Solar concentration thermal drive automatic tracking device

An automatic tracking device and solar concentrating technology, applied in the field of solar tracking, can solve the problems such as the difficulty of keeping the rotation speed of the device unchanged, the tracking error is too large, and the heat energy dissipation, etc., and achieve the effect of synchronous tracking, small intermittent tracking, and high precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

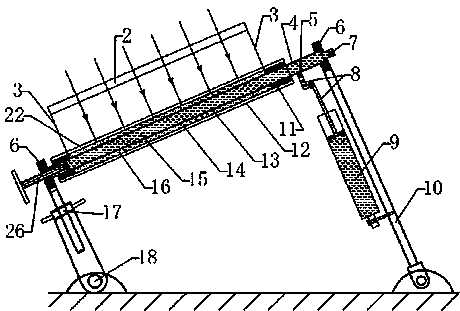

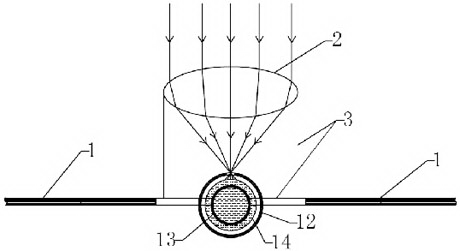

[0031] Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 8 As shown, the solar receiver 1 is two sets of solar photovoltaic cell components installed in parallel, and a solar concentrator 2 is arranged in the middle of the solar receiver 1, and the type of the solar concentrator 2 is a Fresnel-type line-focusing light-transmitting Mirror, on the focal line position of solar concentrator 2, be provided with heat collecting pipe 14, be provided with thermal expansion pipe 13 inside heat collecting pipe 14, heat collecting pipe 14 and expansion pipe 13 are split type, on the inner wall of heat collecting pipe 14 and expand The outer walls of the tubes 13 are filled with a heat-conducting medium 16, cork or rubber plugs 11 are provided at the ports at both ends of the heat collecting tube 14, and a reflective layer 12 is wrapped around the heat collecting tube 14, and the reflective layer 12 faces the solar collector A thin groove 22 is opened at the position of th...

Embodiment 2

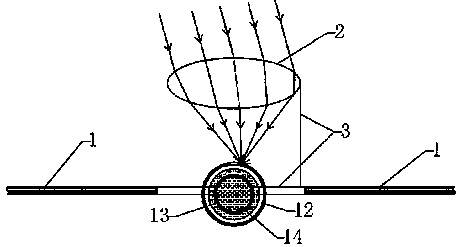

[0036] Such as figure 1 , Figure 4 , Figure 5 , Figure 9 As shown, on the basis of Embodiment 1, the solar receiver 1 is changed into a solar trough concentrator, the type of the solar concentrator 2 is changed into a line focusing trough reflector, and the heat collecting tube 14 and the expansion tube 13 are integrated Type, the inner wall of the heat collecting tube 14 is fused with the outer wall of the expansion tube 13. At this time, there is no heat transfer medium 16, and there is no cork or rubber stopper 11, and an insulating layer is provided between the heat collecting tube 14 and the reflective layer 12. A reflective layer 12 is wrapped outside the thermal insulation layer, and a thin groove 22 is provided at the position where the reflective layer 12 faces the solar concentrator 2 .

[0037] The temperature compensation adjustment device 26 installed on the expansion tube 13 is a screw rod stretched into the thermal expansion fluid medium 15, the displaceme...

Embodiment 3

[0041] Such as figure 1 , Figure 8 As shown, on the basis of Embodiment 1, the solar receiver 1 is changed into a solar dish concentrator, and a solar concentrator 2 is arranged in the middle of the solar receiver 1, and the type of the solar concentrator 2 is changed into a point Focusing disc reflector, the expansion tube 13 and the rotating shaft 4 are split, the heat collection tube 14 and the expansion tube 13 are integrated, the heat collection tube 14 and the expansion tube 13 are spherical, and there is a reflector outside the heat collection tube 14 Layer 12, an insulating layer is provided between the heat collecting tube 14 and the reflective layer 12, and an aperture 22 is provided at the position where the reflective layer 12 faces the solar concentrator 2.

[0042] A pressure relief valve 7 and a temperature compensation adjustment device 26 are installed on the pressure guide pipe 8, the temperature compensation adjustment device 26 is a manual hydraulic pump,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com