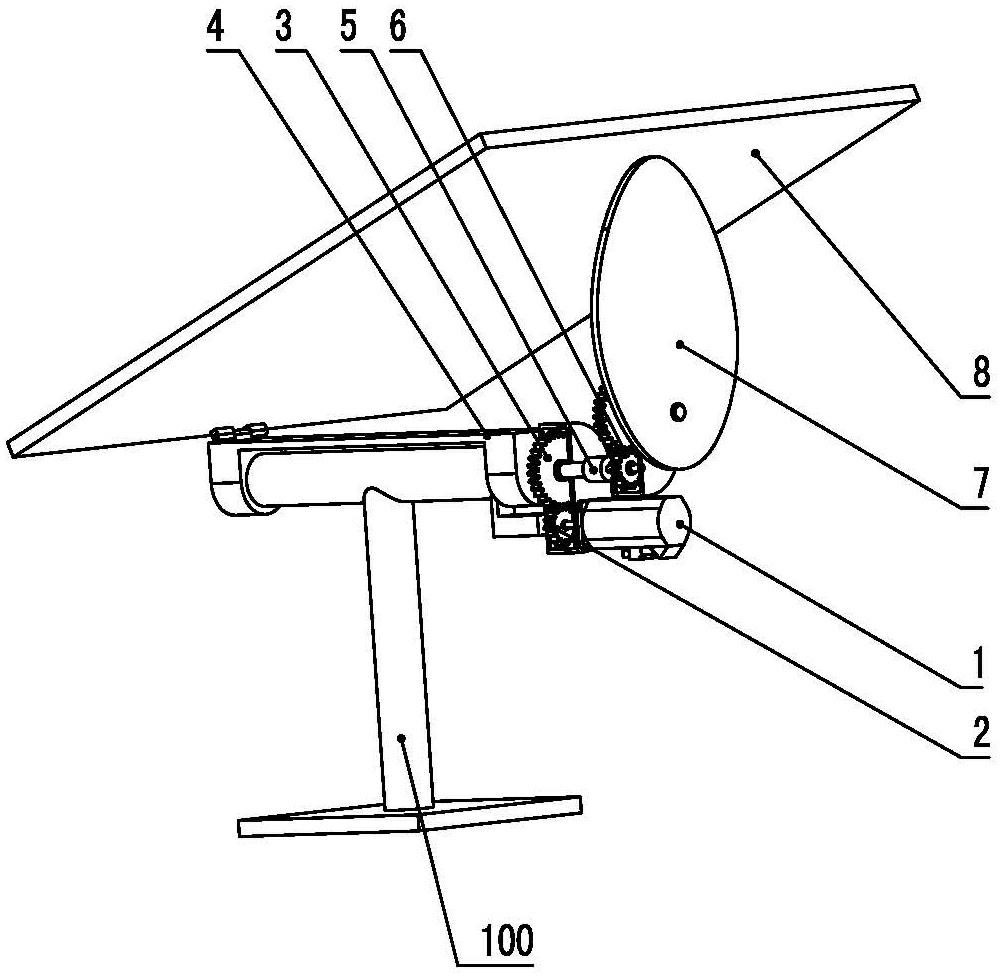

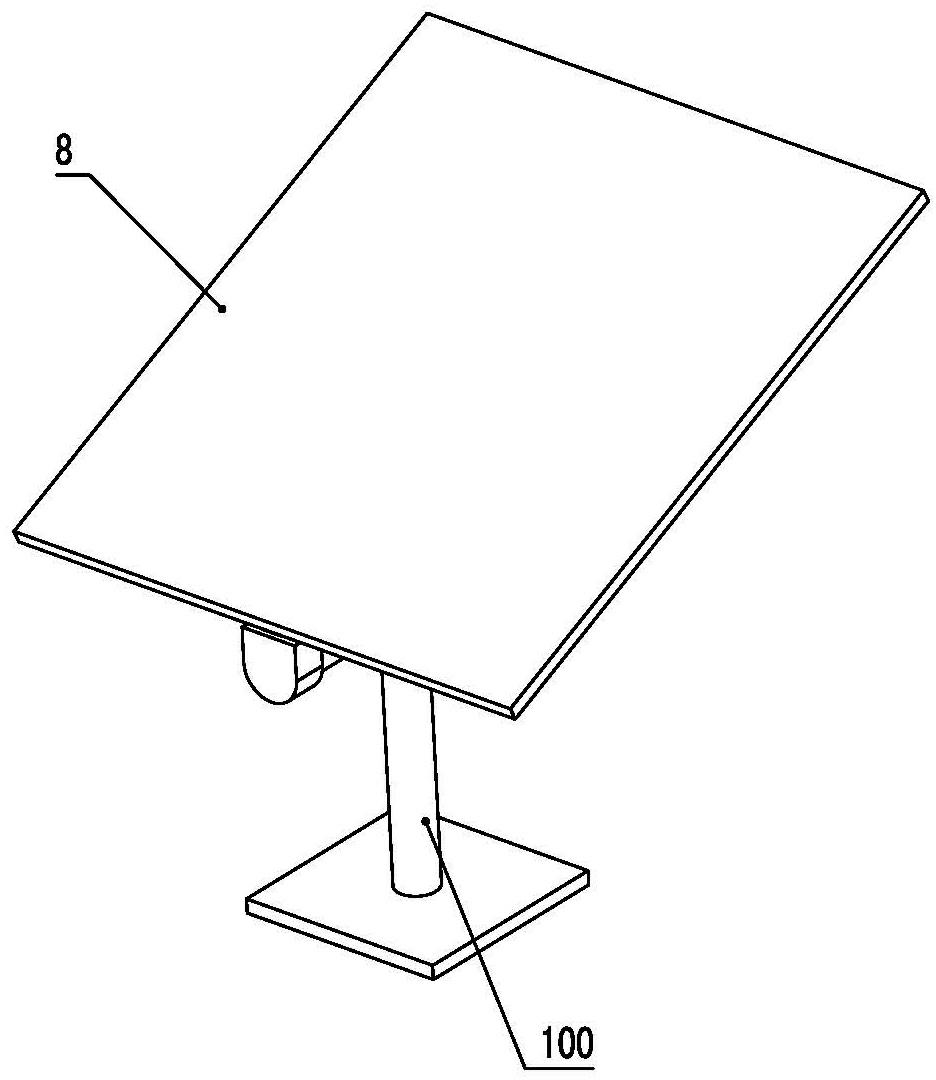

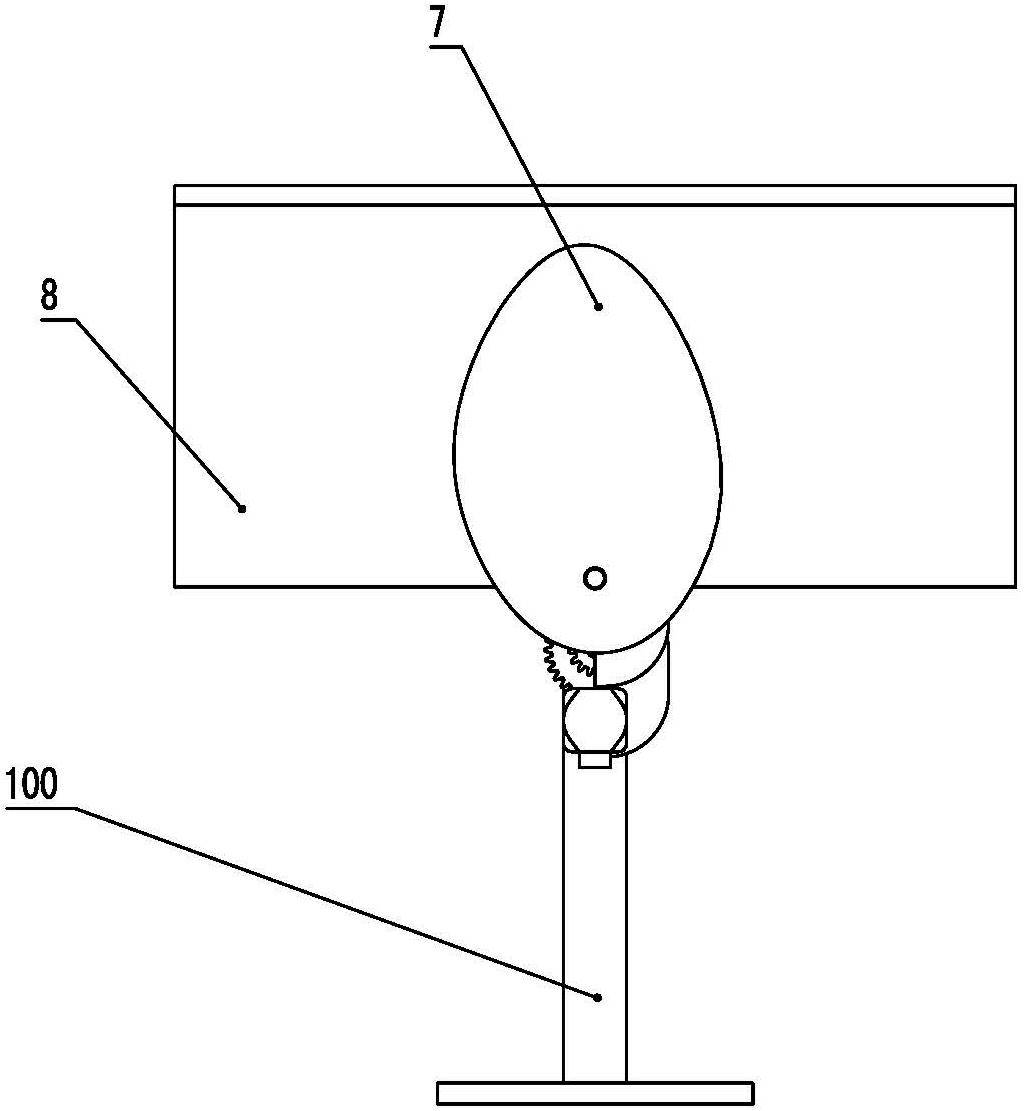

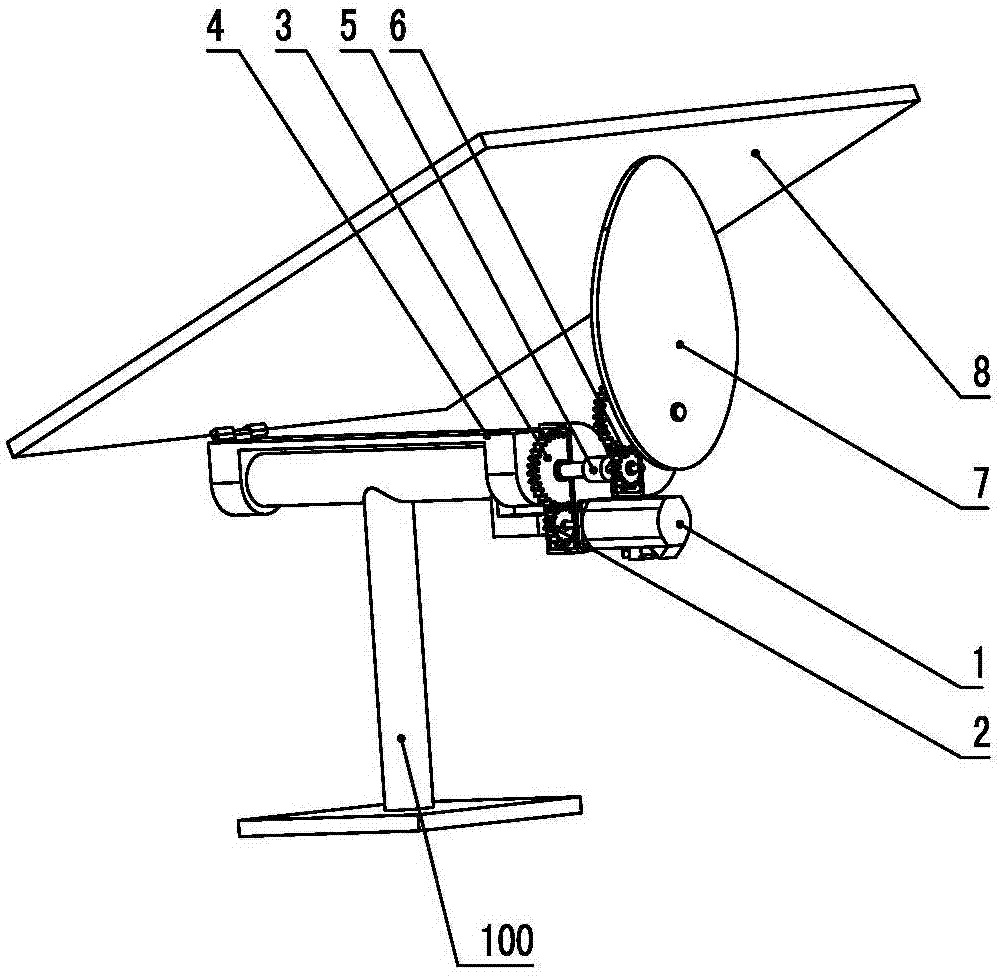

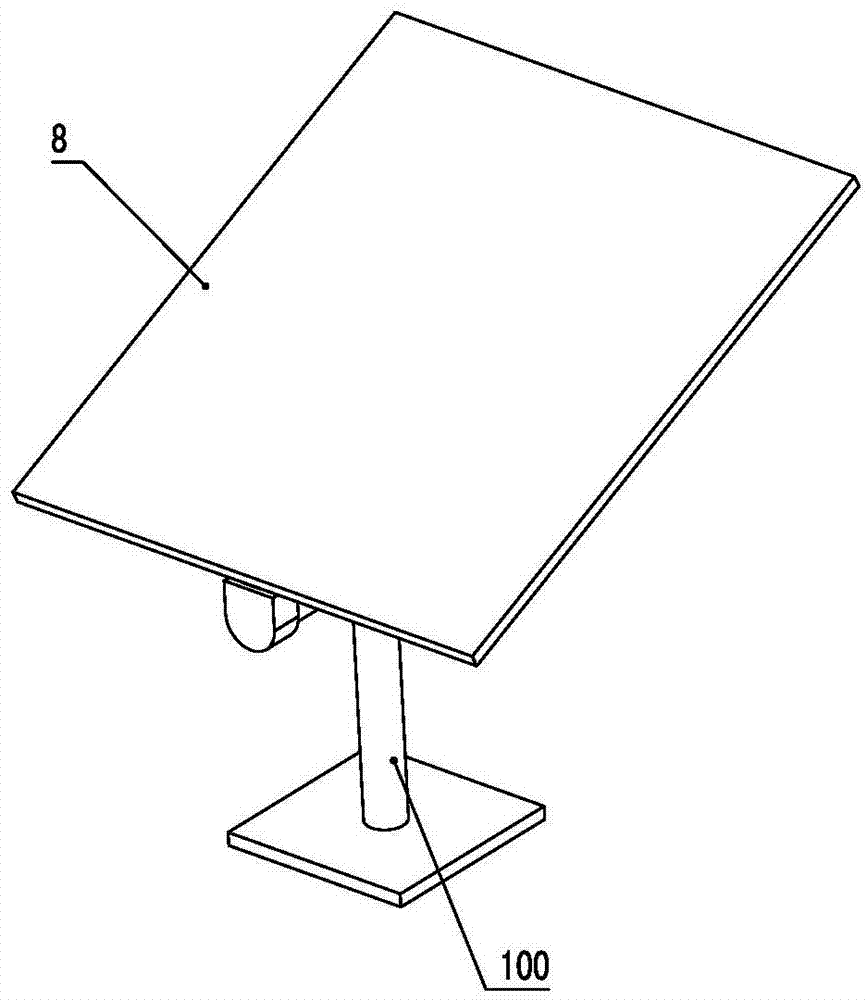

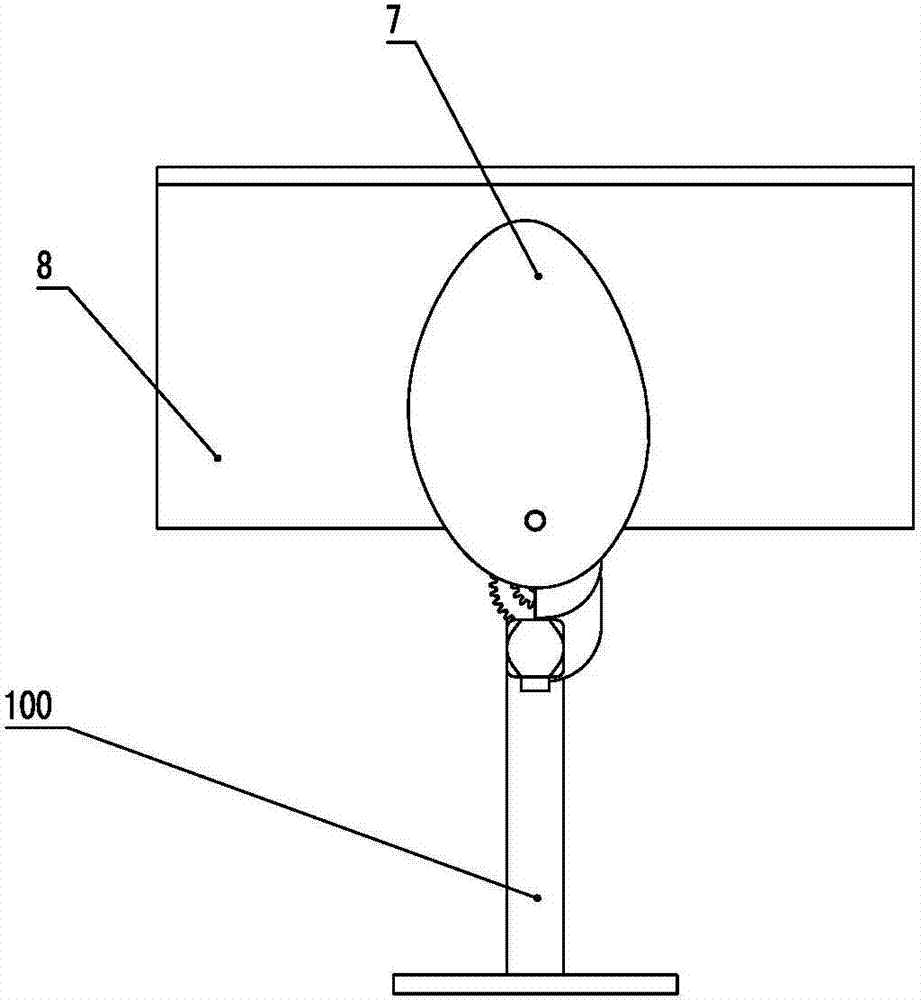

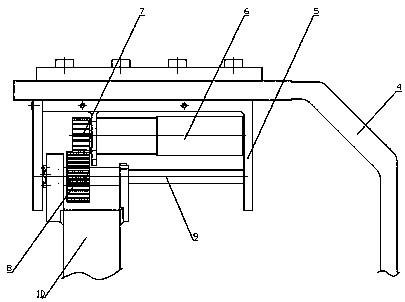

Solar tracking oriented one-dimensional driving two-dimensional output robot mechanism

InactiveCN102541088ATo achieve the purpose of trackingImprove reliabilitySolar heating energySolar heat devicesCouplingButt joint

The invention relates to a solar tracking oriented one-dimensional driving two-dimensional output robot mechanism. The invention provides the solar tracking oriented one-dimensional driving two-dimensional output robot mechanism which comprises a bracket, a solar component mounting plate, a cam, a motor, a first rotating shaft and a one-way coupler, wherein the motor is arranged on the bracket; the motor is connected with the cam through the one-way coupler; the motor is connected with the first rotating shaft; one end of the solar component mounting plate is hinged with the first rotating shaft; the other end of the solar component mounting plate is in contact with and butt-jointed with the cam; and the motor is connected with the solar component mounting plate through the first rotatingshaft and is used for driving the solar component mounting plate to rotate around the edge of the cam. The solar tracking oriented one-dimensional driving two-dimensional output robot mechanism has the beneficial effects that: one motor input is converted into two rotating shaft outputs, the solar motion is tracked and a sunlight receiving surface of a solar component is vertical to the sunlight under a working state, so that the total volume of absorbed energy is increased, the cost is lower and the reliability is higher.

Owner:楼云江 +1

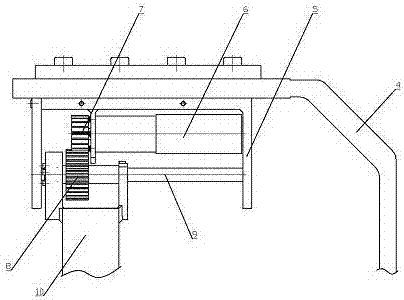

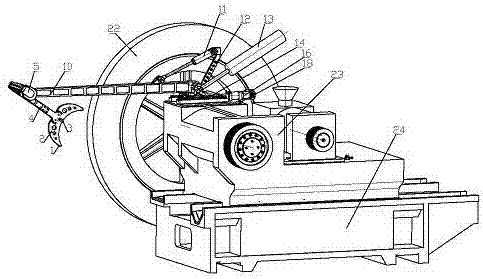

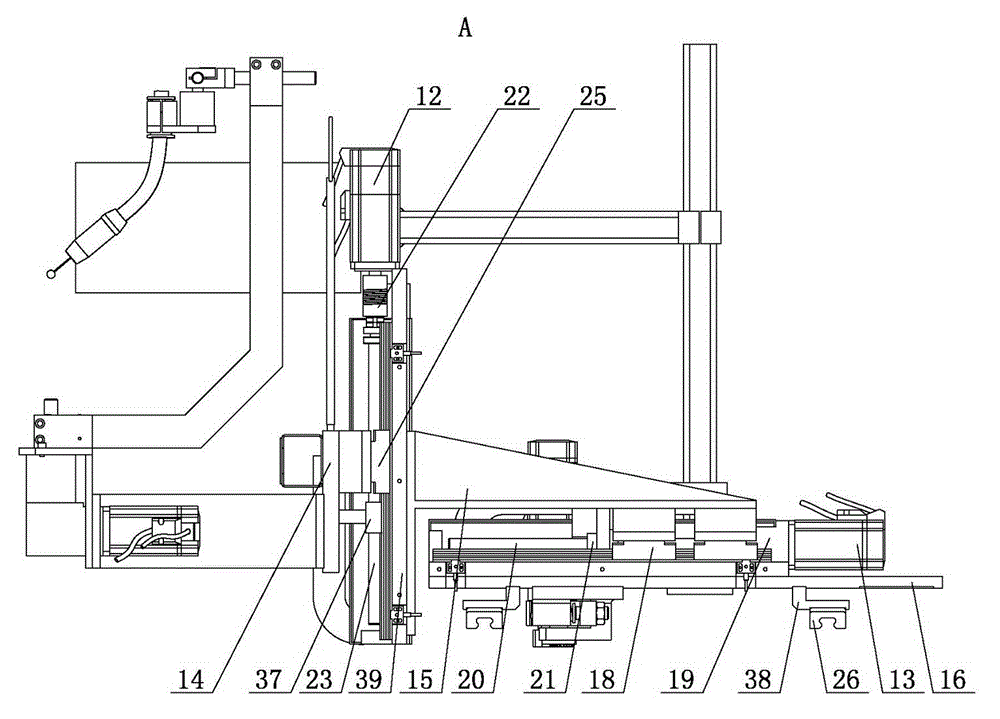

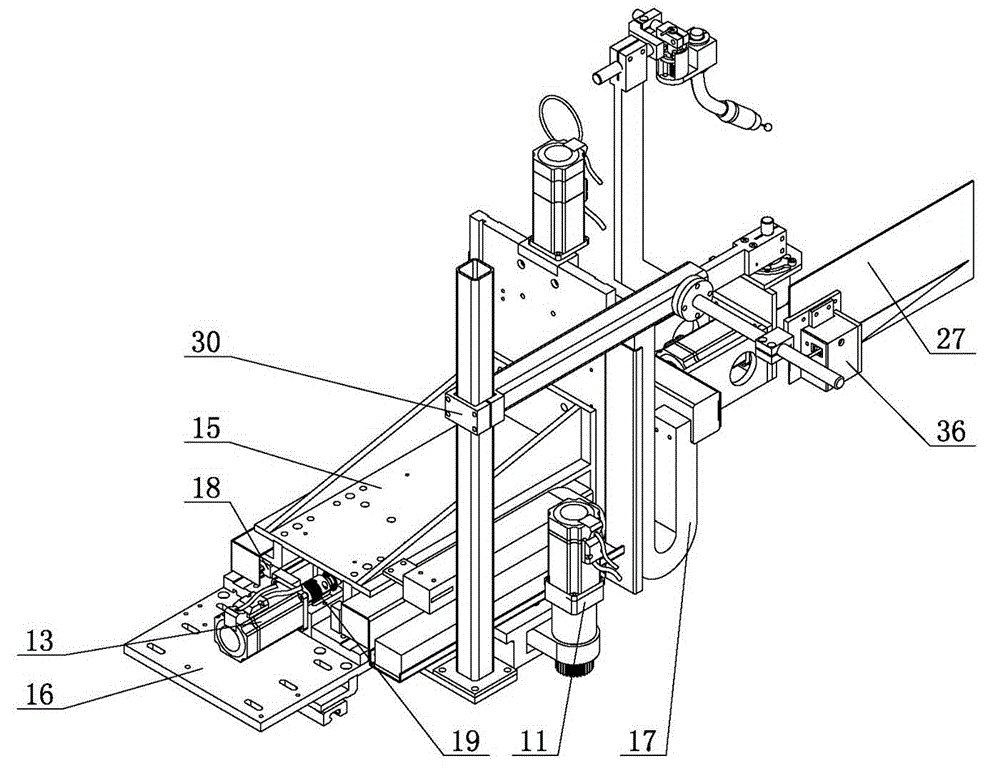

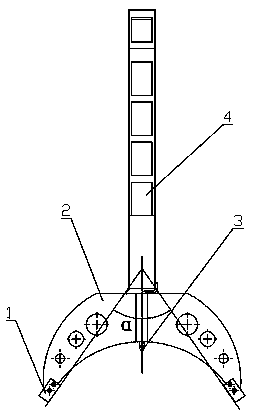

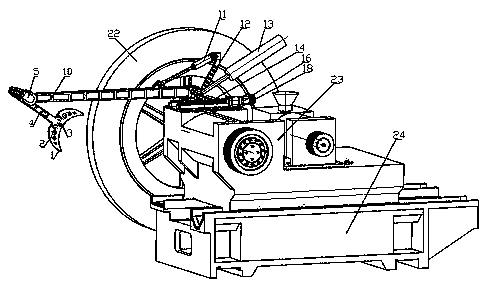

Crankshaft follow-up grinding online measuring instrument

ActiveCN107009228ARealize online measurementAchieve improvementGrinding carriagesGrinding drivesMeasuring instrumentEngineering

The invention discloses a crankshaft follow-up grinding online measuring instrument which comprises a measuring instrument base. A swing arm support is borne on the measuring instrument base in a sliding manner. A measuring swing arm is hinged to the swing arm support. A swing arm oil cylinder is connected between the top end of the oil cylinder support and the measuring swing arm. A center fixed gear is fixedly arranged at the stretching end of the measuring swing arm, a following swing frame is further mounted on the stretching end of the measuring swing arm, and a planet swing gear mounted at the output shaft end of a following swing motor is engaged with the center fixed gear. A measuring tool support is fixedly mounted on a measuring tool following swing arm, two measuring clamping blocks and a displacement sensor are mounted on the measuring tool support, the two measuring clamping blocks are located on two inclined face of a V-shaped base level correspondingly, the displacement sensor is located on the symmetric line of the V-shaped base level, and the inclined included angle alpha of the V-shaped base level is equal to 68 degrees to 72 degrees. The crankshaft follow-up grinding online measuring instrument can achieve real-time online measurement and is high in detecting sensitivity and machining precision.

Owner:SOUTHEAST UNIV

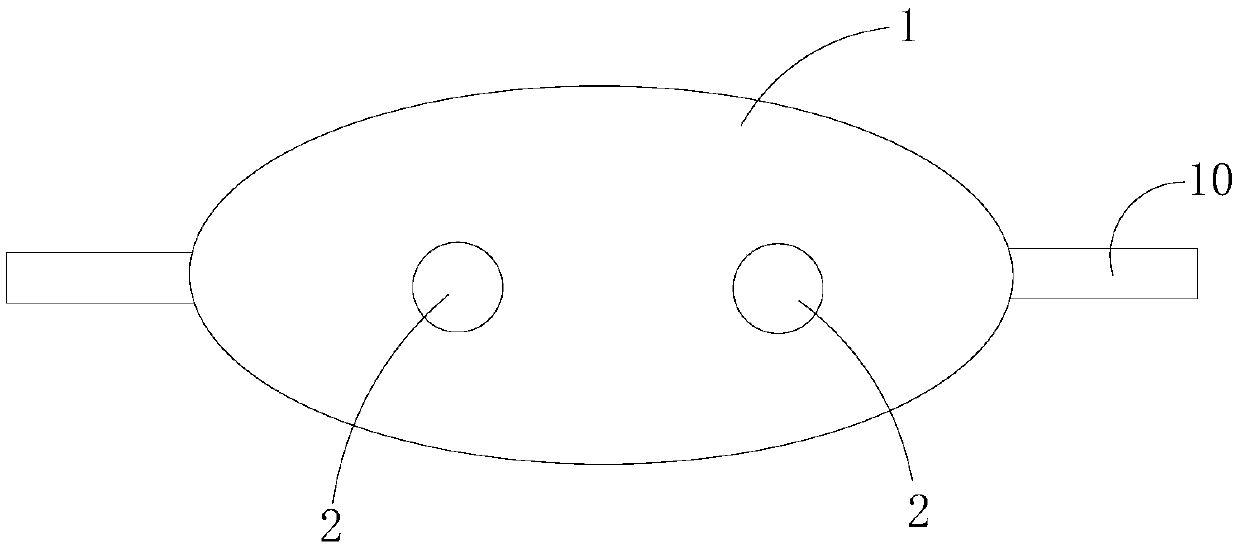

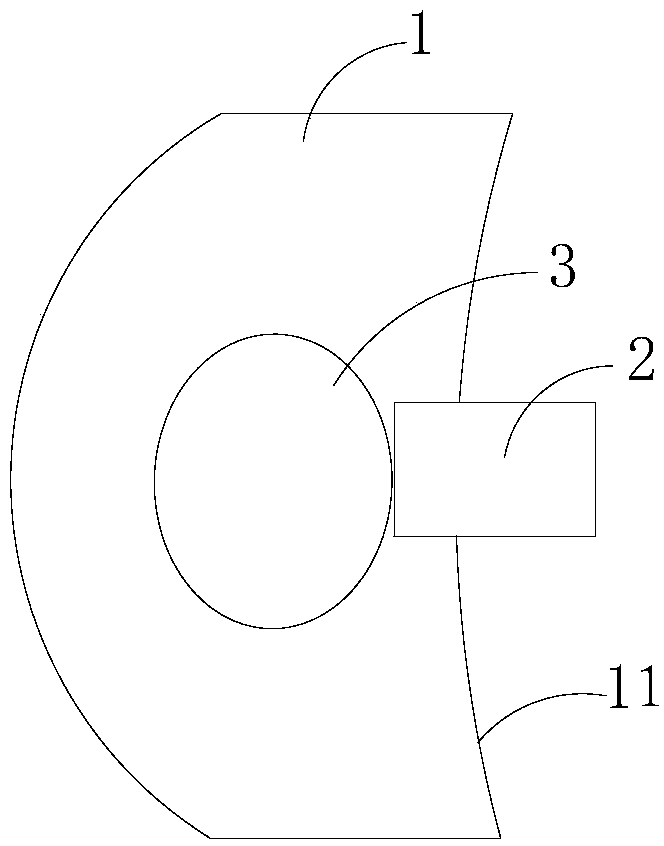

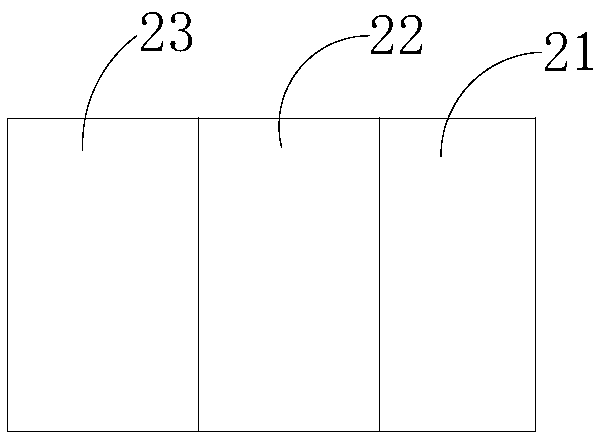

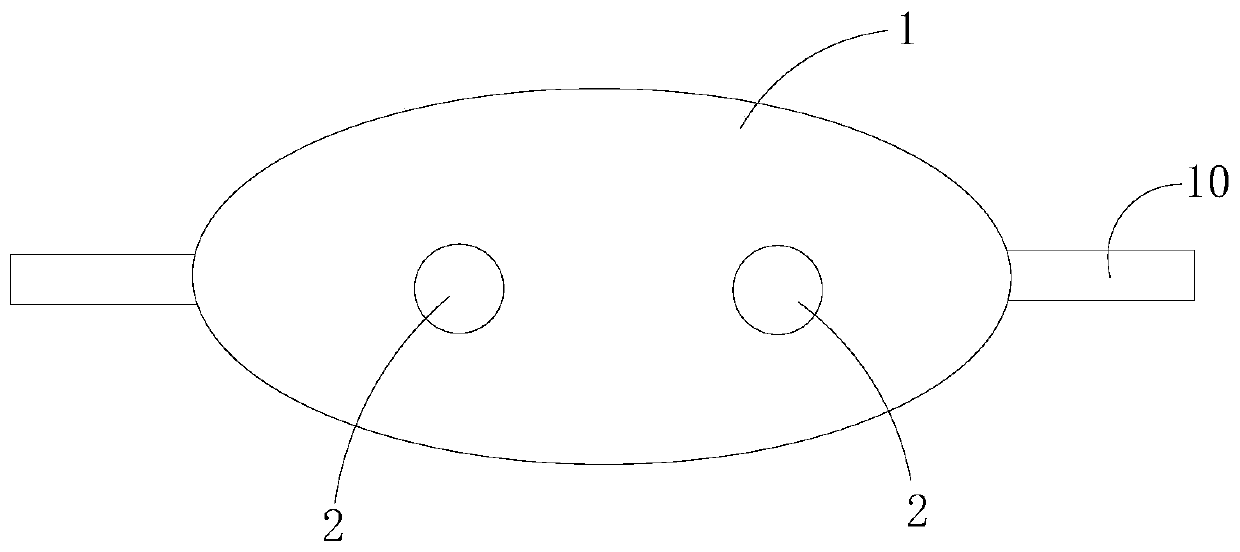

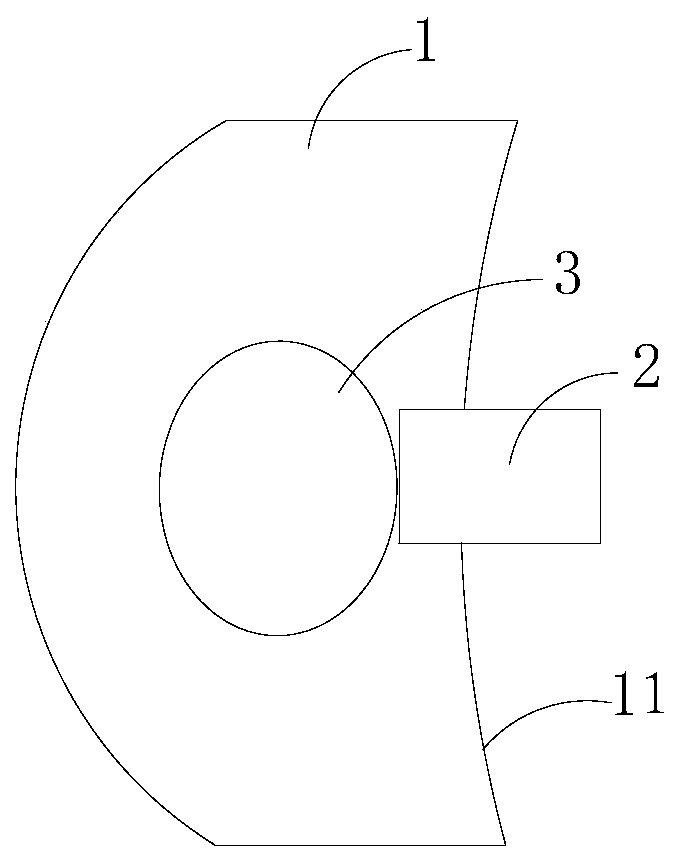

Intraocular pressure tracking measuring instrument

The invention discloses an intraocular pressure tracking measuring instrument which can reduce harm to eyeballs and is convenient to use. The intraocular pressure tracking measuring instrument comprises an eyeshade body and one or two probe assemblies which are fixedly arranged on the eyeshade body and correspond to eyes of a subject, a inflatable air bag is arranged in the eyeshade body, at leastpart material of the eyeshade body is a flexible material to deform after the air bag is inflated so as to allow the air bag to push the one or two probe assemblies to move to exert pressure to eyeballs, and each probe assembly comprises an ultrasonic sensor for detecting whether tops of the eyeballs are pressed to be flat and a pressure sensor connected with the ultrasonic sensor.

Owner:苏州兆乘四海通科技有限公司

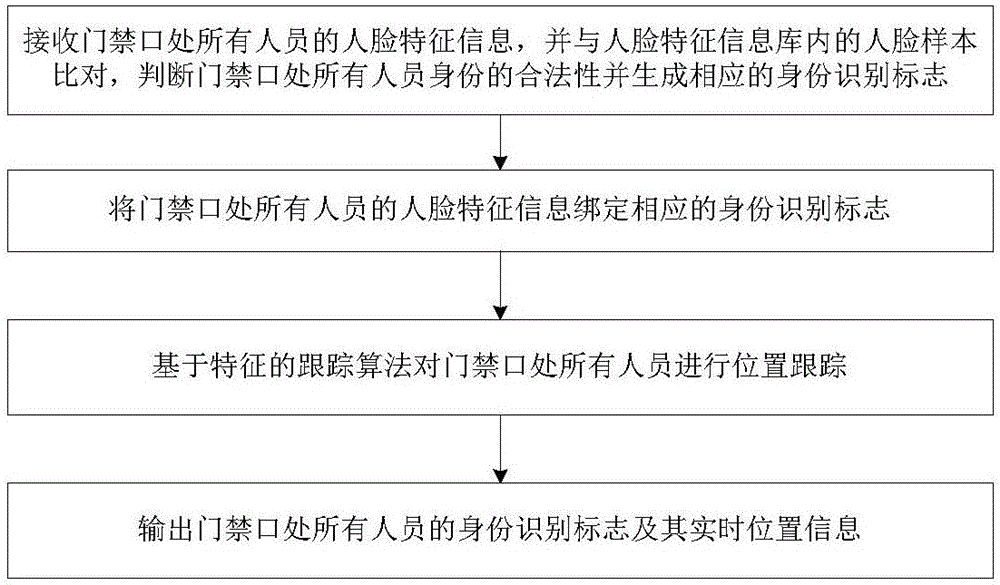

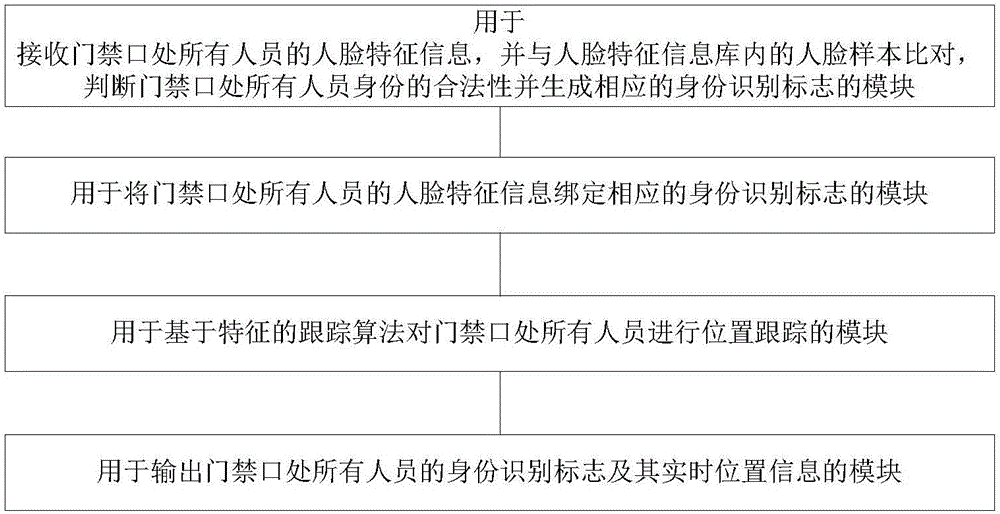

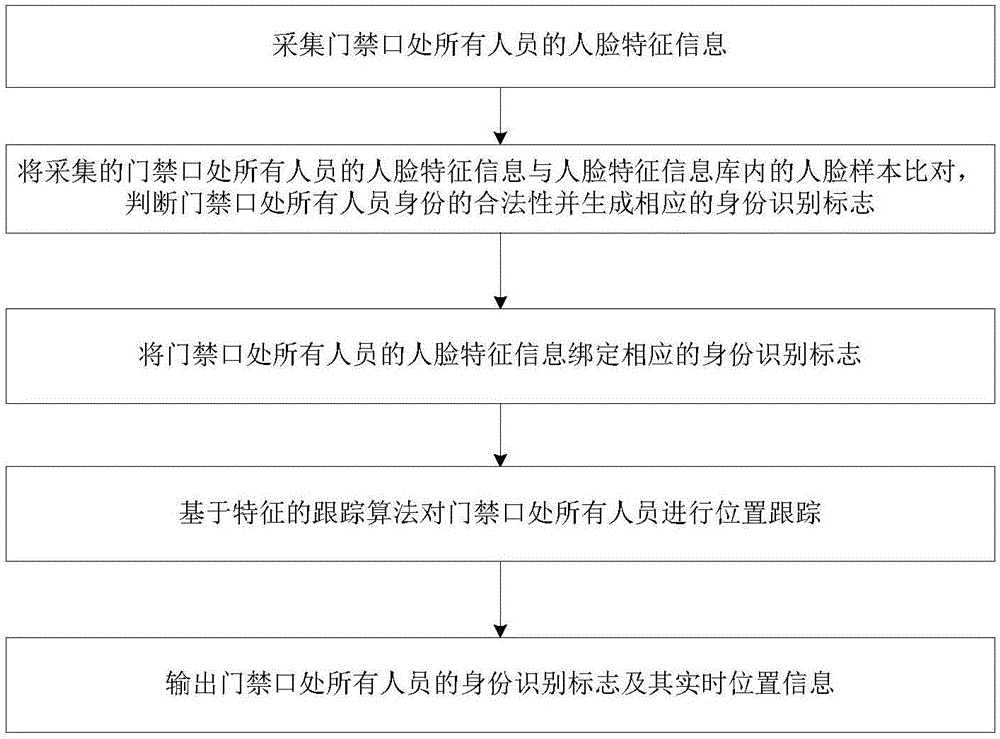

Door access identity tracking method and device, identifying and tracking system and door access system

InactiveCN106127911AAchieve the purpose of strengthening attentionTo achieve the purpose of trackingCharacter and pattern recognitionIndividual entry/exit registersInformation repositoryLocation tracking

The invention discloses a door access identity tracking method and device, an identifying and tracking system and a door access system. The method is used for tracking at least one person passing the door access system and includes: receiving the human face feature information of all people at the entrance of the door access system, and comparing the human face feature information with human face samples in a human face feature information library to judge the identity legitimacy of the people at the entrance of the door access system and generate corresponding identification marks; correspondingly binding the identification marks to the people at the entrance of the door access system according to the human face feature information; tracking the positions of the people according to the tracking algorithm of features; outputting the identification marks and real-time position information of the people. By the method, the identification marks, which can be displayed, of illegal and legal people can move along with the people, and identity tracking can be achieved.

Owner:JINAN NEW GIGANANO LONG DISTANCE MEASURING & CONTROL

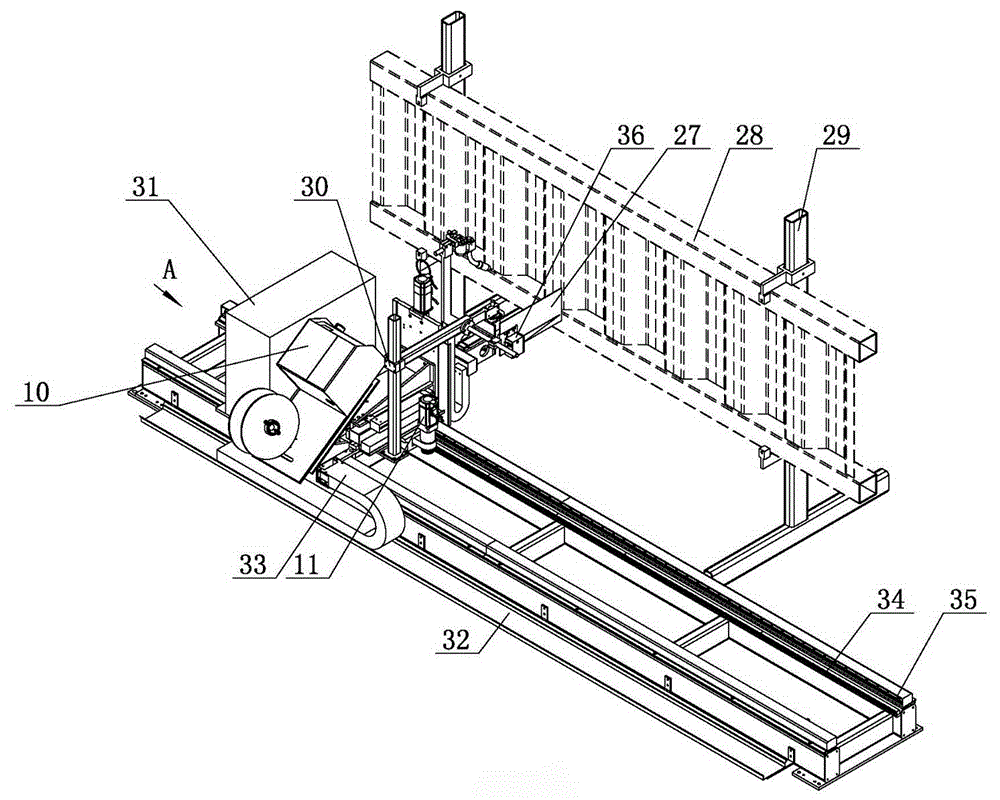

Guardrail plate automatically welding device

InactiveCN104646798APrecision weldingAvoid Welding Through WeldsVehicle componentsMetal working apparatusPistonMechanical engineering

Disclosed is a guardrail plate automatically welding device. The guardrail plate automatically welding device comprises a pressing wheel, a wheel seat, a jacking device and a displacement sensor. The wheel seat is provided with the pressing wheel; the jacking device comprises an oil cylinder or steam cylinder; the bottom of the wheel seat is connected with the jacking device; the displacement sensor is connected with the piston of the oil cylinder or steam cylinder or the wheel seat. According to the guardrail plate automatically welding device, force exerted on the pressing wheel by the oil cylinder or steam cylinder can keep the same, so that pressure between the pressing wheel and a ring piece has no significant change, the problem that the quality of the ring piece is affected by overhigh pressure of the pressing wheel can be voided; the displacement of the pressing wheel can be obtained through accurate measurement of an encoder, so that the measuring precision can be effectively improved, and errors can be effectively reduced.

Owner:刘宪福

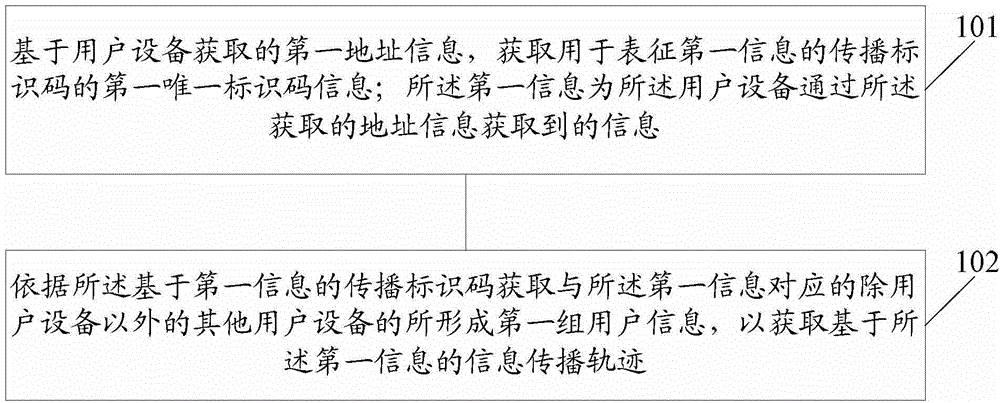

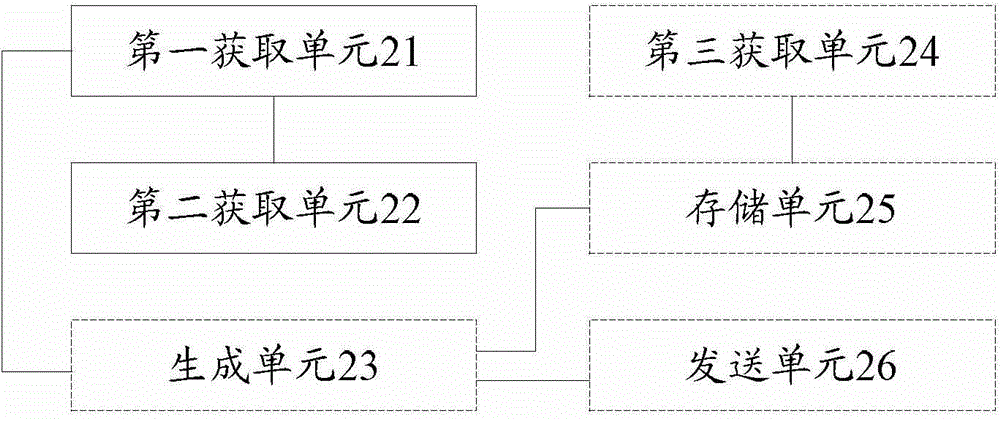

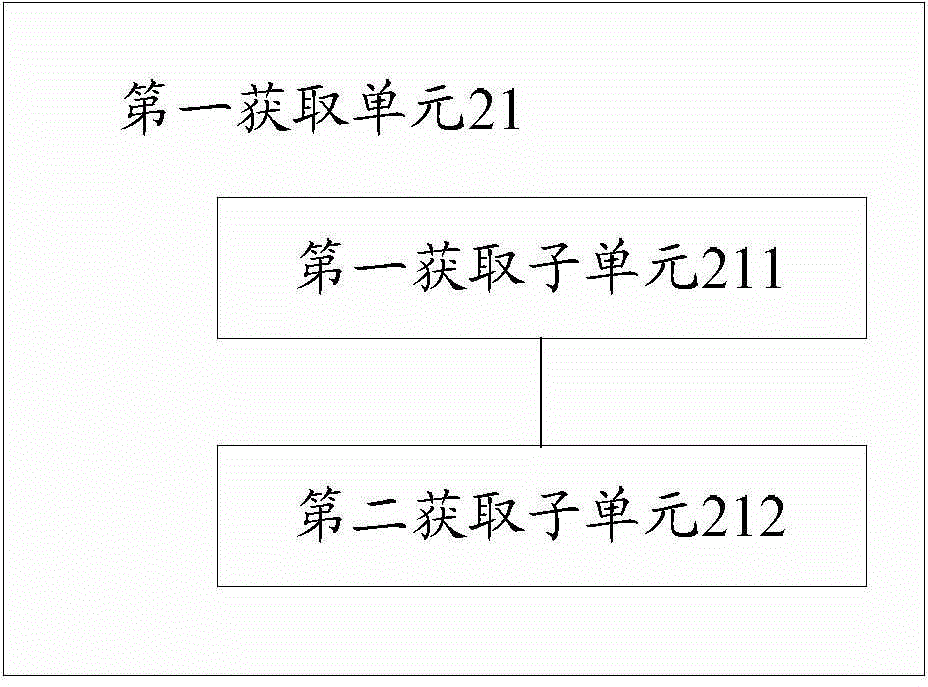

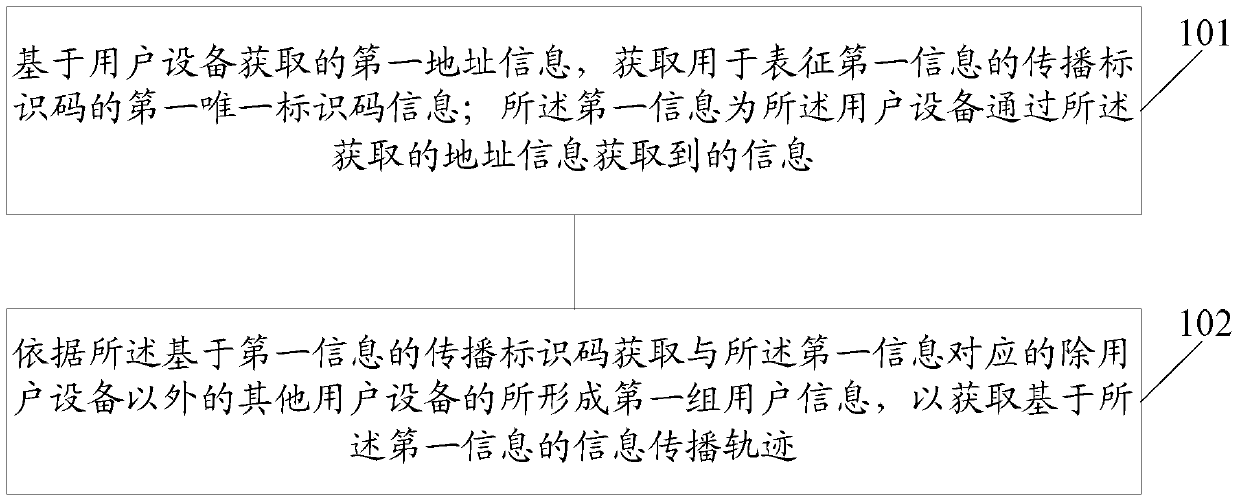

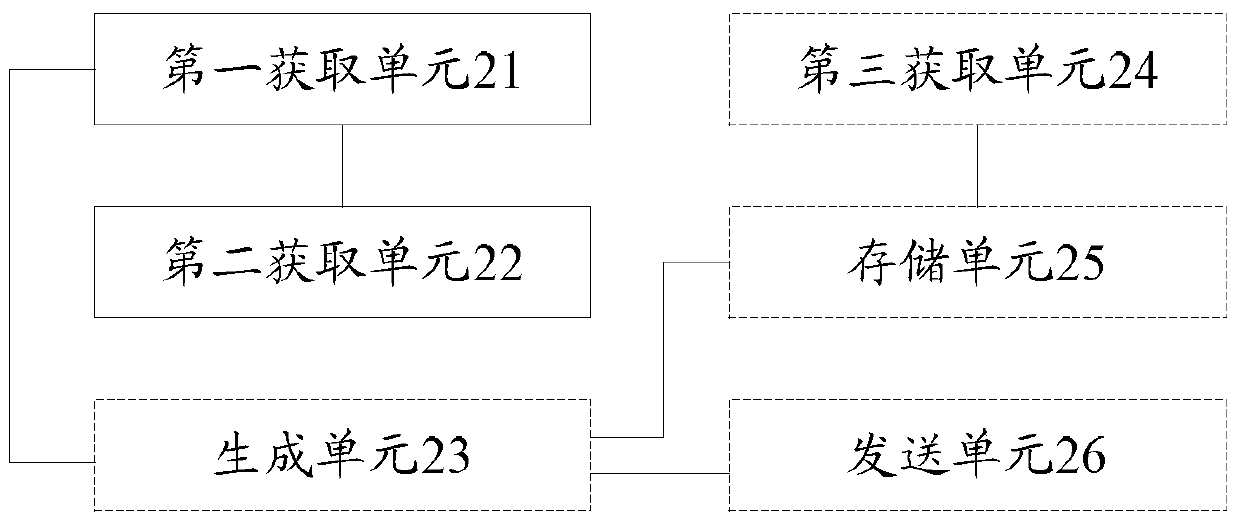

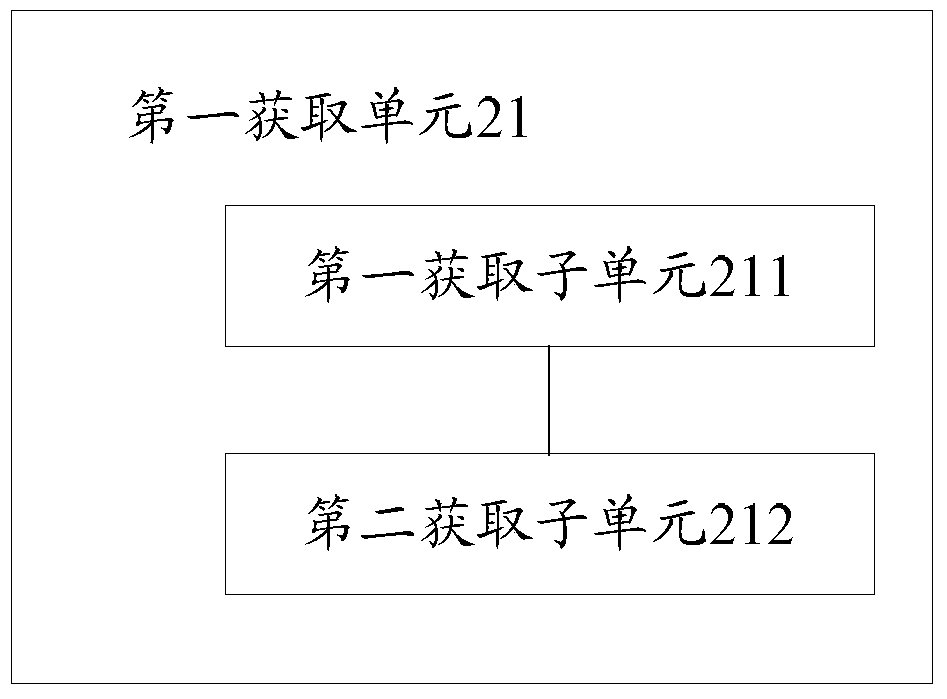

Information transmission tracking method and device thereof

ActiveCN105873090ADissemination to achieveTo achieve the purpose of trackingWireless communicationInformation transmissionInformation gain

The embodiment of the invention discloses an information transmission tracking method. The method comprises steps: based on first address information acquired by user equipment, first unique identification code information for characterizing a transmission identification code of the first information is acquired, wherein the first information is the information acquired by the user equipment via the acquired address information; and according to the first unique identification code information, first group user information formed by other user equipment except the user equipment corresponding to the first information is acquired, and an information transmission trajectory based on the first information is acquired. The embodiment of the invention also discloses an information transmission tracking device.

Owner:LIAONING MOBILE COMM

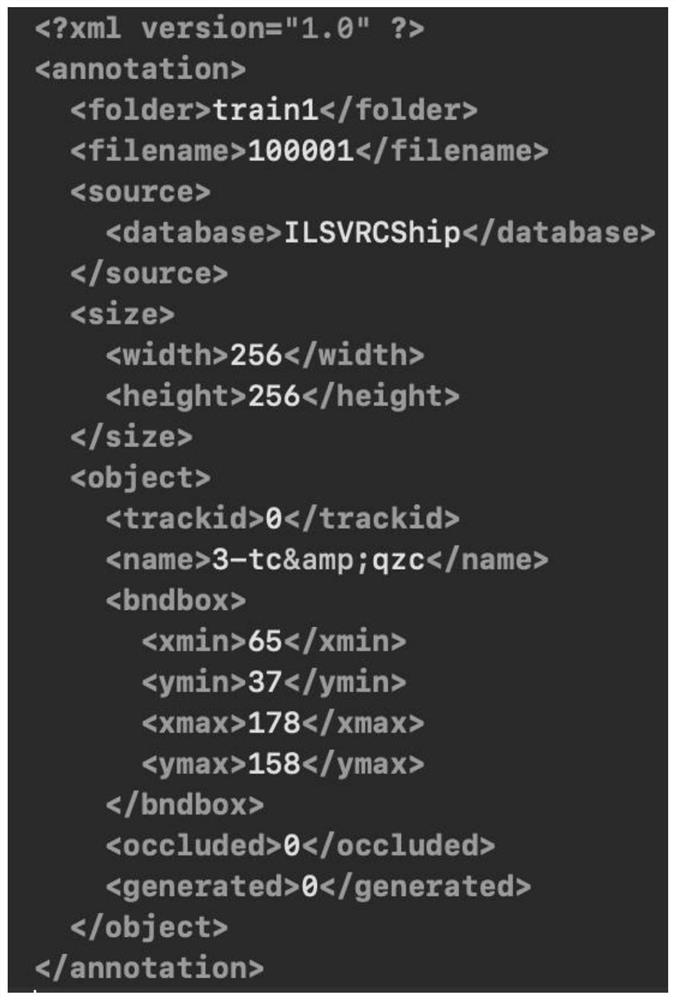

Infrared ship video tracking method based on convolutional neural network

PendingCN112700476AEnhanced spatial informationTo achieve the purpose of trackingImage enhancementImage analysisData setFeature extraction

The invention discloses an infrared ship video tracking method based on a convolutional neural network, and the method improves the model recognition efficiency through fusing three to five layers of a SiamRPN feature extraction network to increase the spatial information of output features. A spatial transformation network composed of a positioning network, a grid generator and a sampler is added to a search branch so as to rotate and zoom the feature map, and the influence of target rotation and zoom on the recognition rate is reduced. In addition, aiming at the problem of lack of an infrared ship video tracking data set, the invention also constructs a data set containing 3000 infrared ship target images. According to the method, more accurate infrared target features are extracted through the multi-layer fusion network and the spatial change network, so that the tracking accuracy is improved; the method is high in operability and expandability and suitable for infrared ship target tracking of the sea surface background.

Owner:BEIJING UNIV OF TECH

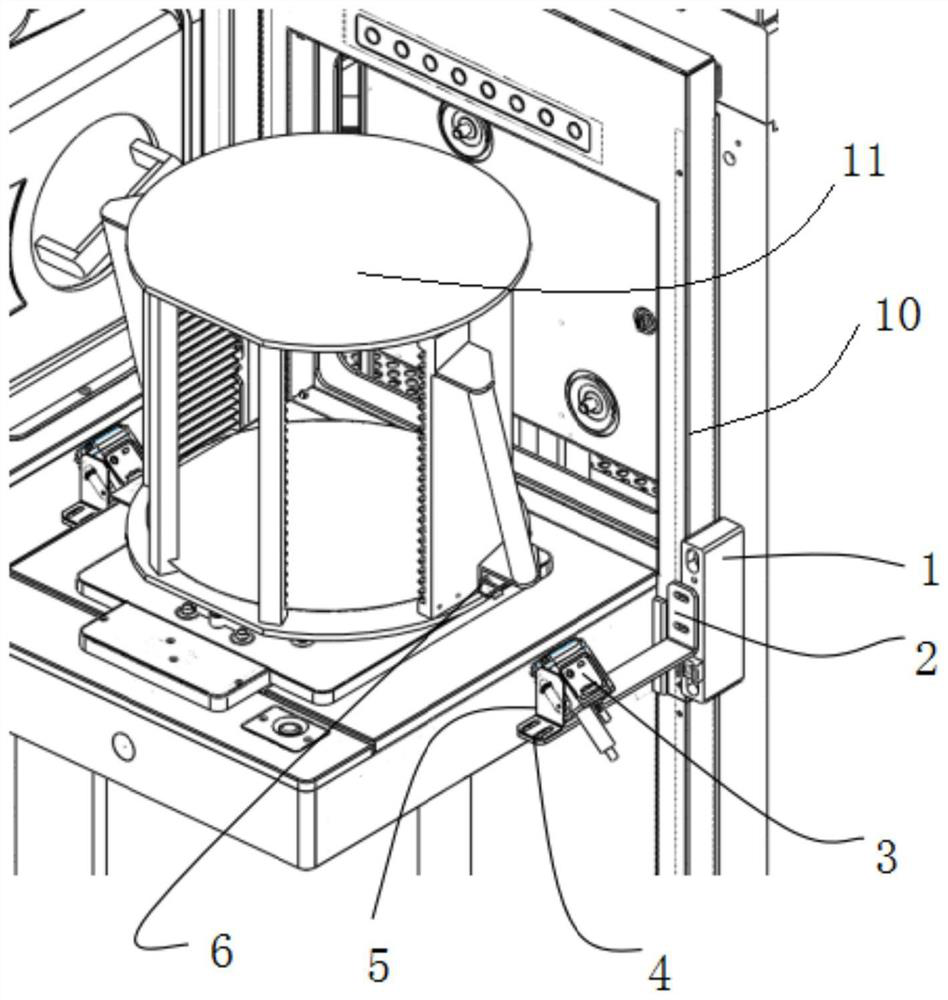

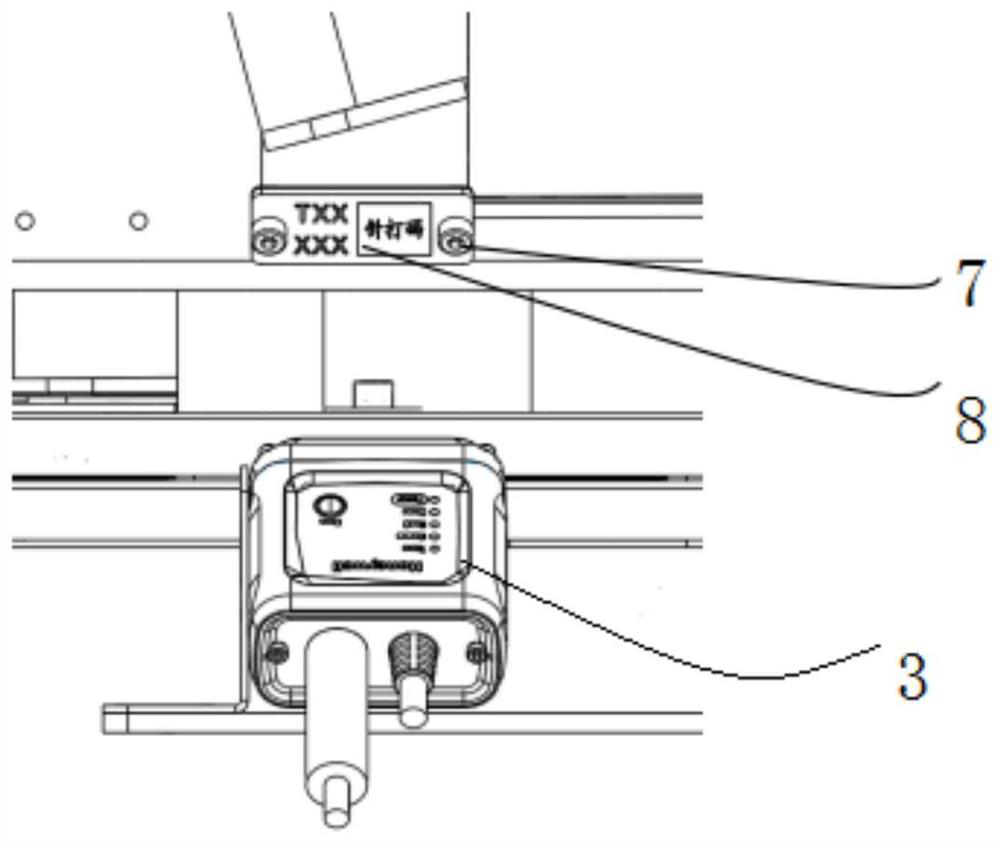

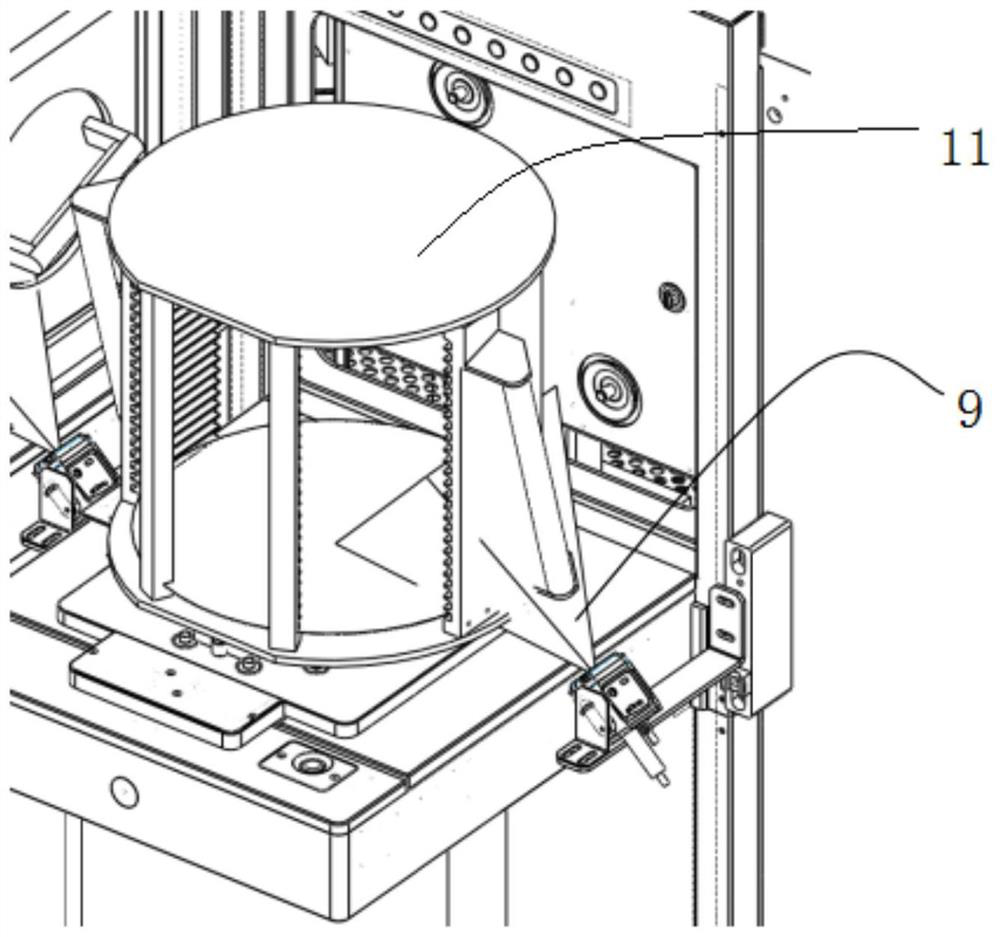

Device and method for automatically identifying wafer iron gridiron and reading ID

PendingCN113642349AImprove compatibilityTo achieve the purpose of trackingSemiconductor/solid-state device manufacturingSensing by electromagnetic radiationProcess engineeringManufacturing engineering

The invention provides a device and method for automatically identifying a wafer iron gridiron and reading an ID, the device comprises an automatic code scanning device and a sorting machine upper computer system, the automatic code scanning device is arranged on a wafer loading and unloading machine and used for reading the ID of the wafer iron gridiron arranged on a wafer loading and unloading machine panel and sending the ID to the sorting machine upper computer system, the upper computer system of the sorting machine automatically identifies whether the iron gridiron is placed on the current wafer loading and unloading machine according to the ID information sent by the automatic code scanning device, judges the size of the current iron gridiron and reports the ID information of the iron gridiron, so that the purpose of wafer tracking is achieved. The problem of automatic identification of the iron gridiron in a semiconductor customer factory is solved, automation is realized on the basis of the original process which cannot be used for automation, the labor cost of customers is reduced, the wafer breakage rate caused by human errors is reduced, and the compatibility of automatic wafer boat identification of the wafer loading and unloading machine is improved.

Owner:华芯(嘉兴)智能装备有限公司

Solar tracking oriented one-dimensional driving two-dimensional output robot mechanism

InactiveCN102541088BTo achieve the purpose of trackingImprove reliabilitySolar heating energySolar heat devicesButt jointElectric machine

The invention relates to a solar tracking oriented one-dimensional driving two-dimensional output robot mechanism. The invention provides the solar tracking oriented one-dimensional driving two-dimensional output robot mechanism which comprises a bracket, a solar component mounting plate, a cam, a motor, a first rotating shaft and a one-way coupler, wherein the motor is arranged on the bracket; the motor is connected with the cam through the one-way coupler; the motor is connected with the first rotating shaft; one end of the solar component mounting plate is hinged with the first rotating shaft; the other end of the solar component mounting plate is in contact with and butt-jointed with the cam; and the motor is connected with the solar component mounting plate through the first rotatingshaft and is used for driving the solar component mounting plate to rotate around the edge of the cam. The solar tracking oriented one-dimensional driving two-dimensional output robot mechanism has the beneficial effects that: one motor input is converted into two rotating shaft outputs, the solar motion is tracked and a sunlight receiving surface of a solar component is vertical to the sunlight under a working state, so that the total volume of absorbed energy is increased, the cost is lower and the reliability is higher.

Owner:楼云江 +1

Crankshaft follow-up grinding online measuring instrument

ActiveCN107009228BRealize online measurementAchieve improvementGrinding carriagesGrinding drivesMeasuring instrumentGear wheel

The invention discloses a crankshaft follow-up grinding online measuring instrument which comprises a measuring instrument base. A swing arm support is borne on the measuring instrument base in a sliding manner. A measuring swing arm is hinged to the swing arm support. A swing arm oil cylinder is connected between the top end of the oil cylinder support and the measuring swing arm. A center fixed gear is fixedly arranged at the stretching end of the measuring swing arm, a following swing frame is further mounted on the stretching end of the measuring swing arm, and a planet swing gear mounted at the output shaft end of a following swing motor is engaged with the center fixed gear. A measuring tool support is fixedly mounted on a measuring tool following swing arm, two measuring clamping blocks and a displacement sensor are mounted on the measuring tool support, the two measuring clamping blocks are located on two inclined face of a V-shaped base level correspondingly, the displacement sensor is located on the symmetric line of the V-shaped base level, and the inclined included angle alpha of the V-shaped base level is equal to 68 degrees to 72 degrees. The crankshaft follow-up grinding online measuring instrument can achieve real-time online measurement and is high in detecting sensitivity and machining precision.

Owner:SOUTHEAST UNIV

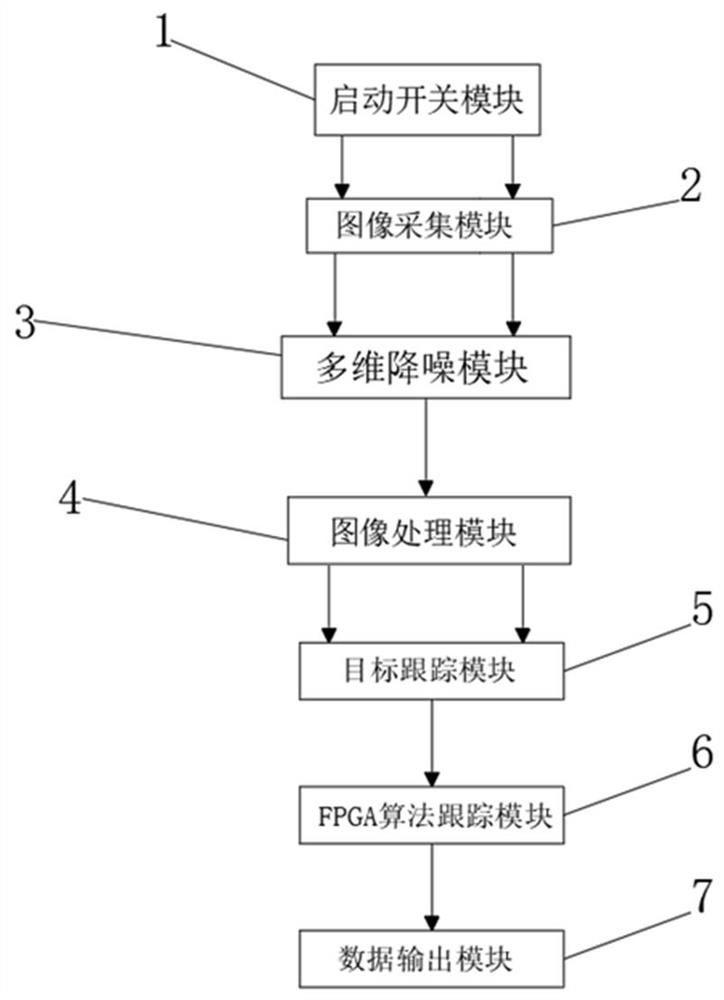

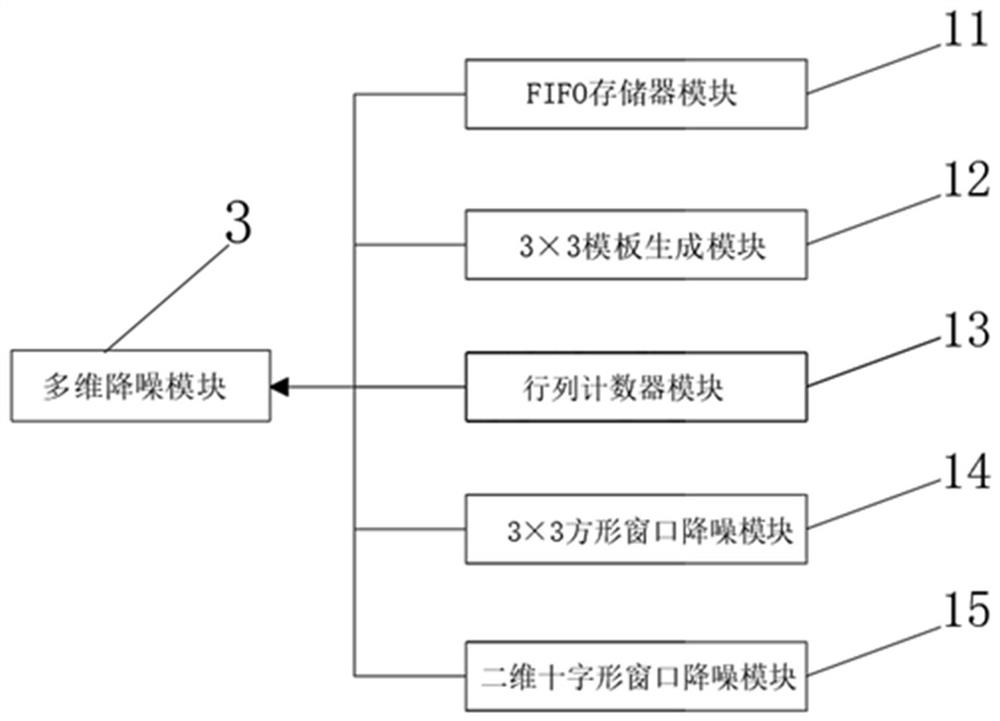

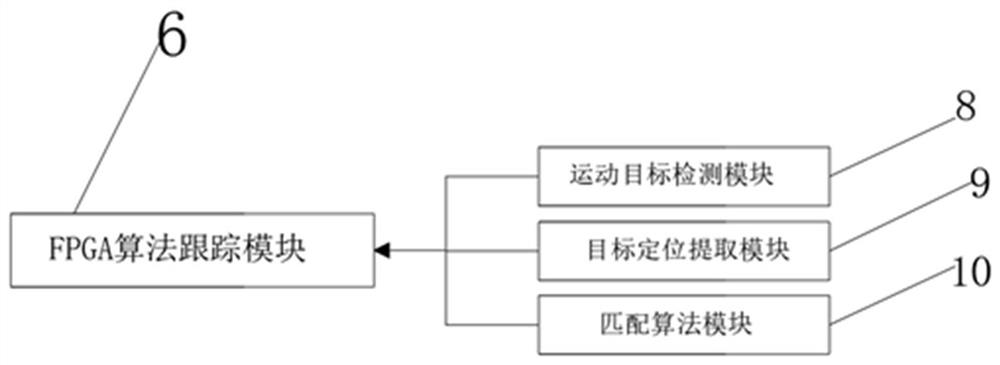

Target positioning system and identification method based on FPGA image processing

PendingCN114217953AReduce occupancyShort runtimeResource allocationData conversionTemplate matchingImaging processing

The invention discloses a target positioning system based on FPGA image processing and an identification method. According to the invention, the output end of a multi-dimensional noise reduction module is connected with the input end of an image processing module, the output end of the image processing module is connected with the input end of a target tracking module, and the output end of the target tracking module is connected with the input end of an FPGA algorithm tracking module. The output end of the FPGA algorithm tracking module is connected with the input end of the data output module, the system can process 30 frames of images per second, the tracking speed is high, the target positioning and extracting module in the system can directly perform target detection on each frame of image and calculate the centroid for a moving target with a simple background, and the tracking speed is high. The tracking algorithm based on template matching can accurately track a target in a complex background, the anti-interference capability is high, the image processing accuracy of the system is improved, and the stability of the system during operation is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

An intraocular pressure tracking measuring instrument

The invention discloses an intraocular pressure tracking measuring instrument which can reduce harm to eyeballs and is convenient to use. The intraocular pressure tracking measuring instrument comprises an eyeshade body and one or two probe assemblies which are fixedly arranged on the eyeshade body and correspond to eyes of a subject, a inflatable air bag is arranged in the eyeshade body, at leastpart material of the eyeshade body is a flexible material to deform after the air bag is inflated so as to allow the air bag to push the one or two probe assemblies to move to exert pressure to eyeballs, and each probe assembly comprises an ultrasonic sensor for detecting whether tops of the eyeballs are pressed to be flat and a pressure sensor connected with the ultrasonic sensor.

Owner:苏州兆乘四海通科技有限公司

A method and device for tracking information dissemination

ActiveCN105873090BDissemination to achieveTo achieve the purpose of trackingWireless communicationInformation transmissionUser equipment

The embodiment of the invention discloses an information transmission tracking method. The method comprises steps: based on first address information acquired by user equipment, first unique identification code information for characterizing a transmission identification code of the first information is acquired, wherein the first information is the information acquired by the user equipment via the acquired address information; and according to the first unique identification code information, first group user information formed by other user equipment except the user equipment corresponding to the first information is acquired, and an information transmission trajectory based on the first information is acquired. The embodiment of the invention also discloses an information transmission tracking device.

Owner:LIAONING MOBILE COMM

Solar concentrating thermal drive automatic tracking device

InactiveCN104006546BMuch sunlight energyNo time lag effectSolar heating energySolar heat devicesHydraulic cylinderThermal dilatation

Solar concentrating heat-driven automatic tracking device, the purpose of which is to use the energy provided by solar heat to drive the device to track changes in the sun's position, improve tracking accuracy, and reduce tracking costs. A solar concentrating device is installed in the middle or around the solar receiver (1). The optical device (2) is provided with a heat collecting tube (14) at the focus or focal line position of the solar concentrator (2), and a thermal expansion tube (13) is arranged inside the heat collecting tube (14), and a thermal expansion tube (13) is arranged inside the heat collecting tube (14). A light-reflecting layer (12) is wrapped on the outside, and small holes or fine grooves (22) are opened on the position where the light-reflecting layer (12) faces the solar concentrator (2), and the thermal expansion tube (13) passes through the pressure guiding tube (8 ) communicates with the inner cavity of the hydraulic cylinder (9), and the inner cavity of the thermal expansion tube (13), the pressure guide tube (8) and the hydraulic cylinder (9) is filled with thermal expansion fluid medium (15), and the hydraulic cylinder (9) One end is connected with the second bracket (10), and the other end is connected with the displacement angle conversion device (5).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Robust Lane Line Detection Method Based on Dynamic Region of Interest

ActiveCN109409202BEfficient extractionAnti-interference improvement and enhancementScene recognitionCarriagewayEngineering

The present invention relates to a robust lane line detection method based on a dynamic region of interest, comprising the following steps: S10, initializing the dynamic region of interest of the lane; S20, dividing the region of interest of the lane line in the current frame from near to far into a straight line recognition area and a curve recognition area; S30, perform pre-extraction of lane line edge feature points for the straight line recognition area and curve recognition area, and then obtain straight line lane parameters in the straight line recognition area and curved lanes in the curve recognition area through a fitting algorithm Parameters, draw the fitted lane line; S40, according to the fitted lane line parameters of the current frame, use Kalman filter to predict the dynamic region of interest DROI in the image of the next frame. The present invention is based on DROI, adopts RANSAC algorithm, can effectively extract the inner edge information of the lane line under complex working conditions, and the anti-interference and accuracy of the method have obvious improvement and improvement; at the same time, Kalman prediction and inter-frame correlation are used constraints for real-time, robust lane line tracking.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

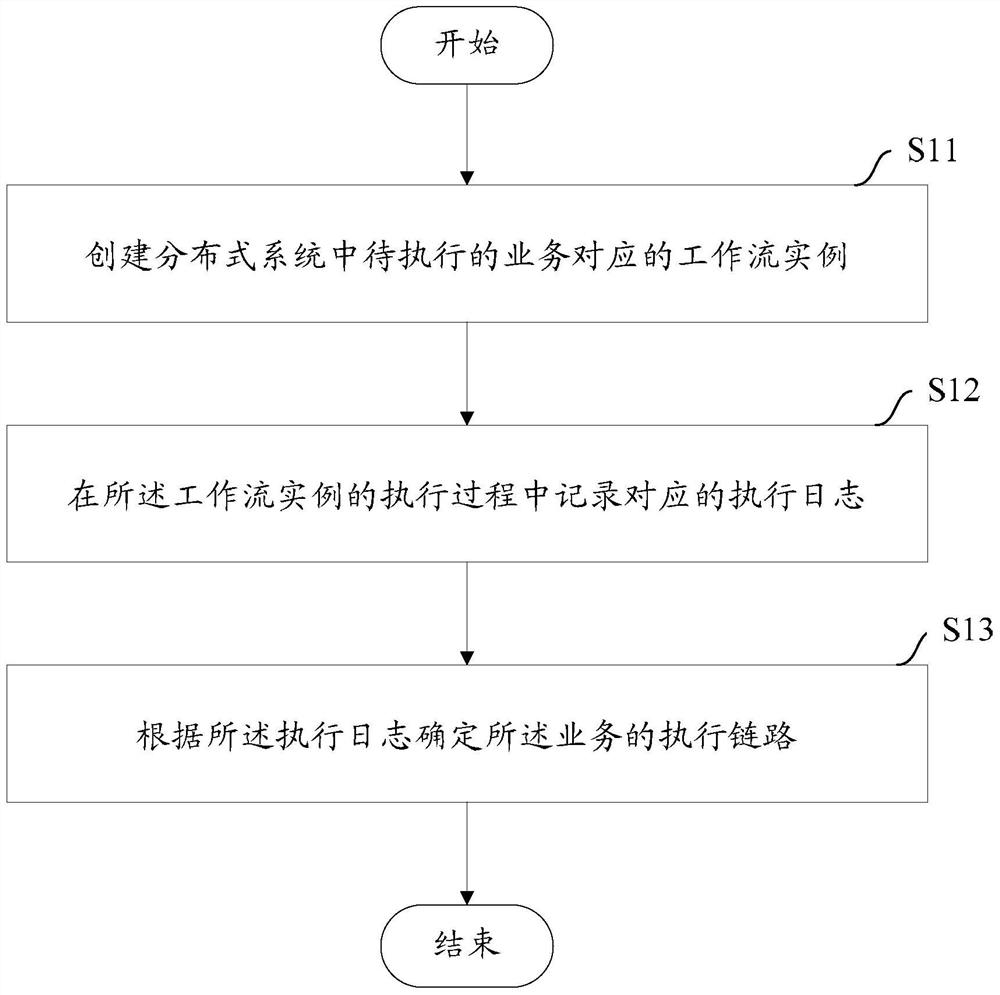

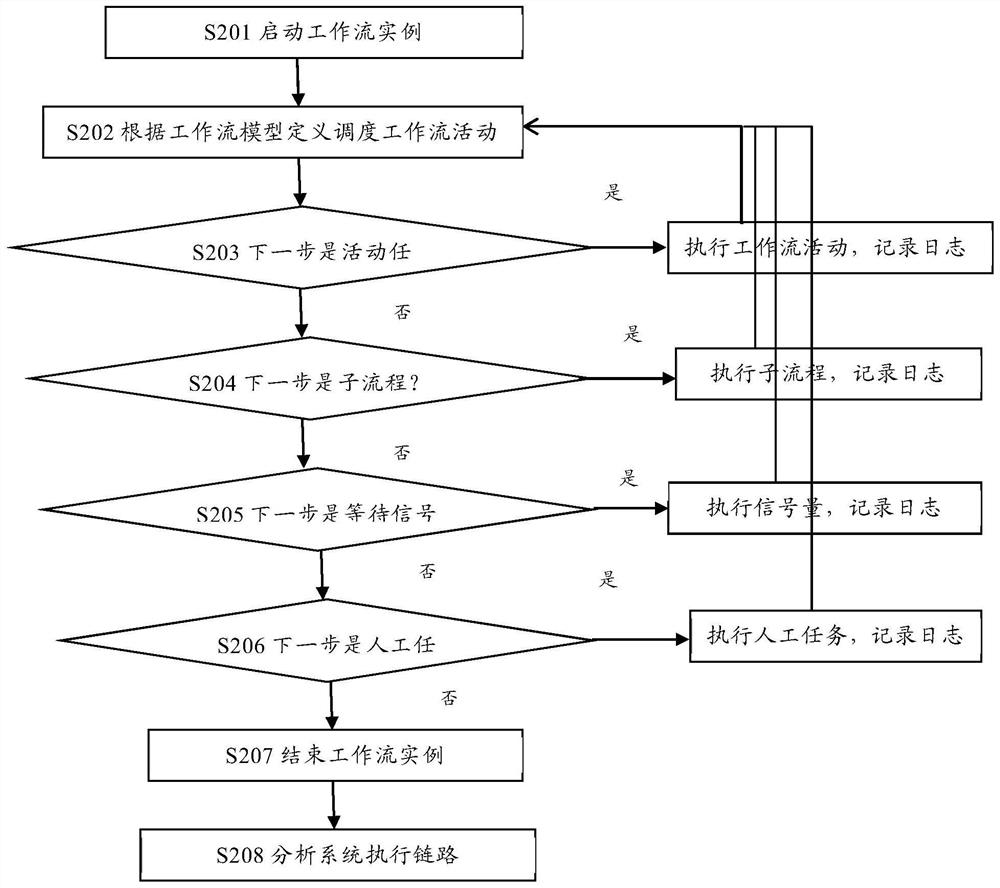

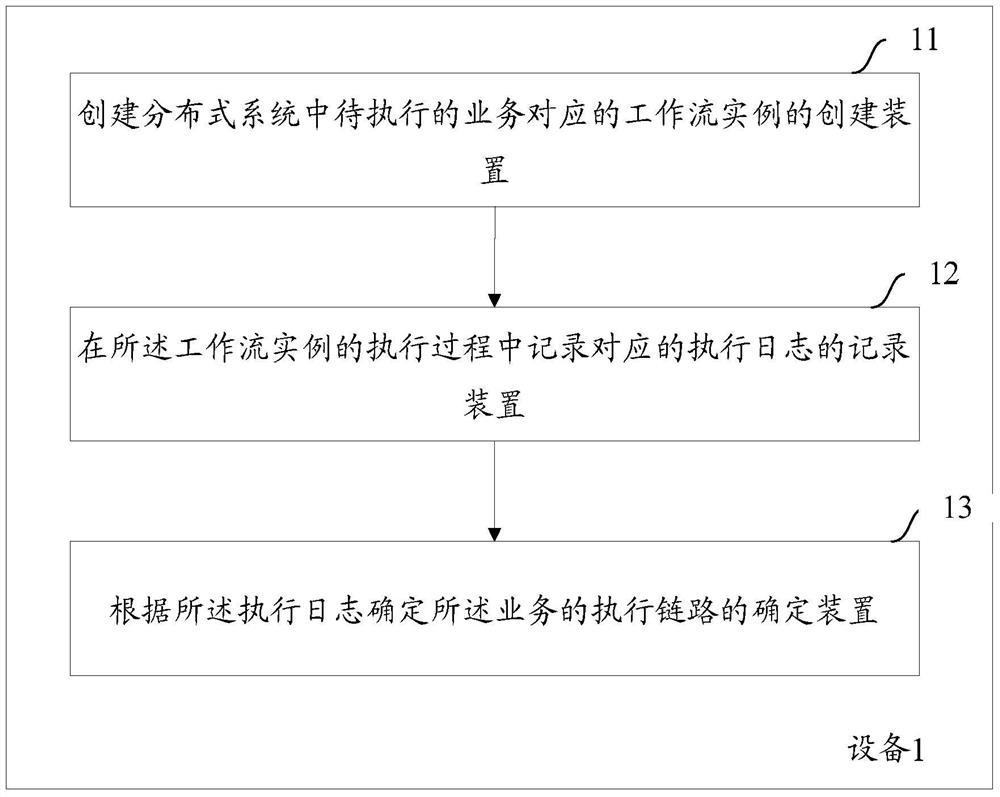

A method and device for determining a service execution link in a distributed system

ActiveCN107577586BImplement trackingTo achieve the purpose of trackingHardware monitoringPathPingParallel computing

The purpose of this application is to provide a method and device for determining the business execution link in the distributed system, by creating a workflow instance corresponding to the business to be executed in the distributed system; during the execution of the workflow instance Record the corresponding execution log; determine the execution link of the business according to the execution log, and realize the tracking of the distributed system link, so as to count the end-to-end calls of the distributed system based on the execution link of each business relationship, in order to achieve the purpose of tracking the distributed system links, and to determine the execution link of the business based on the workflow-related identification information and call nesting relationship information in the execution log, so as to analyze the execution link based on the business The execution path of the distributed system is obtained, and the end-to-end call relationship in the distributed system is counted.

Owner:ALIBABA CLOUD COMPUTING LTD

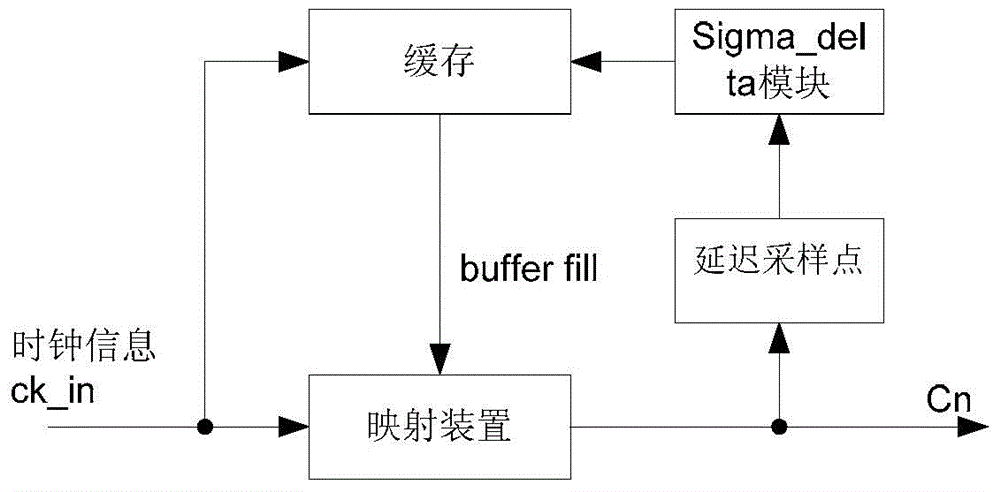

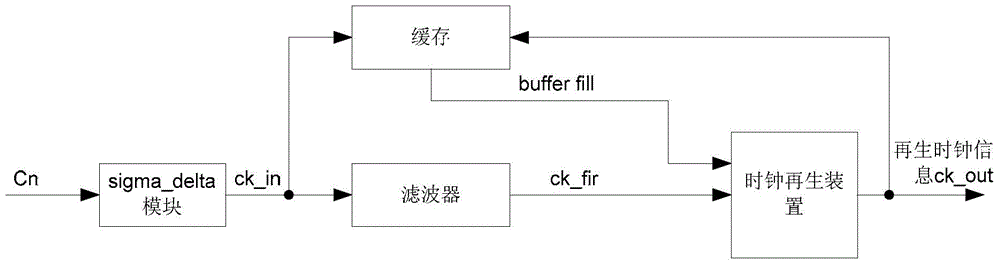

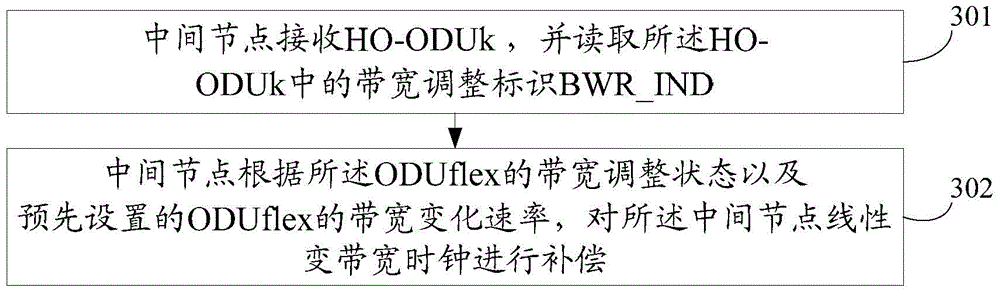

Linear variable bandwidth clock tracking method and device in otn network

ActiveCN102761384BKeep intactTo achieve the purpose of trackingMultiplex system selection arrangementsTime-division multiplexComputer networkComputer science

Disclosed are a method and a device for tracking a linear variable bandwidth clock in an OTN network, which belong to the field of optical transport networks. The method comprises: an intermediate node receiving a high order optical data unit HO-ODUk and reading a bandwidth adjustment identifier BWR_IND in the HO-ODUk, the BWR_IND being used to indicate a bandwidth adjustment status of a flexible rate optical data unit ODUflex; and the intermediate node compensating for a linear variable bandwidth clock of the intermediate node according to the bandwidth adjustment status of the ODUflex and a preset bandwidth variation rate of the ODUflex. The device comprises: a receiving module and a compensation module.

Owner:HUAWEI TECH CO LTD

A navigation and positioning method for a substation inspection robot

ActiveCN104571103BTo achieve the purpose of trackingTo achieve the purpose of positioningPosition/course control in two dimensionsTransformerAngular degrees

The invention discloses a navigation positioning method for a tour inspection robot of a transformer substation. The imaging positions of tracking navigation lamps in an infrared thermal imager are detected, so that the moving direction of a trolley is determined, and the aim of tracking is fulfilled; in order to position the robot in a moving process, a cradle head is horizontally rotated until an image of a positioning navigation lamp in the infrared thermal imager is in the center, the distance to the next fixed point is calculated according to the horizontal rotating angle of the cradle head and the moving distance of the trolley is calculated according to the sizes of images of the tracking navigation lamps in the infrared thermal imager, so that the aim of positioning is fulfilled.

Owner:STATE GRID CORP OF CHINA +3

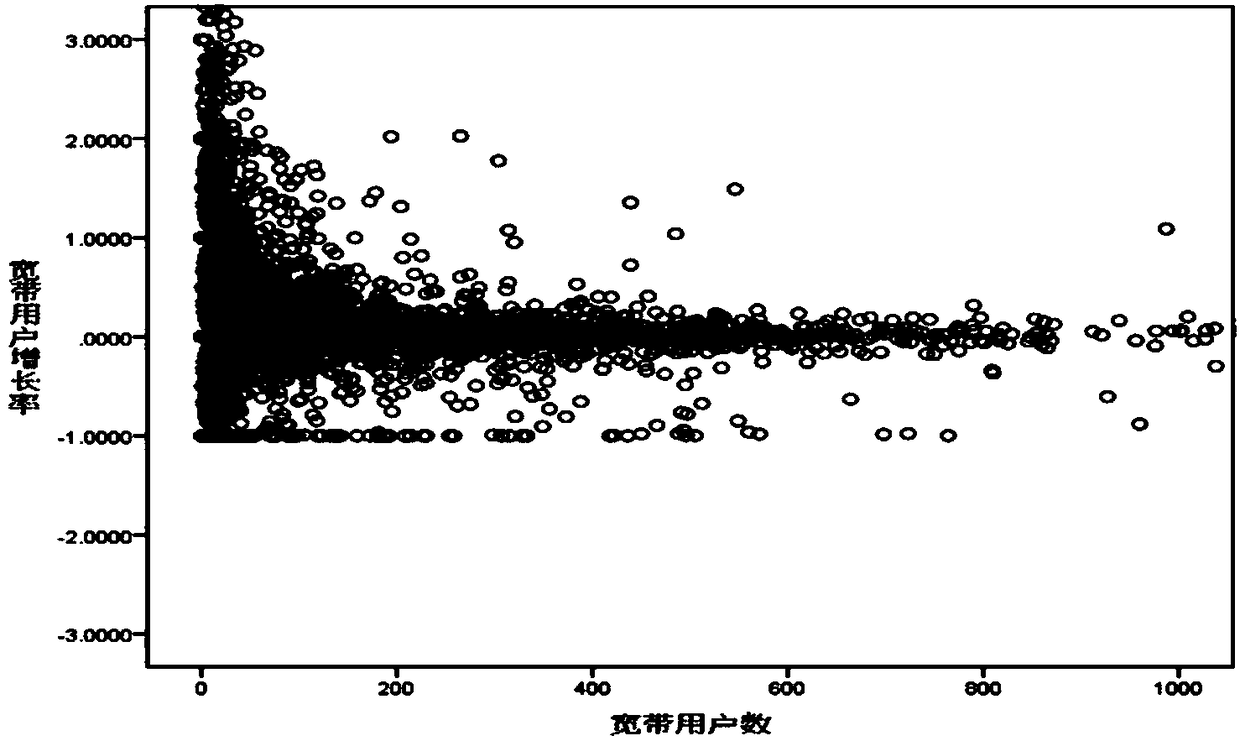

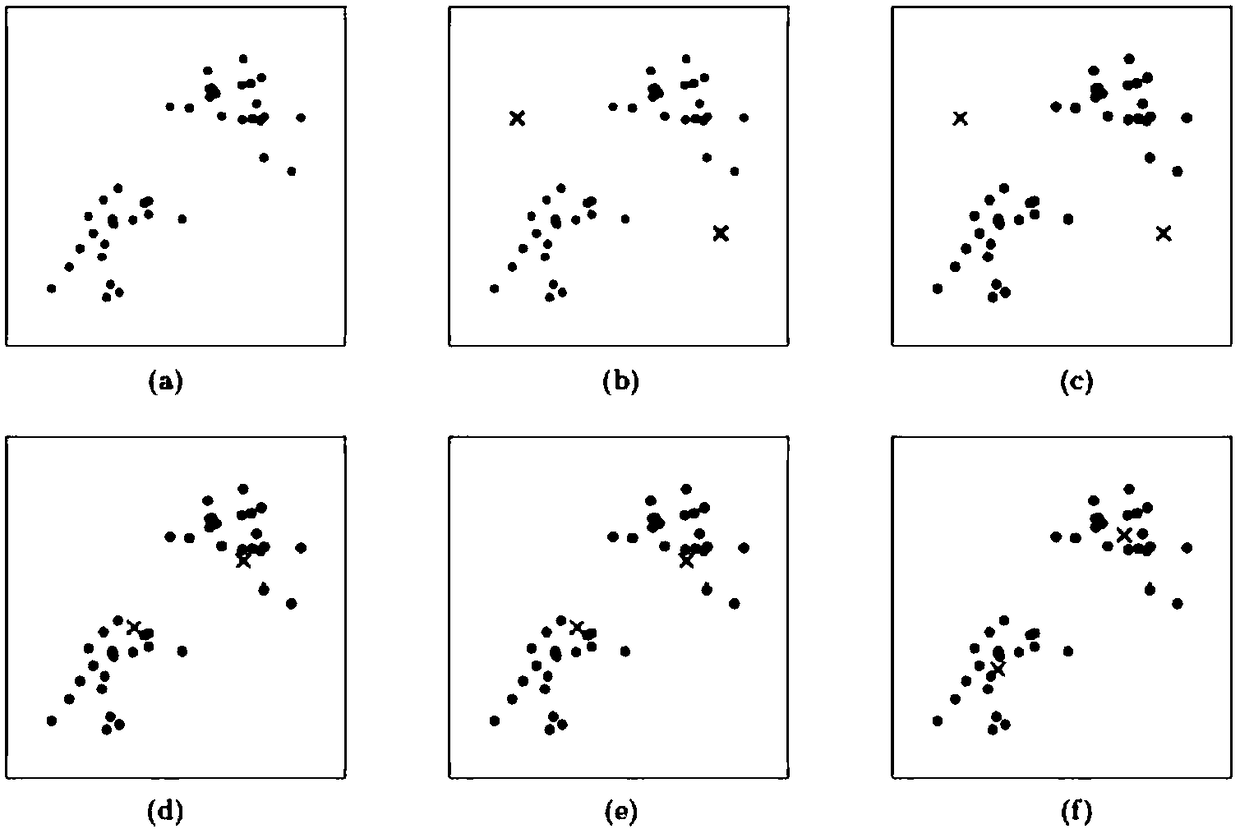

Telecommunication grid data processing method and system

InactiveCN108416005AAchieve showTo achieve the purpose of trackingCharacter and pattern recognitionSpecial data processing applicationsData dredgingSign posting

The invention relates to a data processing method and system, belongs to the technical field of telecommunication data processing, in particular to the telecommunication grid data processing method and system. The method and system take data mining as the core, provide analysis of operation decision and prediction, provide intelligence for management, achieve a 'flattening' management mode for operation to solve a management timeliness problem, meet functions of grid clustering, grid label reference value signing, grid sign post management, grid marketing timing management and the like, and achieve the purpose of displaying and tracking object completion situation.

Owner:HUBEI POST TELECOMM PLANNING DESIGN

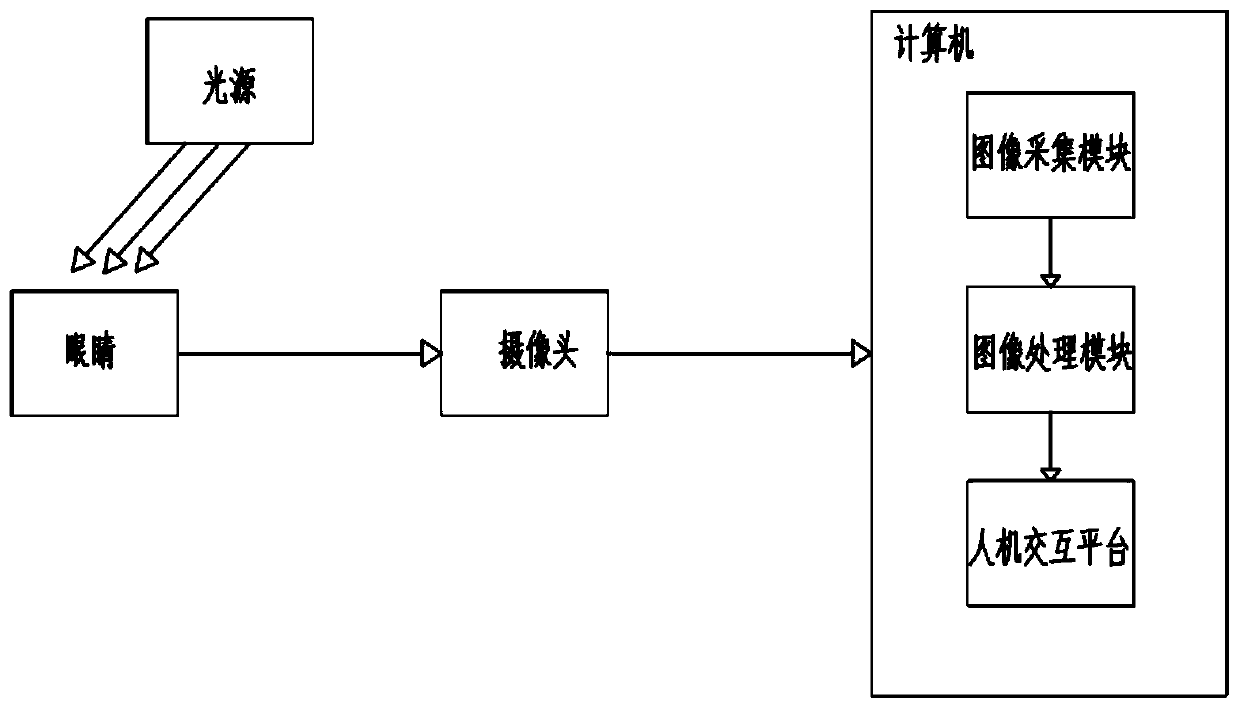

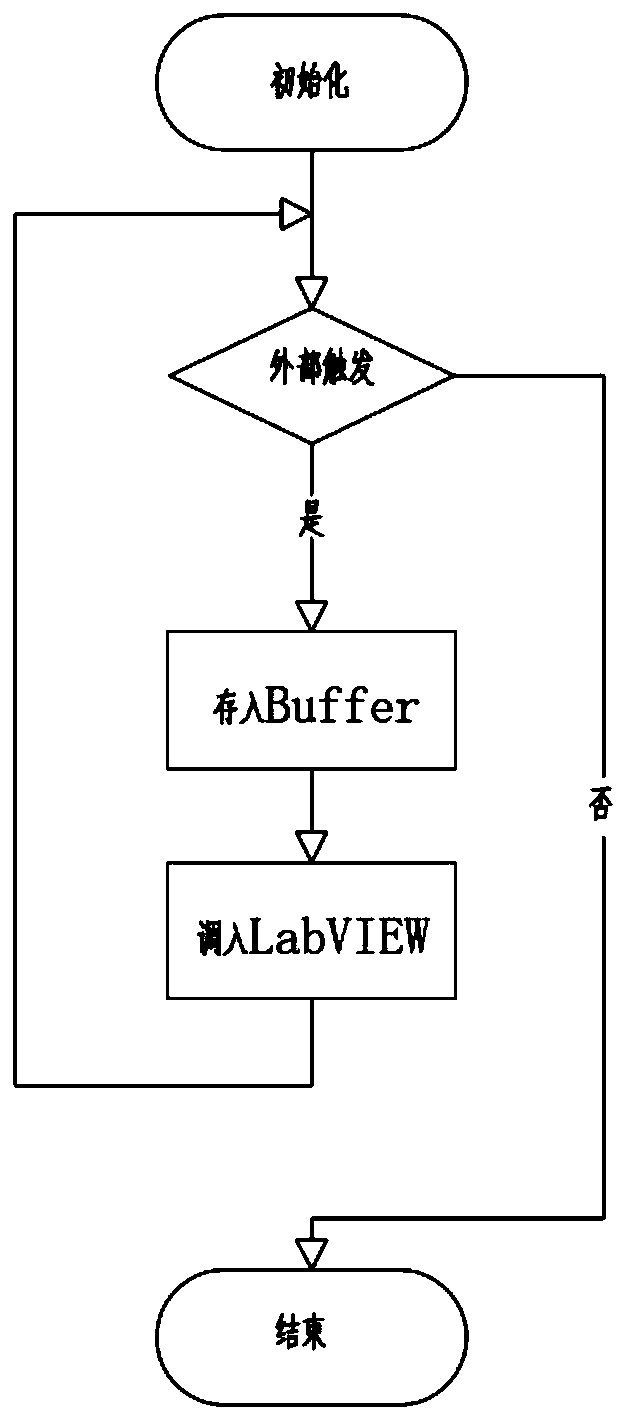

Human eye tracking visual system

InactiveCN109799902AIncrease temperatureIncrease brightnessInput/output for user-computer interactionGraph readingMachine visionHuman–robot interaction

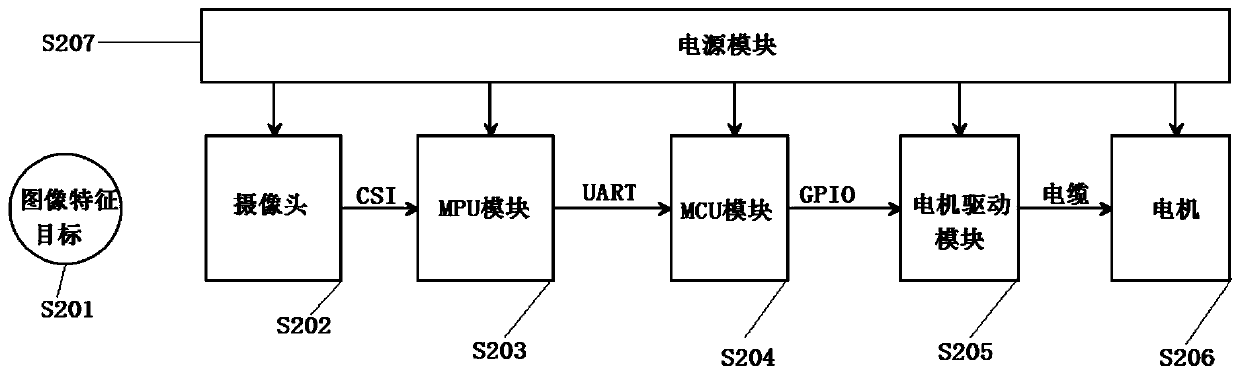

The invention discloses a human eye tracking visual system, which belongs to the technical field of communication and comprises a light source, a controller and a power supply, An image of an object shot by the camera is focused through a lens, charges of a corresponding proportion are accumulated according to the intensity of light, the charges accumulated by all pixels are subjected to video shift, and video signal output is formed after filtering and amplification processing; And system software of the computer adopts a LabVIEW 8.5 platform, and visual auxiliary software MAX and Vision Asset 8.5 software are used as assistance. The human-computer interaction platform has the advantages that the machine vision technology and the virtual instrument are combined to build the human-computerinteraction platform which is simple and effective in human eye tracking. According to the invention, the machine vision technology and the virtual instrument are applied to human eye tracking at lowcost.

Owner:宁波极呈光电有限公司

X-ray protection equipment with image recognition target tracking function

PendingCN110974284AOptimize layoutWith image recognition processing functionRadiation safety meansComputer hardwareImaging processing

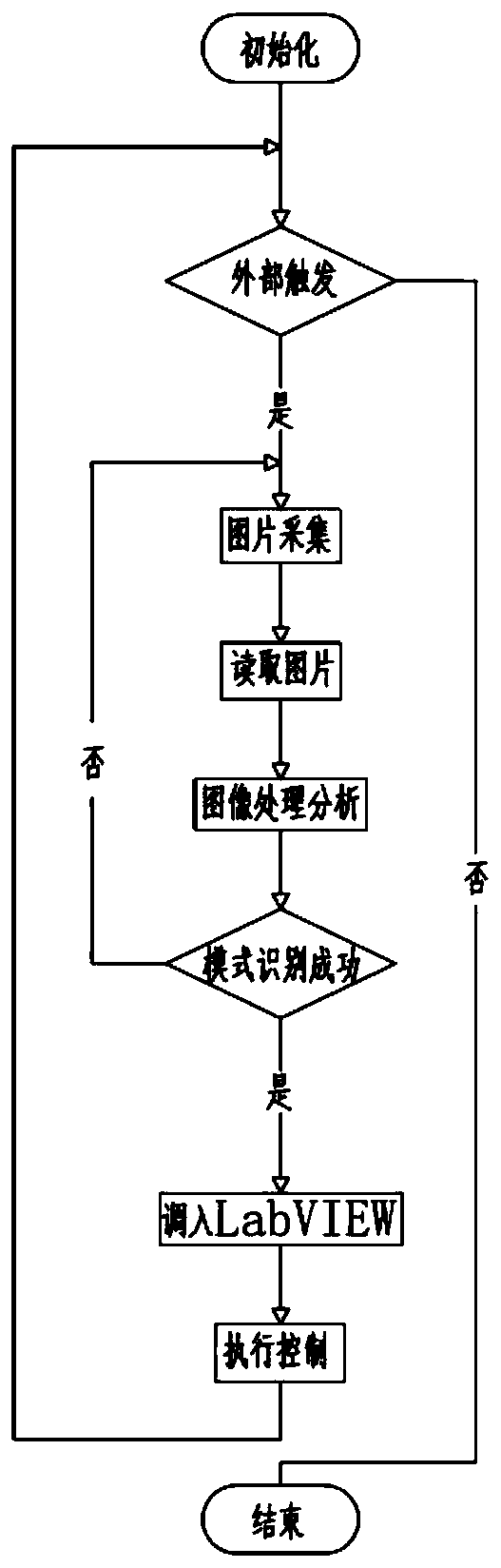

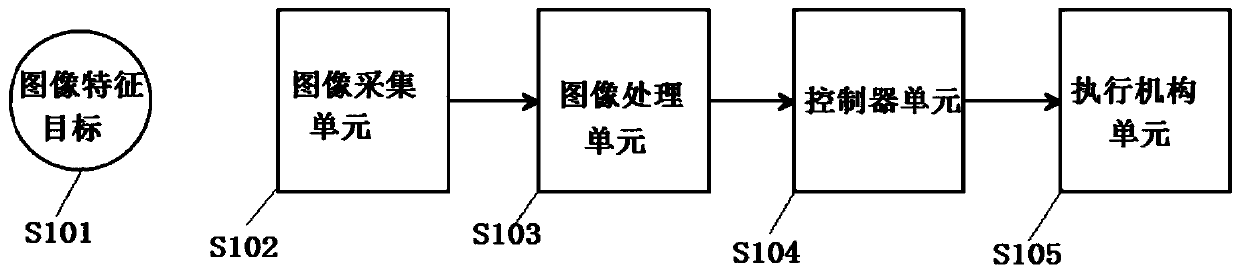

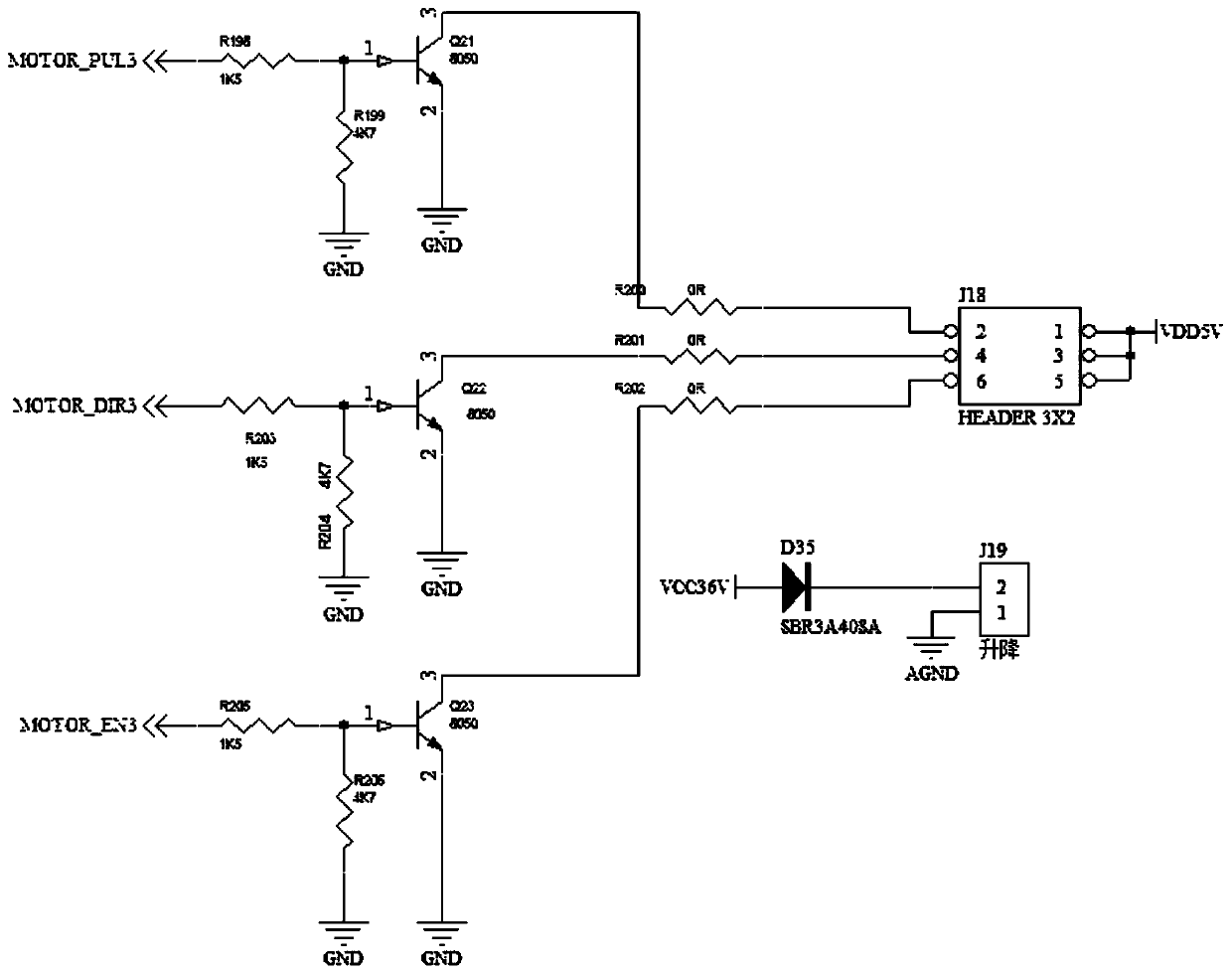

The invention discloses X-ray protection equipment with an image recognition target tracking function. The X-ray protection equipment comprises an image feature target, an image acquisition unit, an image processing unit, a controller unit and an actuating mechanism unit. The image acquisition unit is electrically connected with the image processing unit and transmits image data to the image processing unit for processing. The image processing unit is connected with the controller unit and transmits the identified image feature target coordinate data to the controller unit for processing. Thecontroller unit is connected with the actuating mechanism unit and transmits a control instruction to the actuating mechanism unit for moving operation. According to the X-ray protection equipment, asensor module does not need to be additionally arranged outside the equipment, and the equipment is more convenient to arrange; a sensor module does not need to be added outside the machine, so that the corresponding cost is saved; and a sensor module does not need to be additionally arranged outside the machine, so that wired or wireless data transmission with external equipment is not needed, and the system complexity is reduced.

Owner:NEURON INFORMATION TECH SHENZHEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com