Guardrail plate automatically welding device

An automatic welding and mobile device technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of low welding efficiency, difficult to guarantee welding quality, and high labor intensity of welding workers, so as to avoid welding through the weld seam, The effect of saving manpower and material resources and improving welding efficiency

Inactive Publication Date: 2015-05-27

刘宪福

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, due to the change of welding speed between the straight side and the hypotenuse, and the rotation control of the welding torch on the hypotenuse, the difficulty of controlling the equipment is increased. Therefore, automatic welding cannot be realized in the welding of similar equipment.

Since the above problems have been difficult to solve so far, all semi-trailer railings are currently welded manually, resulting in high labor intensity for welders, low welding efficiency, and difficult to guarantee welding quality.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

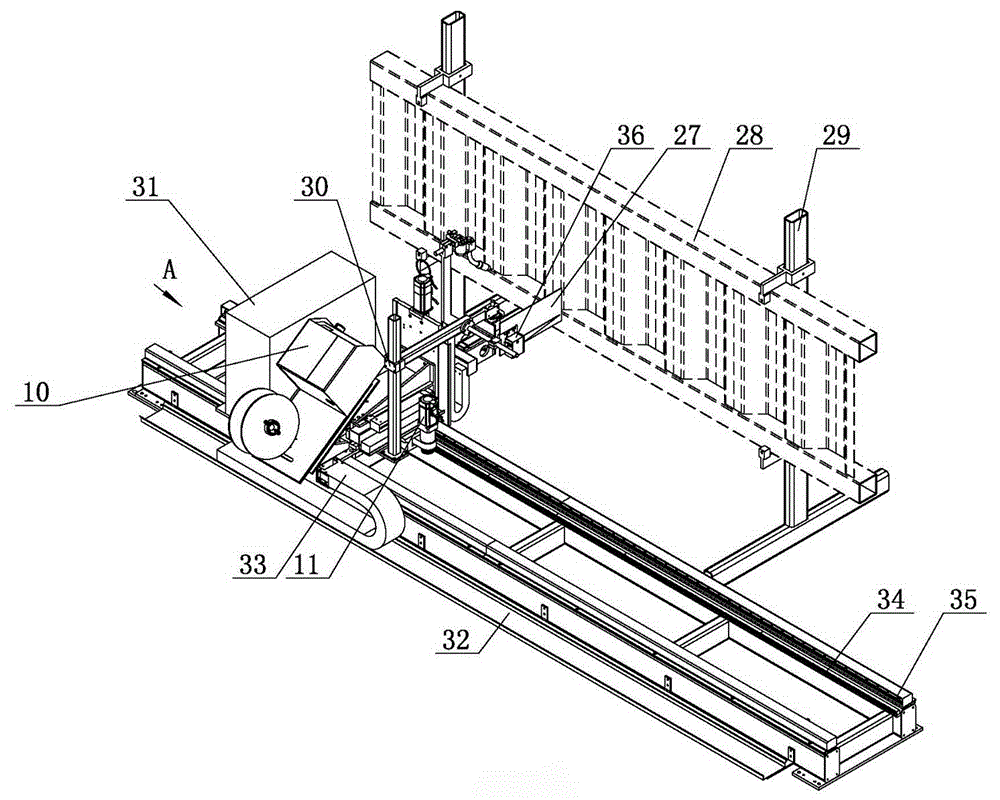

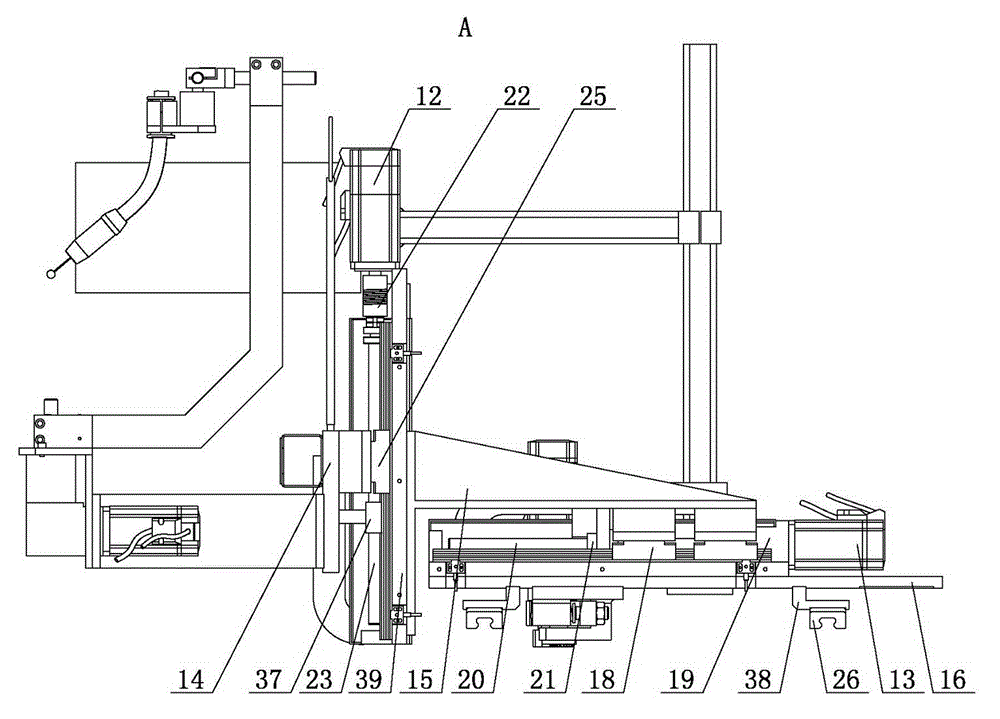

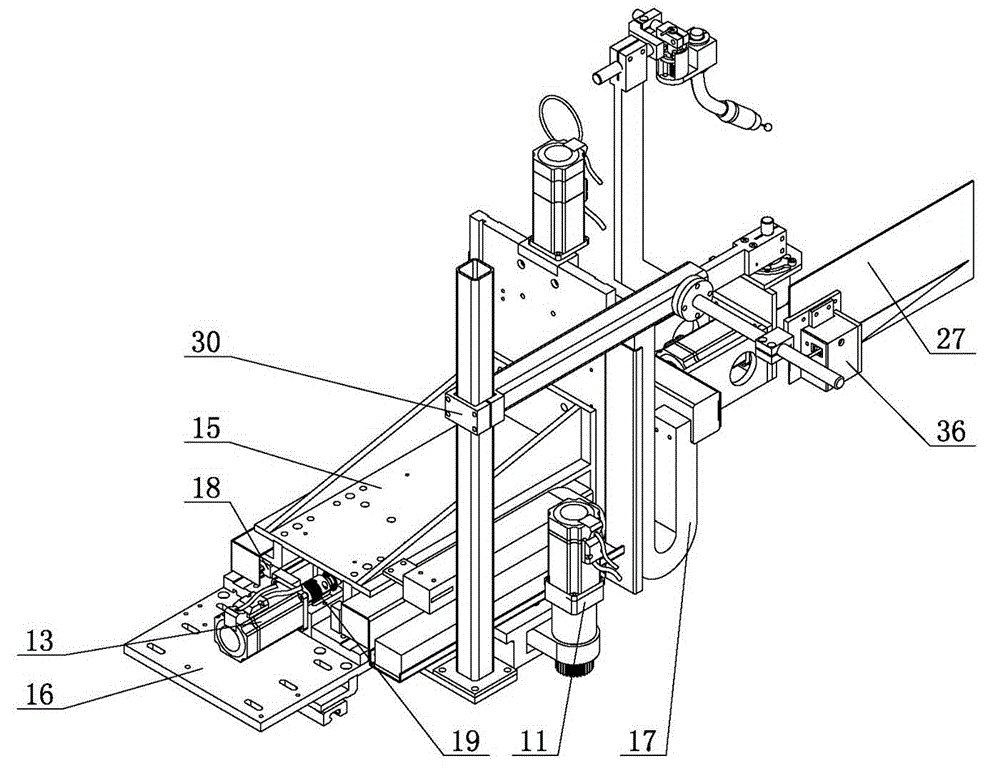

Disclosed is a guardrail plate automatically welding device. The guardrail plate automatically welding device comprises a pressing wheel, a wheel seat, a jacking device and a displacement sensor. The wheel seat is provided with the pressing wheel; the jacking device comprises an oil cylinder or steam cylinder; the bottom of the wheel seat is connected with the jacking device; the displacement sensor is connected with the piston of the oil cylinder or steam cylinder or the wheel seat. According to the guardrail plate automatically welding device, force exerted on the pressing wheel by the oil cylinder or steam cylinder can keep the same, so that pressure between the pressing wheel and a ring piece has no significant change, the problem that the quality of the ring piece is affected by overhigh pressure of the pressing wheel can be voided; the displacement of the pressing wheel can be obtained through accurate measurement of an encoder, so that the measuring precision can be effectively improved, and errors can be effectively reduced.

Description

technical field [0001] The invention relates to a welding device, in particular to an automatic welding device for fences. Background technique Due to the thinner thickness and more bends of the semi-trailer sideboard, the welding seam tracking requirements are relatively high during welding, and the weld seam will be welded through if there is a slight deviation. In addition, due to the change of welding speed between the straight side and the beveled side, and the rotation control of the welding torch on the beveled side, the difficulty of controlling the equipment is increased. Therefore, automatic welding cannot be realized in the welding of similar equipment. Since the above-mentioned problems are difficult to solve so far, at present, all the side panels of semi-trailers are welded manually, resulting in high labor intensity for welders, low welding efficiency, and difficult to guarantee welding quality. Contents of the invention In order to solve the above probl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/12B23K9/095B23K9/32

CPCB23K9/127B23K9/0956B23K9/32B23K2101/006

Inventor 刘宪福

Owner 刘宪福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com