Crankshaft follow-up grinding online measuring instrument

A measuring instrument and grinding technology, which is applied in the direction of grinding frame, grinding bed, grinding slide plate, etc., can solve the problems of unfavorable crankshaft grinding and affecting processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

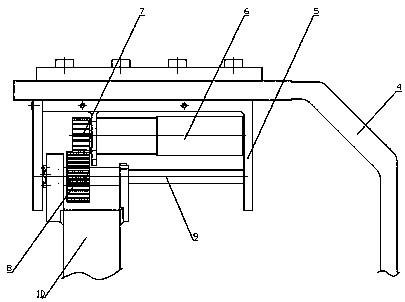

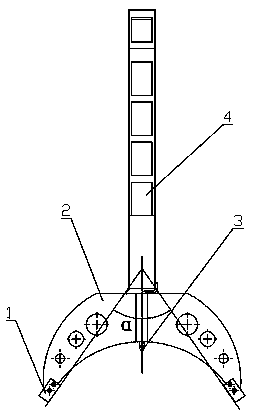

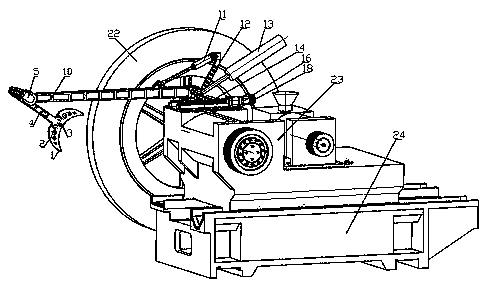

[0019] like figure 1 , figure 2 In the crankshaft follow-up grinding online measuring instrument shown, a grinding power head 23 is slidably supported on the bed 24 of the grinding machine through bed guide rails, and a grinding wheel driven by the main motor of the grinding machine is installed on the grinding power head 23. 22. Install a wired measuring instrument on the grinding power head 23 through the measuring instrument base 18, and the measuring instrument base 18 is fixedly installed on the grinding power head 23.

[0020] The online measuring instrument includes a measuring instrument base 18, on which a swing arm support 14 is slidably supported by a sliding guide rail 19, and a translation drive mechanism is arranged between the swing arm support 14 and the measuring instrument base 18, and the swing arm The support 14 is driven by a translational drive mechanism, which is mounted on a measuring instrument base 18 . The translation drive mechanism includes a le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com